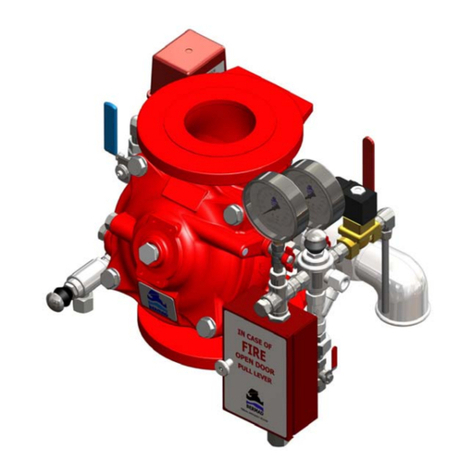

410-01-3NC-200

Electric Remote Control Valve w/ Closing Speed Needle & 3-Way Solenoid- N.C Main Valve

DESCRIPTION

Model 410-01-3NC-200 Electrical Remote Control Valve is

designed to open and close drip-tight in response to an electrical

signal. The valve operates via upper control chamber on a 3-way

control principle. When the 3-way normally open solenoid 15 is

energized, the solenoid vents pressure from the control chamber to

atmosphere to open the main valve wide. When solenoid 15 is de-

energized, the solenoid applies upstream pressure to the control

chamber, via closing speed needle 5, to close the main valve drip-

tight. In addition, the valve comes with a manual operator to

manually open or close the main valve regardless of solenoid

position.

INSTALLATION

1. Allow enough room around the valve assembly for

making adjustments and for future maintenance and

disassembly work.

2. Thoroughly flush the pipeline to remove dirt, scale, and

debris. Failure to perform this operation may render the

valve inoperable.

3. It is recommended that isolation gate valves be installed

upstream and downstream of the Bermad control valve to

allow for future maintenance operations.

4. Install the valve in the pipeline with the valve flow arrow

on the body casting in the proper direction. Use the lifting

eye provided on the main valve cover for raising and lower

the valve. Install the valve horizontally with the cover up for

best performance. Make certain the valve is positioned so

the actuator assembly can be easily removed for future

maintenance requirements.

5. After installation carefully inspect/correct any damaged

accessories, piping, tubing, or fittings. Tighten all fittings.

IN LINE STATIC TEST PROCEDURES

OPEN VALVE STATIC TEST

1. Energize solenoid 15. If power supply is not available

to energize solenoid 15, turn manual operator 0 (black

handle) on solenoid base fully clockwise towards the “O” CW

marked on the solenoid base.

2. Caution: This will allow the valve to fully open. Make

sure this condition wll not cause system damage!

3. Check for leaks at the flange connection, fittings, etc.

CLOSED VALVE STATIC TEST (OPEN NEEDLE 5 OUT CCW)

1. De-energize Solenoid 15 or turn manual operator 0 (black

handle) on solenoid base fully counter-clockwise towards the

“O” marked on the solenoid base.

2. Open upstream gate valve (if applicable), allowing the

valve to close tightly.

3. Check the valve cover and diaphragm area for leaks.

Tighten cover bolts/nuts/fittings if necessary.

START-UP OPERATION

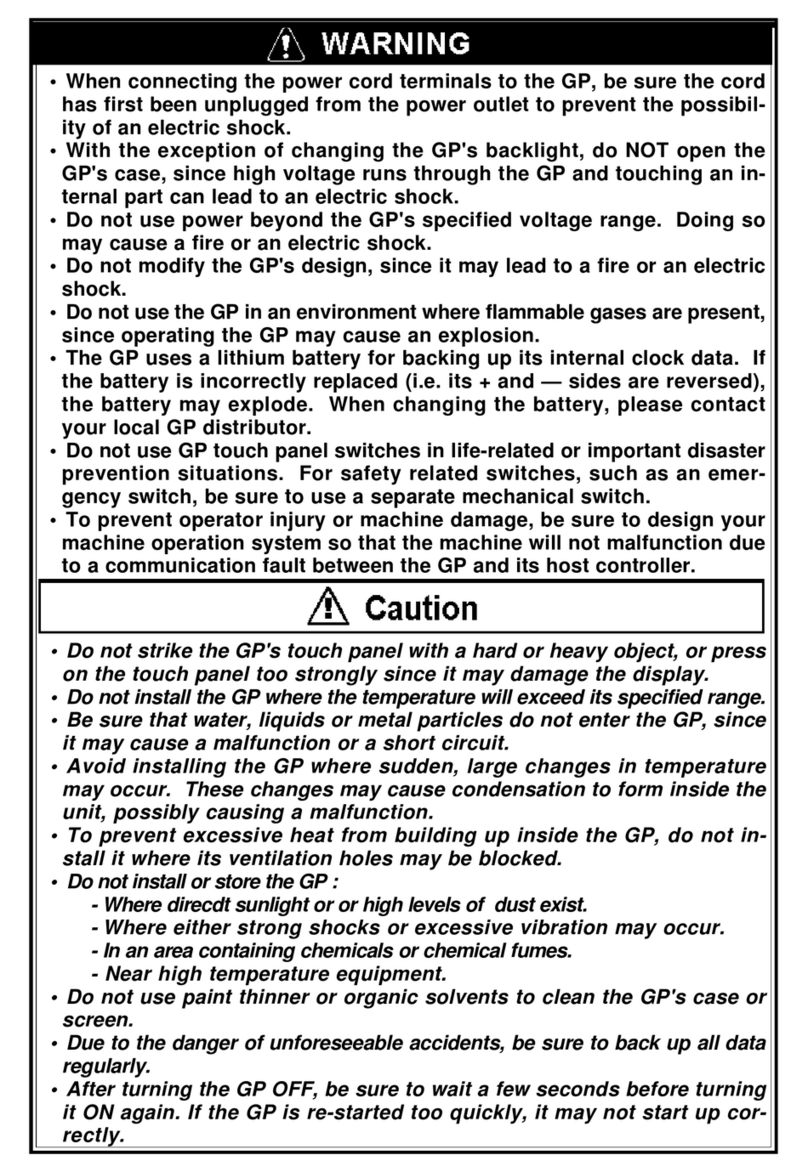

WIRING: Check the solenoid markings on the side of the coil to

verify proper voltage/wattage of coil (i.e 24 AC 3.5 Watt). This is to

prevent coil burn-out/inoperative solenoid. Verify solenoid

connections. There are 2 wires. One wire is power or ’hot’ and the

other wire is common (negative on DC systems). Polarity is not

important. Solenoid voltage at splice (not controller) must be at least

85% of the stamped voltage to function properly. Use safety

precautions.

NOTE: There must be flow through the valve and system to check

and adjust the valve. Insure that a downstream demand is created.

Verify solenoid electrical connections and voltage requirements.

Manual override knob 0 must be in the middle detent position

and neither turned CW or CCW for automatic clock/controller

command operation. Needle valve 5 must be open at least 1-2

turns out counter-clockwise -CCW from the closed position.

1. Open system gate valves if applicable.

2. Make sure manual operator 0 (black toggle on solenoid base)

is set in its middle detent position.

3. Energize solenoid 15 and valve will open. De-energize solenoid

15 and valve will shut drip-tight.

4. Adjust needle 5 in clockwise to increase closing time or counter-

clockwise to decrease closing time.

MODEL

PARTS LIST

1. Black Manual Operator knob

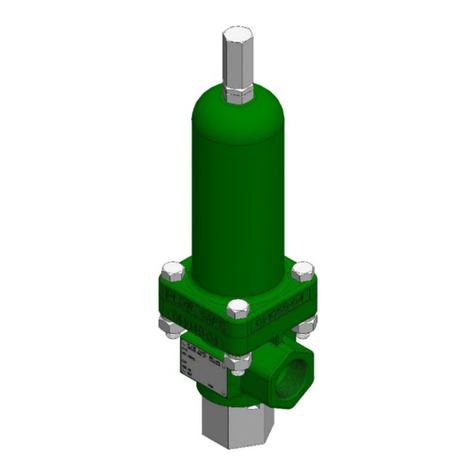

5. Closing Speed Control

4A. In-line Filter

15. 3-way N.O. Solenoid w/Manual Override

405 Main Valve

CONTROL

VALVES