Quality since 1946

Spreader Operation

1. SHPE2000 spreader is equipped with a dual

independent speed Controller with warning lights

and a Vibrator switch. To start the spreader, press

the ON-OFF switch. Switch will illuminate. The

auger will accelerate to full speed for 2 sec., then

slow down to dialed speed. The spinner will accel-

erate to full speed for 2 sec., then slow down to

dialed speed.

2. To activate the Vibrator press the Vibrator

switch ON. Vibrator switch will illuminate.

3. To stop the spreader push ON-OFF switch to

OFF position.

Material Flow Adjustments

Always use screen during spreader operation!

Various materials have different moisture absorp-

tion rate, some materials may not perform as de-

sired. Therefore, the substitution of the alternate

material may be necessary for optimum perfor-

mance.

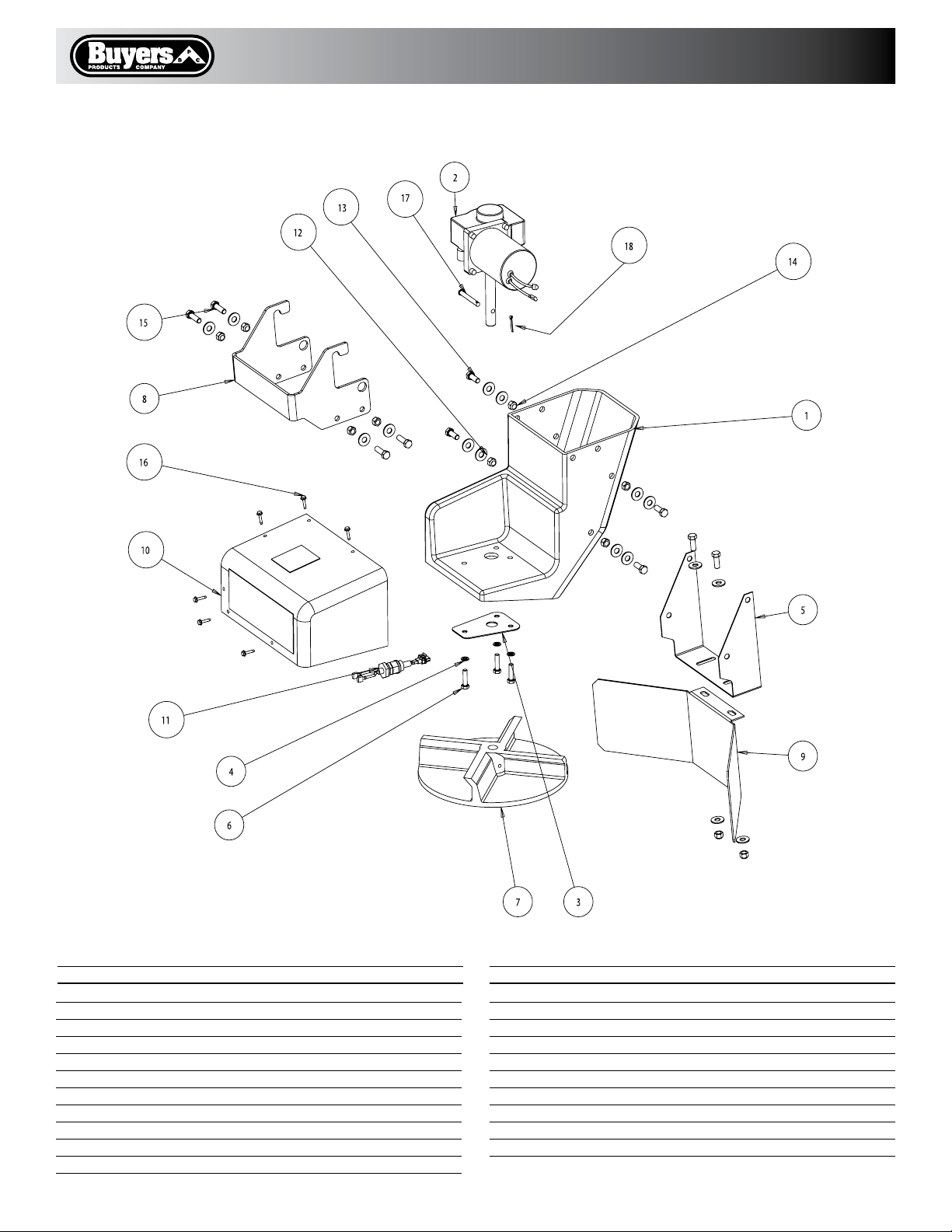

SHPE2000 has two discharge openings in the

bottom of the hopper. Material flow through these

openings can be controlled using two sliding

baffles. The spreader is shipped from the factory

with baffles adjusted for dry bagged salt. In this

setting rear baffle has 4.0” opening and baffle in

the middle of the hopper has 2.5” opening.

However if you are using a sand/salt mixture or

any chunky and hard to flow materials, it is advised

to increase the open portion of discharge openings.

Important!

Always open rear (closer to gear motor compart-

ment) opening first. Always turn off power before

adjusting baffles!

Warning lights.

Salt Dogg Controller has two warning lights:

“Overload” and “Jam”. The “Overload” light will

be illuminated when the auger is in “Unclogging”

mode. In this mode auger will automatically

reverse several times to free itself. If the auger will

not be able to unclog itself, the “Jam” light will be

illuminated and the Controller will shut-off.

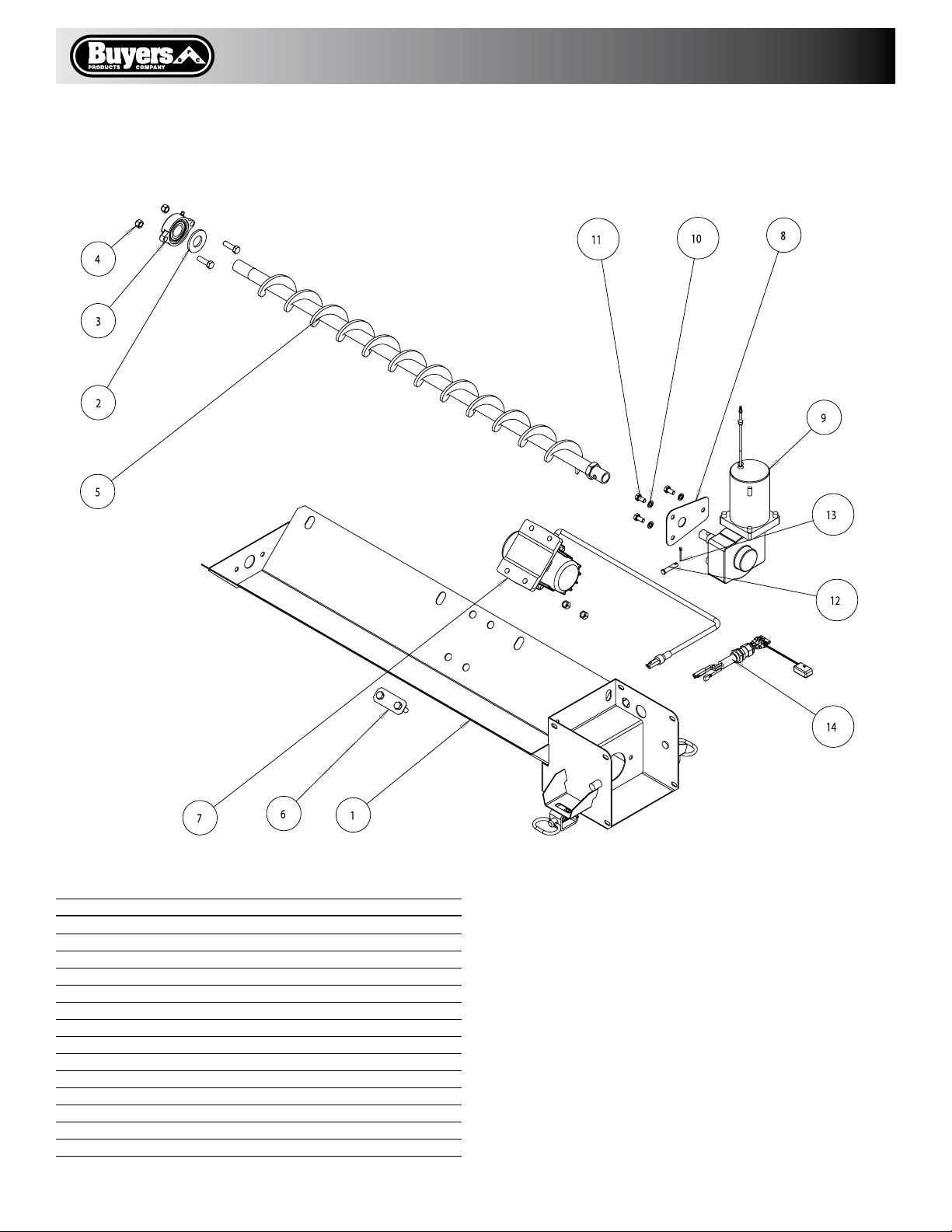

To unclog auger manually, first remove the chute.

Apply 1-1/4” open wrench on auger’s nut. Turn

auger counterclockwise several times.

Salt Dogg controller has an internal circuit breaker

in the vibrator circuit. The vibrator circuit breaker

will trip and the light in the vibrator switch will go

out in an overload situation. To reset the vibrator

circuit breaker: Turn off the vibrator switch for 30

seconds. Turn the vibrator switch on to restart the

vibrator.

Do not run the vibrator longer than 30 minutes with

15 minutes between runs to avoid overheating.

Spreader Maintenance

WARNING! Always disconnect power when

servicing spreader.

1. Use dielectric grease on all electrical connectors

before an electrical connection is made or after con-

nector is disconnected

2. Grease Auger bearing after every 20 hours of

use.

3. Empty the spreader of all ice control materials

when not in use. Wash out the spreader to prevent

material builds up.

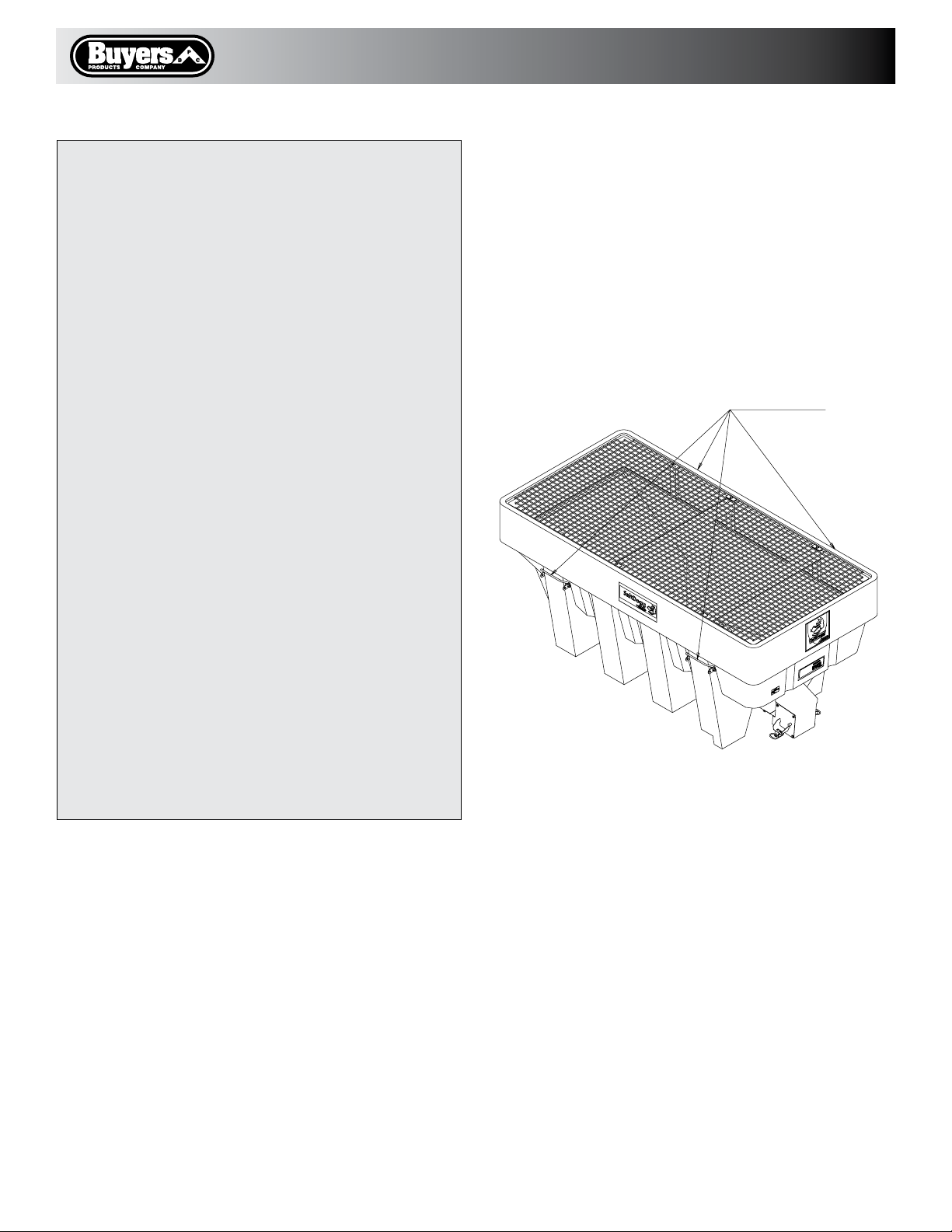

4. It is recommended to cover spreader with the

tarp during storage periods. Tarp can be attached

to anchors on both sides of tie downs.

Vibrator is not serviceable. Controller is not

serviceable.

Warning! Never attempt to remove spreader

with material in hopper.

Never leave material in the hopper for extended

period of time. Material may freeze and seriously

damage spreader!

5