33

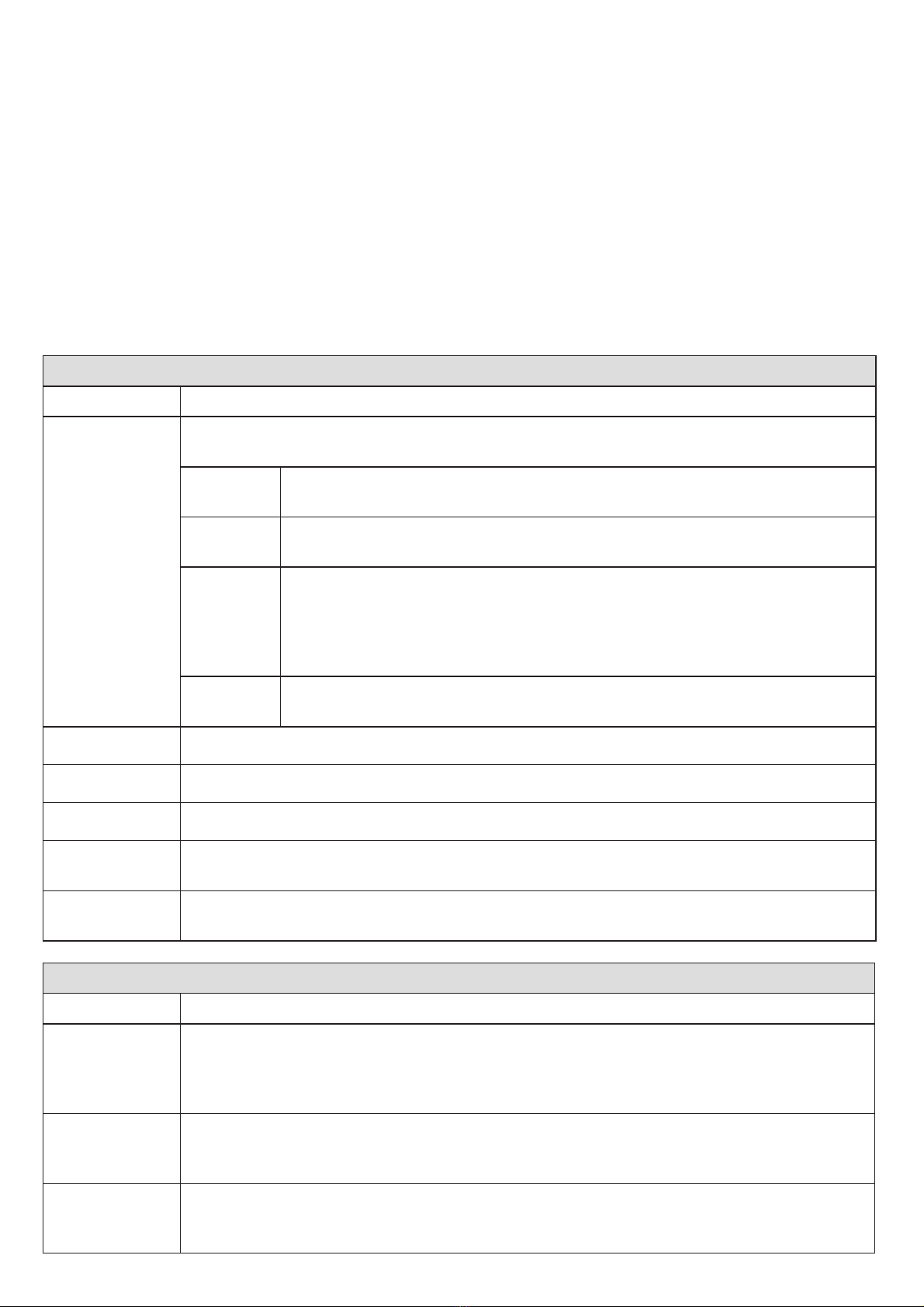

Dichiarazione di Conformità UE (DoC)

Nome del produttore: Automatismi Benincà SpA

Indirizzo: Via Capitello, 45 - 36066 Sandrigo (VI) - Italia

Telefono: +39 0444 751030

Persona autorizzata a costruire la documentazione tecnica:

Automatismi Benincà SpA

Tipo di prodotto: Radioricevitore con frequenza 433,92MHz

Modello/Tipo: ONE4

Accessori: N/A

Il sottoscritto Luigi Benincà, in qualità di Responsabile Le-

gale, dichiara sotto la propria responsabilità che il prodotto

sopraindicato risulta conforme alle disposizioni imposte dalle

seguenti direttive:

Direttiva 2014/30/UE del Parlamento europeo e del Consiglio,

del 26 febbraio 2014, concernente l’armonizzazione delle legi-

slazioni degli Stati membri relative alla compatibilità elettro-

magnetica (EMCD), secondo le seguenti norme armonizzate:

EN 61000-6-2:2005, EN 61000-6-3:2007.

Direttiva 2014/35/EU DEL PARLAMENTO EUROPEO E

DEL CONSIGLIO del 26 febbraio 2014 concernente l’ar-

monizzazione delle legislazioni degli Stati membri relative

alla messa a disposizione sul mercato del materiale elettrico

destinato ad essere adoperato entro taluni limiti di tensione

(LVD), secondo le seguenti norme armonizzate:

EN 60335-1:2012 + A11:2014; EN 60335-2-103:2015.

Direttiva 2011/65/UE del Parlamento europeo e del Consiglio,

dell’ 8 giugno 2011, sulla restrizione dell’uso di determinate

sostanze pericolose nelle apparecchiature elettriche ed elet-

troniche (RoHS), secondo le seguenti norme armonizzate:

EN 50581:2012

Direttiva 1999/5/CE del Parlamento europeo e del Consiglio,

del 9 marzo 1999, riguardante le apparecchiature radio e le

apparecchiature terminali di telecomunicazione e il reciproco

riconoscimento della loro conformità (R&TTE), secondo le

seguenti norme armonizzate:

ETSI EN 301 489-3 V1.4.1 (2002) + ETSI EN 301 489-1

V1.4.1 (2002) + ETSI EN 300 220-3 V1.1.1 (2000) + EN

60950-1 (2001)

Benincà Luigi, Responsabile legale.

Sandrigo, 11/10/2016.

Il Certificato di Conformità di questo documento corrisponde

all'ultima revisione disponibile al momento della stampa e

può risultare differente per esigenze editoriali dall'originale

disponibile presso il produttore.

Il Certificato di Conformità più completo e recente è disponi-

bile consultando il sito: www.beninca.com oppure può essere

richiesto presso:

Automatismi Benincà S.p.A - Sandrigo VI - Italy.

UE Declaration of Conformity (DoC)

Manufacturer's name: Automatismi Benincà SpA

Address: Via Capitello, 45 - 36066 Sandrigo (VI) - Italia

Telephone: +39 0444 751030

Person authorised to draft the technical documentation:

Automatismi Benincà SpA

Product type: 433,92MHz frequency radioreceiver

Model/type: ONE4

Accessories: N/A

The undersigned Luigi Benincà, as the Legal Officer, declares

under his liability that the aforementioned product complies

with the provisions established by the following directives:

Directive 2014/30/UE OF THE EUROPEAN PARLIA-

MENT AND OF THE COUNCIL of 26 February 2014, on

the harmonisation of the laws of Member States relating to

electromagnetic compatibility, according to the following

harmonised regulations:

EN 61000-6-2:2005, EN 61000-6-3:2007 + A1:2011.

Directive 2014/35/UE OF THE EUROPEAN PARLIA-

MENT AND OF THE COUNCIL of 26 February 2014, on

the harmonisation of the laws of Member States relating to

electrical equipment designed for use with certain voltage

limits, according to the following harmonised regulations:

EN 60335-1:2012 + A11:2014; EN 60335-2-103:2015.

Directive 2011/65/EU of the European Parliament and

Council, dated 8 June 2011, on the restricted use of certain

hazardous substances in electrical and electronic devices

(RoHS), according to the following standards:

EN 50581:2012

Directive 1999/5/CE OF THE EUROPEAN PARLIAMENT

AND COUNCIL, 9 March 1999 in relation to radio equipment

and telecommunications terminals and the mutual recognition

of their conformity, per the following harmonised standards:

ETSI EN 301 489-3 V1.4.1 (2002) + ETSI EN 301 489-1

V1.4.1 (2002) + ETSI EN 300 220-3 V1.1.1 (2000) + EN

60950-1 (2001)

Benincà Luigi, Legal Officer.

Sandrigo, 11/10/2016.

The certificate of conformity in this document corresponds

to the last review available at the time of printing and could

differ for editorial requirements from the original available

from the manufacturer.

The most recent and complete certificate of conformity is

available consulting the site: www.beninca.com or can be

requested from:

Automatismi Benincà SpA - Sandrigo VI - ITALY.