Siemens Powermite 599 Series Owner's manual

Other Siemens Controllers manuals

Siemens

Siemens SQM45 Series User manual

Siemens

Siemens SINUMERIK 828D Turning User manual

Siemens

Siemens RDF870KN User manual

Siemens

Siemens SIMATIC Mobile Client900WXN User manual

Siemens

Siemens SSB161.05UT User manual

Siemens

Siemens SIMATIC S7-1200 User manual

Siemens

Siemens Simatic S7-1500 User manual

Siemens

Siemens SIRIUS 3RW40 4 User manual

Siemens

Siemens OpenAir GDE131.1U User manual

Siemens

Siemens SIMOTION D410 Quick start guide

Siemens

Siemens SIRIUS M200D User manual

Siemens

Siemens SIMOTION P320-4 E User manual

Siemens

Siemens SIMATIC ET 200SP User manual

Siemens

Siemens SQM40 Series User manual

Siemens

Siemens RAJA+ 3TE7111-2SC18-1A Series Operating instructions

Siemens

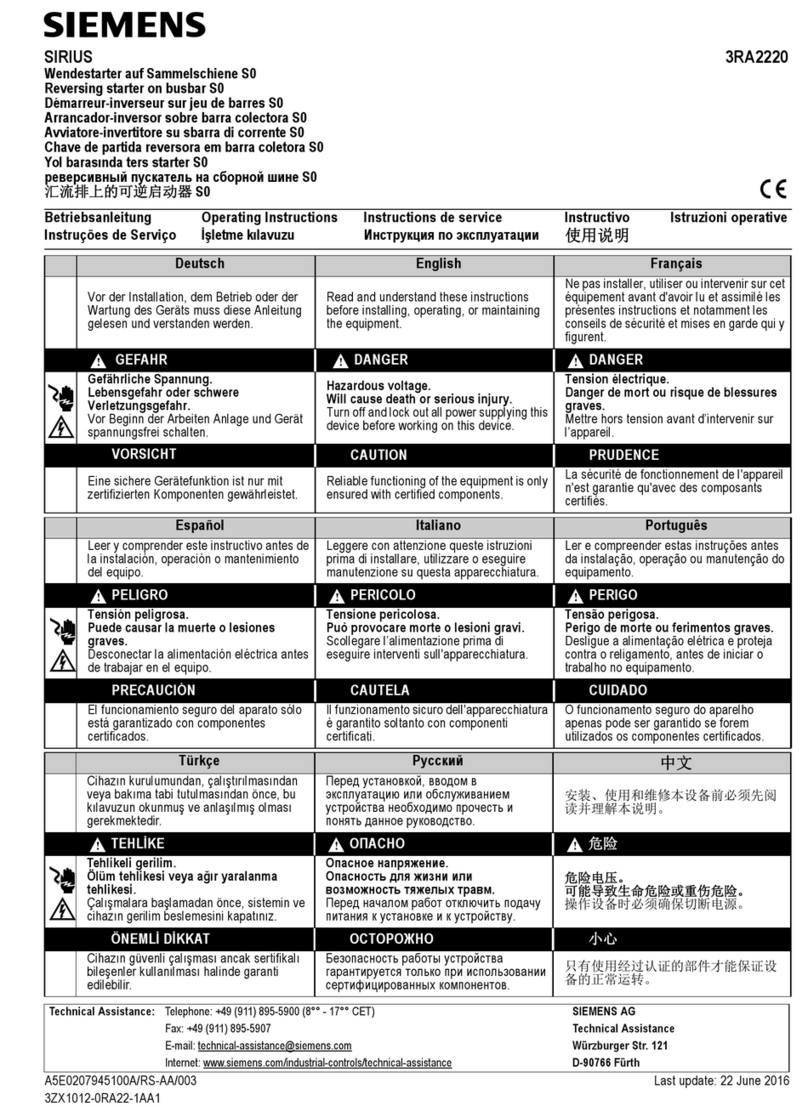

Siemens SIRIUS S0 User manual

Siemens

Siemens RVL469 User manual

Siemens

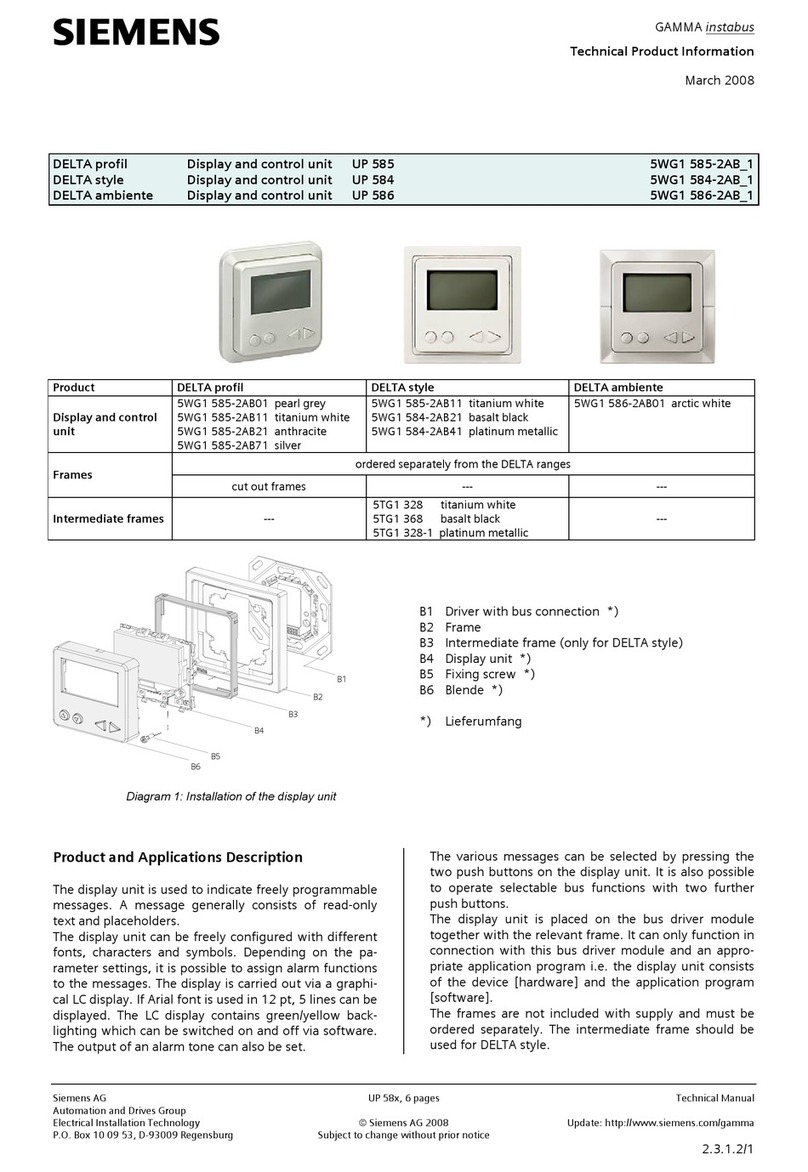

Siemens Delta Series User manual

Siemens

Siemens SIRIUS 3RW52 Technical Document

Siemens

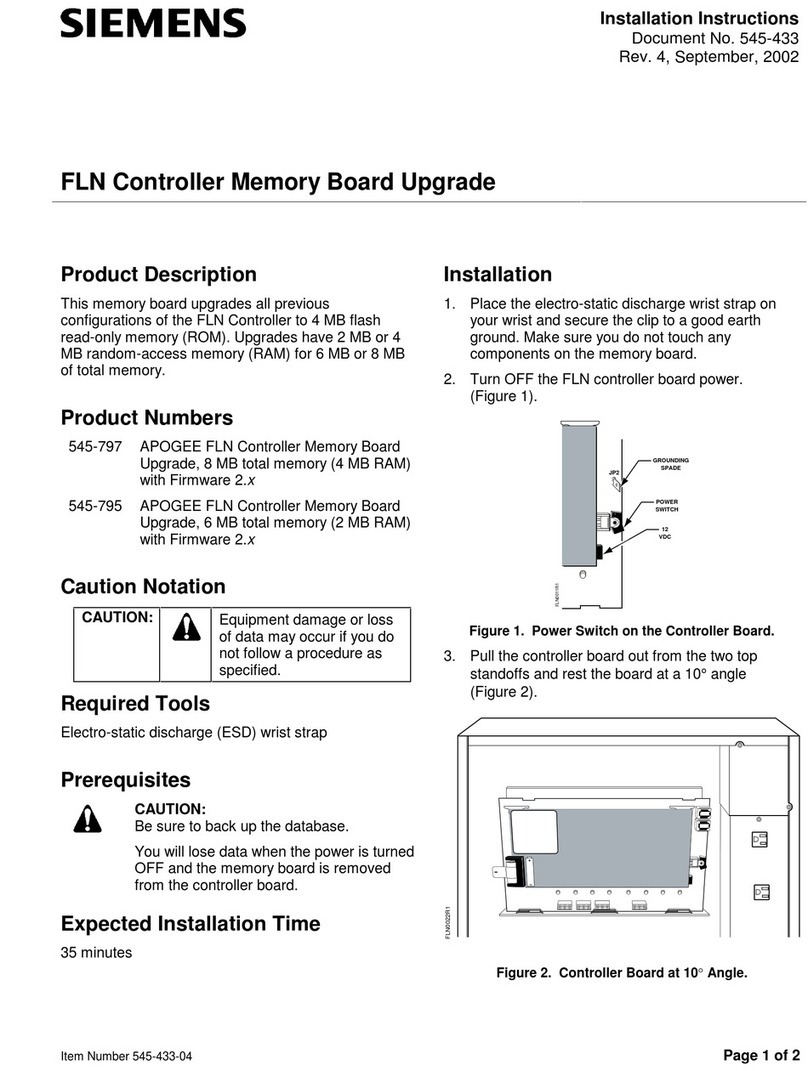

Siemens FLN User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions