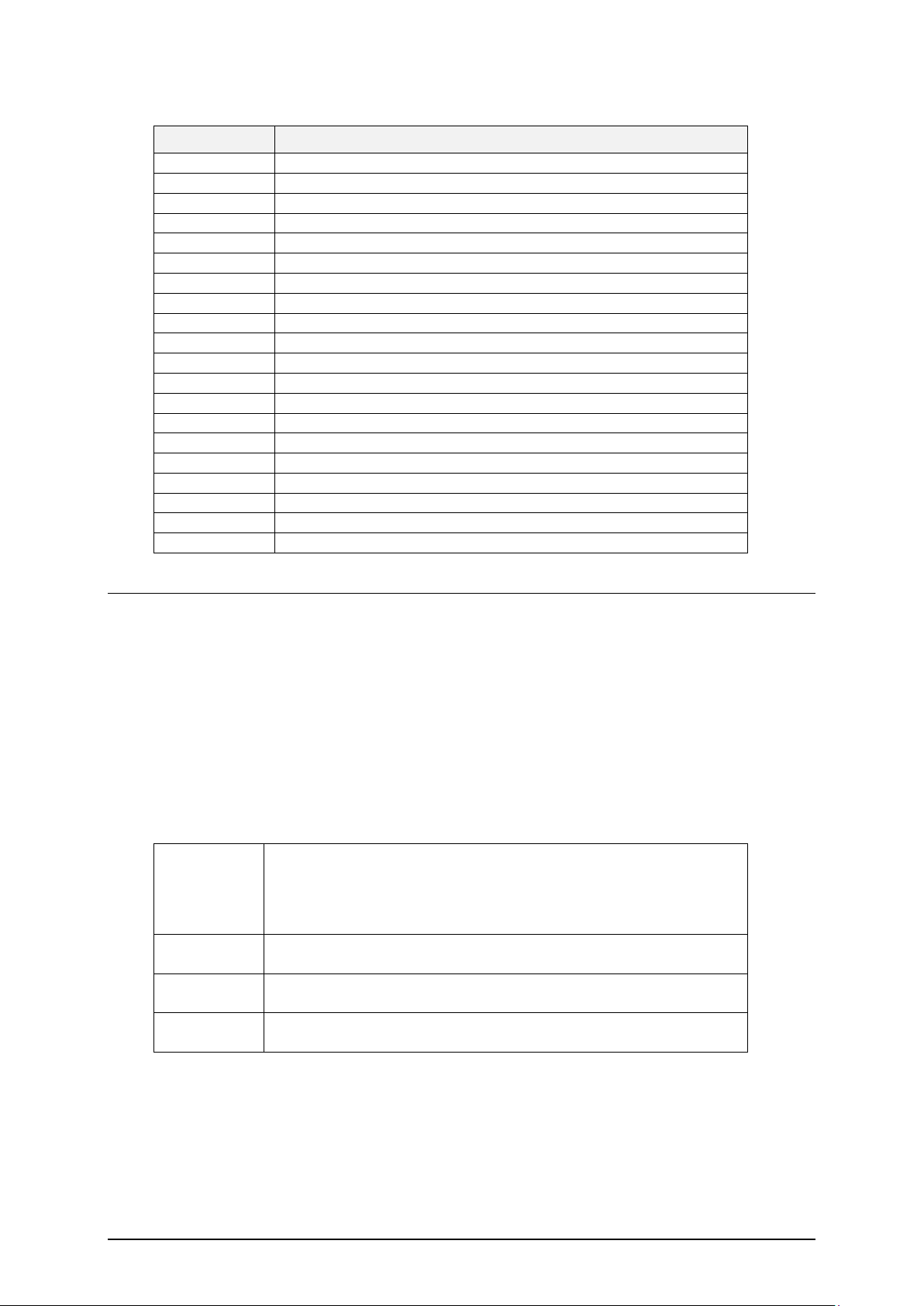

Content

1Introduction.................................................................................................................................... 1

1.1 Precaution................................................................................................................................. 1

1.2 Parts supplied with CAMAG Derivatizer ..................................................................................... 3

1.3 Spare parts for CAMAG Derivatizer ........................................................................................... 4

2Unpacking/Installation .................................................................................................................. 4

2.1 Unpacking ................................................................................................................................ 4

2.2 Installation environment............................................................................................................ 4

2.3 Installation ................................................................................................................................ 5

3Getting started ............................................................................................................................... 5

3.1 Intended use ............................................................................................................................. 5

3.2 Material compatibility ............................................................................................................... 6

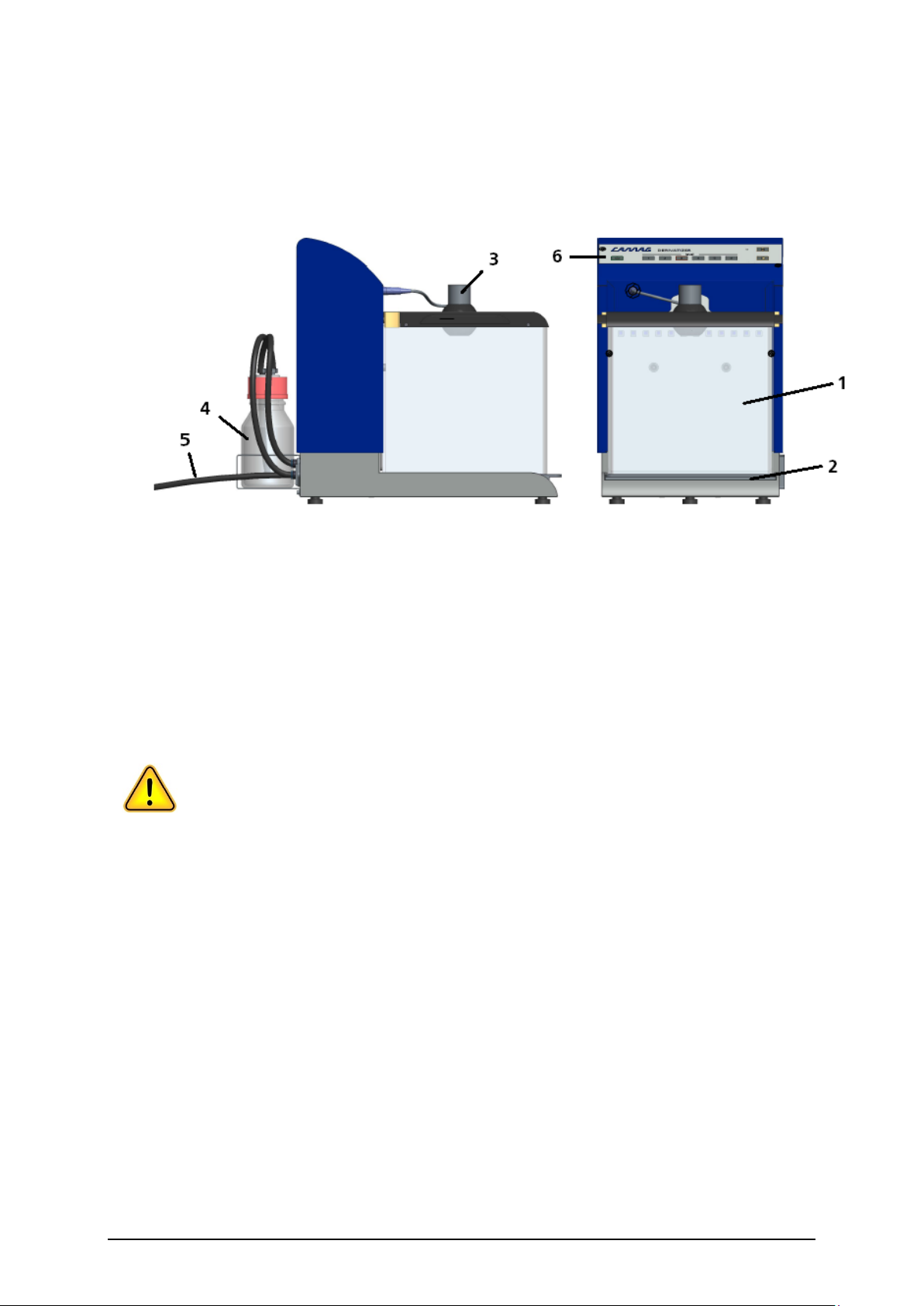

3.3 Instrument ................................................................................................................................ 7

3.4 Control panel ............................................................................................................................ 8

3.5 State diagram ........................................................................................................................... 8

3.6 Nozzles ..................................................................................................................................... 9

3.7 Spraying level............................................................................................................................ 9

3.8 Insert/Remove plate ................................................................................................................ 10

3.9 Derivatization process ............................................................................................................. 11

3.9.1 Preparation of the reagents................................................................................................. 11

Preparation of the cleaning solution................................................................................................ 12

Setting the parameters.................................................................................................................... 12

Cleaning steps ................................................................................................................................ 12

Spraying steps................................................................................................................................. 14

3.10 Method to transfer from manual spraying or immersion to automated spraying ..................... 15

3.11 Recommendations for common derivatization reagents .......................................................... 16

3.11.1 Transfer from manual spraying to automated spraying (20 x 10 cm or 20 x 20 cm hood).... 18

3.11.2 Transfer from immersion to automated spraying (20 x 10 cm hood) ................................... 18

4Maintenance and Service ............................................................................................................ 20

4.1 Cleaning ................................................................................................................................. 20

4.2 Decontamination .................................................................................................................... 20