Content

1Introduction................................................................................................................................................... 2

1.1 Precaution............................................................................................................................................... 2

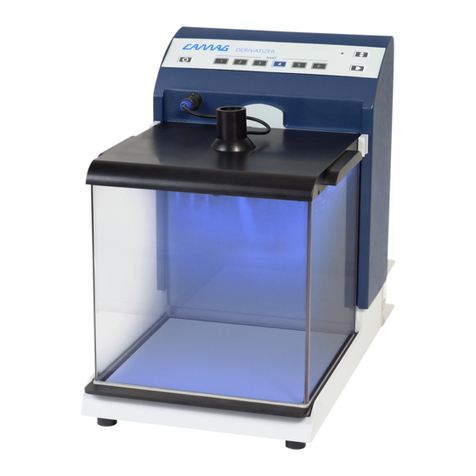

1.2 Parts supplied.......................................................................................................................................... 3

2Unpacking/Installation.................................................................................................................................. 4

2.1 Unpacking............................................................................................................................................... 4

2.2 Installation environment .......................................................................................................................... 4

2.3 Installation .............................................................................................................................................. 4

2.4 Connection of the valve........................................................................................................................... 5

3Getting started .............................................................................................................................................. 6

3.1 Intended use ........................................................................................................................................... 6

3.2 Instrument .............................................................................................................................................. 6

3.3 Functional principle ................................................................................................................................. 7

3.4 Elution process ........................................................................................................................................ 9

3.5 Operation advice ................................................................................................................................... 10

4Maintenance and Service............................................................................................................................ 10

4.1 Cleaning................................................................................................................................................ 10

4.2 Decontamination................................................................................................................................... 10

4.3 User maintenance.................................................................................................................................. 11

4.4 Maintenance Data Sheet ....................................................................................................................... 11

4.5 Replacing of elution head ...................................................................................................................... 12

5Technical data.............................................................................................................................................. 12

6Application hints ......................................................................................................................................... 13

6.1 Practical procedure for elution ............................................................................................................... 13

6.2 Fittings .................................................................................................................................................. 15

6.3 Dead volumes ....................................................................................................................................... 17

6.4 System leaks.......................................................................................................................................... 18

Telltale signs of system leaks .......................................................................................................................... 18

6.5 Application example.............................................................................................................................. 19

Sample: diclofenac in methanol at a concentration of 0.113 mg/mL ............................................................... 19

Separation of Caffeine, Paracetamol, Acetylsalicylic Acid................................................................................. 20

Results ........................................................................................................................................................... 22

EC Declaration of Conformity