Centronics 101 User manual

@~§~&lJ@~§

~&~U:JJ&[b

SERIES

100

PRINTERS

JULY 1975

Centronics

No.

37400001

Rev.

C

I:EnTRDnll:S

data computer corp.

HUDSON, NEW

HAMPSHIRE

03051

TELEPHONE

(603)

883

-0111

TABLE

OF CONTENTS

INTRODUCTION

.......

.

UNPACKING/REPACKING PROCEDURES

SET-UP PROCEDURES

OPERATING NOTES

OPERATING

GUIDE

OPERATOR CONTROLS

AND

INDICATORS

LOADING

PAPER

TOP OF FORM ADJUSTMENT

FORMS THICKNESS CONTROL

VERTICAL

FORMAT

UNIT

VERTICAL

FORMAT

TAPE

RIBBON REPLACEMENT .

RIBBON

AND

PAPER SPECIFICATIONS

RIBBON REPLACEMENT DIAGRAMS

SPECIAL CONTROL CODES . . .

STANDARD

CHARACTER

SETS

...

USASCII CODE

I:EnTROnll:S

CENTRONICS

DATA

COMPUTER

CORP.

HUDSON. N.H. 03051

TELEPHONE (603) 883-0111

TWX (710) 228-6505/TELEX 94-3404

EASTERN REGION: (617) 272-8545 (MASS.)

CENTRAL

REGION: (513) 294-0070 (OHIO)

WESTERN REGION: (714) 979-6650 (CALIF.)

CENTRONICS

DATA

COMPUTER (CANADA) LTD

.•

MISSISSAUGA. ONTARIO (416) 625-0770

CENTRONICS

INTERNATIONAL

CORP.,

BRUSSELS. BELGIUM (02) 762-3572

CENTRONICS

OF

PUERTO RICO, INC.,

DORADO, PUERTO RICO (809) 796-1881

Page

2

3

· 4

4

· 5

6

6

. _

•.

7

8

9

· 10

.10

·

11

·

12

. Back

Cover

Back

Cover

©Copyright

1975 Centronics Data Computer Corp.

A

II

rights reserved

Patents pending in USA and

other

countries

INTRODUCTION

Scope

This manual contains instructions reiating

to

the installation and operation

of

all

Cen-

tronics' Series 100 printers. This includes uncrating and set-up procedures, operating instruc-

tions and

other

reference information useful

to

the printer operator.

General Description

The Centronics Series 100 printers are medium speed, impact printers which use

dot

matrix techniques for character generation. Each

is

a completely self-contained unit which

includes the mechanical and electro-mechanical components, control logic, character pattern

generator, single line buffer (132 characters) and power suppiy.

Available models include:

(a) Model 101 -The basic printer, prints 132-column lines at 165 characters per

second.

(b) Model

lOlA

-Similar

to

the Model 101, but with additional features such

as

paper runaway inhibit, manual line feed switch, remote select/deselect, etc.

(c) Model 101AL -Functionally the same

as

the

lOlA,

but

uses more compact

electronics packaging.

(d) Model 101S -Prints standard O.l-inch characters

as

well

as

large-scale (e.g.,

.2, .3,

.4

and .7-inch high) symbols, using .1-inch

dot

patterns

as

building

blocks.

(e)

Model 102A -Prints at twice the speed

of

the

101

A

by

using two print

heads.

(f) Model 102AL -Functionally the same

as

the 102A, but uses more compact

electron

ics

packaging.

The model number

is

specified on a nameplate located on the back

of

the printer.

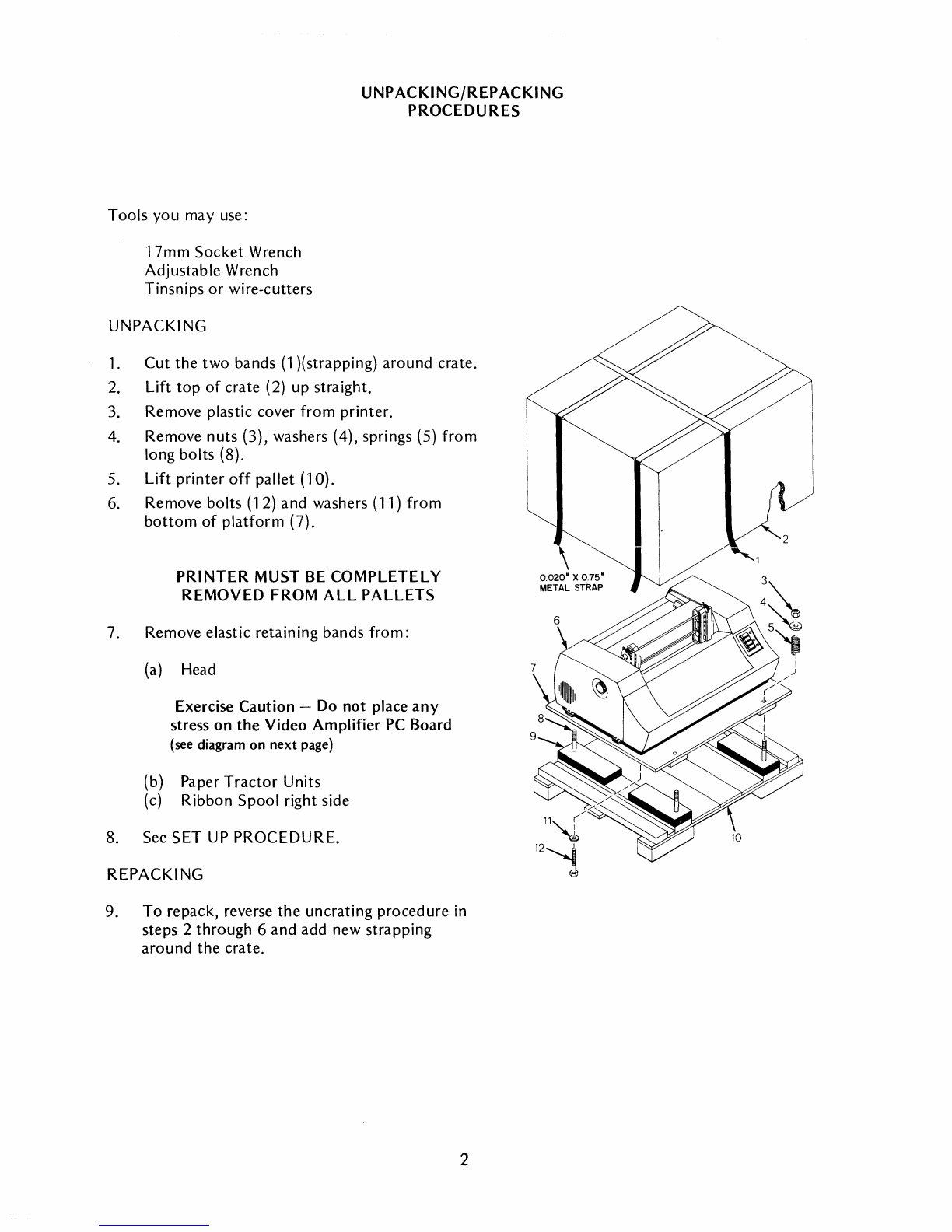

UNPACKING/REPACKING

PROCEDURES

Tools you may use:

17mm Socket Wrench

Adjustable Wrench

Tinsnips

or

wire-cutters

UNPACKING

1.

Cut the two bands

(1

)(strapping) around crate.

2.

Lift

top

of

crate (2) up straight.

3. Remove plastic cover from printer.

4.

Remove nuts (3), washers (4), springs (5) from

long bolts (8).

5.

Lift printer

off

pallet (10).

6.

Remove bolts (12) and washers (11) from

bottom

of

platform (7).

PRINTER

MUST

BE

COMPLETELY

REMOVED FROM ALL PALLETS

7. Remove elastic retain

ing

bands from:

(a)

Head

Exercise Caution -

Do

not place

any

stress on

the

Video Amplifier

PC

Board

(see diagram

on

next

page)

(b) Paper

Tractor

Units

(c)

Ribbon Spool right side

8. See SET

UP

PROCEDURE.

REPACKING

9. To repack, reverse the uncrating procedure

in

steps 2 through 6 and add new strapping

around the crate.

2

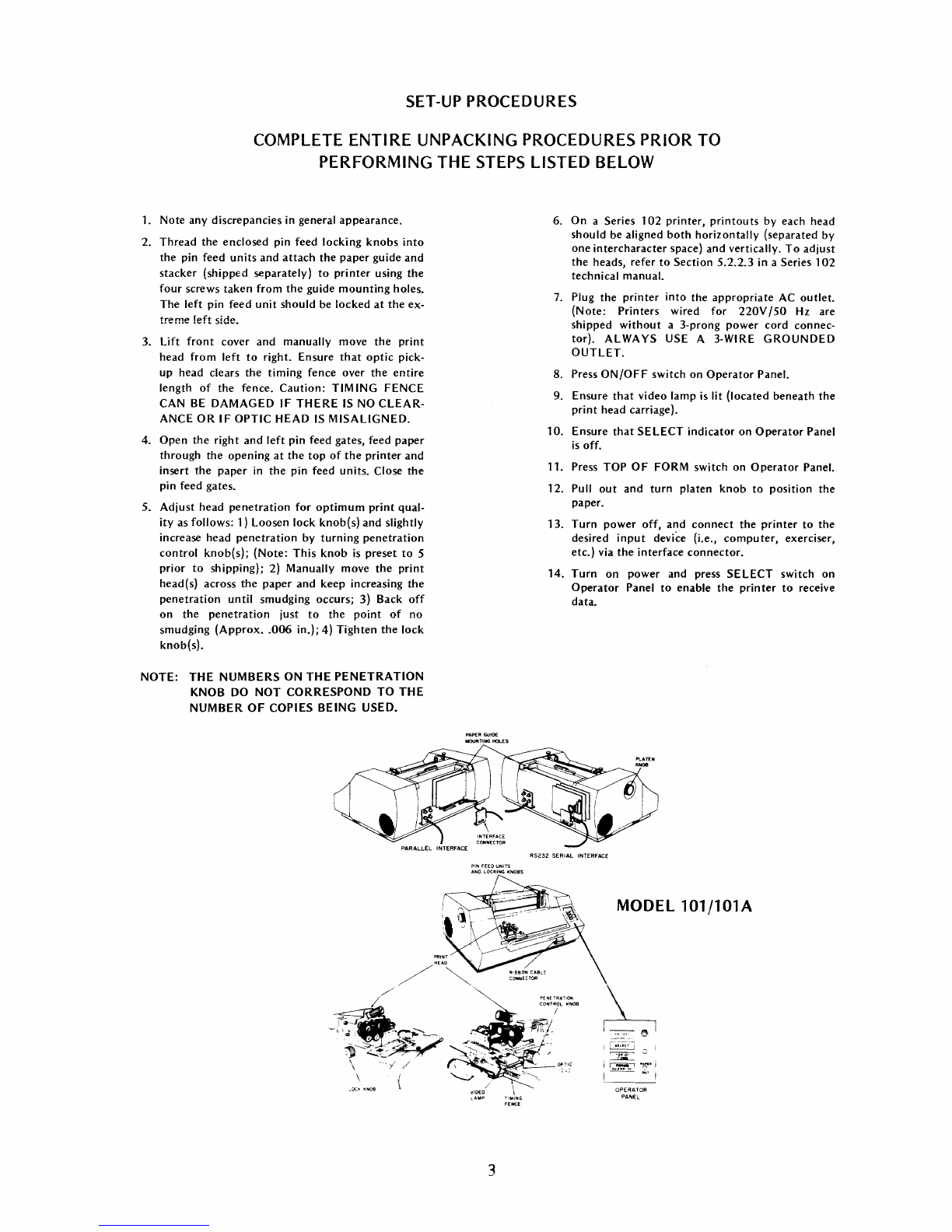

SET-UP PROCEDURES

COMPLETE ENTIRE UNPACKING PROCEDURES PRIOR TO

PERFORMING THE

STEPS

LISTED BELOW

1.

Note any discrepancies in general

appearance.

2.

Thread

the

enclosed pin feed locking

knobs

into

the

pin feed

units

and

attach

the

paper

guide

and

stacker

(shipped separately)

to

printer

using

the

four

screws

taken

from

the

guide

mounting

holes.

The left pin feed

unit

should

be

locked

at

the

ex-

treme

left

side.

3.

lift

front

cover

and

manually move

the

print

head

from

left

to

right. Ensure

that

optic

pick-

up head clears

the

timing

fence over

the

entire

length

of

the

fence.

Caution:

TIM ING FENCE

CAN

BE

DAMAGED IF

THERE

IS

NO

CLEAR-

ANCE

OR

IF

OPTIC HEAD

IS

MISALIGNED.

4.

Open

the

right

and

left

pin feed gates, feed

paper

through

the

opening

at

the

top

of

the

printer

and

insert

the

paper

in

the

pin feed units. Close

the

pin feed gates.

5.

Adjust

head

penetration

for

optimum

print

qual-

ity as follows: 1) Loosen lock

knob(s)

and

slightly

increase head

penetration

by

turning

penetration

control

knob(s);

(Note:

This

knob

is

preset

to

5

prior

to

shipping); 2) Manually move

the

print

head(s) across

the

paper

and

keep increasing

the

penetration

until smudging occurs; 3) Back

off

on

the

penetration

just

to

the

point

of

no

smudging

(Approx

..

006

in.); 4)

Hghten

the

lock

knob(s).

NOTE:

THE

NUMBERS ON

THE

PENETRATION

KNOB DO NOT

CORRESPOND

TO

THE

NUMBER

OF

COPIES BEING USED.

3

6.

On

a Series

102

printer,

printouts

by each head

should

be aligned

both

horizontally

(separated by

one

intercharacter

space)

and

vertically.

To

adjust

the

heads, refer

to

Section

5.2.2.3

in a Series

102

technical manual.

7. Plug

the

printer

into

the

appropriate

AC

outlet.

(Note:

Printers wired

for

220V

/50

Hz are

shipped

without

a 3-prong

power

cord connec-

tor).

ALWAYS USE A 3-WIRE

GROUNDED

OUTLET.

8. Press

ON/OFF

switch

on

Operator

Panel.

9. Ensure

that

video lamp is lit

(located

beneath

the

print

head carriage).

10.

Ensure

that

SELECT

indicator

on

0

perator

Panel

is

off.

11. Press TOP

OF

FORM switch on

Operator

Panel.

12. Pull

out

and

turn

platen

knob

to

position

the

paper.

13.

Turn

power

off,

and

connect

the

printer

to

the

desired

input

device (i.e.,

computer,

exerciser,

etc.) via

the

interface

connector.

14.

Turn

on

power

and press

SELECT

switch on

Operator

Panel

to

enable

the

printer

to

receive

data.

RS232

SERIAL

INTERFACE

MODEL

101/l01A

i

i---I;:~-C·'

",

~

;1?~~1!.:

~---

OPERATOR

PANEL

OPERATING NOTES

•

Always

plug

the

printer

into

a 3-wire

grounded

outlet.

•

Ensure

that

all covers

are

closed

and

secured

during

operation.

• Never

operate

the

printer

without

paper.

• Avoid leaning

or

placing

objects

on

any

part

of

the

printer.

•

Turn

power

off

before

adjusting

print

head

or

replacing

ribbon.

OPERATING

GUIDE

If

the

printer

is

not

operating

properly,

refer

to

the

following

table

for

possible

sou

rces

of

error.

If

the

printer

still fails

to

operate

properly

after

performing

the

indicated

actions,

then

call

for

service.

Symptom

Printer

won't

print

and

ON/OFF

indicator

is

off.

Printer

won't

print,

ON/OFF

indicator

is

on,

but

SELECT

light is

off.

Printer

won't

print,

but

SELECT

indicator

is

on.

Paper

skewing.

Ink

ribbon

tracking

problems.

Poor

print

quality

(e.g.,

smudging

or

light

print).

Missing

dots

in

printed

character.

Form

feed

or

vertical

tab

problem.

4

Action

Try

the

ON/OFF

switch,

check

the

power

cord,

check

fuses.

Press

SELECT

switch.

Ensure

that

front

cover

is

closed,

check

fuses,

ensure

that

interface

cable

at

rear

of

printer

is

secure.

Position

the

paper

feed

tractors

and

tighten

the

fixing

knobs

as

outlined

on

page 6.

Make sure

ribbon

is

installed as

outlined

on

pages 10 &

11.

Adjust

head

penetration

as

outlined

on

page 7.

Open

front

cover

and

carefully

wipe

timing

fence

with

damp

cloth.

Caution:

USE

ONLY

WATER

AND MILD

DETERGENT.

Check

vertical

format

unit.

(See page 8)

OPERATOR CONTROLS AND

INDICATORS

THIS SWITCH IS USED

TO

TURN

AC

POWER

ON

OR

OFF.

IT

LIGHTS

~::~~:::HR::~~::D

~

..........

-------

TO

SELECT

THE

PRINTER

f

AFTER

TURNING

ON POWER. f

IT

LIGHTS

WHEN

THE

_______

I .'

••••

111

PRINTER

IS

SELECTED.

~

iii SELECT

TOP

OF

FORM

THIS

SWITCH

IS

USED.

~

.•

FOR

MANUALLY

SLEWING

______

t

:til

••••

,

PAPER

TO

TOP OF FORM.

~

IT

PERFORMS

THE

SAME ,

FUNCTION

AS A

FORM

..

FEED CODE.

THIS SWITCH WHEN

DEPRESSED

OVERRIDES

THE

INTERNAL

PAPER

OUT

SWITCH,

ALLOWING

THE

LAST

FORM

TO

BE

PRINTED

BEFORE

CHANGING

PAPER.

The printer also contains:

THIS PUSHBUTTON SWITCH

(NOT

CONTAINED

ON

MODEL

101)

IS

USED

FOR

MANUAL

-

.--

-

..

-

...

-- / Li NE FEEDS.

IT

PERFORMS

/

THE SAME

FUNCTION

AS A

LINE

FEED CODE.

,,!,t

THIS

INDICATOR

IS

_______

PROVIDED

FOR

SPECIAL

~

APPLICATIONS.

PAPER

ou~~

THIS

INDICATOR

IS USED

•

~

TO

INDICATE

AN

OUT-

OF-PAPER

CONDITION

(1)

A

Bell

Alarm -consisting

of

a 2-second audible tone sounded

in

response to a

BELL code (octal 007) or a paper empty condition.

(2) A Form Thickness control knob (and lock knob) -located on the print head

carriage, adjusts the penetration

of

the print wires on to the paper.

(3) A Platen Knob -used to manually adjust paper

in

the printer. The knob ODerates

by

pulling

It

out

and rotating it

in

either direction.

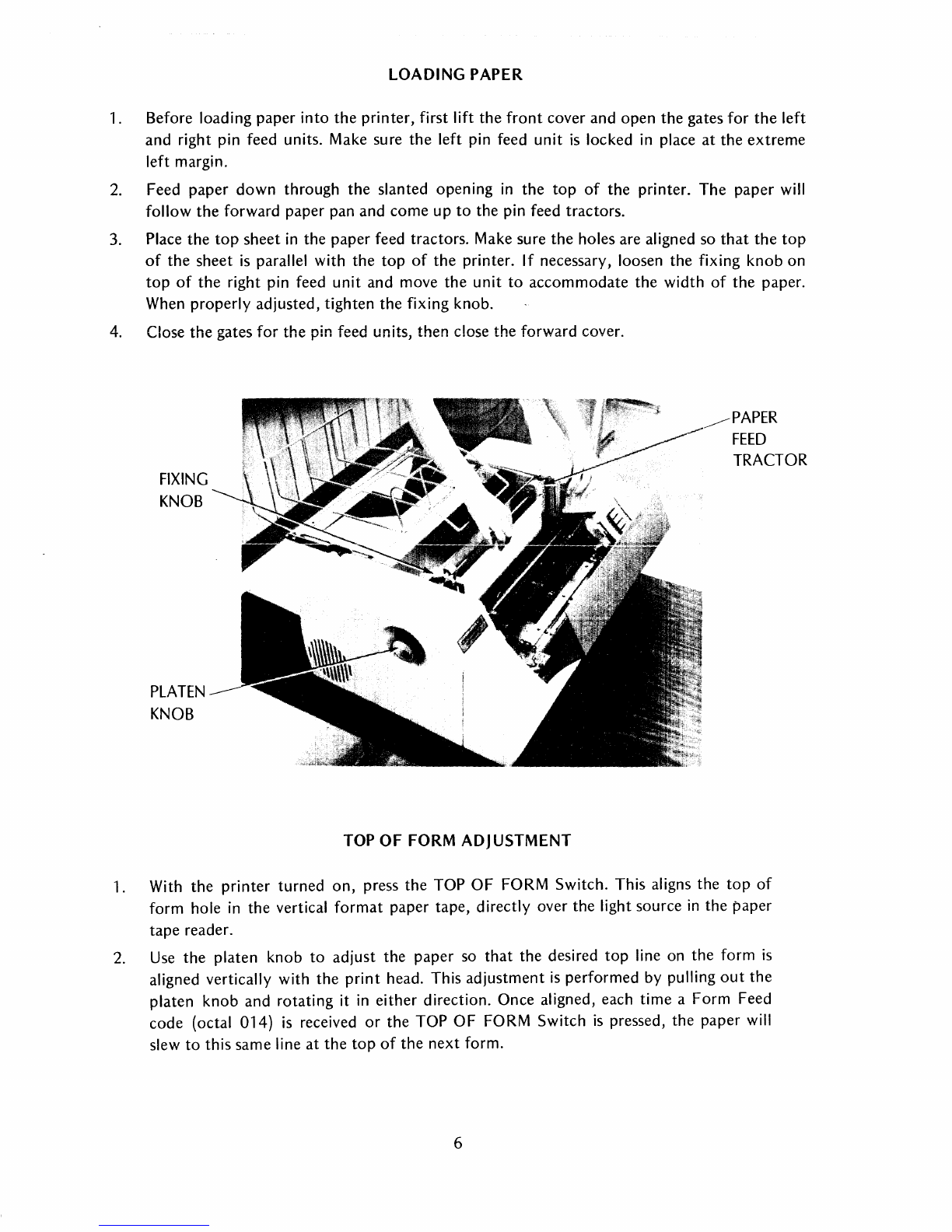

LOADING

PAPER

1. Before

loading

paper

into

the

printer,

first lift

the

front

cover

and

open

the

gates

for

the

left

and

right

pin

feed

units. Make sure

the

left

pin feed

unit

is

locked

in place

at

the

extreme

left

margin.

2.

Feed

paper

down

through

the

slanted

opening

in

the

top

of

the

printer.

The

paper

will

follow

the

forward

paper

pan

and

come

up

to

the

pin feed

tractors.

3. Place

the

top

sheet

in

the

paper

feed

tractors.

Make

sure

the

holes

are

aligned so

that

the

top

of

the

sheet

is

parallel

with

the

top

of

the

printer.

If necessary, loosen

the

fixing

knob

on

top

of

the

right pin feed

unit

and

move

the

unit

to

accommodate

the

width

of

the

paper.

When

properly

adjusted,

tighten

the

fixing

knob.

4. Close

the

gates

for

the

pin feed units,

then

close

the

forward

cover.

FIXING

KNOB

PLATEN

KNOB

TOP OF FORM ADJUSTMENT

PAPER

FEED

TRACTOR

1. With

the

printer

turned

on,

press

the

TOP

OF

FORM

Switch.

This

aligns

the

top

of

form

hole in

the

vertical

format

paper

tape,

directly

over

the

light

source

in

the

paper

tape

reader.

2. Use

the

platen

knob

to

adjust

the

paper

so

that

the

desired

top

line

on

the

form

is

aligned vertically

with

the

print

head.

This

adjustment

is

performed

by pulling

out

the

platen

knob

and

rotating

it in

either

direction.

Once

aligned,

each

time

a

Form

Feed

code

(octal

014)

is received

or

the

TOP

OF

FORM

Switch

is

pressed,

the

paper

will

slew

to

this

same

line

at

the

top

of

the

next

form.

6

FORMS THICKNESS CONTROL

Two adjustment knobs on either side

of

the print head carriage control the clearance

between the platen and the face

of

the print head. This clearance must be adjusted according to

the thickness

of

the forms being used.

On

a Series 102 printer, the two heads must be adjusted

independently.

To adjust the print head for optimum print quality perform the following steps:

1.

Loosen the Lock knob on the left side

of

the print head.

2.

Increase the penetration

of

the print wires on to the ribbon

by

slightly turning the

Penetration Control knob.

3. Manually move the print head across the paper.

Keep

increasing the penetration until

smudging occurs.

4. Back off on the Penetration Control knob just to the point of

no

smudging.

5. Tighten the Lock knob to secure the print head

in

position.

Note

Numbers on Penetration Control knob do not

correspond

to

the number

of

copies used.

LOCK

KNOB

7

----

PENETRATION

CONTROL

KNOB

VERTICAL

FORMAT

UNIT

Vertical

formatting

in

the

Series

100

printers

is

controlled

by

a

paper

tape

in

the

Vertical

Format

Unit. This

unit

is

located

on

the

upper

left side

of

the

printer

just

under

the

left cover.

The

tape

is

a standard

l-inch

wide, 8-channel, black

opaque

paper

tape.

The

sprocket

holes, located

between

Channels 3

and

4,

have a

1/10

inch

pitch

between

holes. Channel 5

defines

the

Vertical

Tab

(VT)

format

and

Channel 7

the

Top

of

Form

(TOF)

format.

The

tape

reader and

paper

feed mechanisms are mechanically linked so

that

each line feed advances

both

the

paper by

one

line

and

the

paper

tape

by

one

sprocket

hole,

on

a 6 line-per-inch printer.

Reception

of

a Vertical

Tab

code

(octal

013)

advances

the

paper

(and tape)

to

the

next

hole

in

Channel 5.

For

example,

if

the

holes

in

Channel 5 are spaced six

sprocket

holes

apart,

each Vertical

tab

will advance

the

paper

six lines

(one

inch).

Similarly,

reception

of

a

Form

Feed

code

(octal

014)

or

pressing

the

TOP

OF

FORM

switch advances

the

paper

(and tape)

to

the

next

hole

in

Channel

7.

As an

optional

feature

on

some

printers, a hole

in

both

channels 5

and

7 indicates

bottom

of

form

(BOF).

Detection

of

this

condition

automatically

advances

paper

to

the

top

of

the

next

form. BOF

and

TOF

indications on

tape

must

be

separated

by

at

least

one

line.

On

the

standard

paper

tape

shipped with

the

printer,

Vertical

Tab

holes

are

spaced six

sprocket

holes

apart

in Channel

5,

(corresponding

to

a

l-inch

tab)

and

Top

of

Form

holes

are

spaced

66

sprocket

holes

apart

in

Channel 7

(corresponding

to

an

l1-inch

form).

VERTiCAL

FORV,':'T

TAPE

READER

\ERTI(AL

FORMAT

TAPE

8

VERTICAL

FORMAT

TAPE

DIRECTION

OF

TAPE

MOTION

•

SPROCKET

HOLES

~

BETWEEN g

CHANNELS

3

&'I

g

BOTTOM

OF

FORM

I 0 0 o-r--

CHANNELS

5 & 7

~

. g I

(OPTIONAL)

SPACING

(1/10"

PITCH)

g I TOP OF

FORM

~

TCHANNEL

7

ONLY

g

VERTICAL

TAB

o

CHANNEL50NLY

o

o

o

o

o

o

o

~l"WIDE~

USING

TELETVPEWRITER

-0

GENERATE

A

TAPE

SPACING:

CONTROL

SHIf- I & P

CH·~,II,J"~[~

-

cO~-:qCi

...

'~

CH.ANNH

7'

"HIFT

P

CHANNEL

5 & 7:

ASCII

P

VERTICAL

FORMAT

TAPE

1.

Generating

a Master

Tape

To

generate

a

master

tape

on

a

Teletypewriter

unit,

use

the

following

procedure:

a.

Turn

LOCAL

Switch

on

Teletypewriter

unit

to

extreme

clockwise

position.

b.

Turn

punch

switch

to

ON.

(Use black

opaque

tape

only.)

c. Press

HERE

IS

key

several

times

to

generate

a

tape

leader.

d.

To

generate

a Vertical

Tab

hole

in Channel 5, press

and

hold

the

CONTROL

key

and

then

press Q.

e.

To

generate

a

Top

of

Form

hole in Channel 7, press

the

SHIFT

and

P keys.

f.

To

generate

a

hole

in

both

Channels

5

and

7 (Vertical

Tab

and

Top

of

Form),

press

the

P key alone.

g.

To

space

the

tape

between

holes, press

and

hold

the

CONTROL

and

SHIFT

keys,

then

press P.

One

sprocket

hole will be

generated

each

time

the

P key

is

pressed.

h.

After

the

tape

has

been

fully

generated,

press

the

HERE

IS

key

to

generate

a rear

trailer

of

sprocket

holes.

Remove

the

tape

from

the

reader.

2. Splicing

the

Tape

a. As

shown

in

the

figure, overlap

the

two

ends

of

the

tape

(A

and

B)

and

place

the

sprocket

holes

over

one

another

to

properly

align

the

two

ends.

Arrange

the

splice

so

that

the

distance

between

consecutive

Form

Feed holes

is

the

same

all

around

the

tape.

b.

Glue

both

ends

of

the

tape

together.

3.

Duplicating

the

Tape

SPROCKET

HOLE

VERTICAL

TAB

HOLES

a.

Insert

the

master

tape

in

a

Teletypewriter

reader

and

lock

it

in.

b.

Turn

the

switch

to

ST

ART

and

a

duplicate

tape

will be

punched

automatically.

9

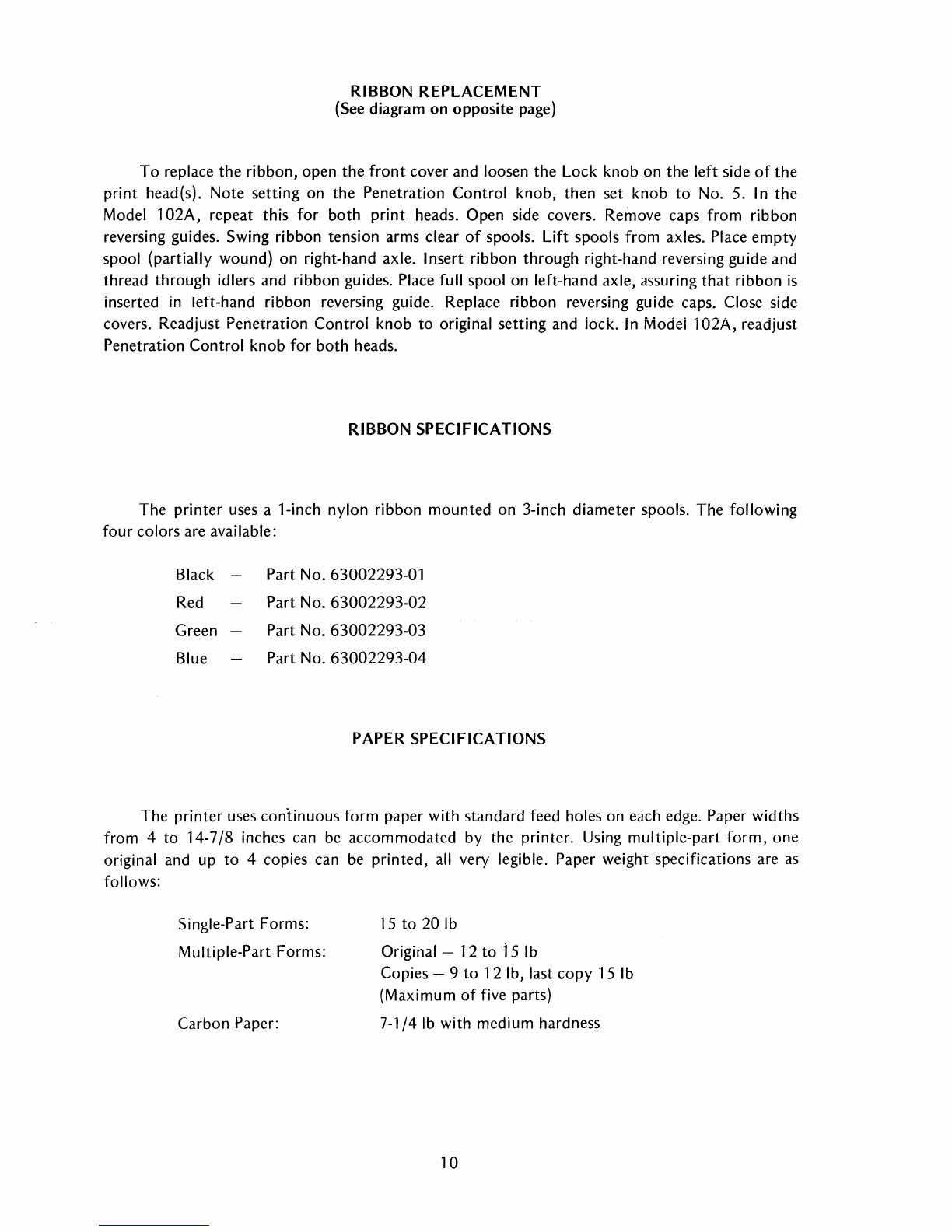

RIBBON REPLACEMENT

(See diagram on opposite page)

To replace the ribbon, open the front cover and loosen the Lock knob on the left side

of

the

print head(s). Note setting on the Penetration Control knob, then set knob to

No.5.

In

the

Model 102A, repeat this for both print heads. Open side covers. Remove caps from ribbon

reversing guides. Swing ribbon tension arms clear

of

spools. Lift spools from axles. Place empty

spool (partially wound) on right-hand axle. Insert ribbon through right-hand reversing guide and

thread through idlers and ribbon guides. Place full spool on left-hand axle, assuring

that

ribbon

is

inserted

in

left-hand ribbon reversing guide. Replace ribbon reversing guide caps. Close side

covers. Readjust Penetration Controi knob to originai setting and iock.

in

Modei 102A, readjust

Penetration Control knob for both heads.

RIBBON SPECIFICATIONS

The printer uses a 1-inch nylon ribbon mounted on 3-inch diameter spools. The following

four colors are available:

Black

Red

Green

Blue

Part No. 63002293-01

Part No. 63002293-02

Part No. 63002293-03

Part

No.

63002293-04

PAPER SPECIFICATIONS

The printer uses continuous form paper with standard feed holes on each edge. Paper widths

from 4 to 14-7/8 inches can

be

accommodated by the printer.

Using

multiple-part form, one

original and up to 4 copies can

be

printed,

all

very legible. Paper weight specifications are

as

follows:

Single-Part Forms:

Multiple-Part Forms:

Carbon Paper:

15

to 20

Ib

Original -12 to 15

Ib

Copies - 9 to 12

Ib,

last copy 15

Ib

(Maximum

of

five

parts)

7-1/4

Ib

with medium hardness

10

RIBBON

REPLACEMENT

DIAGRAMS

RIGHT-HAND~-

-~\

AXLE j

~~

\

(A)

SERIES

101

(8)

SERIES

102

11

IDLER

PENETRATION

CONTROL

KNOB

(NOT

SHOWN)

-----~--rl

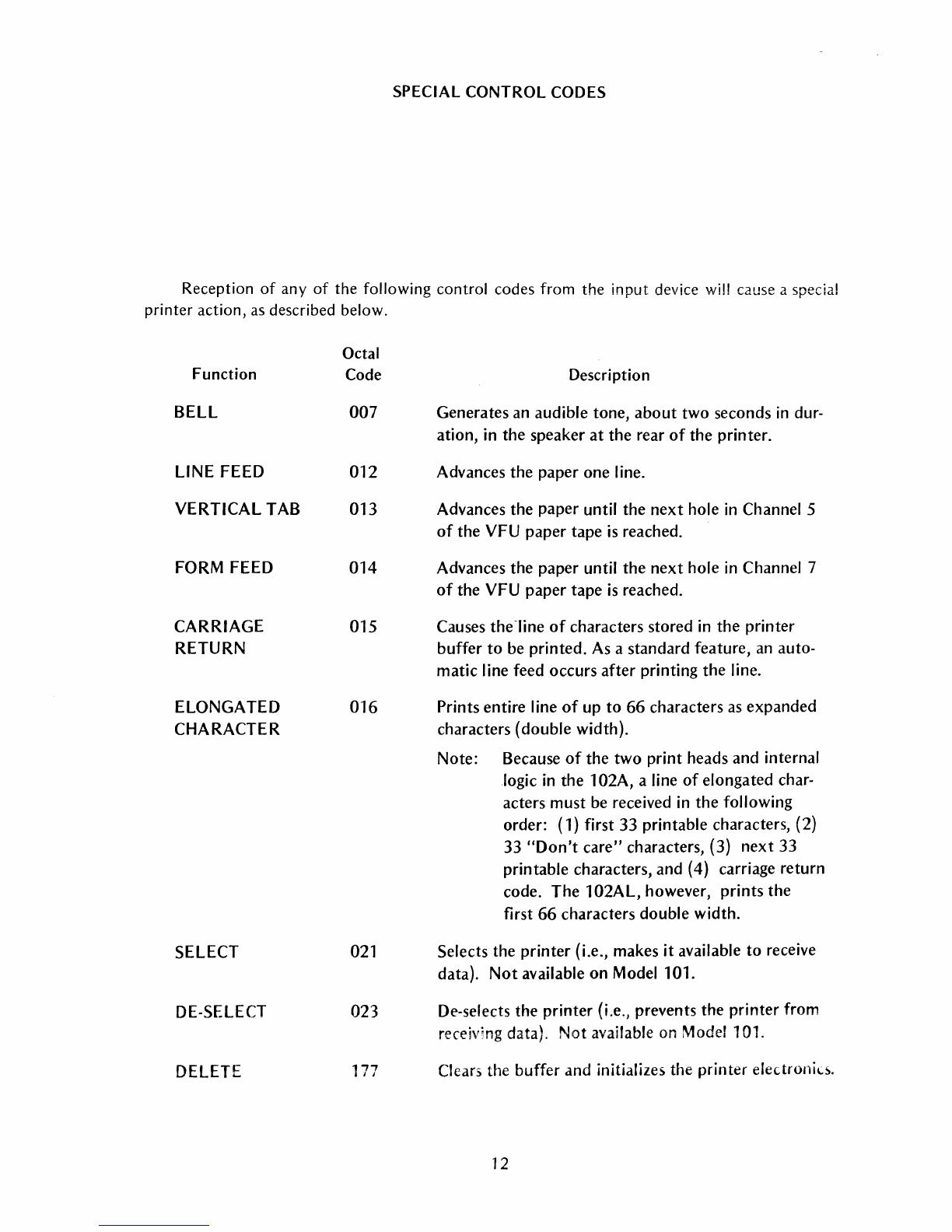

SPECIAL CONTROL CODES

Reception

of

any

of

the following control codes from

the

input device will cause a special

printer action, as described below.

Function

BELL

LINE

FEED

VERTICAL

TAB

FORM FEED

CARRIAGE

RETURN

ELONGATED

CHARACTER

SELECT

DE-SELECT

DELETE

Octal

Code

007

012

013

014

015

016

021

023

1"

I I

Description

Generates

an audible

tone,

about

two

seconds

in

dur-

ation, in

the

speaker

at

the

rear

of

the

printer.

Advances

the

paper

one

line.

Advances

the

paper

until

the

next

hole

in

Channel 5

of

the

VFU

paper

tape

is

reached.

Advances

the

paper

until

the

next

hole in Channel 7

of

the

VFU

paper

tape

is

reached.

Causes the-line

of

characters

stored in

the

printer

buffer

to

be

printed.

As a

standard

feature,

an

auto-

matic

line feed

occurs

after

printing

the

line.

Prints

entire

Iine

of

up

to

66

characters

as

expanded

characters

(double

width).

Note:

Because

of

the

two

print

heads

and

internal

logic

in

the

102A, a line

of

elongated

char-

acters

must

be received in

the

following

order: (1) first

33

printable

characters, (2)

33

"Don't

care"

characters, (3)

next

33

printable

characters, and

(4)

carriage

return

code.

The

102AL,

however,

prints

the

first 66

characters

double

width.

Selects

the

printer

(Le., makes

it

available

to

receive

data).

Not

available

on

Model 101.

De-selects

the

printer

(Le.}

prevents

the

printer

from

receiv'ng data}. Not available

on

Modell

01.

Clears the

buffer

and

initializes the

printer

electronk~.

12

STANDARD

CHARACTER

SETS

STANDARD

5 X 7

CHARACTER

MATRIX

040

041

042

043 044

04e

04e 047

II1IIIII

050

oel

oe2

<le3

oe4

oee

oes

oe7

111111111

060

061

062

OS3 OS4

ose

otiS

otI7

IIIIIIII

070

071

072

073

074

Onl

078

077

IIIIIIII

100

101

102

103

104

lOti

loti

107

IIIIIIII

110

III

112 113 114 115 116

117

IIIIIIII

120

121

122

123

124

12e 12S

127

lmltm:tttmttmmtlffi11lfRlffi11

EElBIBmtHDIM1

130

131

132 133

134

13e

1311

137

II1IIIII

STANDARD

9 X 7

CHARACTER

MATRIX

040

041

042

043

045

04S

047

II1IIIII

050

051

oe2

053

054

oee

OtiS

057

111111111

060

061

062

OS3 OS4

OS5

otiS

OS7

IIIIIIII

070

071

072

073

074

Onl

0711

077

IIIIIIII

100

101

102

103

104

103

lOS 107

IIIIIIII

110

III

112 113 114 115

116

117

IIIIIIII

120

121

122

123

124

12e 12S

127

;m,tm:.lmltm.fmf~tf:Rlmil

EEE.me.E

130

131

132

133 134 135 13S 137

III1IIII

00 00

01 o1 1 0 1 0 1 1 1 1

~

~

b6

~

0 1 0 1 0 1 0 1

B.

b

~

It

~b4b3b2

bl~

t t t

tRow

USASCII CODE

ized

Notes:

1.

~

Indicates

control codesrecogn

by

Centronics printe

rs

7)

2.

Underscore (octal 13

is

replaced by a back

arrow in the standar -

d

9 x 7

matrix

0 0 o 0 0

o 0 o 1 1

o 0 1 0 2

o 0 1 1 3

o 1 o 0 4

0 1 o 1 5

0 1 1 0 6

0 1 1 1 7

1 0 0 0 8

1 0 o 1 9

1 0 1 0

10

1 o 1 1

11

1 1 0 0 12

1 1 0 1

13

1 1 1 0

14

1 1 1 1 15

0 1 2 3 4 5 6 7

NUL

DLE

SP

0 @ P \ P

SOH

DCl

! 1 A 0 a q

STX

DC2

" 2 B R b r

ETX

DC3 # 3 C S c s

EOT DC4 $ 4 D T d t

ENO

NAK

% 5 E U e u

ACK

SYN & 6 F V f v

~EL

ETB , 7 G W g w

BS

CAN ( 8 H X h x

HT

EM

) 9 I Y i y

'''LF SUB * J z j z

ryT

ESC

+ I K [ k {

"'FF

FS

, < L

"-

I I

"'CR

GS

--M ] m }

"'SO

RS

> N " n

"'""

SI

US

/ ? 0 a DEL

-

....

'-

.....

--_"'-----"'''----v----''

CONTROL

STANDARD

OPTIONAL

CODES

Other manuals for 101

1

This manual suits for next models

5

Table of contents

Other Centronics Printer manuals

Centronics

Centronics 101AL User manual

Centronics

Centronics 730-1 User manual

Centronics

Centronics 101A User manual

Centronics

Centronics 101A User manual

Centronics

Centronics 704 User manual

Centronics

Centronics 101 User manual

Centronics

Centronics 306 User manual

Centronics

Centronics 705 User manual

Centronics

Centronics 101A User manual

Centronics

Centronics 101AL Guide