enorossi 16 Series Operating instructions

1

Rev. 0 04.10

USER AND MAINTENANCE MANUAL

Assembly instructions

Spare Parts

Important:

Read all the operating and maintenance instructions in this

manual before assembly (EC Machinery Directive 98/37)

2

Rev. 0 04.10

rev 0 – 04/10

Machine Directive and harmonized standards

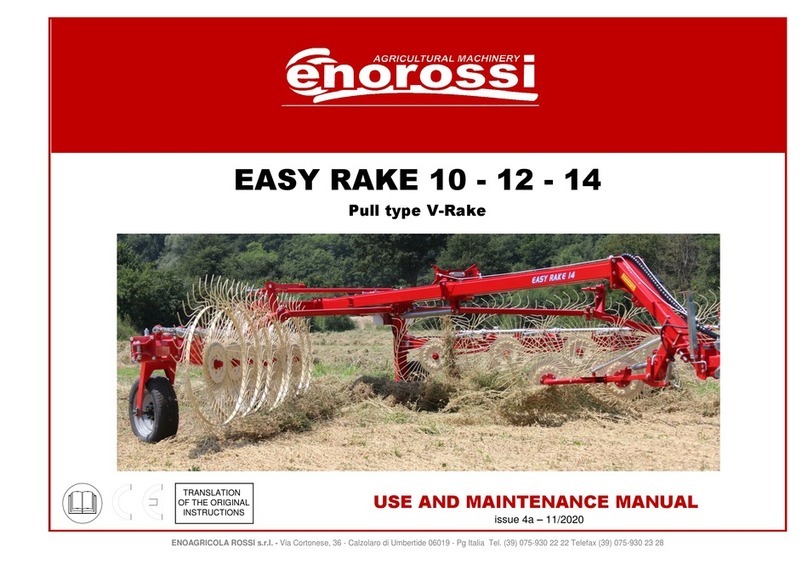

The EASY RAKE SUPER STAR pull type

are designed in accordance with the

provisions of Machine Directive 2006/42/EC and conform to the following harmonized

standards in particular:

EN 349: Safety of Machinery – Minimum gaps to avoid crushing parts of the body (1993)

+ A1 (2008)

EN ISO 4254-1: Agricultural machines – general safety requirements for the design and

construction of agricultural self-propelled ride-on machines and mounted, semi-mounted

or trailed machines (2008)

EN ISO 4254-10: Agricultural machines – mounted, semi-mounted, trailed or self-

propelled agricultural machines – Part 10: rotary tedders, rotary rakes and rotary tedder-

rakes (2010)

EN ISO 11684: Tractors, machinery for agriculture and forestry, powered lawn and

garden equipment – Safety signs and hazard pictorials – General principles (1995)

EN 12100-1: Safety of machinery – Basic concepts, general principles for design – Part

1: Basic terminology, methodology (2003) + A1 (2009)

EN 12100-2: Safety of machinery – Basic concepts, general principles for design – Part

2: Technical principles (2003) + A1 (2009)

EN 12965: Tractors and machinery for agriculture and forestry. Power take-off (PTO)

drive shafts and their guards. Safety (2003) + A1 (2004) + A1 (2009)

EN 13857: Safety of machinery – Safety distances to prevent hazard zones being

reached by lower limbs (2008)

EN 14121-1: Safety of machinery – Risk assessment principles (2007)

CE DECLARATION OF CONFORMITY

The Manufacturer ENOAGRICOLA ROSSI s.r.l.

Headquartered at via Cortonese s.n. - 06018

Calzolaro di Umbertide (PG) - Italy

Declares under its sole responsibility that the machine

the functions of which are described in this manual

conforms to the essential health and safety requirements of Machine Directive 2006/42/EC

We have taken into account the following EN standards to ensure conformity with the above

Directives:

EN 349 (1993) + A1 (2008) - EN ISO 4254-1 (2008)

EN ISO 4254-10 (2010) - EN 11684 (1995)

EN 12100-1 (2003) + A1 (2009) - EN 12100-2 (2003) + A1 (2009)

EN ISO 12965 (2003) + A1 (2004) + A2 (2009)

EN ISO 13857 (2008) - EN 14121-1 (2007)

We hereby authorize Mr Massimo Giovannini

Via Cortonese s.n. - 06018 Calzolaro di Umbertide (PG) - Italy

to draw up the respective Technical Dossier

GIOVANNINI ADELMO

Calzolaro di Umbertide, …….. ….……………………….

Legal Representative

ENOAGRICOLA ROSSI s.r.l.

06018 Calzolaro di Umbertide Perugia Italy

Tel. (39) 075-930 22 22 - Telefax (39) 075-930 23 28

website: http://www.enorossi.it - http://www.enoagricolarossi.com

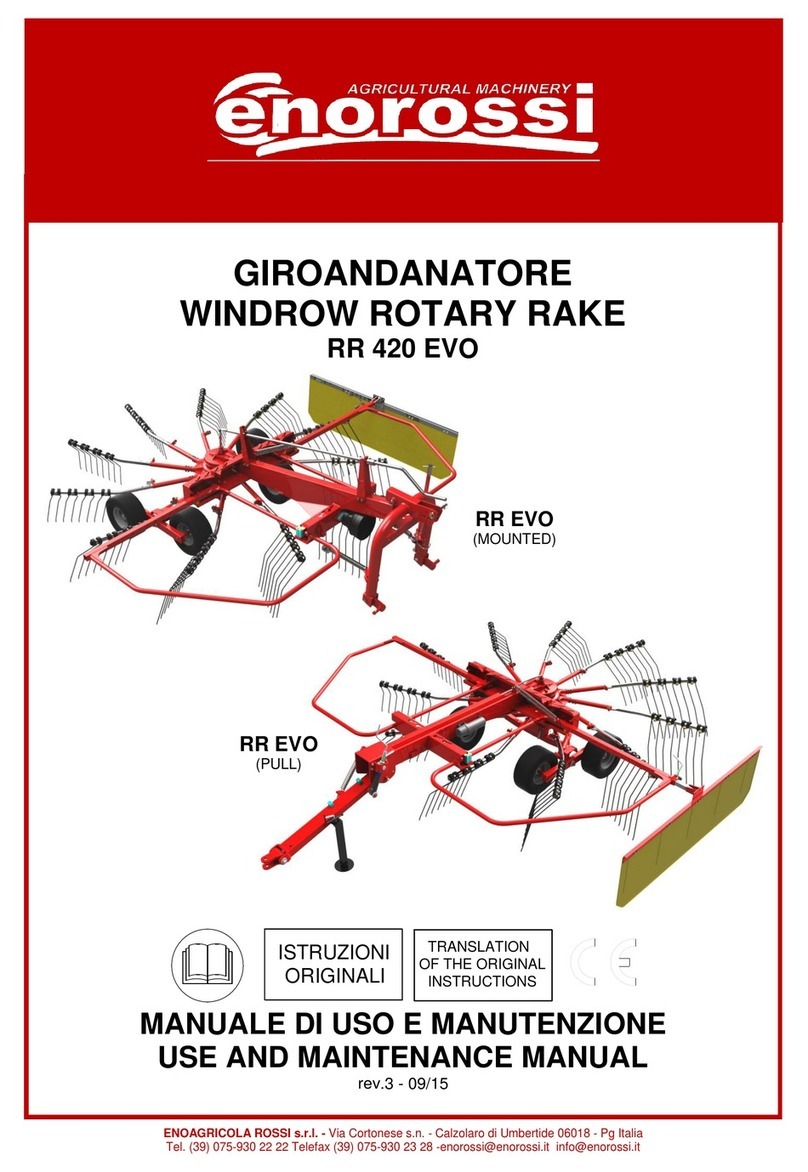

EASY RAKE SUPER STAR PULL TYPE

………………………………………………………………………………………….

General and commercial name

EASY RAKE

SUPER STAR

16-18-20

…………………………..

Series/model

……………………………………………

Serial number

2010

…………….

Year of

manufacture

3

Rev. 0 04.10

INDEX

USER AND MAINTENANCE MANUAL...............................................................................................................................1

Machine Directive and harmonized standards...............................................................................................................................2

CE DECLARATION OF CONFORMITY ...............................................................................................................................................................................2

INTRODUCTION....................................................................................................................................................................................................................4

A1

A

BOUT HAY RAKES

.......................................................................................4

A2

A

BOUT THE MANUAL

.....................................................................................4

A3

W

ARRANTY

..................................................................................................4

A4

EC

CERTIFICATION AND IDENTIFICATION

........................................................5

A5

M

AIN COMPONENTS AND TECHNICAL SPECIFICATIONS

....................................6

Stars........................................................................................................................................................................................................6

SAFETY.................................................................................................................................................................................................................................7

B1

G

ENERAL REGULATIONS

...............................................................................7

B2

H

ANDLING AND TRANSPORTATION

.................................................................7

B3

O

PERATOR

'

S RESPONSIBILITIES AND SAFETY

.................................................9

INSTALLATION...................................................................................................................................................................................................................11

C1

R

AKE ASSEMBLY

........................................................................................11

C2

H

ITCHING TO THE TRACTOR

........................................................................11

C3

H

YDRAULIC CONNECTIONS

..........................................................................11

C4

R

EMOVAL

..................................................................................................12

C5

S

TORING THE RAKE

....................................................................................12

OPERATION AND USE ......................................................................................................................................................................................................13

∆1

P

RELIMINARY INFORMATION

........................................................................13

∆2

O

PERATION AND USE

..................................................................................13

MAINTENANCE...................................................................................................................................................................................................................16

E1

M

AINTENANCE INSTRUCTIONS

.....................................................................16

E2

S

CHEDULED MAINTENANCE

.........................................................................16

E2.1

Checks on a daily basis .................................................................................................................................................................................16

E2.2

Checks on a monthly basis or per 50 hours’ operation..................................................................................................................................16

E2.3

Checks on an annual basis or per 500 hours’ operation................................................................................................................................16

E3

L

UBRICATION

.............................................................................................17

E4

T

ROUBLESHOOTING

...................................................................................17

E5

M

ACHINE DEMOLITION

:

DISPOSAL OF MATERIALS

..........................................17

SPARE PARTS....................................................................................................................................................................................................................45

4

INTRODUCTION

A1 About hay rakes

The hay rake is an agricultural device used to collect cut forage. The “Easy

Rake” models produced by our company, all trailer-type, comprise a

flexible, sturdy frame enabling use on any type of land, even if extremely

irregular or on a slope. The main component is the rake wheel, 14 of which

make up the device. Each wheel is separate from the other and comprises

a shock absorbing spring for the wheel to perfectly follow the surface of the

land.

The hay rake has to be attached to an agricultural tractor for it to work. The

arms and stars move hydraulically and the entire rake is trailed by the

tractor to which it is attached. Operation and use of the rake is described in

greater detail in the relative chapter.

A2 About the manual

The ENOROSSI firm (the “Manufacturer”) designed and created the device

in accordance with the relative safety standards to ensure the safety of

personnel and the entire operating system.

Each rake is supplied with a copy of this manual, which the operator must

read in full before using the equipment. The manual contains all information

relating to transportation, use and maintenance of the equipment, as well

as relative safety instructions.

Poor knowledge of the operating system can lead to accidents and

therefore damage to the equipment. Although the Manufacturer provides

the Customer with all information relating to the rake's operation, use and

maintenance, the Customer is still expected to read this manual and take

note of all the instructions herein.

The manual provides all basic instructions on how to ensure optimum

working and safety conditions, but the most important factors to ensure the

device's good working order are the operator's experience and common

sense.

The manual was drawn up on the basis of both the rake models' current

technical and structural characteristics and does not take previous similar

models into account. The Manufacturer therefore reserves the right to

modify models in production in the interest of improving the product or in

accordance with any new legislation (Machinery Directive) without

obligation for adapting previous models.

This manual is integral to the rake and must therefore be kept intact, clean

and in good condition, and stored in a container, either on the frame of the

equipment or in the tractor cabin, where it can be readily accessed for

consultation.

The manual must be kept in its container if the rake is placed out of

service. Ask the Manufacturer for a duplicate copy if the original manual is

lost.

Please contact the Manufacturer for any clarifications relating to the

instructions in this manual. If the translated copy of this manual is unclear

in any way, the valid text of reference is the original one in Italian.

Symbols used in this manual:

-WARNING, with associated pictogram, indicates

potential danger and therefore the need for the operator

to exercise caution and common sense;

-IMPORTANT indicates that the operator must be aware

of the matter referred to;

-Note indicates that the information referred to can facilitate the

operator's work.

A3 Warranty

The Manufacturer's warranty guarantees that all parts of the rake are free

of defects as they are all tested before delivery to the Customer. The

warranty is valid for a year (or for whatever duration is stipulated in the

purchase contract) from the date specified in the fiscal delivery document,

but is not valid during transportation as the Customer is responsible for its

shipment. The warranty does not cover commercial components that are

covered by the warranty of their original manufacturer.

5

Rev. 0 04.10

The Customer, upon receipt of the shipment, must check the entire

structure for any signs of damage and that the components are intact and

none are missing. Any claims must be made to the Manufacturer in writing

within 8 (eight) days of receiving the rake. Any components found to be

defective within the period of the warranty will be replaced by the

Manufacturer free of charge. Only the Manufacturer or technician employed

by the Manufacturer is entitled to check the defect. Spare parts remain the

property of the Manufacturer. The warranty does not however cover faults

caused by improper use of the rake, the operator's negligence, accidents

or normal wear and tear

The warranty is forfeited when:

-The manual's instructions are not followed;

-The necessary maintenance is not carried out;

-The Customer modifies the equipment without the Manufacturer's prior

written consent;

-The spare parts used are not type approved.

A4 EC certification and identification

An identification plate is affixed to each machine. Details on the plate are:

-The rake's model (and/or version);

-Serial number;

-Tractor's power capacity (kw);

-Overall weight (kg);

-Year of manufacture.

You must have this information at hand when requesting assistance and

spare parts.

IMPORTANT

It is strictly forbidden to alter and/or erase the data on the serial plate. The

operator must check legibility of the data on a regular basis and inform the

Manufacturer if it becomes in any way illegible. The Manufacturer will then

replace the old plate with a new one bearing the same data.

ENOAGRICOLA ROSSI s.r.l.

CALZOLARO DI UMBERTIDE - PERUGIA -

ANNO Kg

MODELLO MATRICOLA Kw

The EC mark indicates that the Manufacturer has complied with the health

and safety regulations, adopted by the EU countries, and known as the

“Machinery Directive”. This means that the Manufacturer designed and

created the equipment in full compliance with all the requisites on use of

the rake and avoidance of all possible risks and hazards associated with

the same. The rake can therefore be freely distributed throughout Europe

providing it features this mark and relative declaration of conformity.

6

Rev. 0 04.10

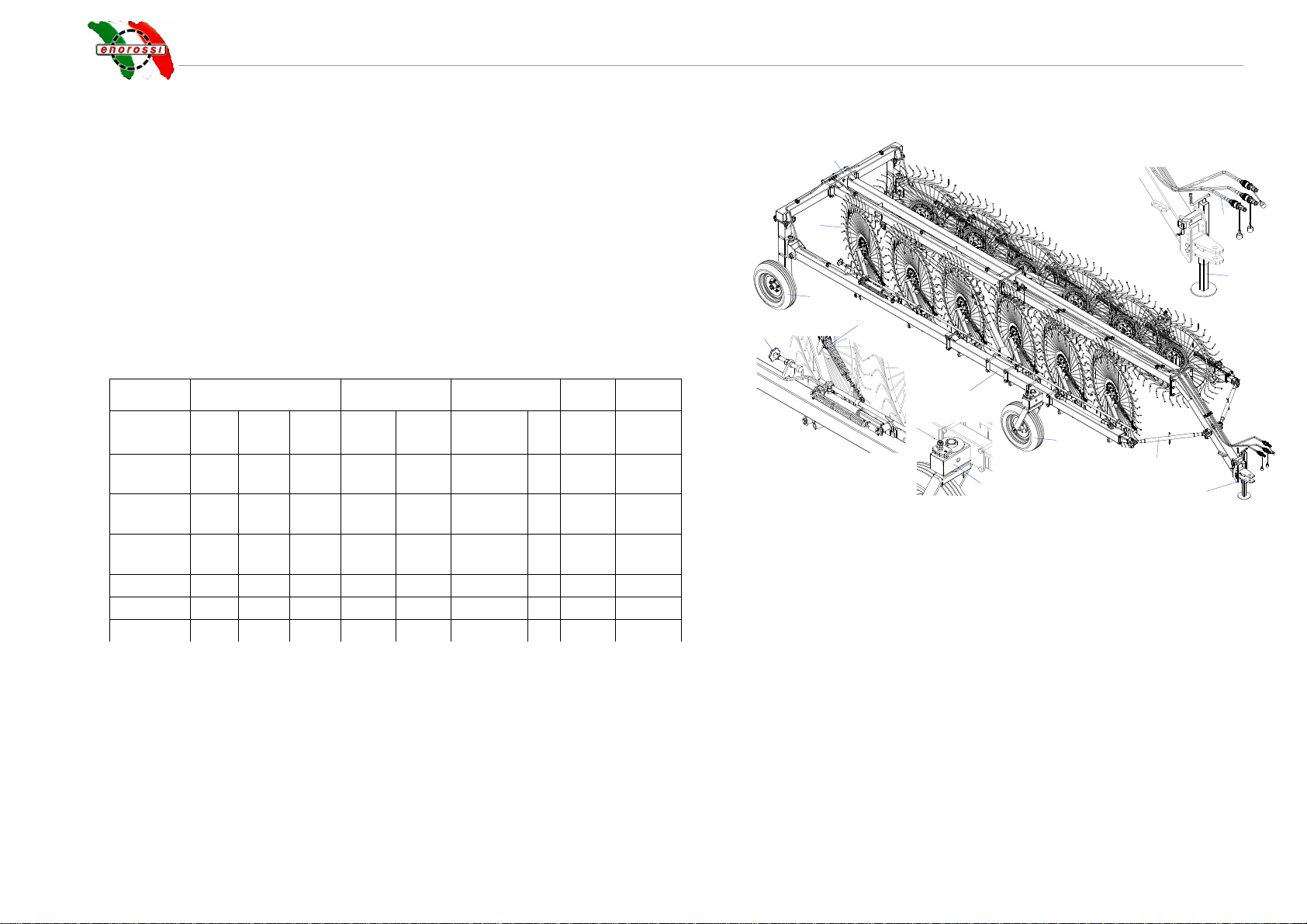

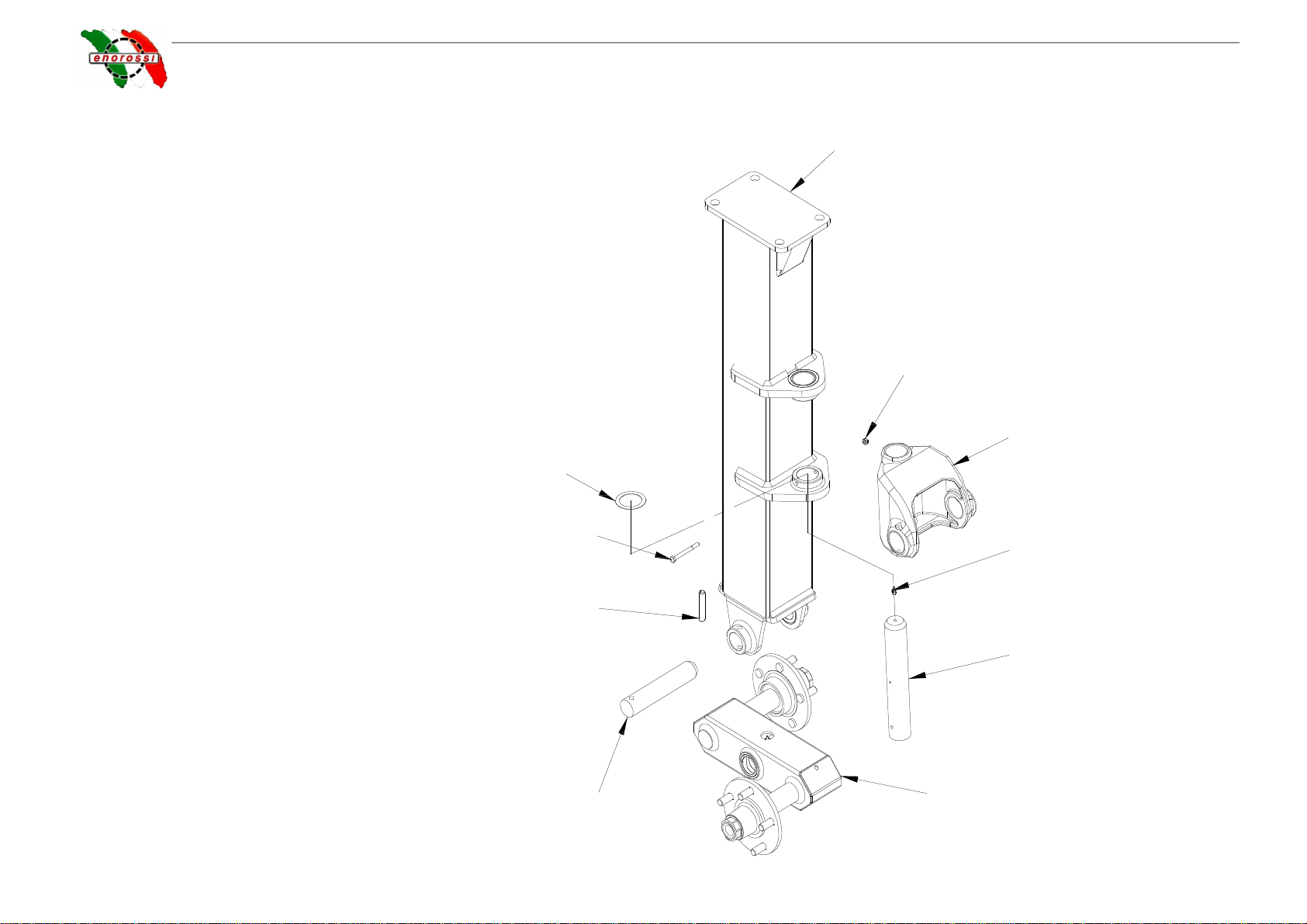

A5 Main components and technical specifications

1. Mechanical end stop (to adjust the rake wheel to the ground)

2. Shock absorbing spring

3. Rear wheel

4. Rake wheel

5. Frame

6. Hydraulic quick couplings

7. Supporting foot

8. Tractor coupling device

9. Tie rod (for road circulation)

10. Front wheel

11. Device to limit pivoting of the front wheel

12. Side arm

Model Stars Width Wheels HP Weight

N° Teeth Ø cm

Work

config

cm

Trnspt

config

cm

Type N°

Kg

Easy RAKE 16 40

149,

5 970 280

205/70.

15 8 50/60

2.250

Easy RAKE 18 40

149,

51.060 280 205/70.15 8 50/60

2.390

Easy RAKE 20 40

149,

51.150 280 205/70.15 8 50/60

2.549

2

1

3

4

5

6

7

8

9

10

11

12

Rev. 0 04.10

SAFETY

B1 General regulations

This manual describes the safety regulations to be followed when using

the rake. As most work-related accidents occur due to non-compliance

with the most basic of safety regulations, it is obligatory to read this

manual before carrying out any work with the rake and to follow all the

instructions.

The equipment must be used by qualified adult personnel trained in its use.

The Manufacturer therefore does not cover accidents caused by the

operator's negligence and/or non-compliance with the safety

instructions. This also forfeits the Manufacturer's responsibility and

the rake's warranty.

B2 Handling and transportation

•Transportation (delivery): the device is fully dismounted and placed in

a crate for transportation. The Customer can then re-assemble the

parts quickly and easily on receipt, following the well detailed

instructions. If the rake is sold or transferred to another user, the rake

can be dismantled by following the instructions in reverse order,

although it can also be delivered fully assembled. The rake can also

be easily transported by road on a suitable means of transport, as

illustrated below.

The rake is loaded or unloaded via a ramp attached to the vehicle. The

equipment, when ready for transportation, is reversed onto the vehicle,

then harnessed in place and fitted with all necessary safety devices for

transportation.

WARNING

Loading and unloading must always be carried out with all due

precautions as they can entail a certain element of risk.

Always take the following precautions:

- Loading/unloading must be carried out on a flat surface and at a

safe distance from slopes or ditches;

-Always ensure the ramps are strong enough to withstand the

rake's weight (given on the identification plate), are firmly attached

to the vehicle and are parallel to each other and perpendicular

with the edge of the vehicle;

-Ensure the ramps are clean, without any traces of oil, grease or

ice;

-Never change direction when moving the rake onto or off the

vehicle. If this does become necessary, bring the rake back down

to change its trajectory.

•Transportation (by road): as this is a trailer-type device, it can only

be transported if attached to an agricultural tractor. In this case, the

device must always be in its transportation configuration for

transportation either by road or in the fields, as illustrated below. This

configuration is necessary as the device can be up to 10 metres in

width in its working configuration.

CONFIGURAZIONE DA LAVORO CONFIGURAZIONE DA TRASPORTO

WORKING CONFIGURATION

TRANSPORTATION CONFIGURATION

8

Rev. 0 04.10

You must remember that the transportation configuration entails

closing the side arms and fitting the equipment with the following

safety devices:

-Tie rods (1) to be fitted in position on the arms and frame, and

locked in place with their relative safety pins;

-End stop device (2) to be inserted on the rod of the jack (to

prevent it from retracting) and blocked with its respective safety

pin;

-Device (3) on the front wheels to limit their movement;

You must also comply with your national road regulations.

•Installation: the device must only be installed on agricultural tractors

with universal three-point hitch system at the back and with hydraulic

lift.

IMPORTANT

The tractor must also, by law, be fitted with a protective roll-bar or

ROPS or FOPS cabin. It is strictly forbidden to install the rake

device on a tractor without the required protection.

Prior to installation, however, the Customer must check the tractor's

operating and maintenance manual to ensure the tractor is suited for

use and operation of the rake, and whether ballasts are needed to

prevent unbalancing that could cause it to tip over.

Instructions on installing the tiller and making the hydraulic

connections are given below.

2m

1

3

26131211 10

9

8

7

4

9

Rev. 0 04.10

Use: the rake must only be put to the use for which it was intended: to

rake up cut forage. Any other use is therefore improper and forbidden.

The rake's technical characteristics must also not be altered in any way to

modify performance otherwise the warranty will be forfeited

immediately and the Manufacturer will refuse all responsibility.

The rake must be used in conditions ensuring good light and visibility.

We recommend you do not work when light and visibility is poor as this

can compromise normal levels of safety. Recommence work only

when light and visibility is good again.

The rake does not require special attention during use as it is not

operated directly, being trailed by the tractor; the operator must,

however, ensure that no persons or animals come too close in the

interest of their safety.

In any case, the rake must only be operated by qualified and well

trained adult personnel who have read the instructions in this manual.

Safety is of paramount importance for personnel operating, repairing

or maintaining the device. As the instructions given in this manual

cannot cover all possible working situations and related risks,

personnel must always act with caution and with common sense.

The operator must take the following precautions when using the rake

device:

-The tractor must not be left running or unguarded, not even for

short periods. The operator must always switch off the tractor's

engine and take the key with him;

-The rake device is relatively quiet and does not require use of

acoustic protection (ear plugs, ear muffs, etc), although this may

not be the case with the tractor. We therefore recommend you

check this in the tractor's operation and maintenance manual.

B3 Operator's responsibilities and safety

Safety is of primary importance to personnel operating the rake device and

therefore each operator is directly responsible for controlling the rake's

operation, maintenance, repairs and/or use of spare parts or consumable

materials. This means the aforementioned personnel must never delegate

their work to operators without the necessary requisites.

The Manufacturer assumes no liability for:

-Improper or incorrect use of the rake device that can cause harm to

persons and animals or damage to objects and the actual rake;

-Employment of personnel who have not received proper training

and/or has not read and understood the instructions in this manual;

-Lack of or insufficient maintenance;

-Use of spare parts that are not type approved or not compatible with

the rake model;

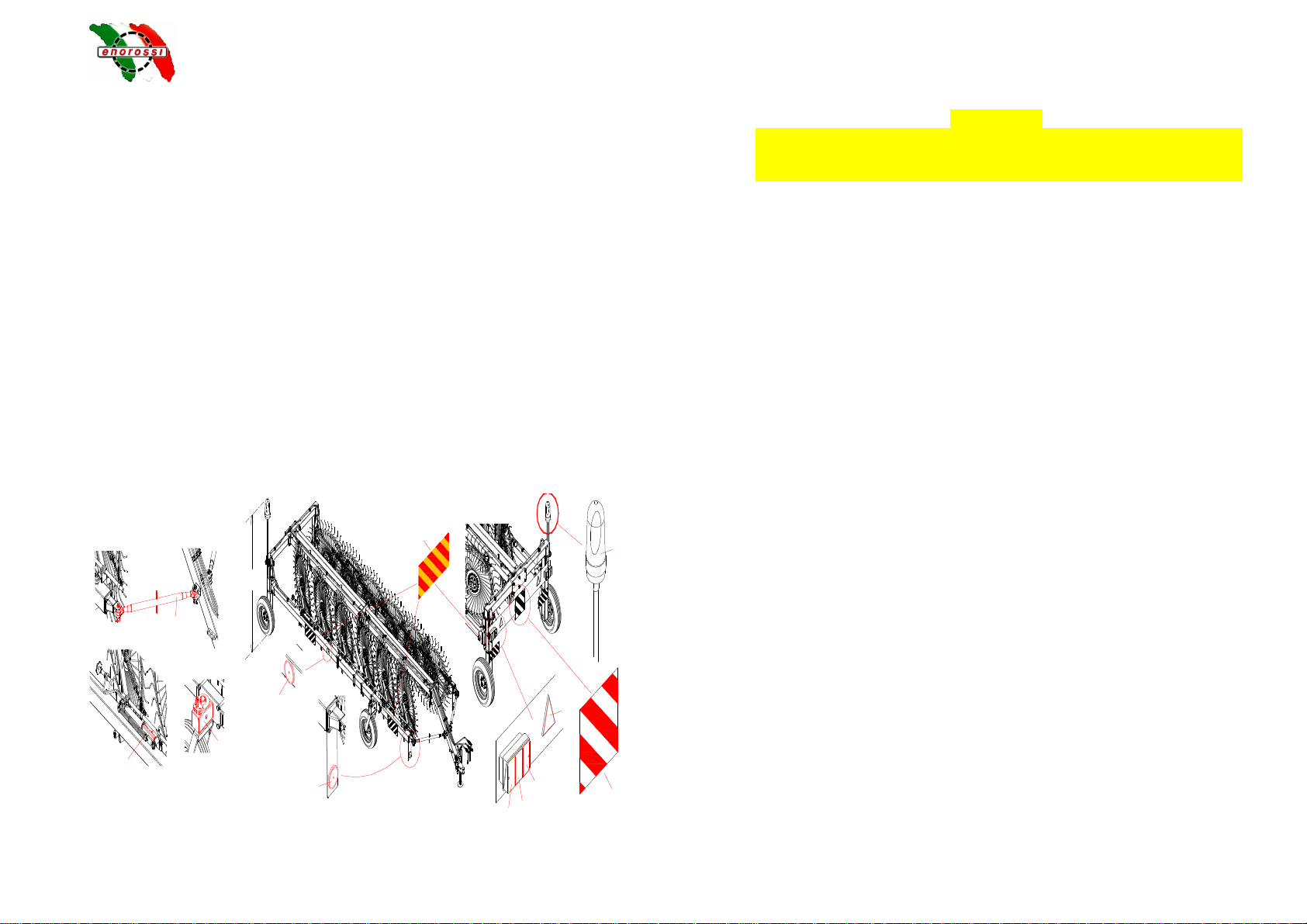

In addition to the instructions in this manual, personnel are given visual

aids in the form of labels (shown in the illustration) attached to the front of

the rake device indicating the necessary safety precautions. These labels

are designed to attract the operator's attention and indicate the level of risk.

These labels, however, differ in shape and colour according to the

instructions. Personnel must therefore know that a circular label indicates

an obligation (blue and white) or a prohibition (red, white and black), and

a triangular label indicates a hazard (yellow and black). Rectangular labels

feature the hazard or prohibition symbol but also indicate the safety

precautions to be taken.

Warnings given on the labels:

a. Risk of flying objects. Objects in the field of operation may be caught

and thrown by the teeth of the rotating rake wheels;

b. Risk of snagging. As the rake wheel rotates, there is a risk that the

teeth snag on the operator's clothes or other objects on the operator's

body.

10

Rev. 0 04.10

c. Obligation to read the user and maintenance manual;

d. Prohibition for unauthorized persons to stand or move in the rake's

field of operation when the rake is being used. Persons must keep at a

safe distance and should they need to move in the rake's field of

operation, they must do taking all due precautions;

IMPORTANT

Warning labels and pictograms must be replaced if they become faded and

risk becoming illegible. In this case, the operator must not use the rake until

any faded labels are replaced with new ones. It is also strictly forbidden to

remove the pictograms and labels from the equipment. Should this occur,

the Manufacturer assumes no liability as the rake no longer meets the

safety requirements for which it was designed and created.

11

INSTALLATION

C1 Rake assembly

As mentioned above, the equipment is fully dismantled for delivery to the

Customer. The rake can be assembled quickly and easily following the

user-friendly instructions (see Page 18). Assembly must be carried out on a

flat surface prepared especially for the purpose. Assembly operators must

be knowledgeable of installation safety regulations and work with all due

care and attention.

The rake, once it has been assembled, can be installed or hitched to a

tractor.

C2 Hitching to the tractor

The rake can be hitched to the attachment of any agricultural tractor. To do

so, the operator must move the rake slowly to a position where the joints

can be easily aligned (1).

IMPORTANT

The holes in the tractor's attachment must be aligned with those on the

rake's attachment with maximum care and attention.

When the tractor is near the rake's attachment (type 1

or 2 – see picture), the operator turns the lever on the

foot support (2) to lift or lower the rake's attachment

and insert it in the tractor's attachment. The operator

can then insert the locking pin (3) through the

attachment holes, as illustrated below, and secure it in

place with the relative safety pin (4).

Next, the operator turns the lever (5) to lift the foot

support off the ground, completing the tractor-rake

attachment procedure. The foot support can then be

removed from its housing and inserted in the housing on the frame.

The operator therefore has to extract pin (6) to free pin (7), extract the latter

from the holes of the foot support and remove the foot support from its

housing (8). The foot support can then be placed in the housing on the

frame (9) and fastened with pin (7) and its relative safety pin.

C3 Hydraulic connections

•The rake wheels are lowered and lifted by retracting and extending a

jack, while the side arms are opened and closed hydraulically by

another jack. Both jacks are powered by the tractor's auxiliary circuit

and therefore commanded by their respective levers in the cabin. As a

result, these functions can only be carried out if the jack connections

1

2

tipo 1

tipo 2

3

4

5

6

78

9

12

are made (quick couplings, as illustrated) to their corresponding

attachments on the tractor's auxiliary circuits.

C4 Removal

To remove the rake from the tractor, follow the above instructions in

reverse order. The hydraulic connections have to be removed before the

actual rake.

C5 Storing the rake

The Customer must set aside a large and easily accessible area on his

premises where the rake can be stored. How to store the rake:

-Park the rake in a safe area set apart for the purpose. The area must

be flat and even;

-Install the foot support supplied with the rake and stored in its relative

housing on the frame, near the attachment;

-Detach the rake from the tractor, following the instructions in

paragraph C2 and C3 in reverse order;

-Chock the wheels;

-Place protective material over the rake.

13

OPERATION and USE

∆1

∆1∆1

∆1

Preliminary information

Suitable and optimal use of the rake not only helps avoid accidents but is

also the only way to ensure high yield and make use of the rake's full

potential and performance.

The rake must be used by trained adult personnel knowledgeable of the

instructions in this manual and on the labels. Safety is of paramount

importance for the personnel that operate, repair and maintain the

equipment. As the instructions given cannot possibly cover all possible

working situations, personnel must always exercise caution and common

sense.

Before the tractor can transport the rake to the work area, it is advisable to

carry out the following preliminary checks:

•Ensure all the parts of the rake are in their intended position and are

securely fitted;

•Ensure the rake is fitted properly to the tractor;

•Check efficiency of all the protection devices;

•Carry out the daily maintenance checks described in the relative

paragraph. Note: should the rake be returned to service after a long

period of inactivity, ensure it has been properly maintained and that it

has not been damaged in any way by poor weather or storage

conditions.

∆2

∆2∆2

∆2 Operation and use

The rake must be taken to the work area in keeping with the instructions in

paragraph B2 “Handling and Transportation”.

The tractor driver is personally responsible for the general procedure of

conveying the rake and must therefore prepare the rake for transportation

as follows:

•Firstly, the operator must remove any safety devices that need to be

removed for transportation, i.e. The jacks' end stop devices (B) and

the arms' tie rods (A):

-End stop device: remove the safety pin to free the device, lift the

latter from the jack rod and move it further back, as shown in the

illustration. Re-fasten the device with the safety pin (do one side

at a time);

-Arms' tie rods: remove the safety pin from the locating pin and

remove the latter from its housing. Repeat the same procedure

on the other side of the tie rod and then remove it from the

rake's pinned supports. Move the tie rod to the points on the

frame shown in the illustration. Screw the body of the tie rod into

place at the new points.

•After removing the safety devices, the operator uses the respective

controls in the cabin to fully open the rake’s arms (control A) into

the working configuration, and then lower the rake wheels (control

B), which all move together, as shown in the illustration.

B

A

14

The rake is now ready for use. It is extremely easy to operate as it just has

to be hitched to the tractor which trails it in the required direction. The rake

wheels, which have been adjusted according to the type of ground, turn as

they are pulled along and the teeth

collect the cut forage.

The rake’s working configuration, as

illustrated, allows the cut forage to

be collected and conveyed into a

single central swath. This

configuration, which can reach 10

metres for some models,

considerably simplifies the process

thereby reducing end costs.

IMPORTANT

You must remember that the tractor

must drive in a more or less straight

line. To change direction a few

metres before the end of the field,

the driver needs to apply the

command to lift the rake wheels and

close the side arms.

Only after the rake wheels have

been lifted and the arms are closed

can the operator change the

tractor’s direction, which requires

several maneuvers.

Once the operator has turned the tractor, he can apply the command to re-

open the side arms and then lower the rake wheels to continue the work.

To move the forage in the central swath, one or more additional rake

wheels need to be installed at the centre of the frame. A set of additional

rake wheels can be supplied with the Easy Rake series (the set, shown in

the illustration, is called Kicker wheel and is available on request).

Swath adjustment: the swath can be narrowed by moving the two rear

rake wheel arms, as indicated in the illustration by the arrow.

Easy Rake with Kicker wheel

CONTROL A

CONTROL B

15

Kicker wheel adjustment

After installing the kicker wheel (assembly instructions on page 40), the

rake wheels can be better adapted to the ground by adjusting their

inclination in relation to the direction in which they move:

Loosen the counter nut (pos 2) and screw or unscrew the bushing (pos 3)

to increase or decrease inclination of the two rake wheels.

1) Decreased inclination FIG. 1: hay is discharged

better from the rake wheels, but the ground isn’t

cleared as efficiently.

2) Increased inclination FIG. 2: hay isn’t discharged as

efficiently from the rake wheels, but the ground is

cleared better.

Figure 1 Figure 2

Prior to work breaks (even short ones) the operator must always:

•Switch off the tractor’s engine

•Apply the parking brake

•Place the gear stick in neutral

•Remove the keys from the ignition;

When the operator has finished work for the day, he must place the rake

back in its transportation configuration before returning the tractor to its

parking area.

Rake storage instructions are given in paragraph C5.

Kicker wheel

16

MAINTENANCE

E1 Maintenance instructions

The Manufacturer has drawn up a rake maintenance schedule based on

functional tests. This schedule, if followed assiduously by the Customer,

can maintain the rake’s working efficiency and capacity without risk of

damage. The operator, who must be a qualified technician of working age,

must follow these rules:

-All maintenance and repairs must never be left unfinished or

postponed;

-The operator must never rely on his memory alone, but always read

and follow the instructions in this manual without fail;

-The operator must install a “Maintenance in progress” sign in a

prominent position on the tractor’s dashboard before starting work. This

ensures the operator’s safety and can prevent damage to the rake.

-All maintenance must be carried out on a flat and well lit surface, with

the rake standing in a stable position and the tractor at standstill, with

the parking brake applied, the engine off and the keys removed from

the ignition;

-Tools for maintenance must be used in accordance with relative

accident prevention regulations. Equipment must not, therefore, be put

to improper use, e.g. do not use petrol instead of detergent, or pliers

instead of a wrench;

-Only use spare parts that are type approved or recommended by the

Manufacturer.

After maintenance or repairs, always clear the area of any water, oil,

grease, dirty cloths, tools and any other material.

IMPORTANT

Take extra care when checking for leaks of pressurized fluid as the fluid

can leak out of tiny, virtually invisible holes, burn through skin and cause

serious infections. You must therefore use safety glasses with side

protection and a piece of cardboard or wood to look for leaks.

E2 Scheduled maintenance

Scheduled maintenance is purely informative and depends on normal

operating conditions. It may therefore differ in relation to the type of

service, working environment (which may be dusty), the season, etc.

Maintenance should be stepped up the tougher the machine’s operating

conditions.

E2.1

Checks on a daily basis

Checks to be carried out on a daily basis:

-

Check condition of all the labels;

-

Check condition of all the fittings (tightness of connections,

condition of sleeves and leaks or overflowing of hydraulic oil);

-

Use a grease pump to re-fill all the greasers on the equipment,

or apply grease with a brush where necessary;

-

Ensure all the nuts and bolts are properly fastened.

E2.2

Checks on a monthly basis or per 50 hours’ operation

Checks to be carried out on a monthly basis or per 50 hours’

operation:

-Check condition of all the labels;

-Check condition of all the fittings (tightness of connections,

condition of sleeves and leaks or overflowing of hydraulic oil);

-Check presence and condition of fasteners and safety devices;

-Ensure all the nuts and bolts are properly fastened;

-Check condition of the entire structure.

E2.3

Checks on an annual basis or per 500 hours’ operation

Checks to be carried out on an annual basis or per 500 hours’

operation:

-Check condition of all the fittings (tightness of connections,

condition of sleeves and leaks or overflowing of hydraulic oil);

-Check presence and condition of fasteners and safety devices;

-Ensure all the nuts and bolts are properly fastened;

-Check condition of the entire structure.

17

E3 Lubrication

To top up the greasers, remove their protection caps (if

present), remove all traces of dust and then use the

pump to inject the grease. Afterwards, use a cloth to

remove any excess grease on the greasers. Use a

brush to apply grease wherever there aren’t any

greasers.

All grease top-up points on the rake are indicated by

labels like the one shown in the illustration.

IMPORTANT

To avoid pollution, it is strictly forbidden to dispose of

oil, lubricants, filter cartridges or other noxious

materials in the environment. Comply with all

regulations in force on disposal of liquid and solid substances.

E4 Troubleshooting

The jack activation

command does not

respond

Hydraulic oil level

low

Hydraulic system

piping is damaged

Hydraulic pump is

damaged

Filter is clogged

Top up oil level

Replace piping

Replace pump

Replace filter

The jacks only move

intermittently

Air in the hydraulic

circuit

Operate the pump at

no load for a few

minutes, using the

jacks, to expel any air

in the hydraulic

circuit.

The jacks move even

when the command

isn’t given

Jack seals are worn

out

Replace seals

Overheated oil

Filter is clogged

Pipes are crushed

Oil level low

Replace filter

Check and replace

pipes

Top up oil level

Oil loss

Slow connection

Worn out seal

Squeeze the pipe

Replace the seal

Note: contact the Manufacturer about any faults or trouble not mentioned

in the table.

E5 Machine demolition: disposal of materials

When the rake is placed out of service, you must make harmless all parts

that could pose a safety risk to persons, animals and the environment

when sent for disposal. Materials that make up the rake and should be set

aside for segregated disposal are:

-Iron

-Hydraulic oil

-Rubber

-Plastics

These materials must be disposed of in compliance with relative national

legislation in force.

PUNTI DA

INGRASSATORI

LUBRIFICARE

18

Rev. 0 04.10

5

1

23

4

2

6

7

IM1 ERS 16-18-20

Machine assembly instructions

Assembly 1

For Easy-Rake SUPER STAR 16-18-20

A) Connect the cross drawbar

Pos. 1 to the rear pullbar

Pos. Fix the 920x230x15

plate Pos. 3 using the 10

T.E. M20x200 screws Pos.

4 and the M20 self-locking

nuts Pos. 2.

B) Connect the central pullbar

Pos. 7 with the rear pullbar

Pos. 5. Fix using the T.E.

M20x55 screws Pos. 6

and the M20 self-locking

nuts pos. 2.

19

Rev. 0 04.10

IM2 ERS 16-18-20

8

7

9

10

8

9

11

MOD. ERS18

MOD. ERS20

A

B

Assembly 2

For Easy-Rake SUPER STAR 16-18-20

A) Connect the pullbar

Pos. 10 with the rear

pullbar Pos. 7. Fix

using the six T.E.

M20x55 screws Pos. 9

and the M20 self-

locking nuts pos. 8.

B) Connect the front

pullbar Pos. 11 with

the pullbar Pos. 10. Fix

using the six T.E.

M20x55 screws Pos. 9

and the M20 self-

locking nuts pos. 8.

20

Rev. 0 04.10

IM3 ERS16-18-20

12

14

13

17

18

19

20

21

15

16

Assembly 3

For Easy-Rake SUPER STAR 16-18-20

A) Assemble the joint for the right and left frame Pos. 14

into the right and left leg support Pos. 12, by placing

the antisiezure fifth wheel AS 5070 Pos. 21 under the

joint bush and on the leg support bracket. Insert pin

Ø50x297 Pos. 16 and fix it with T.E. M8x80 screw

Pos. 20 and M8 self-locking nut Pos. 13.

B) Assemble the tandem axle Pos. 17 in leg support

Pos. 12, insert pin Ø42x220 Pos. 18. Fix with circlip

Ø14x75 Pos. 19.

This manual suits for next models

2

Table of contents

Other enorossi Farm Equipment manuals

enorossi

enorossi RAKE CADDY Series Operating instructions

enorossi

enorossi DR 420 4R User manual

enorossi

enorossi ENOSPE US User manual

enorossi

enorossi RR 350 EVO PROFI User manual

enorossi

enorossi G4V-3P User manual

enorossi

enorossi MAXIMUS 12 User manual

enorossi

enorossi G2 Series User manual

enorossi

enorossi ENODUO TRACER 780 User manual

enorossi

enorossi HAY TOP 300 User manual

enorossi

enorossi RR 400 EVO Series User manual