THIS INSTRUCTION MANUAL IS THE PROPERTY OF

CALPEDA S.P.A. ANY REPRODUCTION, EVEN IF PAR-

TIAL, IS FORBIDDEN

SU ARY

1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 TECHN CAL DESCR PT ON . . . . . . . . . . . . . . . . . . . 6

3 TECHN CAL FEATURES. . . . . . . . . . . . . . . . . . . . . . 7

4 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5. TRANSPORTAT ON AND HANDL NG . . . . . . . . . . . 7

6. NSTALLAT ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7. START-UP AND OPERAT ON. . . . . . . . . . . . . . . . . . 8

8 MA NTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

9 D SPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

10 SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

11 TROUBLESHOOT NG . . . . . . . . . . . . . . . . . . . . . . . . 9

12 ANNEXES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

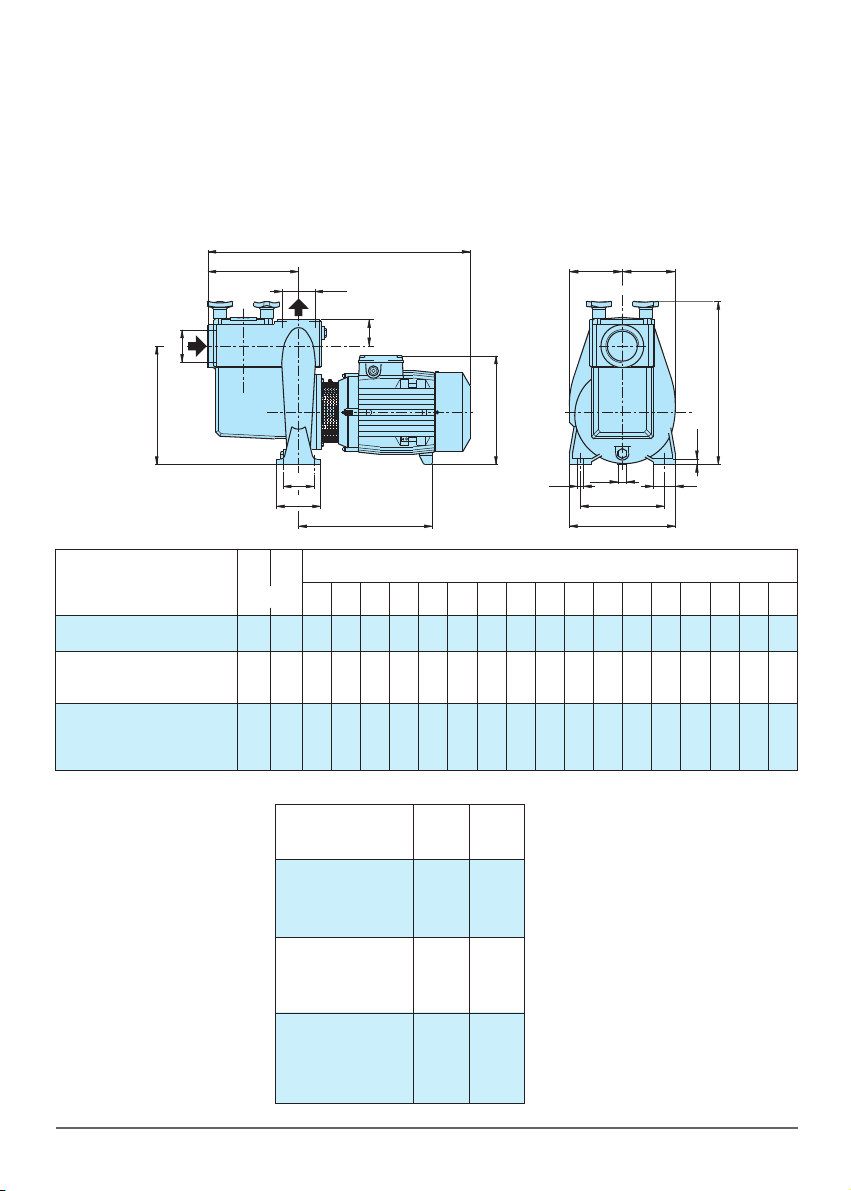

12.1 Dimensions and weights . . . . . . . . . . . . . . . . . . . . . 42

12.2 nstallation examples . . . . . . . . . . . . . . . . . . . . . . . . 43

12.3 Designation of parts . . . . . . . . . . . . . . . . . . . . . . . . . 44

12.4 Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Copy of the declaration of conformity . . . . . . . . . . . . . . . . 47

1 GENERAL INFOR ATION

Before using the product carefully read the information con-

tained in this instruction manual, the manual should be kept

for future reference.

talian is the original language of this instruction manual, this

language is the reference language in case of discrepancies

in the translations.

This manual is part of the essential safety requirement and

must be retained until the product is finally de-commissioned.

The customer, in case of loss, can request a copy of the

manual by contacting Calpeda S.p.A. or their agent, spe-

cifying the type of product data shown on the label of the

machine (see 2.3 Marking)

Any changes, alterations or modifications made to the pro-

duct or part of it, not authorized by the manufacturer, will

revoke the "CE declaration" and warranty.

This appliance should not be operated

by children younger than 8 years,

people with reduced physical, sensory

or mental capacities, or inexperienced

people who are not familiar with the

product, unless they are given close

supervision or instructions on how to

use it safely and are made aware by a

responsible person of the dangers its

use might entail.

Children must not play with the

appliance.

t is the user's responsibility to clean

and maintain the appliance. Children

should never clean or maintain it

unless they are given supervision.

Do not use in ponds, tanks or

swimming pools or where people may

enter or come into contact with the

water.

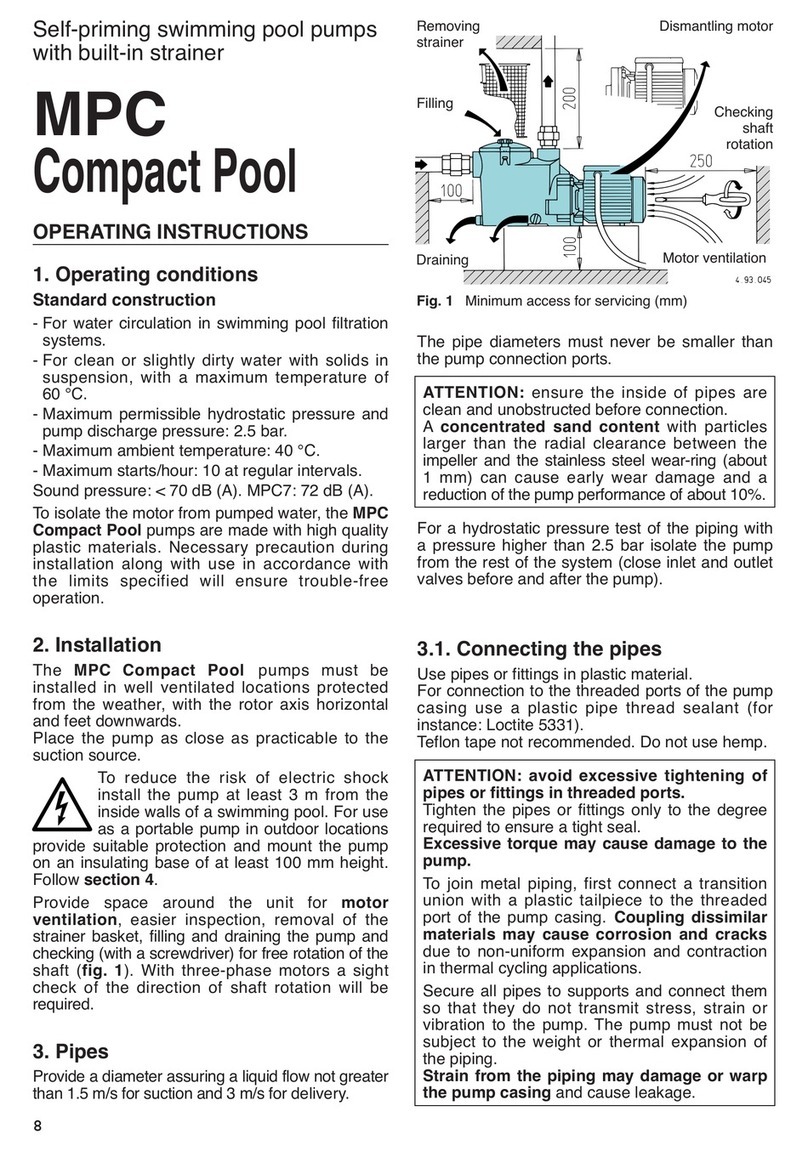

Read carefully the installation section

which sets forth:

- The maximum permissible structural

working pressure (chapter 3.1).

- The type and section of the power

cable (chapter 6.5).

- The type of electrical protection to be

installed (chapter 6.5).

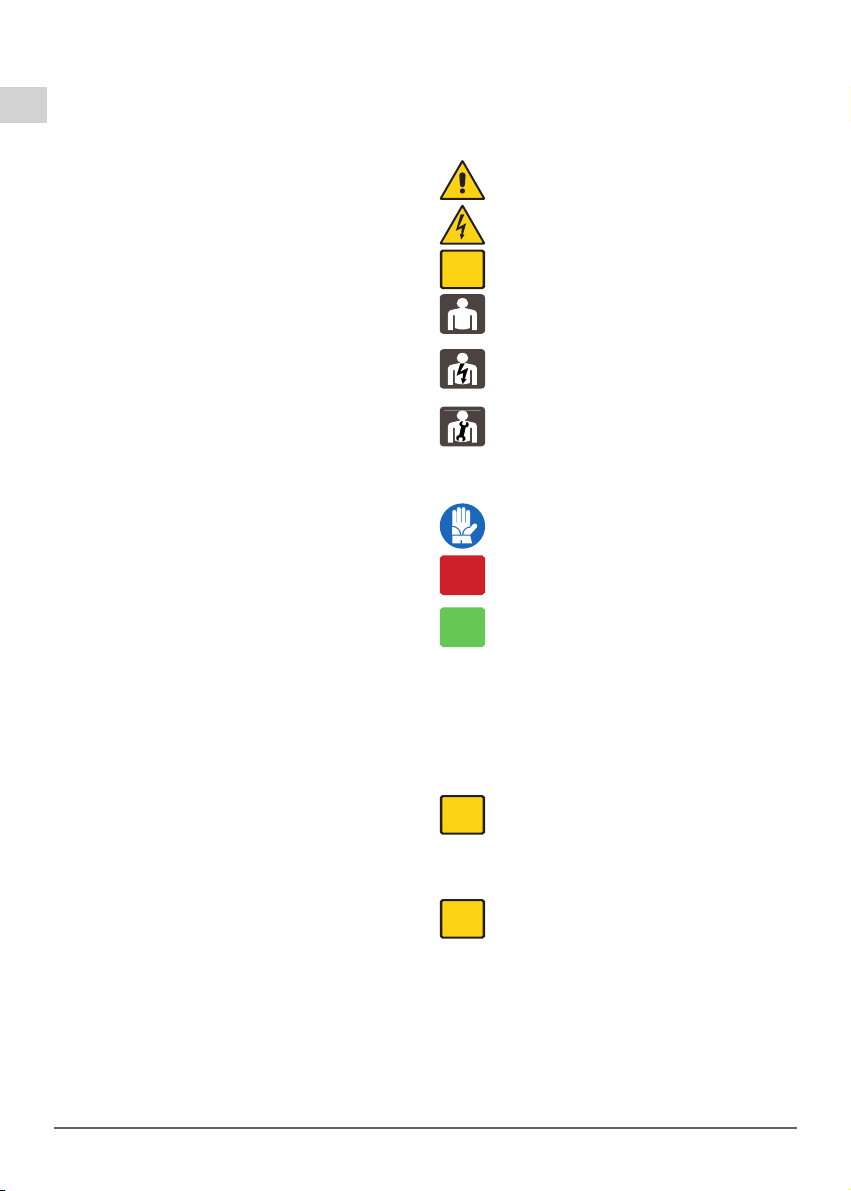

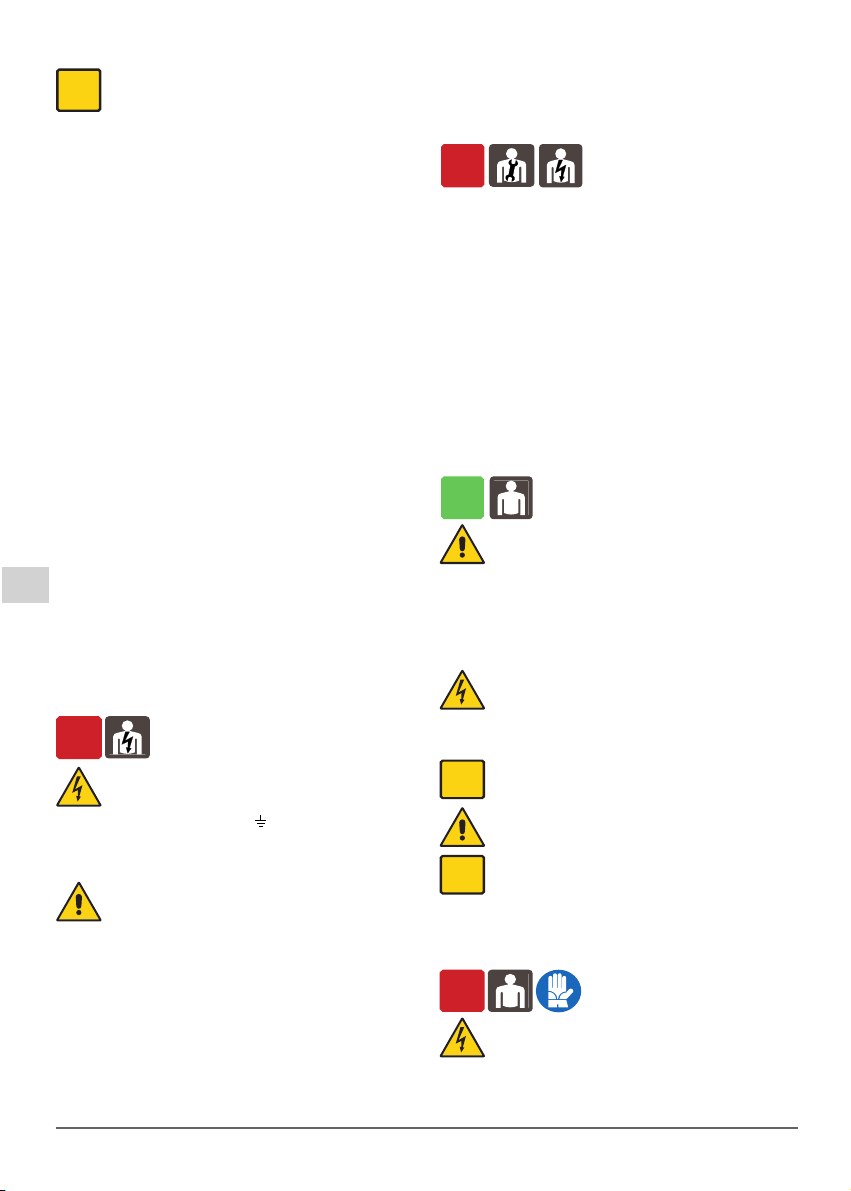

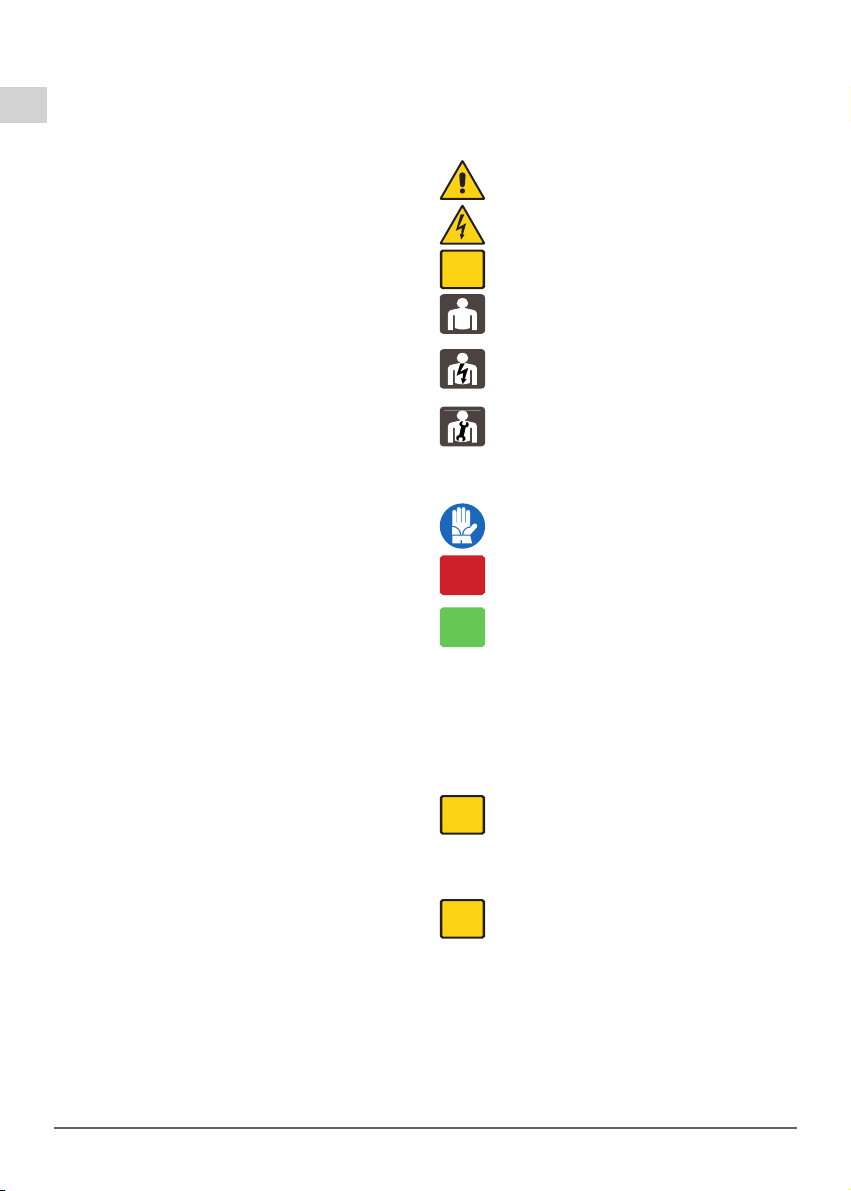

1.1 Symbols

To improve the understanding of the manual, below are indica-

ted the symbols used with the related meaning.

nformation and warnings that must be observed,

otherwise there is a risk that the machine could damage

or compromise personnel safety.

The failure to observe electrical information and

warnings, could damage the machine or compromise

personnel safety.

Notes and warnings for the correct management of

the machine and its parts.

Operations that could be performed by the final user.

After carefully reading of the instructions, is responsible

for maintenance under normal conditions. They are

authorized to affect standard maintenance operations.

Operations that must be performed by a qualified

electrician. Specialized technician authorised to affect all

electrical operations including maintenance. They are

able to operate with in the presence of high voltages.

Operations that must be done performed by a qualified

technician. Specialized technician able to install the

device, under normal conditions, working during

"maintenance", and allowed to do electrical and

mechanical interventions for maintenance. They must be

capable of executing simple electrical and mechanical

operations related to the maintenance of the device.

ndicates that it is mandatory to use individual

protection devices.

Operations that must be done with the device

switched off and disconnected from the power supply.

Operations that must be done with the device

switched on.

1.2 anufacturer name and address

Manufacturer name: Calpeda S.p.A.

Address: Via Roggia di Mezzo, 39

36050 Montorso Vicentino - Vicenza / talia

www.calpeda.it

1.3 Authorized operators

The product is intended for use by expert operators divided

into end users and specialized technicians. (see the symbols

above).

t's forbidden, for the end user, carry out operations

which must be done only by specialized technicians.

The manufacturer declines any liability for damage

related to the non-compliance of this warning.

1.4 Warranty

For the product warranty refer to the general terms and con-

ditions of sale.

The warranty covers only the replacement and the

repair of the defective parts of the goods (recognized

by the manufacturer).

The Warranty will not be considered in the following cases:

- Whenever the use of the device does not conform to the

instructions and information described in this manual.

- n case of changes or variations made without authorization

of the manufacturer.

- n case of technical interventions executed by a non-authori-

zed personnel.

- n case of failing to carry out adequate maintenance.

1.5 Technical assistance

Any further information about the documentation, technical

assistance and spare parts, shall be requested from: Calpeda

S.p.A. (paragraph 1.2).

GB

NMP Rev. 15 - Operating nstructionsPagina 6 / 48

ST NMP 06_2016_MXS 11_03con gall 03/06/16 08:53 Pagina 6