Centronics 730-1 User manual

MODEL 730-1 PRINTER

©MNlg^ AMtUJAlL

DECEMBER 1979

Centronics No. 37400741 Rev. -2

CERTRDniCS

data computer corporation

Hudson, New Hampshire 03051

Telephone (603) 883 -0111

TABLE OF CONTENTS

SECTION

SPECIFICATIONS

OPERATION

MAINTENANCE

7/

_i-

PAGE

INTRODUCTION ••1

2

SETTING UP •3

RIBBON INSTALLATION 8

10

PRINCIPLES OF OPERATION •12

PRINTER INTERFACE •••^

21

INTRODUCTION

The Model 730-1 is an operationally simple, compact, microprocessor controlled,

dot-matrix, impact printer. The unit prints 7x7 dot matrix characters at 10

characters per inch in line lengths up to 8inches at arate of 100 characters

per second. The printer features three-way paper handling.

1. 9-1/2" (9" pin to pin) wide standard computer fanfold forms, with fixed

position pins to ensure pinfeed paper registration. The paper can be

multipart up to three parts.

2. Rolled paper, 3-1/2 to 8-1/2- wide, 1" core and up to 5" diameter. The

printer includes aroll paper holder. Abuilt-in rip-and-read cutting

edge allows easy removal of paper. The first line of following page is

printed within five lines of tear edge. Two ply paper may be used with

operator attendance.

3. Single sheets of 8-1/2 inch wide paper, hand fed as with an ordinary

typewriter.

The printer's character set consists of 96 US ASCII characters. Normal size

characters can be printed at up to 80 characters per line. Elongated characters

which are double-width characters can be printed at up to 40 characters per line

Other significant features include:

1. Reliable free-flight head.

2. Microprocessor technology.

3. Full line buffer.

4. Fast carriage return at 10" per second.

5. Special line feed buffer for host-controlled forms control.

6. Compact size (5"H x14-1/2"W x11 MD).

-1-

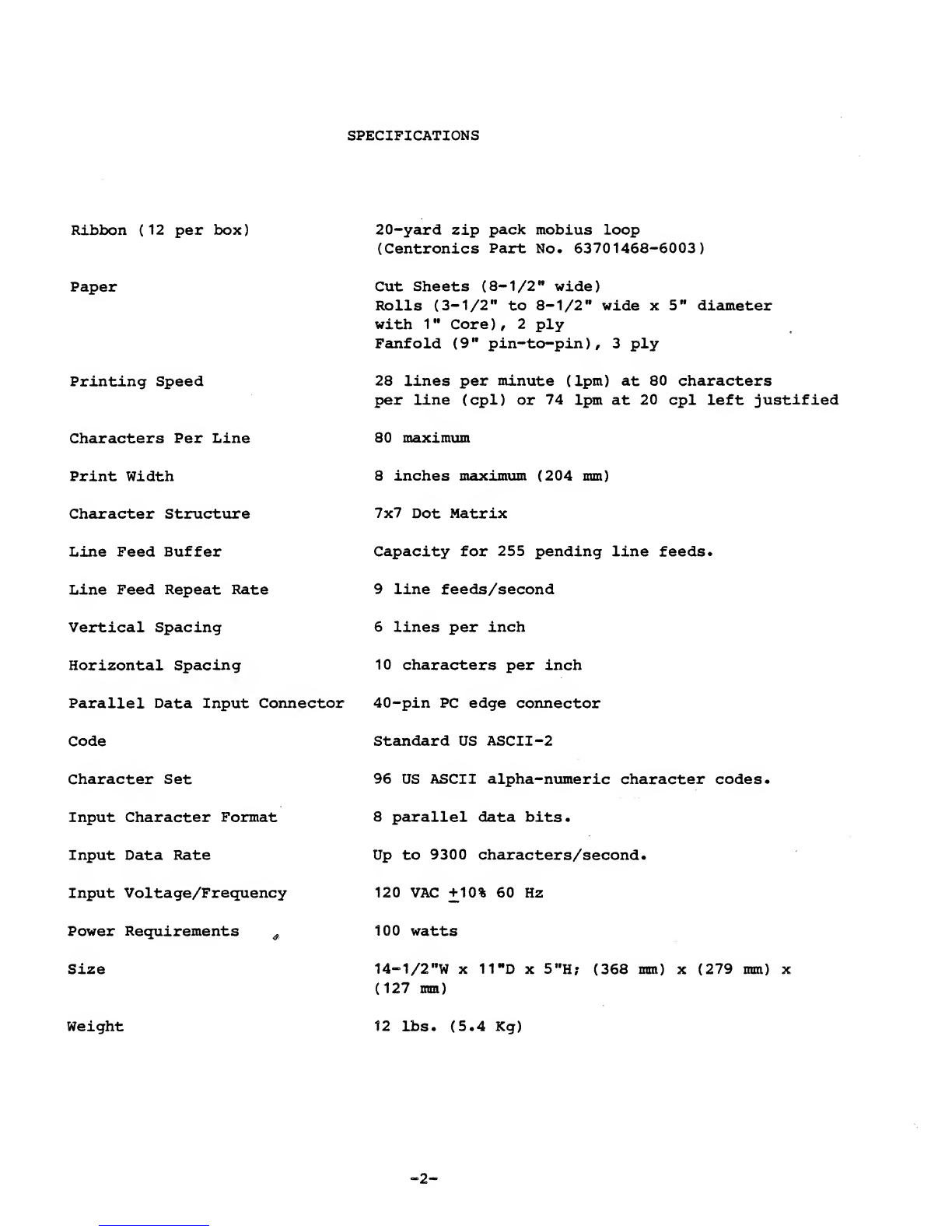

SPECIFICATIONS

Ribbon (12 per box)

Paper

Printing Speed

Characters Per Line

Print Width

Character Structure

Line Feed Buffer

Line Feed Repeat Rate

Vertical Spacing

Horizontal Spacing

Parallel Data Input Connector

Code

Character Set

Input Character Format

Input Data Rate

Input Voltage/Frequency

Power Requirements #

Size

Weight

20-yard zip pack mobius loop

(Centronics Part No. 63701468-6003)

Cut Sheets (8-1/2- wide)

Rolls (3-1/2" to 8-1/2" wide x5Hdiameter

with 1*' Core ),2ply

Fanfold (9 Wpin-to-pin), 3ply

28 lines per minute (1pm) at 80 characters

per line (cpl) or 74 1pm at 20 cpl left justified

80 maximum

8inches maximum (204 mm)

7x7 Dot Matrix

Capacity for 255 pending line feeds.

9line feeds/second

6lines per inch

10 characters per inch

40-pin PC edge connector

Standard US ASCII-2

96 US ASCII alpha-numeric character codes.

8parallel data bits.

Up to 9300 characters/second.

120 VAC +10% 60 Hz

100 watts

14-1/2-W x11"D x5"H? (368 mm) x(279 mm) x

(127 mm)

12 lbs. (5.4 Kg)

=2-

SETTING UP

INSPECTION

Visually inspect the printer for signs of damage received during shipment.

Notify the common carrier immediately of any discrepancies.

NOTE

Any attempt to operate adamaged

printer voids the warranty and may

cause further damage.

QUICK SET-UP PROCEDURES

1. Install roll paper holder and roll paper, fanfold paper, or single-sheet

paper.

2. Remove top cover and check ribbon, then reinstall cover and install top

paper guide. Ensure that head restraint and ribbon cover packing has been

removed. CAUTION

When turning power on or off, the

RESET ON/OFF switch should always

be placed in the ON position to

prevent erroneous communications be-

tween the host device and the printer

and to prevent damage to the printer.

3. Place POWER switch in the OFF position and place RESET ON/OFF switch

in ON position.

4. Connect power cord to a3-wire, grounded AC outlet.

5. Connect interface cable to printer interface connector.

6. Place POWER switch in ON position and observe that the LED illuminates

through paper exit slot.

7. Place RESET ON/OFF switch in OFF position to receive data.

Figure 1. MODEL 730-1 PRINTER

-3-

ROLL PAPER HOLDER INSTALLATION

1

.

Set the printer on aflat surface with enough room in back of the printer

for the roll paper holder.

2. Refer to Figure 2and squeeze the support arms together slightly.

3. Insert support arms into two holes provided at rear of printer and release

support arms.

4. Remove core hub from plain end and insert roller through standard 1-inch

paper roll core and place roll on holder as shown with paper feeding from

bottom of roll.

m\

SLIDE CORE ON AXLE

FOR PROPER ROLL

ALIGNMENT

£7

PLAIN END /

PUSH THIS PORTION OF HUBS

INTO CORE ENDS

TOP PAPER GUIDE PAPER

PAPER

ROLL

PAPER ROLL

HOLDER

PLATEN FACE

PAPER

GUIDE

ARM SUPPORT ARM

PAPER DRIVE

ROLLER

PRINTER

CABINET

(CUTAWAY)

Figure 2. ROLL PAPER HOLDER INSTALLATION

-4-

PAPER INSTALLATION

Printer Forms Selection Guide

The printer has the unique ability to handle three common types of paper;

cut sheet, roll, and fanfold. Line registration can vary depending on the

type of paper being used. To select the ideal type of paper or form for

your application, you should consider the following guidelines:

1. Precise registration, 6lines to the inch, can be best maintained by using

continuous fanfold edge-punched paper. This type of paper should be used

wherever registration is critical such as in preprinted forms applications.

2. The last line can be printed up to 1.6" (40.6 mm) from the bottom of the

page when using cut sheet paper.

3. In pinch-feed applications when using roll paper or cut-sheet paper, the

line spacing can vary depending upon the finish and weight of the paper.

Check the paper for your application before use or procurement of preprinted

forms.

Refer to the appropriate procedure to install roll paper, fanfold paper,

or single sheets/forms.

NOTE

When installing ribbon or paper,

always back print head away from

.5-

Roll Paper

1

.

Install the roll on the paper holder as described previously.

2. Remove top cover by lifting rear edge until latches are clear of main

cover and then slide cover back to disengage front clips.

3. Retract head to the paper/ribbon load position by rotating head release

lever fully counterclockwise.

4. Push the pinch-roller release lever towards rear of printer.

5. Feed the paper over the paper guide arm and through the bottom rear of the

printer under the paper drive roller.

6. Align the edges of the free end of paper with paper-drive roller edges and

straighten as required.

7. Remove any skew between paper roll and the paper-drive roller by sliding

the roll on the holder axle to align the paper as shown in Figure 3.

THUMB WHEELS

ALIGN ROLL PAPER WITH

"THIS DIMENSION

Figure 3. PAPER DRIVE ROLLER

8. Push the pinch-roller release lever forward to secure paper.

9. Advance paper into printer by turning either thumbwheel until paper exits

through the top of the printer.

10. Check ribbon position, remove slack if necessary, move head-release lever

to print position, and install top cover. Print position numbers on print

head assembly indicate head-release lever positions for number of plies of

paper as ageneral rule. Note that print-head position may vary depending

upon type of paper being used.

-6-

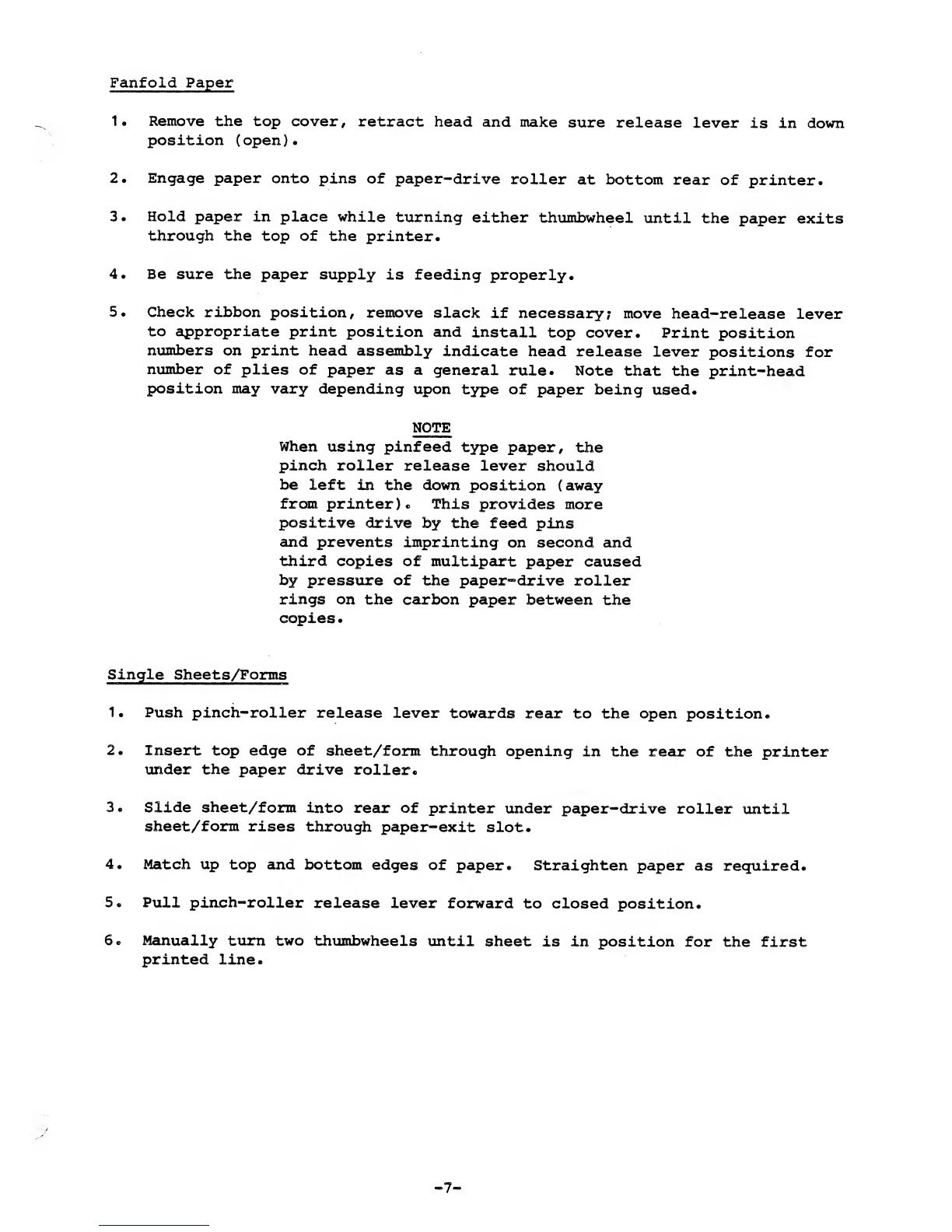

Fanfold Paper

1. Remove the top cover, retract head and make sure release lever is in down

position (open).

2. Engage paper onto pins of paper-drive roller at bottom rear of printer.

3. Hold paper in place while turning either thumbwheel until the paper exits

through the top of the printer.

4. Be sure the paper supply is feeding properly.

5. Check ribbon position, remove slack if necessary; move head-release lever

to appropriate print position and install top cover. Print position

numbers on print head assembly indicate head release lever positions for

number of plies of paper as ageneral rule. Note that the print-head

position may vary depending upon type of paper being used.

NOTE

When using pinfeed type paper, the

pinch roller release lever should

be left in the down position (away

from printer). This provides more

positive drive by the feed pins

and prevents imprinting on second and

third copies of multipart paper caused

by pressure of the paper-drive roller

rings on the carbon paper between the

copies.

Single Sheets/Forms

1. Push pinch-roller release lever towards rear to the open position.

2. Insert top edge of sheet/form through opening in the rear of the printer

under the paper drive roller.

3. Slide sheet/form into rear of printer under paper-drive roller until

sheet/form rises through paper-exit slot.

4. Match up top and bottom edges of paper. Straighten paper as required.

5. Pull pinch-roller release lever forward to closed position.

6. Manually turn two thumbwheels until sheet is in position for the first

printed line.

-7-

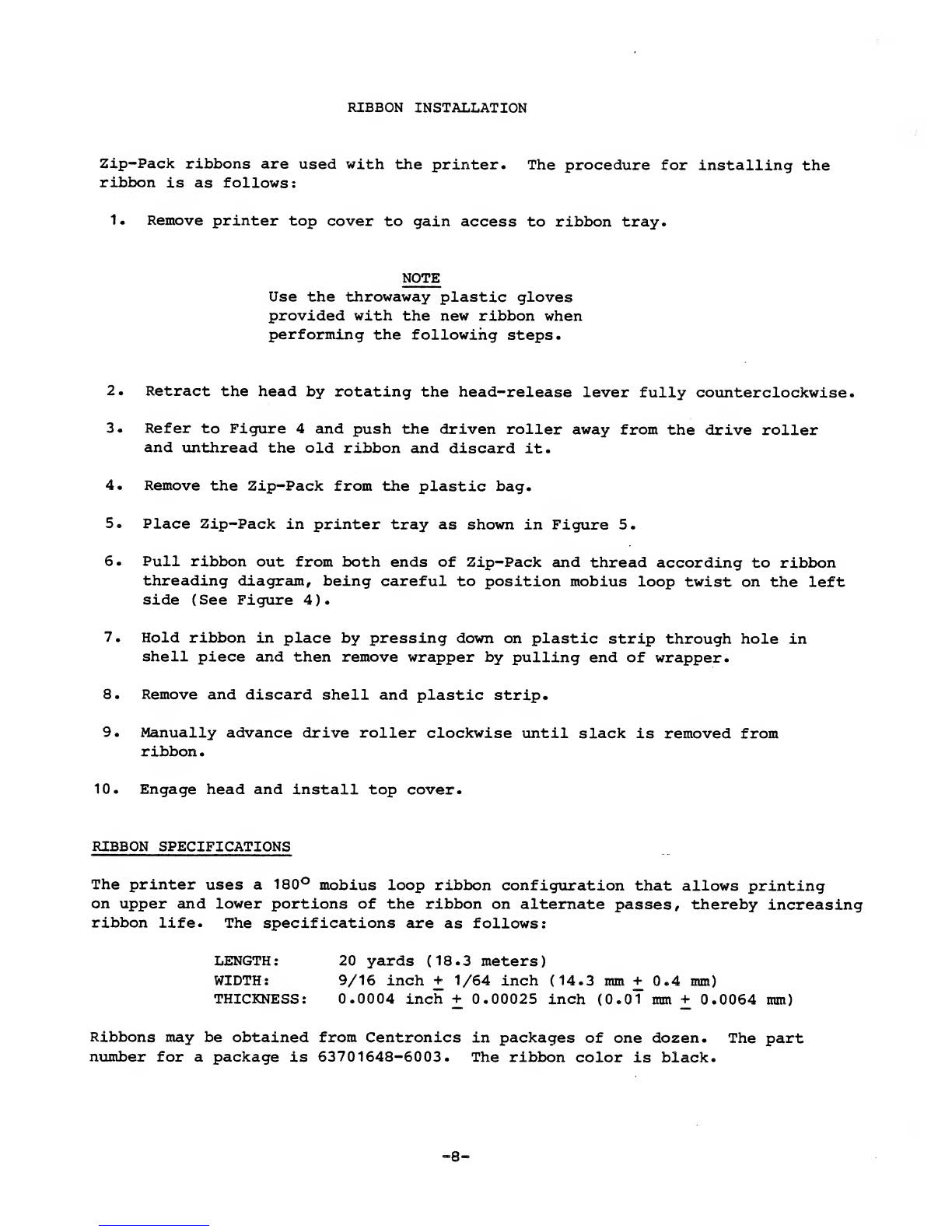

RIBBON INSTALLATION

Zip-Pack ribbons are used with the printer. The procedure for installing the

ribbon is as follows:

1. Remove printer top cover to gain access to ribbon tray.

NOTE

Use the throwaway plastic gloves

provided with the new ribbon when

performing the following steps.

2. Retract the head by rotating the head-release lever fully counterclockwise.

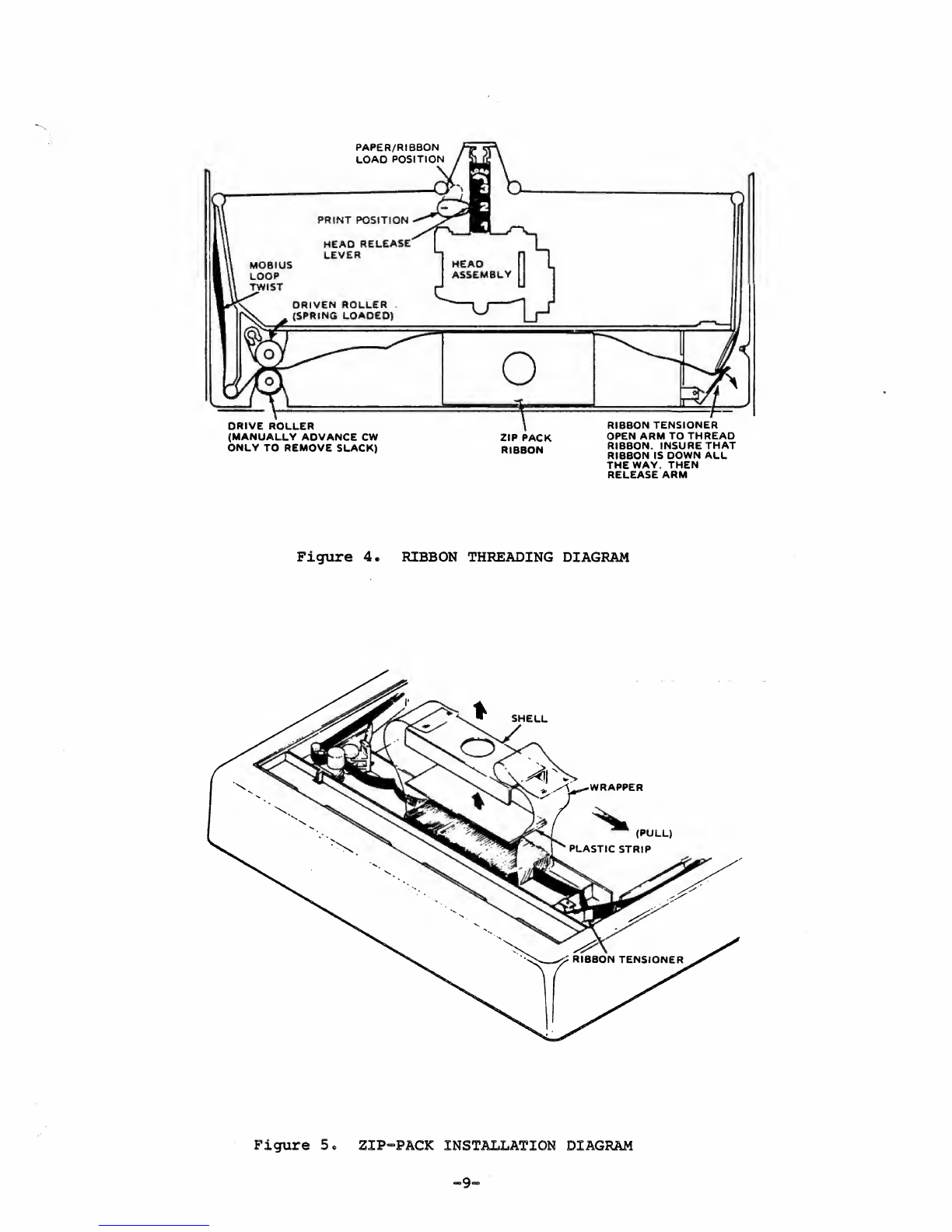

3. Refer to Figure 4and push the driven roller away from the drive roller

and unthread the old ribbon and discard it.

4. Remove the Zip-Pack from the plastic bag.

5. Place Zip-Pack in printer tray as shown in Figure 5.

6. Pull ribbon out from both ends of Zip-Pack and thread according to ribbon

threading diagram, being careful to position mobius loop twist on the left

side (See Figure 4).

7. Hold ribbon in place by pressing down on plastic strip through hole in

shell piece and then remove wrapper by pulling end of wrapper.

8. Remove and discard shell and plastic strip.

9. Manually advance drive roller clockwise until slack is removed from

ribbon

.

10. Engage head and install top cover.

RIBBON SPECIFICATIONS

The printer uses a180° mobius loop ribbon configuration that allows printing

on upper and lower portions of the ribbon on alternate passes, thereby increasing

ribbon life. The specifications are as follows:

LENGTH: 20 yards (18.3 meters)

WIDTH: 9/16 inch +1/64 inch (14.3 mm +0.4 mm)

THICKNESS: 0.0004 inch +0.00025 inch (0.01 mm +0.0064 mm)

Ribbons may be obtained from Centronics in packages of one dozen. The part

number for apackage is 63701648-6003. The ribbon color is black.

_o

PAPER/RIBBON

LOAD POSITION

DRIVE ROLLER

(MANUALLY ADVANCE CW

ONLY TO REMOVE SLACK) ZIP PACK

RIBBON

RIBBON TENSIONER

OPEN ARM TO THREAD

RIBBON. INSURE THAT

RIBBON IS DOWN ALL

THE WAY. THEN

RELEASE ARM

Figure 4. RIBBON THREADING DIAGRAM

SHELL

Figure 5. ZIP-PACK INSTALLATION DIAGRAM

_9_

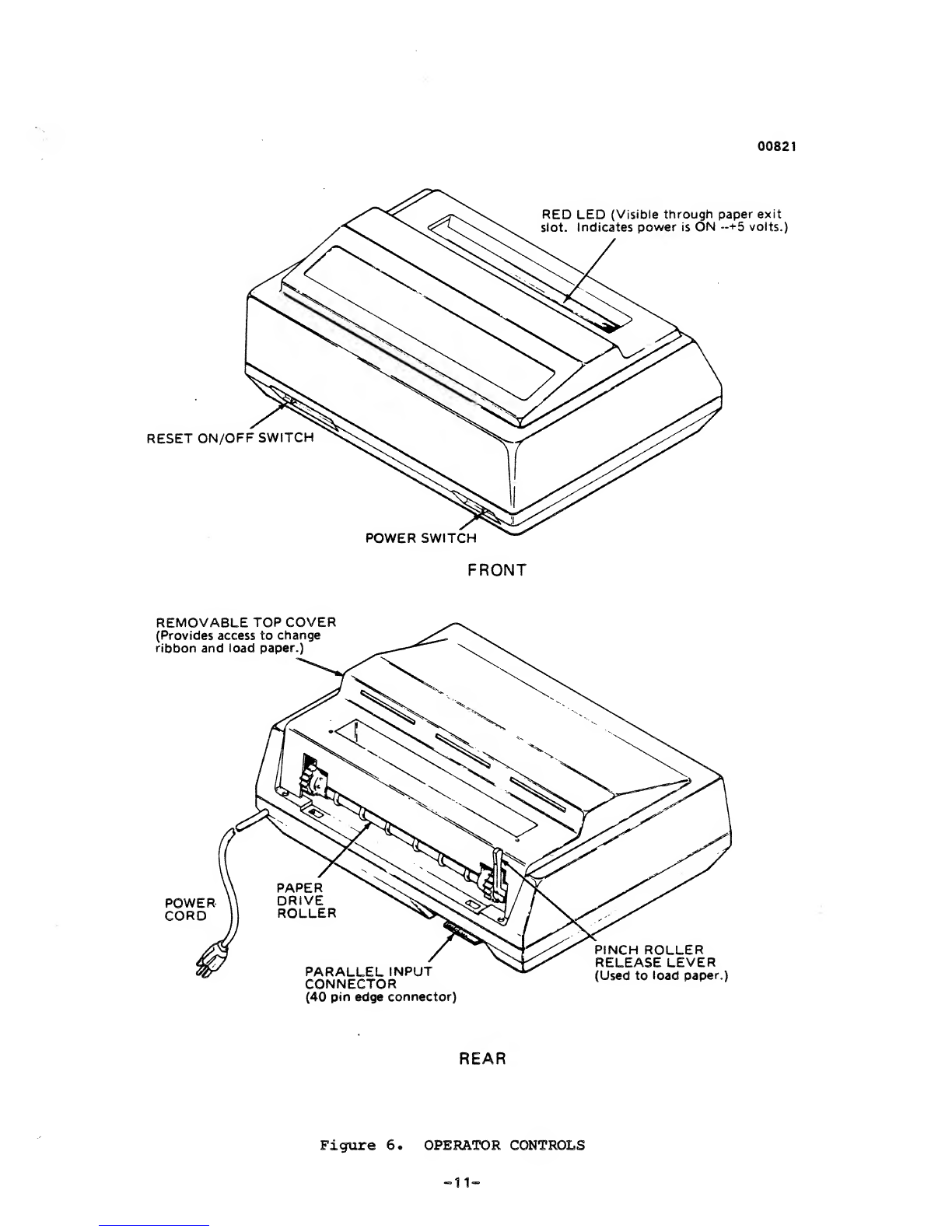

OPERATION

USING THE PRINTER

1

.

Be sure that aribbon is installed in the printer and an adequate supply

of paper has been installed.

2. Place RESET ON/OFF switch in the ON position. (Refer to Figure 6.) This

prevents the printer from printing and keeps it "off-line".

CAUTION

When turning power on or off, the

RESET ON/OFF switch should always

be placed in the ON position to

prevent erroneous communications be-

tween the host device and the printer

and to prevent damage to the printer.

3. Place POWER ON/OFF switch in ON position. "Power On" LED should be

visible through paper-exit slot.

4. Place RESET ON/OFF switch in the OFF position. Printer is ready to

accept data.

5. To turn printer off, place RESET ON/OFF switch in ON position. Then,

place POWER ON/OFF switch in OFF position.

HINTS AND TIPS

•Always plug printer into a3-wire grounded outlet.

•Do not leave or place objects on any part of printer.

•Do not subject printer to temperatures below +40°F (4°C) during operation,

to asudden change in temperature, to dust, or to extreme shock.

•Use only adry, soft cloth to clean printer surfaces. Do not use harsh

detergents or chemicals.

•Avoid touching print-head print wires when handling paper or changing

ribbons

•

•Periodically clean ink build-up from ribbon guide path and remove paper dust

from interior.

-10 -

00821

RED LED (Visible through paper exit

slot. Indicates power is ON ~+5 volts.]

RESET ON/OFF SWITCH

POWER SWITCH

FRONT

REMOVABLE TOP COVER

(Provides access to change

ribbon and load paper.)

POWER

CORD

PARALLEL INPUT

CONNECTOR

(40 pin edge connector)

PINCH ROLLER

RELEASE LEVER

(Used to load paper.)

REAR

Figure 6» OPERATOR CONTROLS

PRINCIPLES OF OPERATION

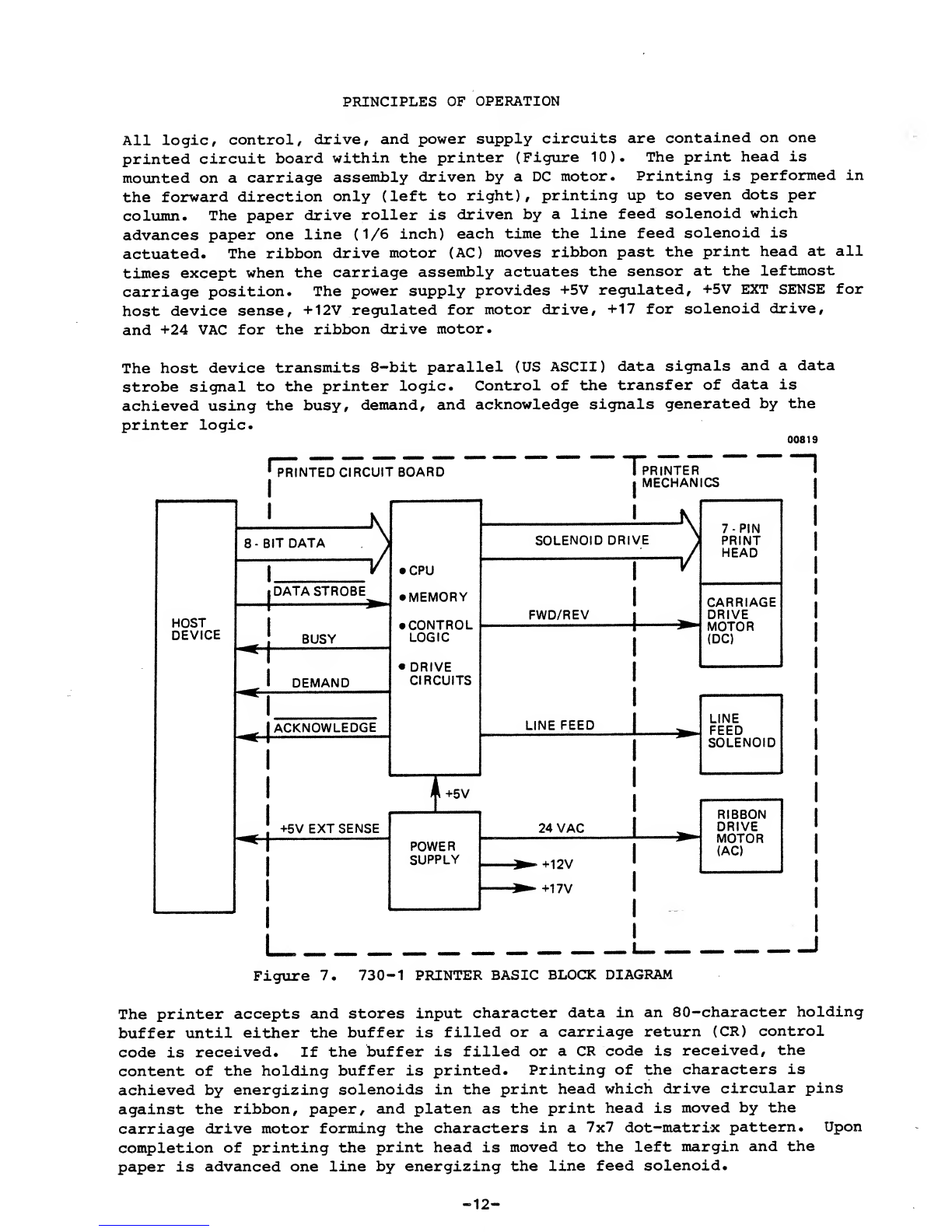

All logic, control, drive, and power supply circuits are contained on one

printed circuit board within the printer (Figure 10). The print head is

mounted on acarriage assembly driven by aDC motor. Printing is performed in

the forward direction only (left to right), printing up to seven dots per

column. The paper drive roller is driven by aline feed solenoid which

advances paper one line (1/6 inch) each time the line feed solenoid is

actuated. The ribbon drive motor (AC) moves ribbon past the print head at all

times except when the carriage assembly actuates the sensor at the leftmost

carriage position. The power supply provides +5V regulated, +5V EXT SENSE for

host device sense, +12V regulated for motor drive, +17 for solenoid drive,

and +24 VAC for the ribbon drive motor.

The host device transmits 8-bit parallel (US ASCII) data signals and adata

strobe signal to the printer logic. Control of the transfer of data is

achieved using the busy, demand, and acknowledge signals generated by the

printer logic. 00819

PRINTED CIRCUIT BOARD IPRINTER «

•MECHANICS I

HOST

DEVICE

8-BIT DATA

IDATA STROBE

BUSY

DEMAND

ACKNOWLEDGE

•CPU

•MEMORY

•CONTROL

LOGIC

•DRIVE

CIRCUITS

+5V EXT SENSE I

SOLENOID DRIVE

FWD/REV

7-PIN

PRINT

HEAD

CARRIAGE

DRIVE

MOTOR

(DC)

LINE FEED LINE

FEED

SOLENOID

+5V

POWER

SUPPLY

24 VAC »- RIBBON

DRIVE

MOTOR

(AC)

I

Figure 7. 730-1 PRINTER BASIC BLOCK DIAGRAM

The printer accepts and stores input character data in an 80-character holding

buffer until either the buffer is filled or acarriage return (CR) control

code is received. If the buffer is filled or aCR code is received, the

content of the holding buffer is printed. Printing of the characters is

achieved by energizing solenoids in the print head which drive circular pins

against the ribbon, paper, and platen as the print head is moved by the

carriage drive motor forming the characters in a7x7 dot-matrix pattern. Upon

completion of printing the print head is moved to the left margin and the

paper is advanced one line by energizing the line feed solenoid.

-12-

Line feed (LF) control codes received by the printer control paper movement.

Each line feed code received causes the paper to be advanced one line. The

printer has aspecial line feed buffer, separate from the holding buffer,

which can store up to 255 line feed commands. LF control codes are received

at the same data transfer rate as character data (up to 9300 characters per

second). The initial LF code causes an immediate advance of one line.

Additional line feed codes received are stored as acount in the line feed

buffer. Line feed codes and character data sent to the priinter may be

intermixed, however, all line feeds received are performed before printing the

next line of data.

Automatic line feed upon completion of printing each line may be disabled by

removing resistor R34 on the printer logic printer circuit board. If this

function is disabled, the first line of data will be printed when aCR control

code is received or abuffer full condition occurs. After printing the first

line of data, the print head is returned to the left margin and the paper is

not advanced. The second line (and subsequent lines) of data must have at

least one LF control code preceed each CR control code or buffer full condition,

or overprinting will occur.

Line feed codes may be used for limited paper handling functions. Each line

feed code moves the paper one-sixth of an inch. Thus, for example, if it is

desired to move the paper 12 inches, 72 line feed codes are required before a

CR control code is sent.

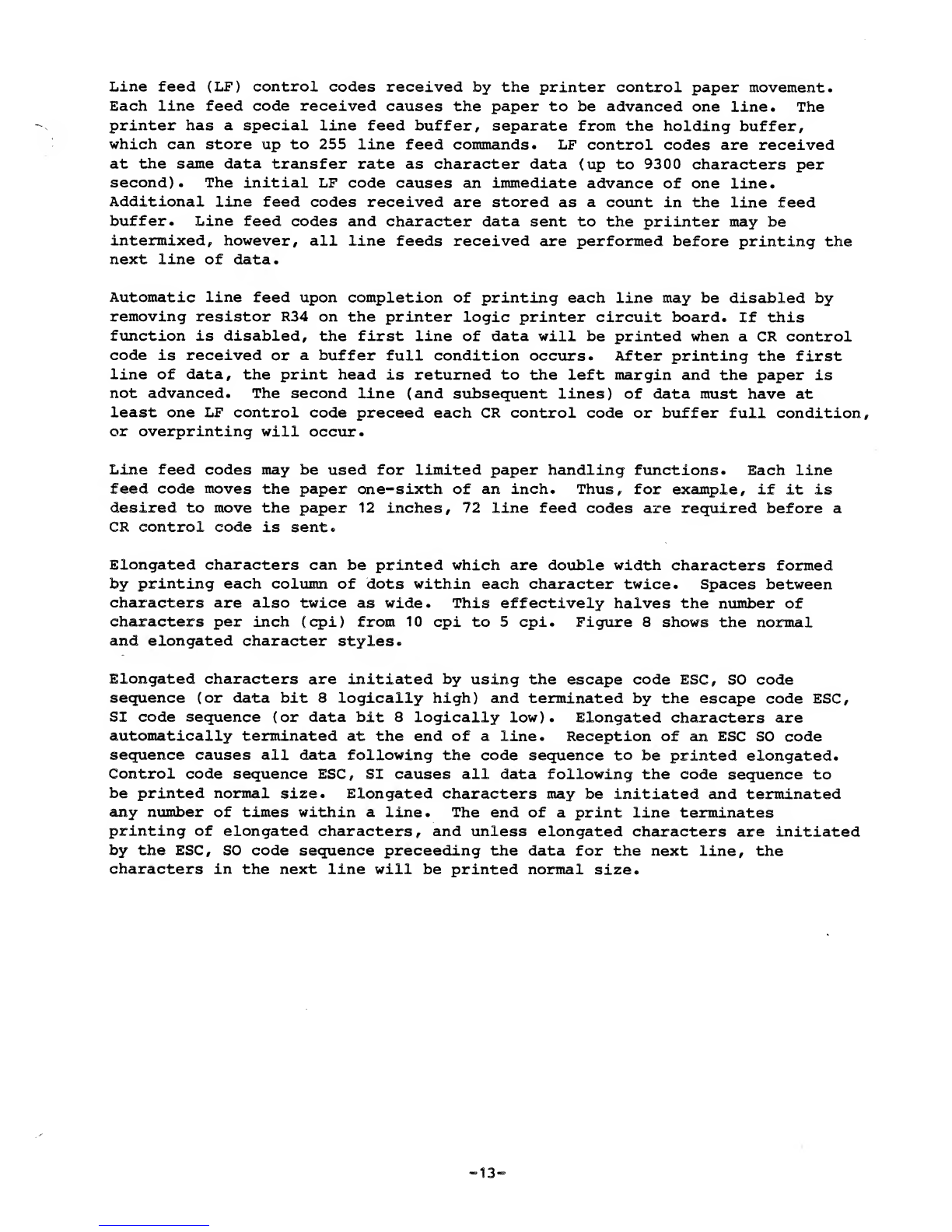

Elongated characters can be printed which are double width characters formed

by printing each column of dots within each character twice. Spaces between

characters are also twice as wide. This effectively halves the number of

characters per inch (cpi) from 10 cpi to 5cpi. Figure 8shows the normal

and elongated character styles.

Elongated characters are initiated by using the escape code ESC, SO code

sequence (or data bit 8logically high) and terminated by the escape code ESC,

SI code sequence (or data bit 8logically low). Elongated characters are

automatically terminated at the end of aline. Reception of an ESC SO code

sequence causes all data following the code sequence to be printed elongated.

Control code sequence ESC, SI causes all data following the code sequence to

be printed normal size. Elongated characters may be initiated and terminated

any number of times within aline. The end of aprint line terminates

printing of elongated characters, and unless elongated characters are initiated

by the ESC, SO code sequence preceeding the data for the next line, the

characters in the next line will be printed normal size.

-13-

!t*X&1

()X + t-/

1234567

89•*

ts>?

ABCDEFG

HI J KLMN

PQRSTUUW

XYZC\3tf

*3b c defG

hiJ k 1mn

u

NORMAL CHARACTERS

1II *iu %^i

<>>K .+. *—/

o:l 22 3*+ l^* A^

Q<? A

r..•* -:: .!•• *?

(>? AKit Ci:> e: F-\j»

I--I xU K i... MNCD

RaR3*r UVW

XVif: i:: \::i t> <-•

^Hi fc> en- cl frek •r C3

hl :i. *.j KXITl r*i CD

ys> c:* T* <» •b i..I vUl

*•* *rf 'J3Z •<: 1>•* tt

ELONGATED CHARACTERS

Figure 8. 730-1 PRINTER CHARACTER STYLES

-14-

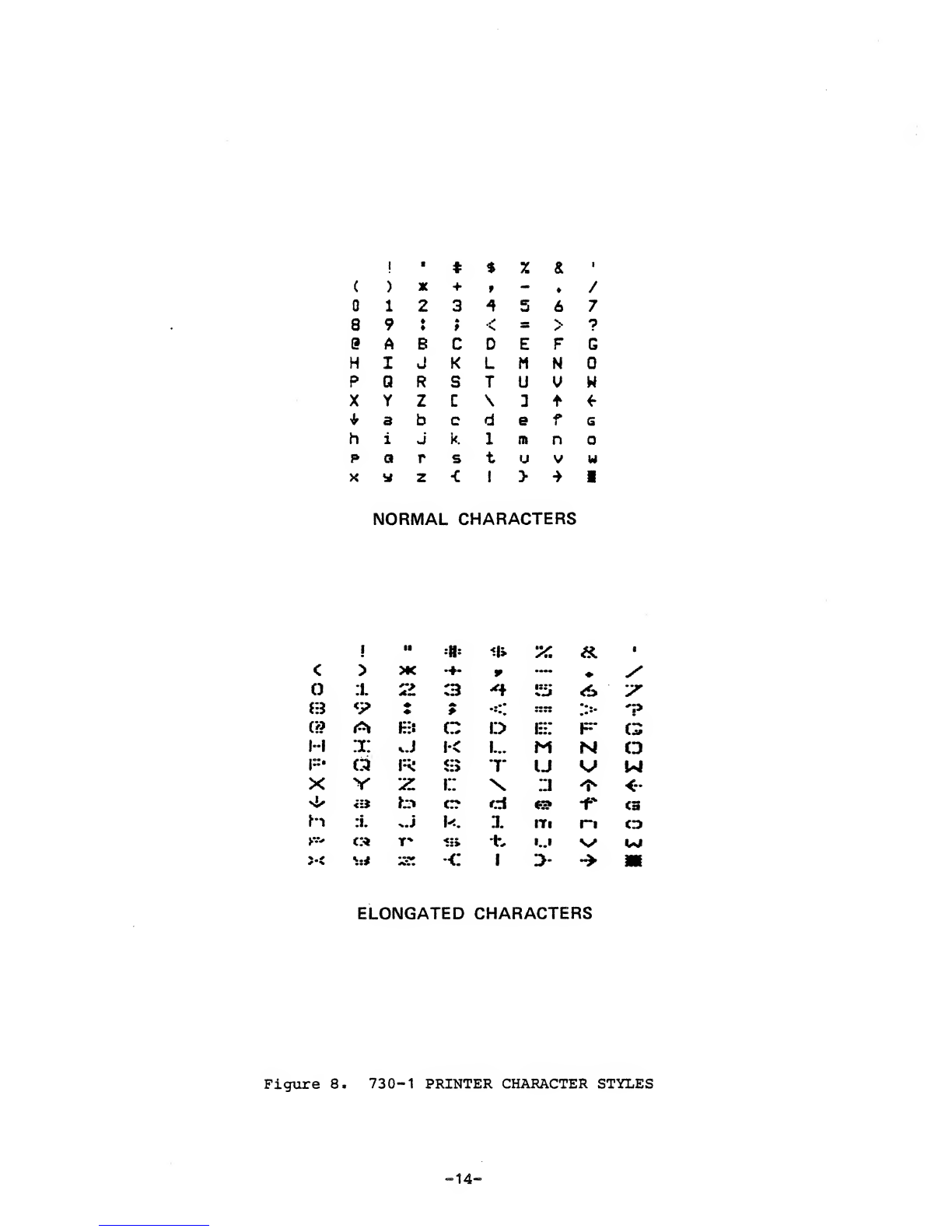

Figure 9shows the printer interface timing. Eachset of data bits (1-8)

sent to the printer is strobed by the DATA STROBE signal sent to the printer

by the host device. Within 50 nsec following the trailing edge of the DATA

STROBE signal aBUSY signal is generated by the printer which is sent to the

host device. The BUSY signal informs the host device that the printer is

processing the input data and that no additional data from the host device

will be accepted by the printer. After completion of processing the input

data an acknowledge (ACK) signal is sent to the host device indicating that

the data sent by the host device has been accepted and processed. Within 50

nsec following the leading edge of the ACK signal the BUSY signal is terminated

indicating that the printer is again ready to accept additional input data. A

DEMAND signal is also generated by the printer and is available to the host

device. The DEMAND signal is the inverse of the BUSY signal and when present

(positive) indicates that the printer is not busy and is ready to accept

data.

MTA "™ Jis+aH-Jsfc

DATA STROBE

**

\h

•as--"

ACK

BUSY

-th

-!V

J^t-i-t^"

Hi

S5T-- h-

Hp^

DEMAND lb

•100 usee is for data reception and line feeds that

do not fill tha line feed buffer. For line feeds that

is 110 msec +10%. -0%.

the maximum time i

Figure 9. INTERFACE TIMING

The time between the trailing edge of the DATA STROBE signal and the leading

edge of the ACK signal (data transfer cycle time) varies with the functions to

be performed by the printer. For normal data inputs and LF control codes

which do not fill the line feed buffer, the duration is nominally 160 usee.

For LF control codes which fill the line feed buffer, the maximum time is 110

msec +10, -0%. The maximum time for carriage return codes is 2.6 seconds. In

approximately 10% of the normal data transfer cycles amicroprocessor interrupt

occurs which extends the time from anonimal 100 usee to approximately 200 usee.

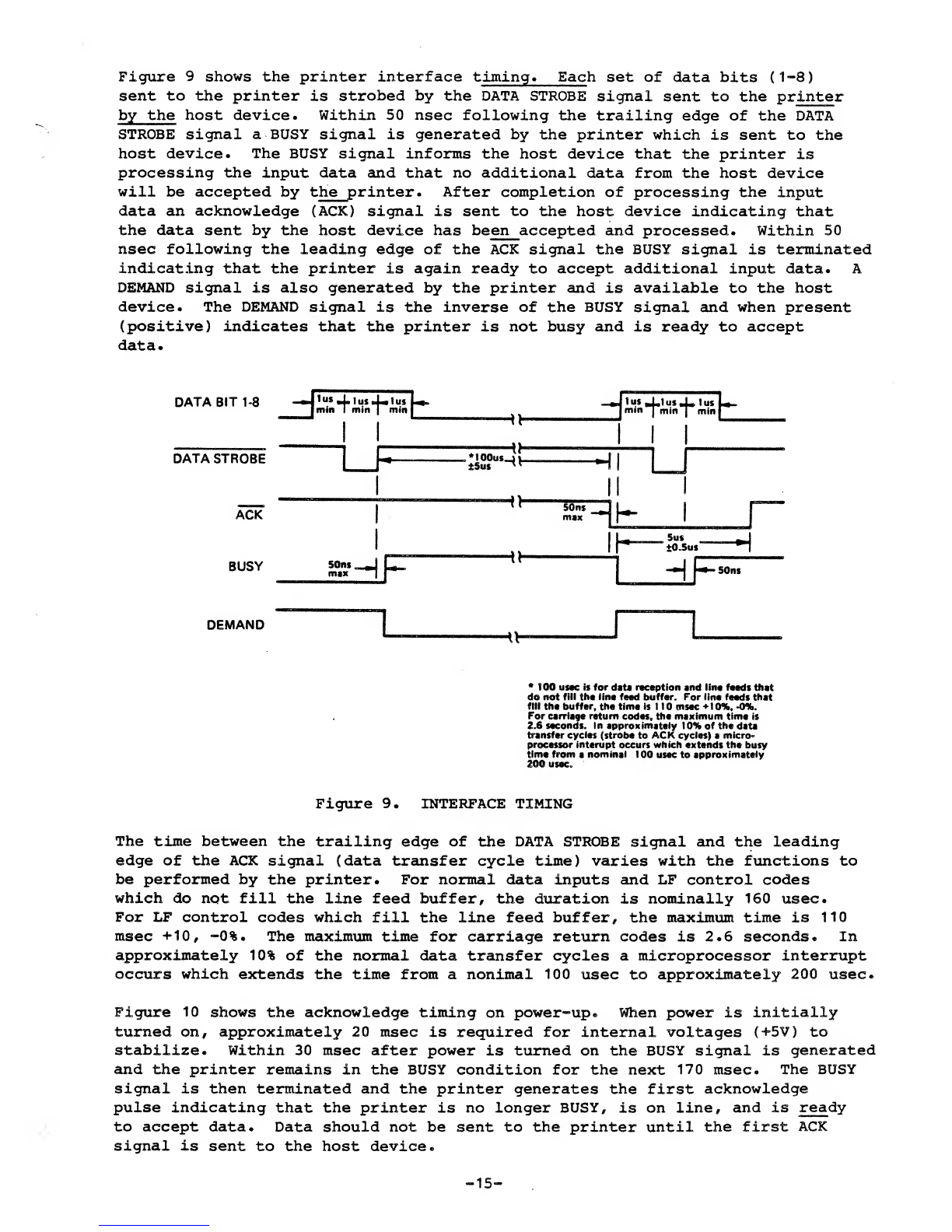

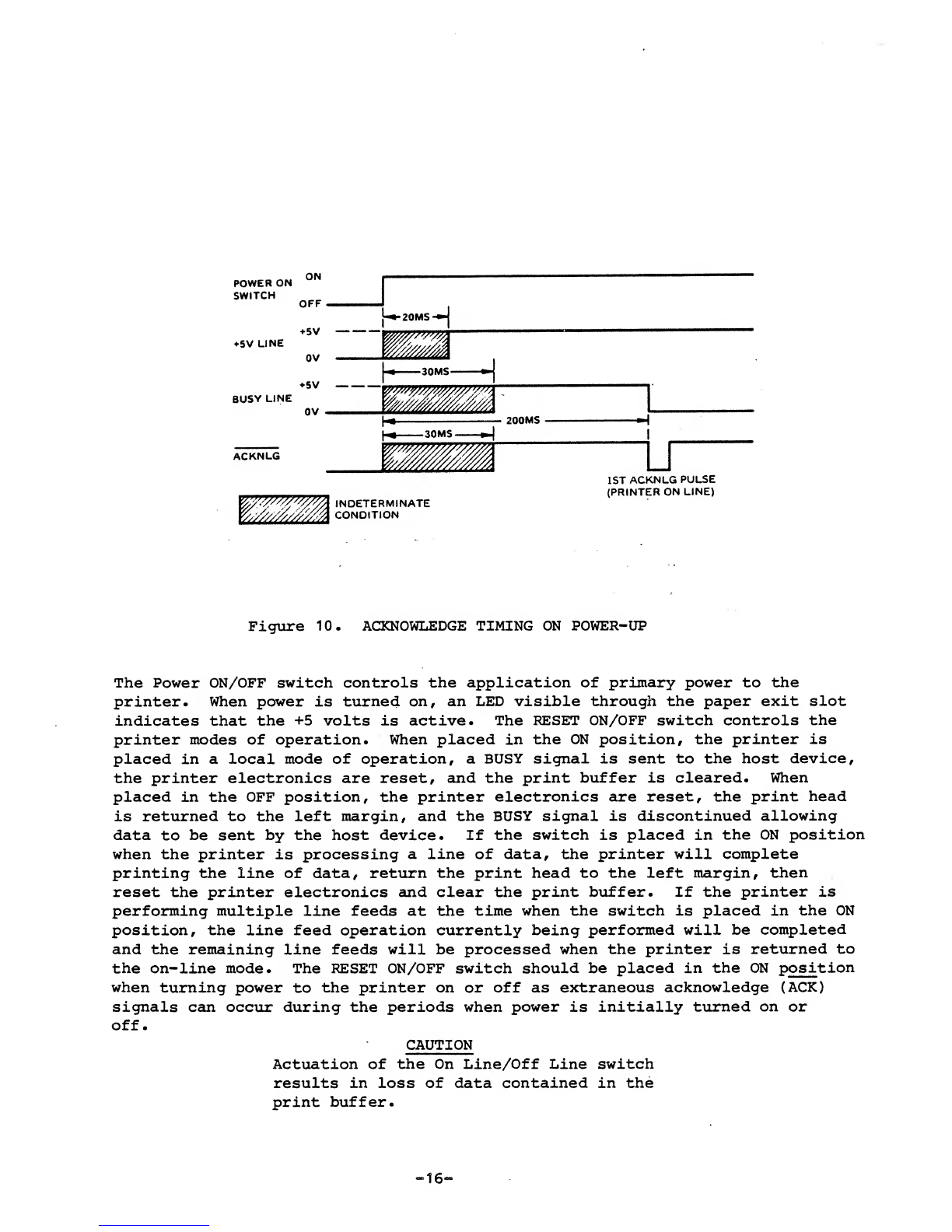

Figure 10 shows the acknowledge timing on power-up. When power is initially

turned on, approximately 20 msec is required for internal voltages (+5V) to

stabilize. Within 30 msec after power is turned on the BUSY signal is generated

and the printer remains in the BUSY condition for the next 170 msec. The BUSY

signal is then terminated and the printer generates the first acknowledge

pulse indicating that the printer is no longer BUSY, is on line, and is ready

to accept data. Data should not be sent to the printer until the first ACK

signal is sent to the host device.

-15-

POWER ON

SWITCH

5V LINE

BUSY LINE

ON

OFF

+5V

OV

+5V

OV

ACKNLG

20MS H

-30MS-

200MS

-30MS-

WVWWA indeterm.nate

W/M////M COND.T.ON

1ST ACKNLG PULSE

(PRINTER ON LINE)

Figure 10. ACKNOWLEDGE TIMING ON POWER-UP

The Power ON/OFF switch controls the application of primary power to the

printer. When power is turned on, an LED visible through the paper exit slot

indicates that the +5 volts is active. The RESET ON/OFF switch controls the

printer modes of operation. When placed in the ON position, the printer is

placed in alocal mode of operation, aBUSY signal is sent to the host device,

the printer electronics are reset, and the print buffer is cleared. When

placed in the OFF position, the printer electronics are reset, the print head

is returned to the left margin, and the BUSY signal is discontinued allowing

data to be sent by the host device. If the switch is placed in the ON position

when the printer is processing aline of data, the printer will complete

printing the line of data, return the print head to the left margin, then

reset the printer electronics and clear the print buffer. If the printer is

performing multiple line feeds at the time when the switch is placed in the ON

position, the line feed operation currently being performed will be completed

and the remaining line feeds will be processed when the printer is returned to

the on-line mode. The RESET ON/OFF switch should be placed in the ON position

when turning power to the printer on or off as extraneous acknowledge (ACK)

signals can occur during the periods when power is initially turned on or

off. CAUTION

Actuation of the On Line/Off Line switch

results in loss of data contained in the

print buffer.

16-

Other Centronics Printer manuals

Centronics

Centronics 352 User manual

Centronics

Centronics 306 User manual

Centronics

Centronics 101 User manual

Centronics

Centronics 101 User manual

Centronics

Centronics 702 User manual

Centronics

Centronics 101AL Guide

Centronics

Centronics 101AL User manual

Centronics

Centronics 101A User manual

Centronics

Centronics 705 User manual

Centronics

Centronics 101A User manual