6

1. Before you begin

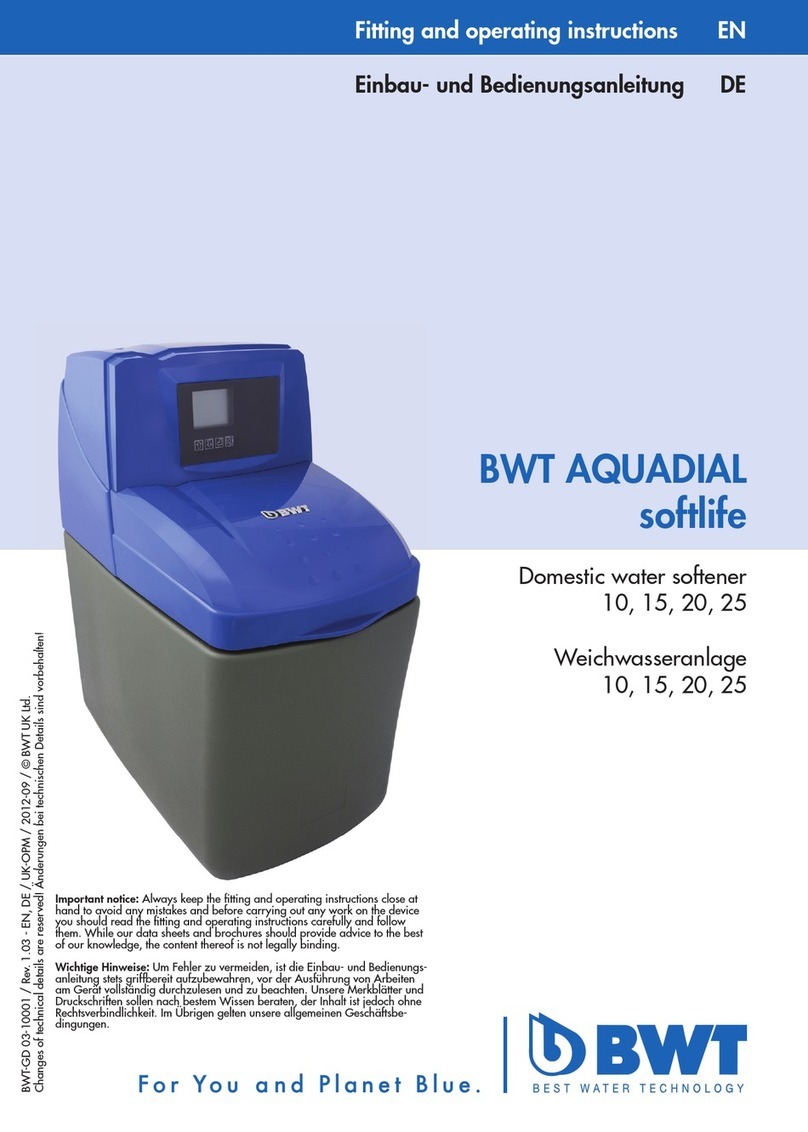

The installation of your new water softener is relatively straightforward. However, we

would recommend that either a qualified plumber or a person with relevant plumbing

experience carries out the installation.

Before embarking on the installation, please ensure you have familiarised yourself with

both these instructions and the components required to complete the installation.

2. Positioning the water softener

Please measure your water softener to ensure that it will fit into the area you are placing

the unit into. PLEASE remember to include additional space for connecting pipe work in

your calculations along with the regular access that is needed for topping the unit up with

salt and future service.

Where possible, the distance of both the incoming water supply and nearest drain should

be kept to a minimum. Two metres is an ideal distance, however, longer distances are

permissible, dependant on the incoming water pressure.

Please remember the weight of your new water softener will increase considerably once

installed and filled with salt. Therefore, please ensure your chosen location is strong

enough to support an approximate total weight of 50 Kg.

Your new water softener has been designed to operate efficiently and effectively with an

incoming water pressure of between 1.7 to 5 BAR. If your water supply is likely to fall

outside these limits, then we would recommend that a booster pump or pressure-

limiting valve should be fitted respectively.

PLEASE NOTE: UK Water Regulation guidelines on the installation of water softeners indicate that a minimum of one tap

is left as a source of untreated water / drinking water within the home. It is also recommended that any garden taps should

also be left untreated.

If the property is to be left unattended for any length of time e.g. holidays, the water softener should be bypassed /

isolated from the mains water supply by reversing the 3 valve positions as shown in the installation diagram on page 8.

After prolonged periods of non-use, ensure inlet and outlet valves are open and bypass valve is closed and start a manual

regeneration as described on page 14.

Important - do not install the water softener where it, or its connections (including the

drain overflow lines) will be subject to temperatures under 5ºC or above 40ºC.

INSTALLATION AND

OPERATING CONSIDERATIONS

PART ONE

INSTALLATION AND

OPERATING CONSIDERATIONS

There are several types of plumbing systems in common use:

1) Static Head – These systems are fitted with storage tanks. The water softener can be

installed using the standard 15mm or 22mm installation kit supplied with your water

softener.

2) Systems using Combination Boilers (15mm) – For these systems, we recommend that

your water softener be “hard plumbed” using copper tube of flexible high flow braided

hoses.

3) Unvented Fully Pressurised Systems (22mm) –As for combination boilers above.

The water softener should be installed within a container with no less than100 litre

capacity, to which there should be connected an overflow pipe of no less than 20mm

diameter. The overflow should be connected at the bottom of the container and not less

than 150mm below the height of any electrical components mounted on the water

softener. It is recommended that an anti vacuum valve be fitted to the inlet pipework

supplying the water softener.

3. Loft installation

If you are planning to install the water softener above ground level e.g. In the loft,

the following instructions should be strictly adhered to.

4. Plumbing systems

5. Backflow prevention device

Your water softener installation must include at least one drinking water tap that is

not fed by the water softener.

It is recommended that individuals on a low sodium diet should follow the Department of

Health's advice that water from a domestic water softener should not be used for

drinking or cooking. Softened water contains a small amount of sodium, it has been

calculated that 1 pint of softened water contains a similar amount of sodium as two slices

of white bread or ¼ pint of milk.

Water that is used for mixing powdered milk for babies must only be taken from an un-

softened mains tap as some powdered milks and softened water both contain sodium for

which young babies have a limited tolerance.

6. Drinking water

P RA T ENO

When fitted to the supply feeding a single dwelling, a check valve complying with BS6282

Part 1 must be fitted on the cold water feed prior to the installation. All other types of

installation require the fitting of a double check valve.

INSTALLATION AND

OPERATING CONSIDERATIONS

The installation of your new water softener is relatively straightforward. However, we

would recommend that either a qualified plumber or a person with relevant plumbing

experience carries out the installation.

Before embarking on the installation, please ensure you have familiarised yourself with

both these instructions and the components required to complete the installation.

2. Positioning the water softener

Please measure your water softener to ensure that it will fit into the area you are placing

the unit into. PLEASE remember to include additional space for connecting pipe work in

your calculations along with the regular access that is needed for topping the unit up with

salt and future service.

Where possible, the distance of both the incoming water supply and nearest drain should

be kept to a minimum. Two metres is an ideal distance, however, longer distances are

permissible, dependant on the incoming water pressure.

Please remember the weight of your new water softener will increase considerably once

installed and filled with salt. Therefore, please ensure your chosen location is strong

enough to support an approximate total weight of 50 Kg.

Your new water softener has been designed to operate efficiently and effectively with an

incoming water pressure of between 1.7 to 5 BAR. If your water supply is likely to fall

outside these limits, then we would recommend that a booster pump or pressure-

limiting valve should be fitted respectively.

PLEASE NOTE: UK Water Regulation guidelines on the installation of water softeners indicate that a minimum of one tap

is left as a source of untreated water / drinking water within the home. It is also recommended that any garden taps should

also be left untreated.

If the property is to be left unattended for any length of time e.g. holidays, the water softener should be bypassed /

isolated from the mains water supply by reversing the 3 valve positions as shown in the installation diagram on page 8.

After prolonged periods of non-use, ensure inlet and outlet valves are open and bypass valve is closed and start a manual

regeneration as described on page 14.

Important - do not install the water softener where it, or its connections (including the

drain overflow lines) will be subject to temperatures under 5ºC or above 40ºC.

INSTALLATION AND

OPERATING CONSIDERATIONS

PART ONE

INSTALLATION AND

OPERATING CONSIDERATIONS

BWT VOSFT Water Softener Dec 2015 20pp A5.indd 6 17/02/2016 08:45