Content

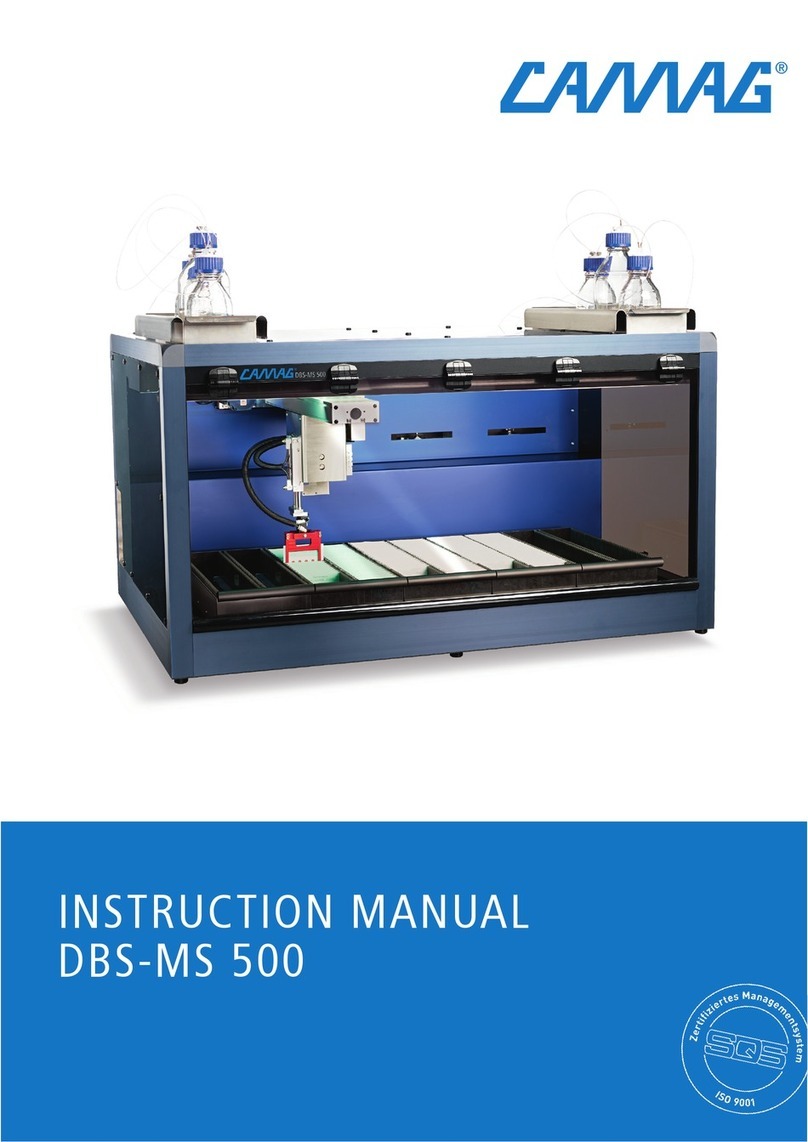

1Introduction.................................................................................................................................... 3

1.1 Precaution................................................................................................................................ 3

1.2 Parts supplied.......................................................................................................................... 4

2Unpacking/Installation .................................................................................................................. 4

2.1 Removal of shipping protection............................................................................................... 4

2.2 Installation of the instrument.................................................................................................... 6

Fluidics............................................................................................................................................. 6

Electrics........................................................................................................................................... 8

Software........................................................................................................................................... 8

Priming............................................................................................................................................. 9

3Hardware Connections ............................................................................................................... 10

3.1 CAMAG DBS-MS500 contact closure................................................................................... 10

3.2 Connectors on measurement systems.................................................................................. 11

Agilent APG remote interface........................................................................................................ 11

AB Sciex AUX/ I/O interface.......................................................................................................... 12

Shimadzu event interface.............................................................................................................. 12

Waters Xevo TQD with AQUITY UPLC system ............................................................................ 13

Thermo system under Xcalibur...................................................................................................... 14

3.3 Connection examples............................................................................................................ 16

LC/MS system of Agilent and Sciex .............................................................................................. 16

LC/MS system of Waters and Sciex.............................................................................................. 18

Thermo system under Xcalibur...................................................................................................... 19

3.4 Coupling a PAL fraction collector .......................................................................................... 19

4Software coupling ....................................................................................................................... 22

4.1 Preparation of the network configuration............................................................................... 22

4.2 Masslynx coupling................................................................................................................. 23

4.3 Analyst coupling .................................................................................................................... 24

4.4 Xcalibur coupling ................................................................................................................... 26