(2) Periodic maintenance

No periodic maintenance is necessary.

(3) Periodic replacement parts

There are no parts in this machine that require periodic replacement by a service engineer.

(4) Replacement consumables

There are no consumables that require replacement by a service engineer.

1-2. Customer Maintenance

1-3. Product Life

(1) Machine

Specified print volume (I) or the years of use (II), whichever comes first.

(I) Print volume

(II) Years of use

5 years of use

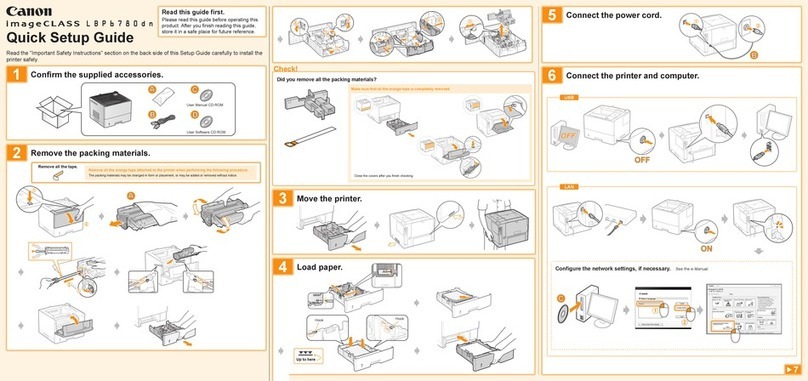

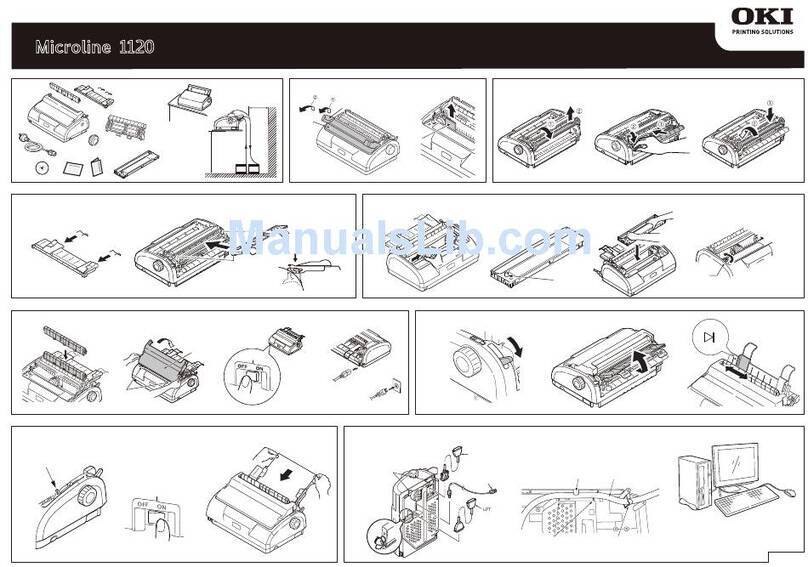

Adjustment Timing Purpose Tool Approx.

time

Print head

alignment When print quality is not

satisfying. To ensure accurate dot

placement. - Machine buttons

(automatic

alignment by

scanning the head

alignment sheet)

- Computer (manual

alignment via the

MP driver)

3 min.

Print head

cleaning When print quality is not

satisfying. To improve nozzle conditions. - Machine button

- Computer (settings

via the MP driver)

1 min.

Print head deep

cleaning When print quality is not

satisfying, and not improved by

print head cleaning.

To improve nozzle conditions. - Machine button

- Computer (settings

via the MP driver)

2 min.

Ink cartridge

replacement When an ink cartridge becomes

empty. (No ink error) ----- ----- 2 min.

Paper feed roller

cleaning When paper does not feed

properly. To clean the paper feed

rollers. Machine button 2 min.

Bottom plate

cleaning When the back side of the paper

is smeared To clean the platen ribs. - Machine button

- Computer (settings

via the MP driver)

1 min.

MP170 / MP450

8,000 pages

Black 1,500 character pattern 4,000 pages

Color A4, 7.5% duty per color pattern 3,200 pages

A4, 30 % duty per color pattern 160 pages

4 x 6, 30 % duty per color pattern 400 pages

Postcard, 30 % duty per color pattern 240 pages