2- 20

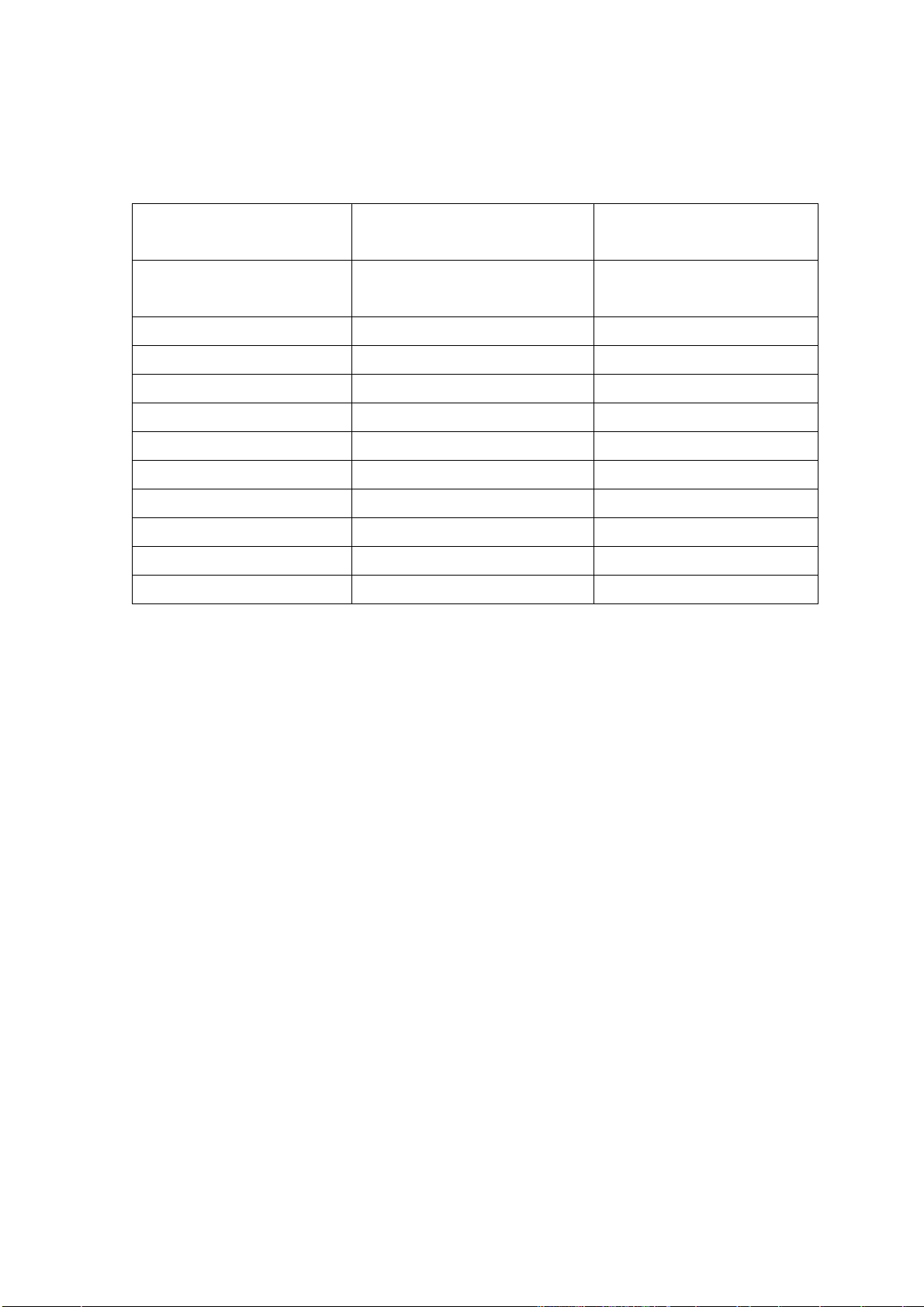

目錄

1 應用範圍 .............................................................................................................. 3

2 基礎操作 ............................................................................................................... 3

2-1 安全措施 ......................................................................................................... 3

2-1.1 安裝前 ...................................................................................................... 3

2-1.2 加油之前 ................................................................................................... 3

2-1.3 發生故障時 ............................................................................................... 3

2-2 潤滑器組成元件 ............................................................................................ 4

2-3 產品標籤 ......................................................................................................... 4

2-3 產品標籤 ......................................................................................................... 5

2-4 安裝 ................................................................................................................. 6

2-4.1 安裝潤滑器 .............................................................................................. 6

2-4.2 加入油料 .................................................................................................. 6

2-4.3 油管接法 ................................................................................................... 7

2-4.4 手動打油 .................................................................................................. 7

2-4.5 安裝電源和警報器 ................................................................................. 8

3 使用說明 .............................................................................................................. 8

3-1 設定吐出油量 ................................................................................................. 8

3-2 補充油料 ......................................................................................................... 9

4 保養 ....................................................................................................................... 9

5 保養異常處理 / 故障排除 ................................................................................ 9

6 保證 ....................................................................................................................... 9

7 技術資料 ............................................................................................................ 10

8 聯繫方式 ............................................................................................................. 20