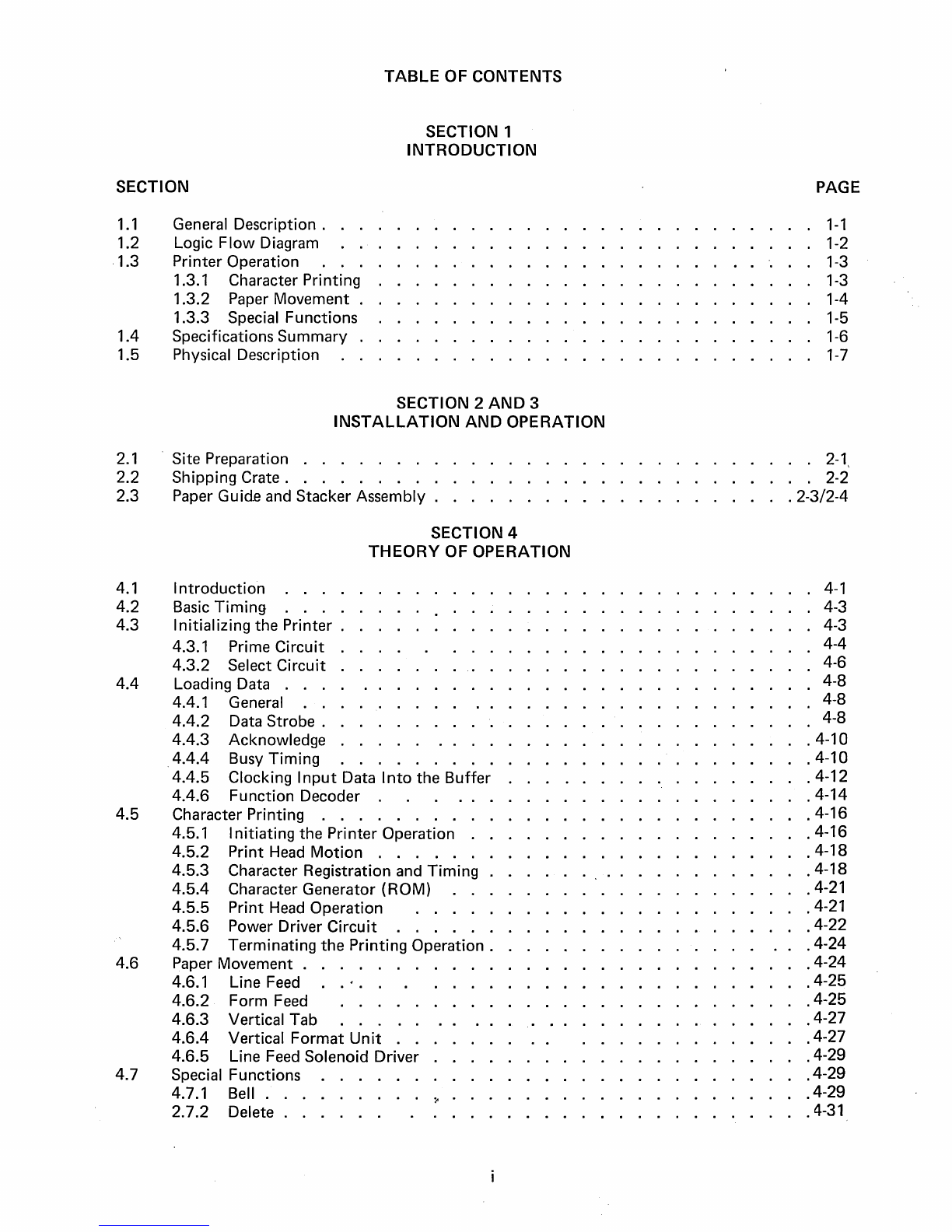

LIST OF ILLUSTRATION (cont'd)

FIGURE

5-15 Backlash Adjustment,

Bevel

Gear (HI-43, 59)

5-16 Driving

SI

ide Shaft A - Adjustment .

5-17 Ribbon Reversing Rod

Adjustment.

. . .

5-18 Ribbon

Reverse

Timing . . . . . . . . .

7-1

Schematic Diagram, Electronic Card

No.1

(Sheet 1

of

3)

7-2 Schematic Diagram, Electronic

Card

No.1

(Sheet 2

of

3)

7-3 Schematic Diagram, Electronic

Card

No.1

(Sheet 3

of

3)

7-4 Schematic Diagram, Electronic Card

No.2

(Sheet 1

of

2)

7-5 Schematic Diagram, Electronic Card

No.2

(Sheet 2

of

2)

7-6 Schematic Diagram, Power Driver Board (Sheet 1

of

2)

.

7-7 Schematic Diagram, Power Driver Board (Sheet 2

of

2)

7-8 Schematic Diagram, Diagram,

+5V

Regulator . . . .

7-9 Schematic Diagram, ±12 V

Regulator.

. . . . . .

7-10 Schematic Diagram, Video

Amplifier

.......

.

7-11

Schematic Diagram, Elapsed Time Indicator (Optional)

7-12 Schematic Diagram, Multitap Transformer

50/60

Hz

.

7-13 Schematic Diagram,

Motor

Control.

. . . . .

7-14 Wiring Diagram, Printer Mechanism. . . . . .

7-15 Interconnecting Diagram; Connector Board

7-16 Schematic Diagram,

LED

Tape Reader (Optional)

7-17 Component Board Assembly, Electronic Card

No.1

7-18 Component Board Location, Electronic Card

No.2

7-19 Component Board Assembly, +5

Volt

Regulator.

7-20 Component Board Assembly, ±

12V

Regulator

7-21

Component Board Assembly, Connector Board

7-22 Component Board Assembly, Power

Driver.

. .

7-23 Component Board Assembly, Video

Amplifier

7-24 Component Board Assembly, Elapsed Time Indicator (Optional)

7-25 Electronic Cavity Assembly. . . .

7-26

W1

Harness

Assembly . . . . . .

7-27

W2

Cable Assembly, Computer

Input

7-28

W3

Power Cable Assembly . . . .

7-29 Component Board Assembly,

Motor

Control (Optional) .

7-30

Harness

Assembly,

Motor

Control .

8-1

Mechanical Subassemblies Series

101

8-2 Cover Assembly A . . . . . . .

8-3 Carriage Mechanism

HA

. . . . .

8-4 Drive Mechanism

HB

(Part

1)

Series

101

8-5 Drive Mechanism (Preload Clutches), (Part

2)

Series

101

8-6 Spring Drum

HC

8-7 Damper

HD.

. . . . .

8-8 Frame

HE

. . . . . .

8-9 Paper

Feed

Mechanism

HF

8-10

Pin

Feed

Mechanism

(Left

and

Right)

HG

8-11

Form

Feed

Mechanism

HH

. . . . . .

8-12 Ribbon

Feed

Mechanism HI

.....

8-13 Electrical Hardware

HJ

(No Illustration) .

8-14 Print

Head

and Associated Assemblies. .

iv

PAGE

.5-31

.5-32

.5-33

.5-33

7-3

7-4

· 7-5

7-6

7-7

7-8

7-9

.7-10

·

7-11

.7-12

.7-13

.7-14

.7-15

· 7-16

·

.7-17

.7-18

· 7-19

· .7-21

.7-23

.7-25

.7-27

.7-29

·

7-31

.7-3:

.7-35

.7-37

.7-39

.7-41

.7-43

.7-45

8-3

8-5

8-7

8-9

·

8-11

.8-13

.8-15

.8-17

·

.8-19

.8-21

.8-23

.8-25

.8-27

.8-28