CASE

nir

Service

Bulletin

FILING INSTRUCTIONS

Binder: AG EQUIPMENT BINDER Page: 1 of 26

Binder Section: AGRICULTURAL TRACTORS Document No.: NTR SB 026 96

I

Mach

Loc

Code: 40000

Issued By: PRODUCT MANAGEMENT,

RACINE,

WISCONSIN, USA

Family: Magnum

Model:

7210,7220,7230,7240,7250

Supersedes:

Date Issued: 1

1/20/96

Subject:

Magnum Hitch Diagnostic Codes and Service Manual Update

Background The following service bulletin will provide the dealer with more detailed troubleshooting

nformation on the Magnum 7200 series hitch system. The dealer should make a copy of this bulletin

and

place in section 4002 page 45 or section 8009 of the 7200 series Service Manual.

Note: The hitch calibration procedure is found in the 7200 series Service Manual section 8009

Of

Service Manual is no longer Correct.

Note:

The 7100 and 8900 series tractor require a different calibration procedure.

This

bulletin will cover the following items.

1.

General information

...............................................................................................

page

2

2.

General testing of the hitch system

........................................................................

Reading and erasing error codes page

3

-

4

3.

...........................................................................

page

5

4.

Hitch performance codes (during field operations)

................................................. page

6

-

10

5.

7200 series hitch calibration procedure

.................................................................

page

11

-

12

6.

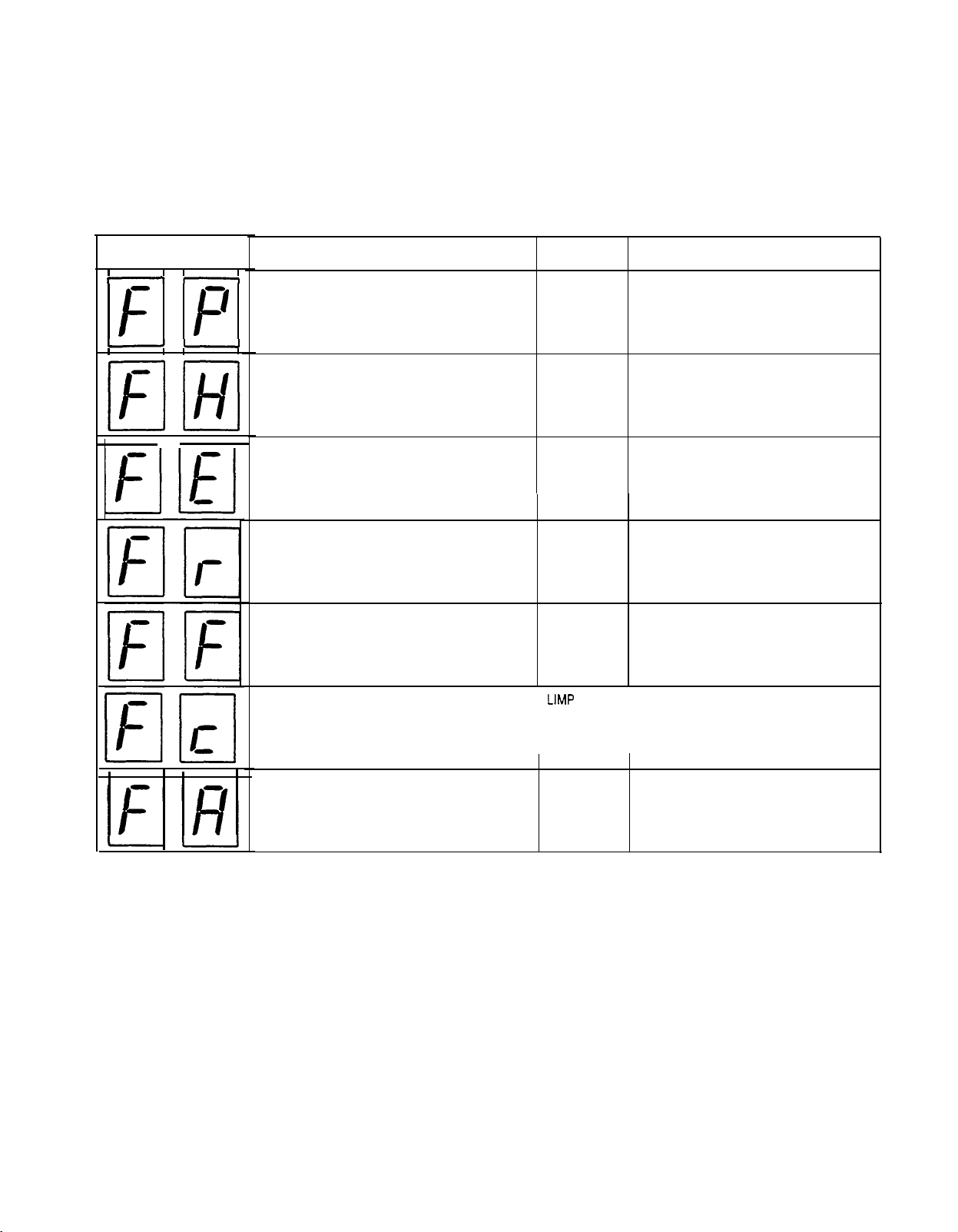

Hitch diagnostic codes (during calibration)

.............................................................

7.

Hitch diagnostics by problem.. page 13

-

14

........

....................................................................... page

15

-

16

8.

Hitch component function and troubleshooting

....................................................

--page 17

-

18

9.

Hitch electrical component part numbers

...............................................................

page

19

10.. Eliminating load pins and draft control from the Magnum tractor

.........................

19

1

1. Testing rockshaft and position lever potentiometers

- - page

..............................................

20

12. Bench testing rockshaft and position lever potentiometers

page

....................................

20

13. Testing wiring harness at the 37 pin, 16 pin amp connector

page

.................................page 21

-

24

14.

Testing the EDC relay on tractors below serial number JJA0064978

....................

15. Testing hitch enable relay page 25

..................................................................................... page25

16. Correction to wiring schematic found in section 4002 page 27

.............................page26

SERVICE BULLETINS DO NOT CONSTITUTE WARRANTY AUTHORIZATION TO UPDATE UNITS