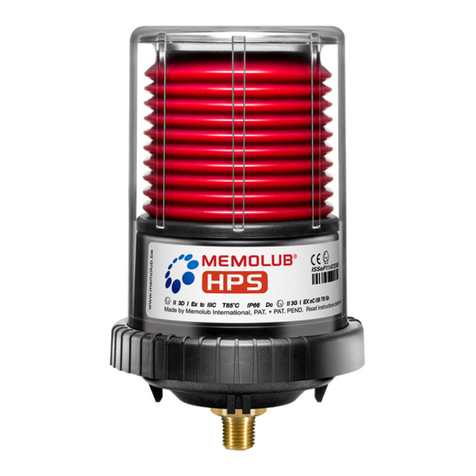

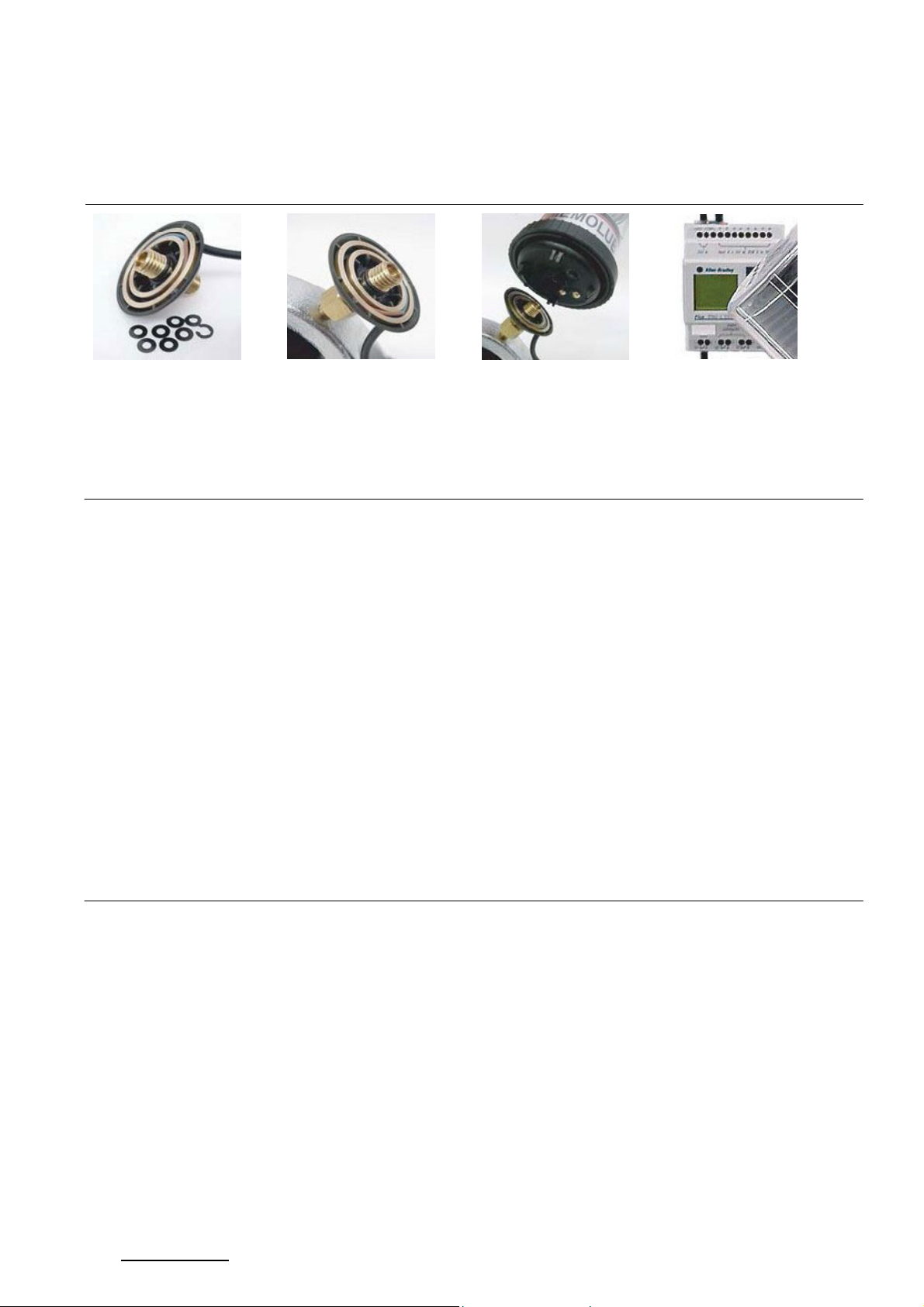

MEMOLUB® PLCD (PLC)

Lubricant dispense

www.memolub.com 5/ 7

Installation regulations for the lubricator 24 V DC-PLC

1. Program the lubrication

amount by inserting the

dosage washers.

General instructions

2. Mount the MEMO directly

on the lubrication point or

the progressive distributor.

3. Screw the

MEMOLUB® onto the

MEMO.

4. Connect the MEMOLUB® 24

V DC-PLCD (PLC) to a PLC.

The PLC regulates the

frequency of the lubrication

cycles.

(PLC is not included)

Maintenance

Operation with an empty cartridge should be avoided. To make the pump suck again, use a grease gun

without grease nipple. One or two strokes are enough.

Stop / Start

Five seconds after being screwed into the lubrication point, the lubricator starts the first lubrication cycle. The

MEMOLUB can be switched off and on (machine standstill, weekends, vacation closedown, etc.) at any time.

The MEMOLUB is simply screwed out and back in by three rotations for this. After being screwed in, the

MEMOLUB runs a self-test and is immediately operational.

Caution! In progressive distributors and/or long lines filled full with lubricant, decompression can occur in these

systems. The MEMO is then filled with lubricant. When screwing the MEMOLUB onto the MEMO, pressures of

up to more than 100 bar can occur, and this may damage the MEMOLUB. Use a "SAFETY-MEMO" for

progressive distributors and/or long lines.

Line lengths for central lubrication

The lengths of the lines depend on the type of grease to be conveyed and the ambient temperature. With

multi-purpose grease and temperatures of over 100 °C, the following line lengths are used. At 4 mm inner

diameter: max. 6 m for single lubrication point, max. 8 x 2.5 m for progressive distributors.