enorossi ENOSPE US User manual

Table of contents

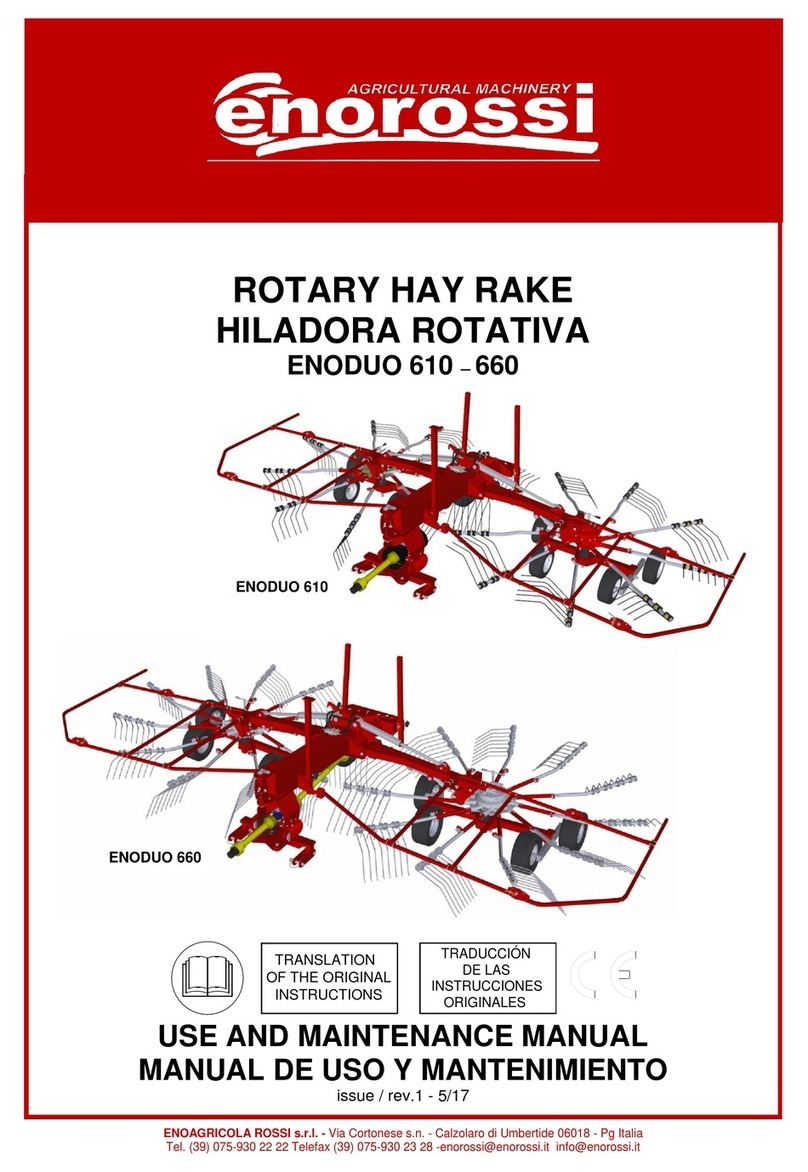

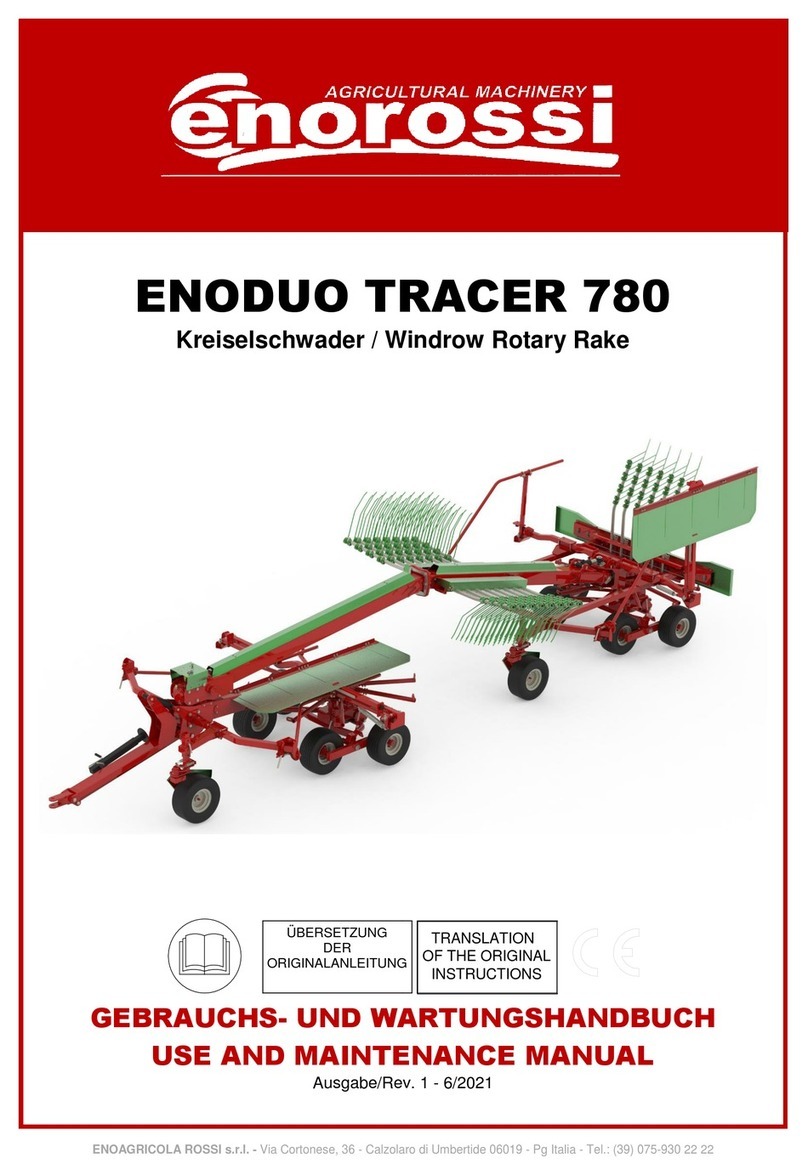

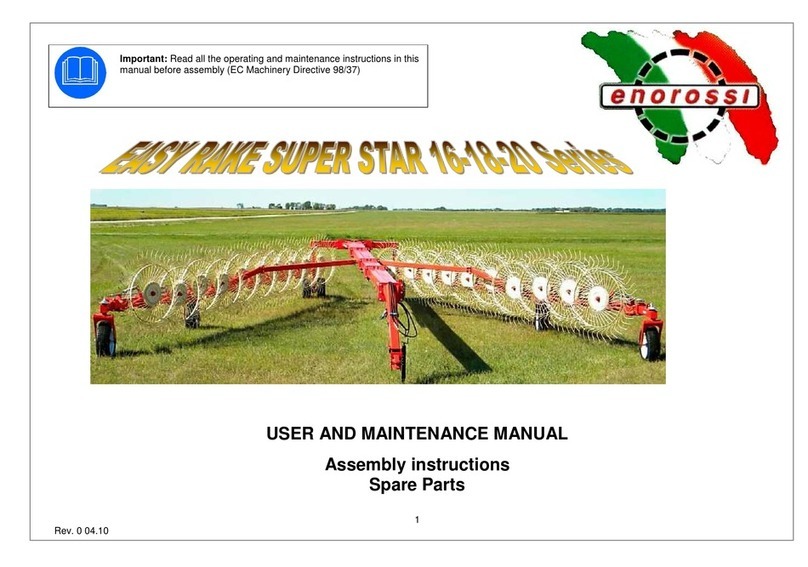

Other enorossi Farm Equipment manuals

enorossi

enorossi DR 420 4R User manual

enorossi

enorossi RR 350 EVO PROFI User manual

enorossi

enorossi RR 420 EVO User manual

enorossi

enorossi G2 Series User manual

enorossi

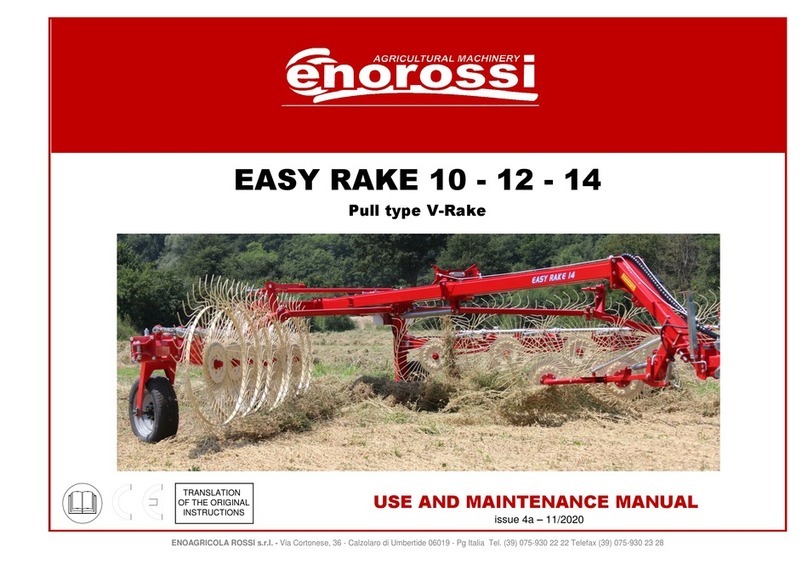

enorossi EASY RAKE 10 User manual

enorossi

enorossi RAKE CADDY Series Operating instructions

enorossi

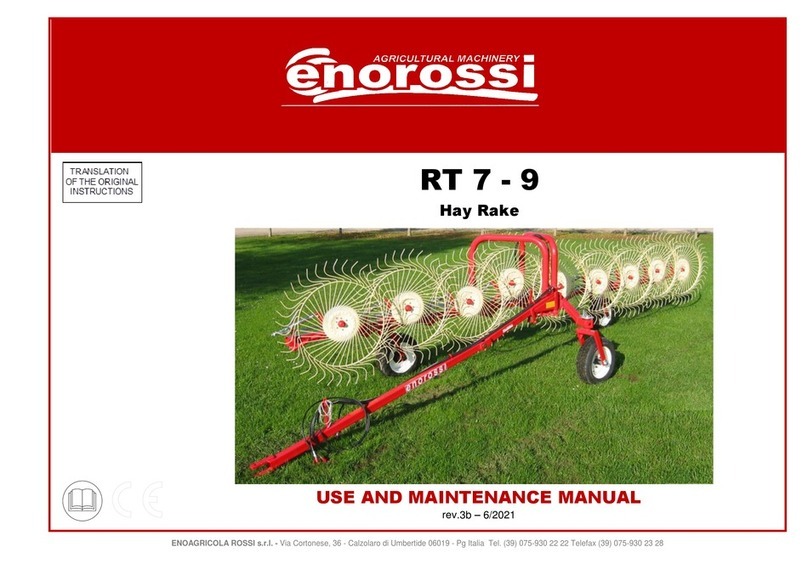

enorossi RT7 User manual

enorossi

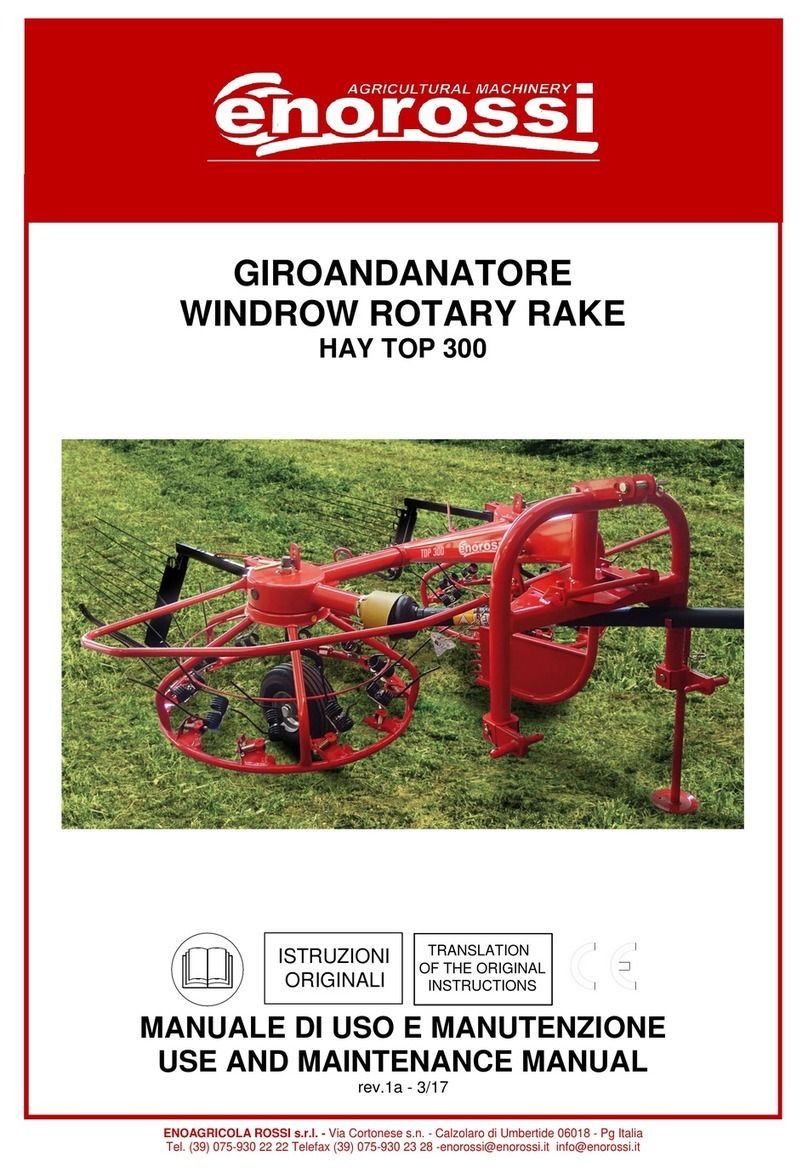

enorossi HAY TOP 300 User manual

enorossi

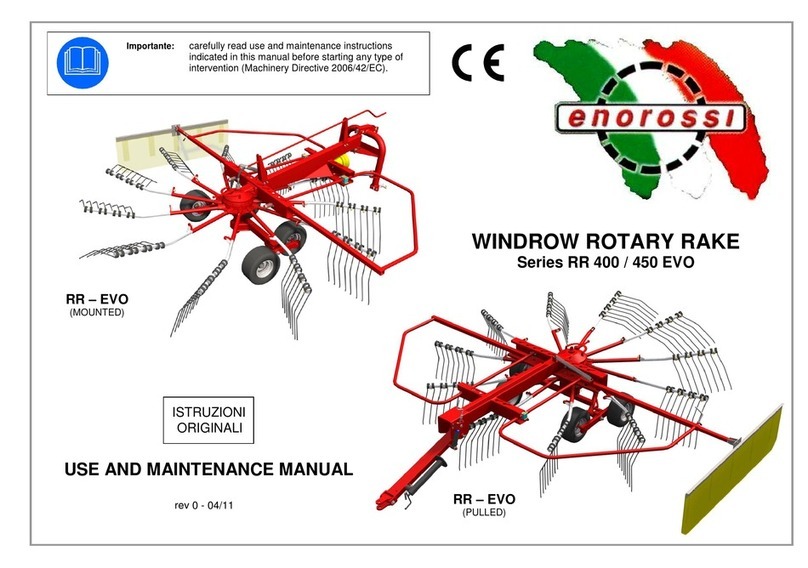

enorossi RR 400 EVO Series User manual

enorossi

enorossi EASY RAKE Series Operating instructions

Popular Farm Equipment manuals by other brands

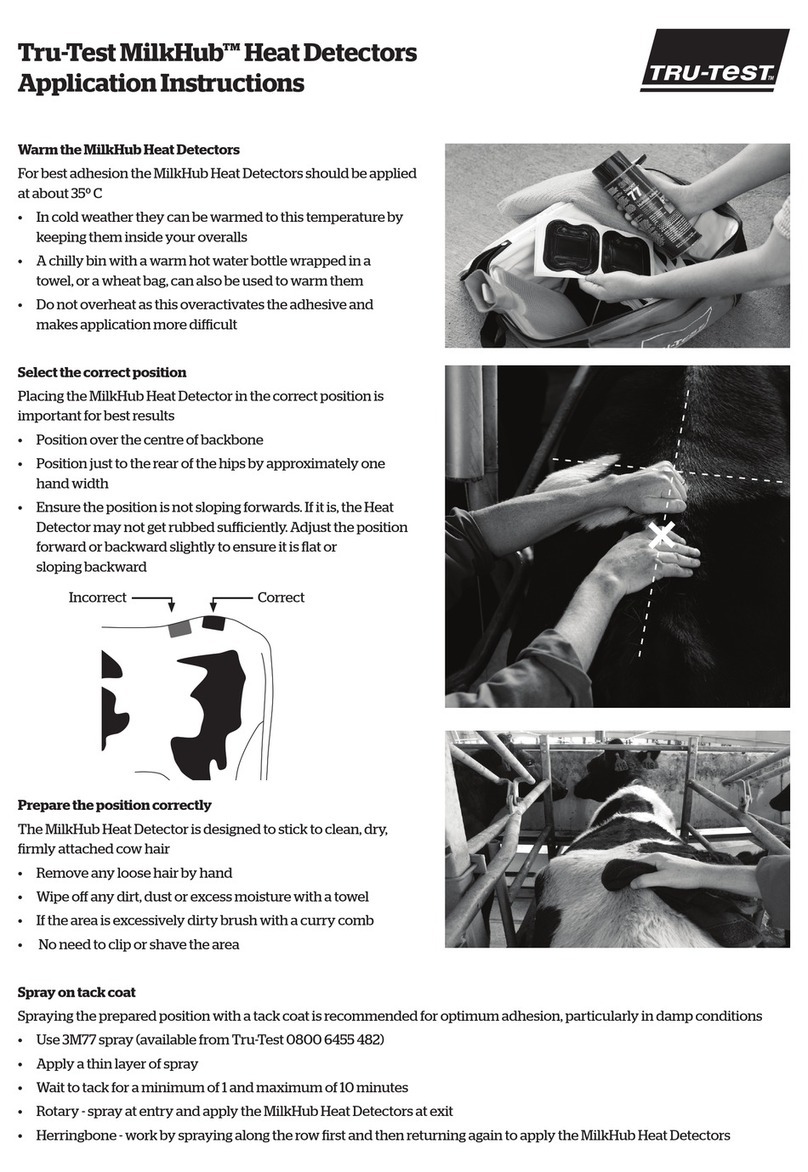

Tru-Test

Tru-Test MilkHub Application Instructions

360 Yield

360 Yield 360 Y-DROP JOHN DEERE 4930 instruction manual

AMAZONEN-Werke

AMAZONEN-Werke Catros 5500 Quick manual

Suevia

Suevia 5900 Mounting instructions

Goldacres

Goldacres Crop Cruiser G6 Operator's manual

LOFTNESS

LOFTNESS Battle Ax 207460 Owner's manual and parts book

Checchi & Magli

Checchi & Magli SP 150 onion Use and maintenance manual

GREAT PLAINS

GREAT PLAINS Terra Max HT1100-20 FIELD ADJUSTMENT GUIDE

Egholm

Egholm City Ranger 2200 Operator's manual

Fratelli Camisa

Fratelli Camisa TP 280 ECO Instruction manual for use and maintenance

Rauch

Rauch AXIS-M 20.2 EMC instruction manual

Yetter

Yetter 2565-980 owner's manual