2. Features & Main Function

Features

Appropriate for Weight and Measurement System

Easy Operation

Full Digital Calibration

Weight Back-Up [ Weight Memory at Sudden Power Failure ]

4 Multi-Point Calibration

Command Mode Function (Control by PC – Request and Set the Data)

Kg/lb Conversion & kg/lb Calibration

Lock Function of Front Key

User Message Print Function

Preset Tare

Gravity Compensation

3. Specification

Load Cell & A/D Conversion

Load Cell Excitation Voltage DC 5V (Connectable up to 6 EA)

CAPACITY Max = 30 Kg

e = 10 g

Max = 15 Kg

e = 5 g

A/D Internal Resolution 1/60000 1/60000

A/D External Resolution 1/3000 1/3000

Zero Adjustment Range 0.05 mV ~ 5 mV

Input Sensitivity 2 Uv / D (OIML, Ntep, KS)

0.5 uV / D (Non OIML, Ntep, KS)

Non-linearity 0.01% Full Scale

Calibration Full Digital Calibration : SPACTM

(Single pass automatic span calibration)

Tare Full Tare

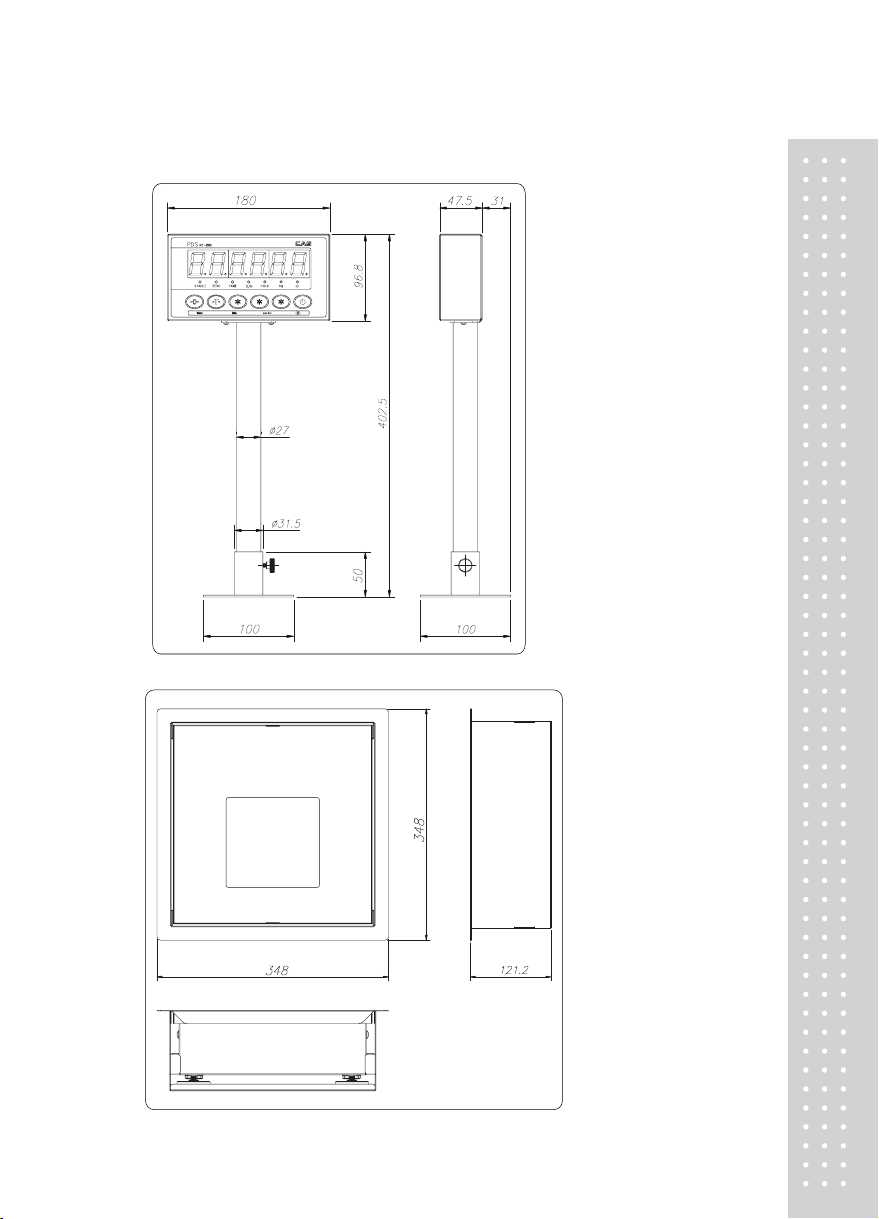

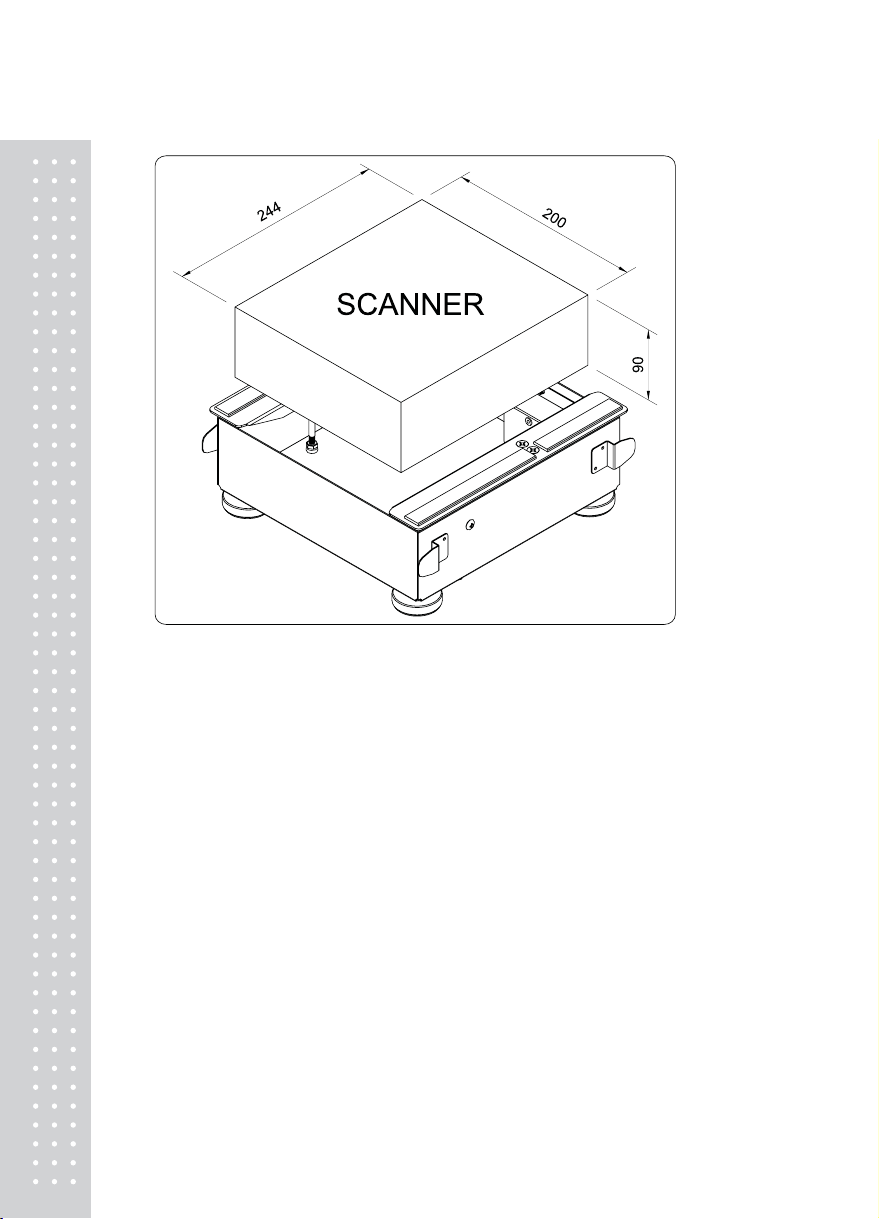

Product Weight Body 7.5kg, Head 1.5kg

*It is possible to set communication speed and a use of RS 232, RS422.