△Coolingsystemfaults.

○Howtodiagnosefaults:

Itshouldtakeapproximate3hourstoreachthelowestsettingtemperatureof5℃foranemptyunit(assuming ambient

tempof32degreescentigradeandcontinuousoperation). Ifnot,checkthecompressor,coolingfans,controller, andsensors.

Ifall theseareworking normally,thereisprobablyacoolingsystem’sfault.

○Howtorepairthedefualt

1. Checkthe compressor

Turnonthe unitandcheckthere iselectricitycurrentflowingtothecompressorusinga calipertypeAmpmeter,the

currentshouldbewithin0.6to2Amps.Ifthereadingsarenotinthisrange, turnoffandcutoffthepipes (See Fig.8

showingG) andthesealpliers (See Fig.8showing E.) fromthecompressor,thenturntheunit onagain(inthiscase

onlyrun thecompressorforafewminuets,soastoavoidthecompressorabsorbmoistair)andrecheckthe

currentand ifthereispressureattheoutletpipe. Ifthecurrentreadingisstill outofrangespecifiedaboveandno

pressurefromthe compressoroutlet, replace the whole compressor.

2. Checkthecoolingsystempipe work:

Carefullycheckthecooling systemafterverifying thecompressorisworking normally.Thenfollowtheprocedure

below.

1>. Thencutoffprocess pipeandchecktherefrigerant.Ifthereisnotenoughrefrigerant,thedefualt oftherefrigerant

systemshouldbecausedbytheleaking.Ifthe refrigerantissufficient., itisprobablyjamedinthecapillary.

2>.Ifthedefault is concentratedon thecooling system,thechecking procedureis as below.

A.Cutoff theventpipeofthecompressor, andinfuse0.8-1MPnitrogenby process pipe, andpleaseputthehandclose

tothecutkerfoftheventpipe.Ifthereis alittlegas leakformtheterminal,it meansnormal, orit is jamed.

B. Makesurethecapilaryisworkingnormally,whenthedrainpipeisconnetcedagain,and infuse0.8-1MPnitrogen

thentesttheleakageifthecoolingsystemofthesoldering pointwiththesoapwater.Checkfromthethesoldering

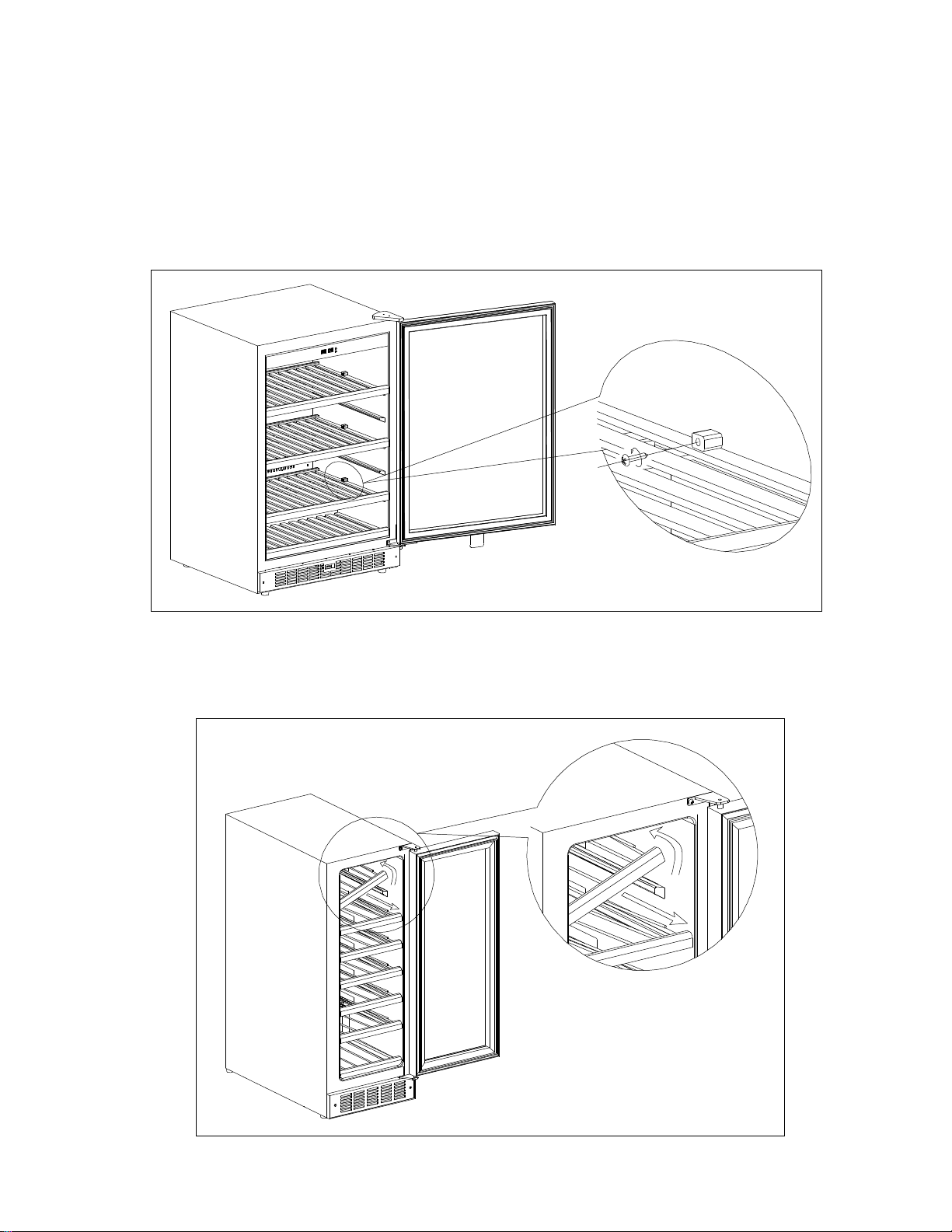

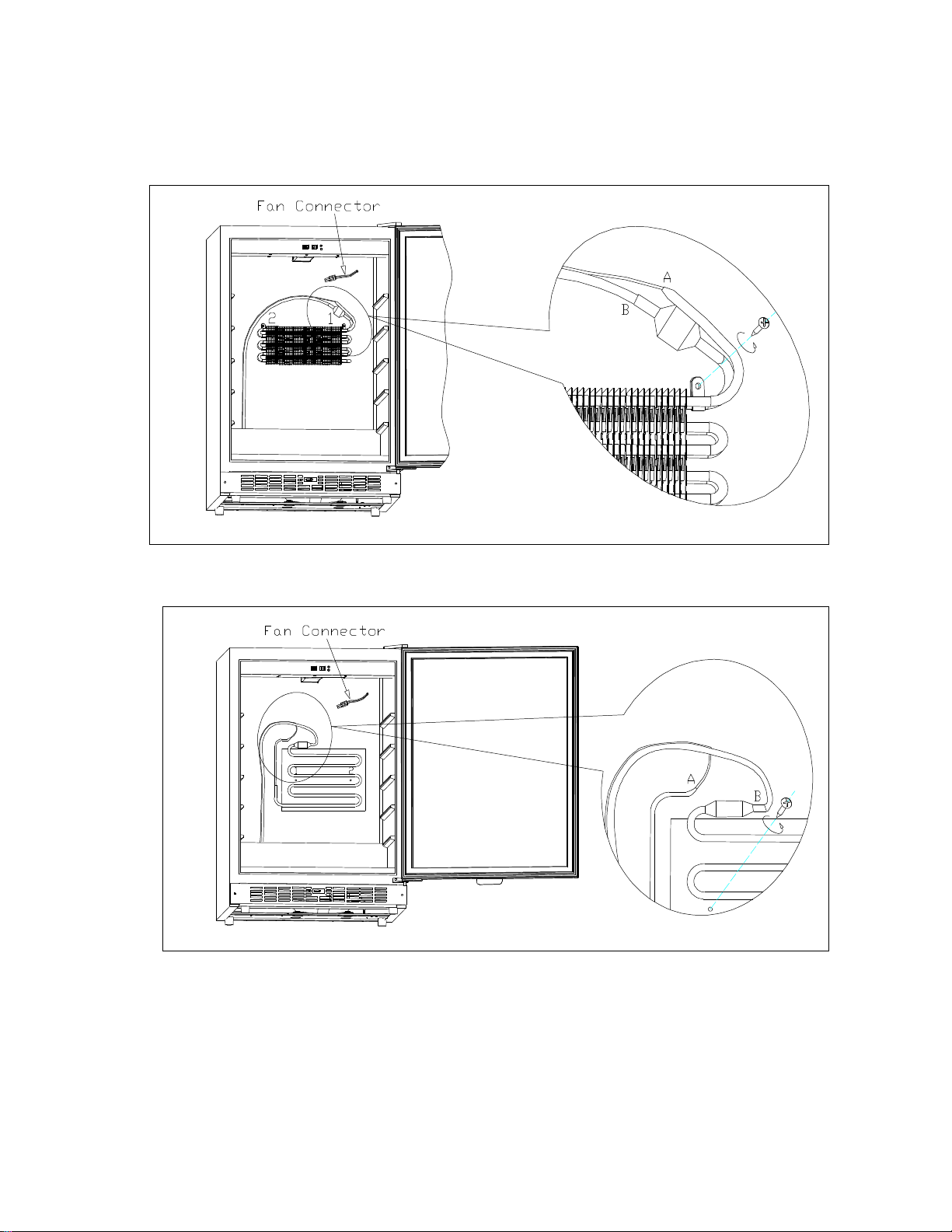

pointarroundthecompressor(Fig.8&Fig.9、Fig.9.1),andifeverythingis ok,removetheair-ductboardand chech

thesoldering pointaround evaporator(Fig.6 &Fig.7).pleaseseetheremovemethodand theprocedureasbelow.

(Fig.1,Fig.2,Fig.3,Fig.4&Fig.5)

C.IfallthesolderingpointinB isnotleaking,therearetwopossibility, oneis leakageintheinnercondenser,another

isthedamageon theparts(suchas evaporator,condenserand soon)inthecoolingsystem.Ifitis theinnerdamage,

itcannotberepaired,andifthedamageontheparts, replace them.

3>.Makesurethatthereis notleakageinthecooling system, refilltherefrigerant.

3.Refillthe refrigerant:

1>. Using thevacuumpumpforma vacuuminthesystem,via the jointofthelow-pressureprocesspipeonthecompressor,

thehigh-pressurepipelineisontheprocess pipeofthefilter.Applythevacuumpumpforapproximately20 minutes.Until

thevacuumislowerthan100Pa.Thensolderthecompressorprocess pipeofthefilter.Keepthevacuumrunningwhile

solderingthisjoint

2>.FillCooling systemwithrefrigerantviatheprocesspipe. (TherefrigerantisR134a.Regardingrefrigerantquantity

Pleaserefertotheinstructionatbacklabelofwinecellar).Thensolderthecompressorprocess pipeafterthesystemis

chargedwithrefrigerant.

4.Running test:

Replaceall thecomponentsaftertheproceduresaboveandturntheuniton.Toverifytheeffectiveness oftherepair,

monitor