FIGURE

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

7-15

7-16

7-17

7-18

7-19

7-20

7-2'1

7-22

7-2:3

8-i

8-1

8-2

8-3

8-3A

8-4

8-5

8-6

8-7

8-'8

8-9

8-1

()

8-12

LIST

OF

ILLUSTRATIONS

CONTINUED

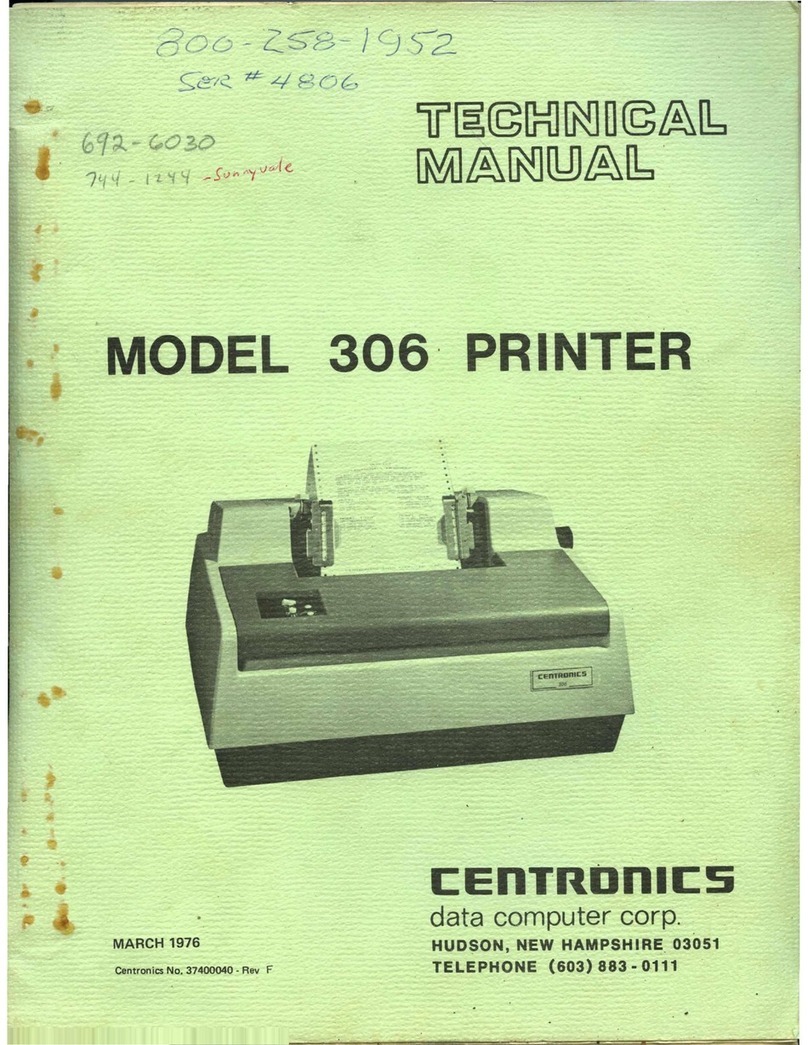

Schematic Diagram, Logic/Power

Supply

+5Volts

(Sheet 1)

Schematic Diagram, Logic/Power

Supply

+5

Volts

(Sheet 2)

Schematic Diagram, Logic/Power

Supply

+5Volts

(Sheet

3)

Schematic Diagram, Logic/Power

Supply

+5Volts

(Sheet

4)

Schematic Diagram, Power Driver Board (Sheet

1)

Schematic Diagram, Power Driver Board (Sheet 2)

Schematic Diagram,

Video

Amplifier

. . . . .

Schematic Diagram, Power Connections

101AL

.

Schematic Diagram,

Motor

Control.

. . . . . .

Multitap

Transformer

50/60

Hz..

. . . . . .

Wiring Diagram, Printer Mechanism. . . . . . . . . . .

Interconnection Diagram, Connector Board and Power

Supply

. .

101

AL

Connector

Configuration.

. . . . . . . . . . . . .

Component

Board Assembly, Logic/Power

Supply

Board

+5Volts

..

Component Board Assembly, Logic/Power

Supply

Board

+5Volts

Component Board Assembly, Power

Driver.

. . . . . .

Component Board Assembly,

Video

Amplifier

Component Board Assembly, Connector Card

Component Board Assembly,

Motor

Control

Electronic Cavity

Assembly.

. . .

Harness Assembly (W1)

-.

. . . .

I

nput

Cable

Assembly.

. . . . .

Power Cable Assembly (W3)

Mechanical Subassemblies, Series

101

Cover Assembly

-"

A . . . .

Carriage Mechanism. . . . .

Drive Mechanism -HB (Part 1)

Drive Mechanism -HB (Part 2)

Spring

Drum

-

He

Damper -HD

......

.

Frame -

HE

. . . . . . . .

Paper Feed Mechanism . . . . .

Pin

Feed

Mechanism

(Left

and Right) -

HG

.

Form Feed Mechanism - HH . . . . .

Ribbon

Feed

Mechanism -HI . . . . . .

Print

Head and Associated Assemblies

(B)

.

NOTE

Refer

to

the

Engineering Change

Notice

(ECN) sheets

shipped

with

the

printer

for

changes made

to

the

prin-

ter

which

have

not

yet

been incorporated

into

the

draw-

ings in

this

technical manual. Always keep these Engin-

eering Change

Notice

sheets

with

the

manual.

Revision

IIBvel

indications

at

the

lower

right-hand corner

of

a

page

reflect

at

what

revision

of

the

manual

that

page

was

updated.

-iii/iv-

PAGE

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

7-15

7-16

7-19

7-21

7-23

7-25

7-27

7-29

7-31

7-33

8-2A

8-3

8-5

8-7

8-9

8-11

8-13

8-15

8-17

8-19

8-21

8-23

8-26

Rev. F