DECLARATION OF CONFORMITY

IN ACCORDANCE WITH ISO/IEC 17050:2004

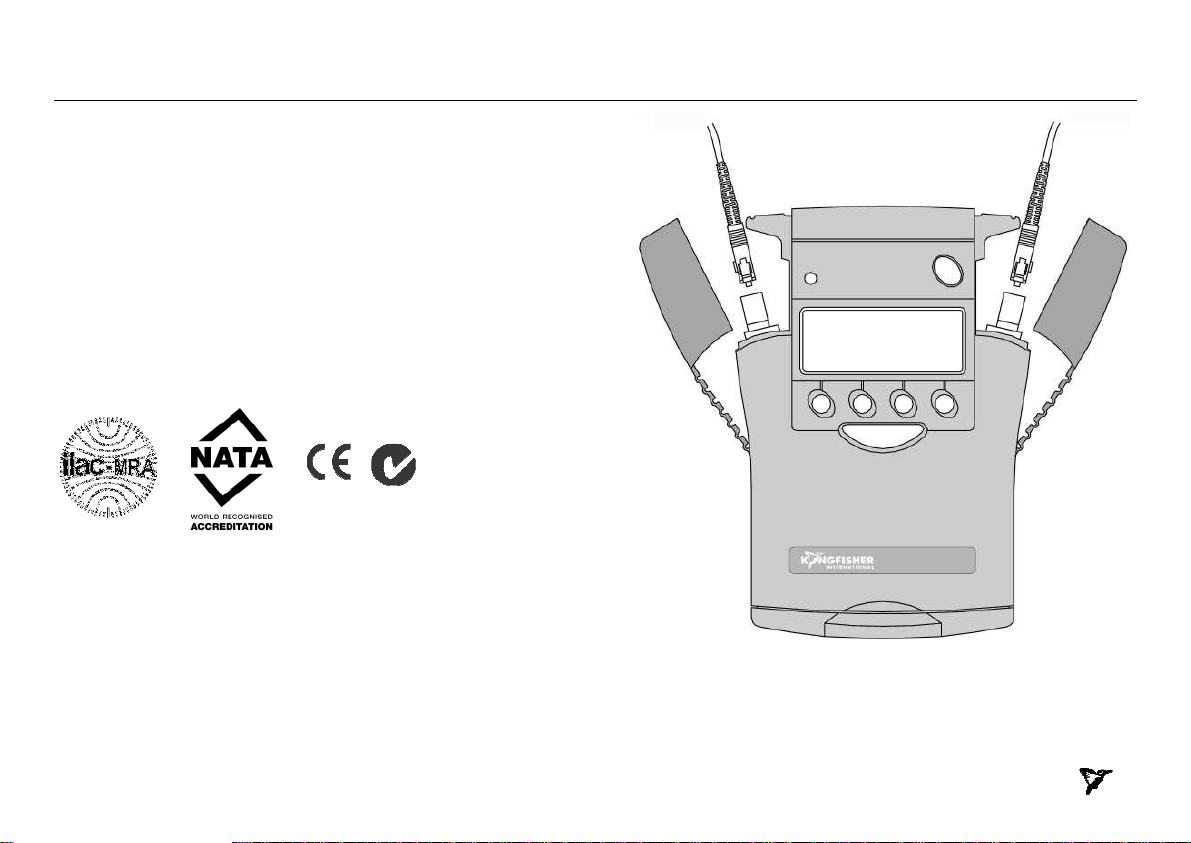

Manufacturer’s Name: Kingfisher International Pty. Ltd.

Manufacturer’s Address: 30 Rocco Drive, Scoresby, Victoria 3179, Australia

hereby declares, that the products listed below

Product Name: Optical Loss Test Set, Light Source, Power Meter

Model Number: KI7300/7700 Series, KI7400/7800 Series, KI7600 Series

Product Options: This declaration covers all options of the above product(s)

comply with the essential requirements of the applicable European Directives:

•Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC, amended by 93/68/EEC, and carries the CE marking accordingly

•Directive 2002/95/EC on restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS)

•Directive 2002/96/EC on waste electrical and electronic equipment (WEEE)

and conform to the following standards and specifications:

MIL-PRF-28800F: 1996 Performance specification-Test equipment for use with electrical and electronic equipment, general specification

IEC 60529: 2001/ EN 60529:1993+A1:2003 Degrees of protection provided by enclosures

Optical Loss Test Set and Power Meter conform to:

IEC 61315:2005 Calibration of fibre-optic power meters

EMC Limit

IEC 61326:2002 / EN 61326-1:1997+A1:1998+A2:2001+A3:2003

IEC CISPR 11: 2004/ EN 55011:1998+A1:1999 Limits applicable to Group 1 Class B equipment

IEC CISPR 16-1:1999 Limits applicable to Class B equipment

IEC CISPR 16-2:1999 Limits applicable to Class B equipment

IEC 61000-3-2: 2005/EN 61000-3-2:2006

IEN 61000-3-3:2002/EN 61000-3-3:1995

IEC 61000-4-2:2001 / EN 61000-4-2:1995+A1:1998+A2:2001 4kV CD, 8kV AD

IEC 61000-4-3:2002/ EN 61000-4-3:2002 3V/m, 80-1000MHz

IEC 61000-4-4:2004/EN 61000-4-4:2004 1kV signal lines, 2kV power lines

IEC 61000-4-5:2005/EN 61000-4-5:2006 1kV line-line, 2kV line-ground

IEC 61000-4-6:2004/EN 61000-4-6:1996+A1:2001 3V, 0.15-80 MHz

IEC 61000-4-11:2004/EN 61000-4-11:2004 0.5 cycle/100%/each polarity

ICES-001: 2006 (Canada)

CFR 47 FCC Part 15, Subpart B (Class B) (USA)

FCC registration number: 90891

Safety

Laser/LED products conform to:

IEC 60825-1:2001 Safety of laser products-Equipment classification, requirements and user’s guide

IEC 60825-2:2005 Safety of laser products-Safety of optical fibre communication systems (OFCS)

CFR 21 part 1040.10 (USA) Performance standards for light-emitting products- Laser products

Supplemental Information:

The product was tested in a typical configuration with Kingfisher International test systems.

2007-September -14

Date

Bruce Robertson

Name

Technical Director

Title

For further information, please contact your local Kingfisher International sales office, agent or distributor.

Revision: E Issue Date: 2007- September -17