IM-PP 724607 0815 7

1.4.3 Special features

Viega ProPress copper, 316 stainless steel and

Zero Lead bronze fittings meet the federal lead-free

requirements of NSF 61-G through testing under

NSF/ANSI 372 (0.25% or less maximum weighted

average lead content). Fast and easy; one squeeze

of the trigger makes the connection on any size

tube in four to seven seconds.

1.4.4 Viega Smart Connect feature

In Viega ProPress ½" to 4" fittings, the Smart

Connect feature (Figure 1.2) assures the escape of

liquids or gases from inside the system past the

sealing element of an unpressed connection. The

function of this feature is to provide the installer

quick and easy identification of connections that

have not been pressed prior to putting the system

into operation (Figure 1.4).

Figure 1.3: Section of a press fitting in unpressed

(A) and pressed (B) condition

Figure 1.2: The Smart Connect feature of Viega

press fittings is color marked on the bead

3Viega ProPress

connections are fast,

flameless and guaranteed.

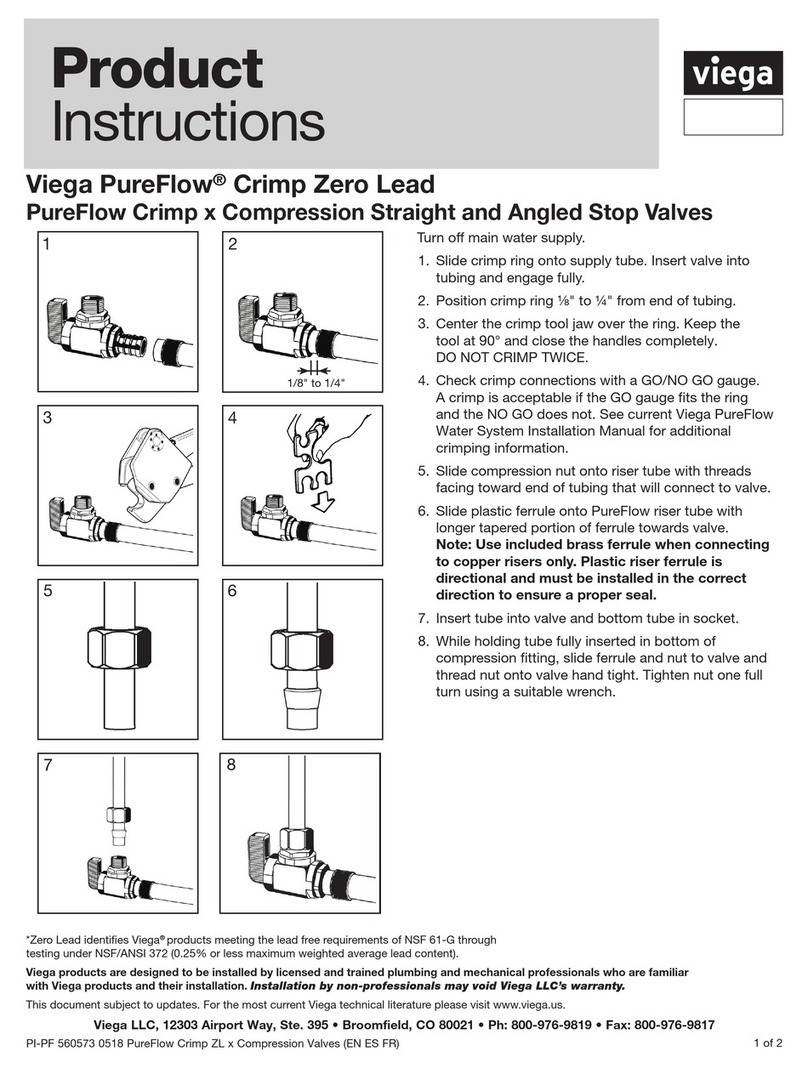

1Identify an unpressed

connection during

pressure testing

when water flows past the

sealing element.

2

Upon identification,

use the press tool

to press the fitting,

making a permanent leak-

proof connection.

Figure 1.4

When the fitting is pressed (Figure 1.3), a

permanent, sealed, non-detachable, mechanical

connection is created.

Unpressed fittings from other manufacturers,

without the patented Smart Connect feature,

may not leak during the initial system pressure

test. However, they can unseat in future system

operation. The Smart Connect feature is designed

to protect from this potential risk.

1.4.5 Sealing elements

Viega ProPress EPDM sealing element

Operating temperature:

0°F to 250°F (-18°C to 120°C)

Viega ProPress and ProPress for stainless 316

fittings are manufactured with a high-quality EPDM

sealing element installed at the factory. This sealing

element is used mainly in the applications of

potable water, hydronic heating, fire sprinkler and

compressed air installations. EPDM, or ethylene-

propylene dienemonomer, is shiny black in color.

The EPDM sealing element is

a synthetically manufactured and peroxide

cross-linked, general-purpose elastomer with

a wide range of applications.

It possesses excellent resistance to aging, ozone,

sunlight, weathering, environmental influences, most

alkaline solutions and chemicals used in a broad

range of applications.

The EPDM sealing element has particularly good

resistance to hot water, making it ideal for seals

and gaskets in heating systems, fittings and

household appliances (e.g. washing machines,

pumps, dishwashers).

All sealing elements are inserted into the fitting using

an H1 Grade lubricant registered with NSF, the

USDA and approved for use under FDA 21 CFR.

Viega ProPress FKM sealing element

Operating temperature:

0°F to 284°F (-18°C to 140°C)

FKM is well known for its excellent resistance

to petroleum products and solvents as well as

exceptional high-temperature performance.

The FKM sealing element is a special-purpose

elastomer typically installed where higher

temperatures are required.

FKM, a fluoroelastomer, is dull black in color. It

possesses excellent resistance to aging, ozone,

sunlight, weathering, environmental influences,

oils and petroleum-based additives. Its superb

resistance to high temperatures and petroleum-