3-3 Other problem

Tire: The tires should be inspected frequently for damage, the presence of foreign bodies, unusual wear

and sufficient tread depth. If replacement tires are needed, please contact the nearest dealer.

The following areas require periodic inspection:

-Tire pressure between 30-50 psi

-Tread depth drops below 0.5 mm

Recommended range of storage, Temperature: -30oc ~ +50oc, Humidity : 25% ~ 85%

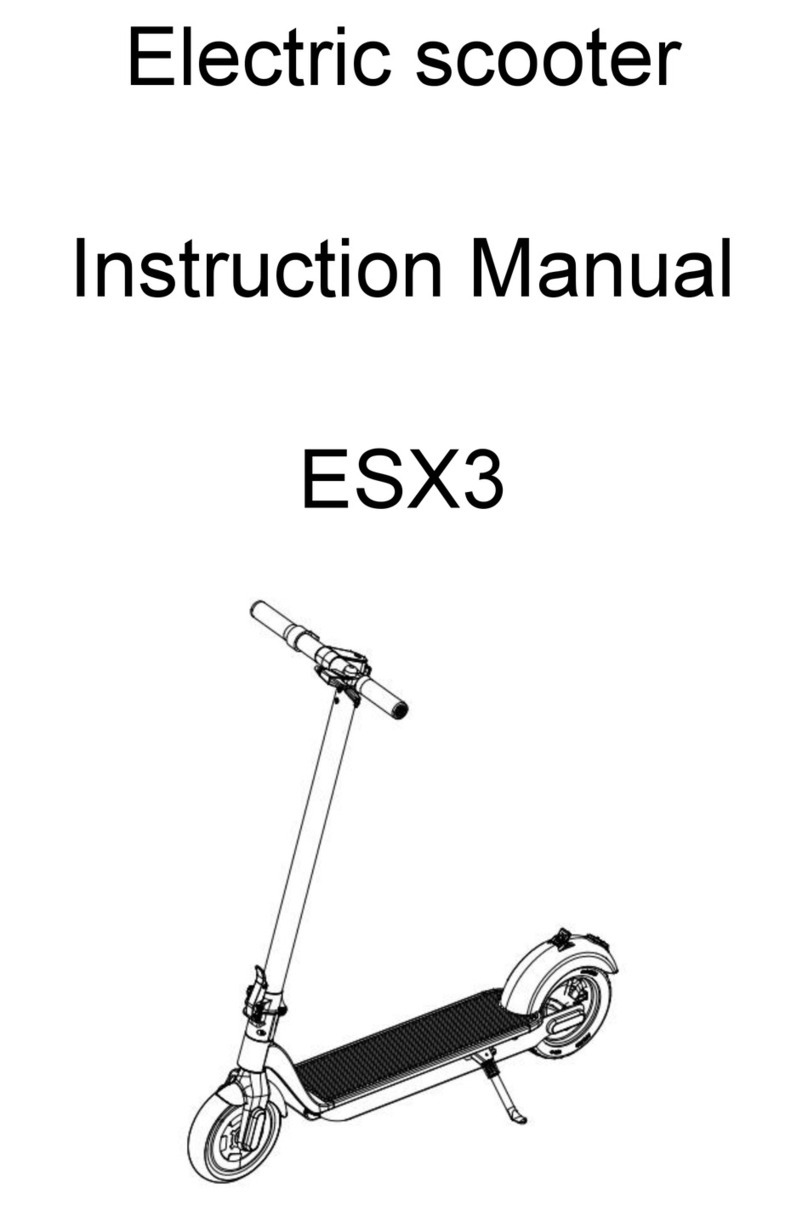

Follow these easy steps to replace the tire:

-Turn off the scooter and remove the key. Make sure the lever is in D position before you lift the scooter.

-Use a ratchet and socket to remove the drive wheel screw from the center hub of the wheel. Pull the

wheel off of the axle.

-Separate the tire from the rim.

-Remove the old tire and replace it with a new tire.

-Slide the wheel back onto the shaft.

-Install the drive wheel nut into the center hub and verify the key is lined up with axle and wheel, and

then tighten to secure it in place. (Torque 300±30kgf-cm)

Charger: During charging, light on charger doesn’t change to green. If LED (POWER) light is off

-Check the input voltage (115V/230V) is the same as you adjust.

-If light is still off, please check and repair the battery charger. (B)If LED (CHARGE) light is off

-Check to see clips connection is correct.

-If the battery is fully charged, the LED (CHARGE) light will be off.

-If light is still off, the battery may be defective. (C)If ORANGE light can turn to GREEN

-The battery cannot be charged. Please check and recover it. (D)If ORANGE light turns to GREEN

immediately

-Check to see the battery is fully charged, if not, the battery may be defective Check and recover it.