Centronics 101AL User manual

TECHNICAL

MIZAINUZATL

MODEL

101AL

PRINTER

CENTRONICS

ara

OC

eaie!

OC

CENTRONAICS

data

computer

corp.

HUDSON,

NEW

HAMPSHIRE

03051

Centronics

No.

37400050

Rev.C

TELEPHONE

(603)

8383

ts

0111

APRIL

1975

CENTRONICS

centronics

data

computer

corp.

hudson,

n.h.

0305!

telephone

(603)

883-Oill

eastern

region:

(617)272-8545

(mass.)

central

region:

(513)

294-0070

(ohio)

western

region:

(714)

979-6650

(calif.)

;

©

Copyright

Centronics

Data

Computer

Corp.

centronics

data

computer

(canada)

Itd.

mississauga,

ontario

(416)

625-0770

All rights

reserved.

derteariiettn

a

aeaso

melee

Patents

Pending

in

U.S.A.

and

Other

Countries

brussels,

belgium

(02)

762-3572

(Printed

in

U.S.A.

4/75)

‘TECHNICAL

MANUAL

MODEL

101AL

PRINTER

APRIL

1975

THE

INFORMATION

CONTAINED

HEREIN

IS

PROPRIETARY

AND

IS

NOT

TO

BE

RELEASED

OR

REPRODUCED

WITHOUT

WRITTEN

PER—

MISSION

OF

CENTRONICS

data

computer

corp.

CENTRONICS

data

computer

corp.

HUDSON,

NEW

HAMPSHIRE

03051

TELEPHONE

(603)

883

-

0111

TABLE

OF

CONTENTS

SECTION

1

INTRODUCTION

Section

1.1

GENERAL

DESCRIPTION...

...

1...

1

1

we

ee ee

we

tw

et

1.2

LOGIC

FLOW

DIAGRAM

...........

2

ee

ee

eevee

ee

1.3.

PRINTER

OPERATION.

.......

ee

ee

ew

we

ee

1.3.1

Character

Printing

........+4+464-0+6006-8

eee

1.3.2

Paper

Movement

......

2. 2.

2

6

ee

ee ee

ew

ws

1.3.3

Special

Functions.

.

....

1...

2

ee

eww

ee

wes

1.4

SYSTEM

FEATURES...

..

eee

ee

ee

ee

ee

ee

ne

1.4.1

Features,

Standard

&

Optional

Specification

Summary.

.

,

1.4.2

Specification

Summary

«+

+

+

+

+

eee

ee

ee

ee es

1.5

PHYSICAL

DESCRIPTION

-

+++

+++

+e:

ee,

SECTIONS

2

&

3

INSTALLATION

AND

OPERATION

SITE

PREPARATION.

.

2...

2

2 1 2

ee

we

ww

we

ee

we

SHIPPING

CRATE.

.

2.

1.

1 1

6

ww

we

ww ew

ee

ww we

te

ew

PAPER

GUIDE

AND

STACKER

ASSEMBLY.

~~...

1 1

ee

ee

ee

eee

SECTION

4

THEORY

OF

OPERATION

4,1

INTRODUCTION.

.

2.

1.

2 1 1

2

www

we

ew

we

ww

te

ee

ee

4.2

BASIC

TIMING.

.

2.

2.

1 1

ew we

we

ww

we

te

ee

we

ee

te

4.3.

INITIALIZING

THE

PRINTER.

. .

2.

1.

7

2

we

ew

ee

we

we

wee

4.3.1

Prime.

.....

2...

eee

nee

ee

eke

ke

kas

4.3.2

Select

.......2

06.2

6

«©

© © ©

©

© ©

ee

we

ee

th

ws

Rev.

A

TABLE

OF

CONTENTS

(cont'd)

Section

Page

4.4

DATA

INPUT.

...........

ee

ee

ew

we

ee

ew

4-6

4.4.1

Data

Input

Timing.

........2.2.2.2.208080c86-.8

4~6

4.4.2

Busy...

2.

2. 2.

ew

ew

ew

we

ww

te

ww

he

we

4-9

4.4.3.

Function

Decoder

.........6-6246464654c84e88

4-10

4.5

SHIFT REGISTER

(BUFFER).

.....

be

ww ee

tw

tw

we

4-12

4.6

CHARACTER

PRINTING.

.......

22.

2

0

ee

ee

we

ee

4-14

4.6.1

Initializing

the

Printing

Operation.

.......

4-14

4.6.2

Character

Registration

and

Timing.

........

4-15

4.6.3

Character

Generator

(ROM).

.........2...

4-18

4.6.4

Print

Head

Operation.

.......24646404688-8

4-20

4.6.5

Power

Driver

Circuits.

.

......

26

2

ee

eee

4-21

4.7

PAPER

MOVEMENT...

2. 2.

2

2

ee

ew

ee ew

we

ee

we

we

ee

4-24

4.7.1

Line

Feed...

...

1.

2 1

ew

we ew

tw

ww

4-25

4.7.2

Form

Feed.

......

2.

1

eo

ee

ew

ew

ew

ew

ew

ww

4-26

4.7.3

Vertical

Tab.

.........0242484

00 ee ee

4-27

4.7.4

Wertical

Format

Unit.

.......2.0.60464208-8

4-28

4.7.5

Line

Feed

Solenoid

Driver.

.........e6.6-.

4-29

4.8

SPECIAL

FUNCTIONS.

...

.

2...

1

ee

ww

ew

ew

et

te

4-30

4.8.1

Bell

(Optional).

........

06.6.6

2

ee

eee

4-30

4.8.2

Delete...

..

1.

1

ew

ew

we

ew

ew we

tt

te

4-30

4.8.3.

Paper

Empty.

........

505656

0

«© we

ee

eee

4-3]

4.8.4

Motor

Control

(Optional)

..........0.e-.

4-31

4.9

POWER

SUPPLIES

........

2.

©

© ©

we

ee

we

ew

ws

4-34

4.9.1

+5V

Regulator.

.......4.2.2.66.26c86858484

0848

4-36

4.9.2

+12V

and

-12V

Regulators

..........e8e8-

4-37

4.9.3.

+35V

Power

Supply,

Unregulated

...........

4-37

4.10

OUTPUTS

FROM

LSI

CHIPS

..........

0404248488088

4-38

4.10.1

Outputs

from

LSI

Chip

ME5......2.2.2.2.4.2...

4-38

4.10.2

LSI

Chip

ME9...........0

2628

2

we

eee

4-4)

i1

Rev.

A

Section

o.1

9.2

6.1

6.2

6.3

TABLE

OF

CONTENTS

(cont'd)

SECTION

5

REMOVAL,

REPLACEMENT

AND

ADJUSTMENT

PROCEDURES

INTRODUCTION.

MECHANICAL

ASSEMBLIES.

AnaInrianinnn

ooo

ot

ND RO AD PO

AO

NAD

NO

NAD [PO

lo NO

lO

PO

WO

CONN

OP

WNMrF

Cover

(A)

.

.

Carriage

Mechanism

(HA)

Driving

Mechanism

(HB).

Spring

Drum

(HC).

Damper

(HD)

Frame

(HE)

. .

tk

Paper

Feed

Mechanism

(HF).

Pin

Feed

Unit

(HF).

. .

Form

Feed

Mechanism

(HH)

.

Ribbon

Feed

Mechanism

(HI)

Electrical

Hardware

(HJ)

.

Paper

Stacker

and

Guide

...

Printer

Head

and

Associated

Assemb1

ies

SECTION

6

MAINTENANCE

ADJUSTMENTS

.

;

PREVENTIVE

MAINTENANCE

TROUBLESHOOTING

GUIDE

SECTION

7

DRAWINGS

AND

PARTS

LISTS,

ELECTRICAL

SECTION

8

DRAWINGS

AND

PARTS

LISTS,

MECHANICAL

APPENDIX

A

~1O1AL

SIGNAL

GLOSSARY,

SOURCE

AND

DESTINATION

LISTING

APPENDIX

B

STANDARD

9 x

7

64-CHARACTER

SET

APPENDIX

C

PARALLEL

INTERFACE

SPECIFICATIONS

oO

eo

QO

ep)

|

O1

O1

II

-—

eed

i

Pm BP

B

WN

AOPO

PO FF

FN

WD

PO

Mmmm

PhocOo

mRO

wo

CO

6-1

6-3

Rev.

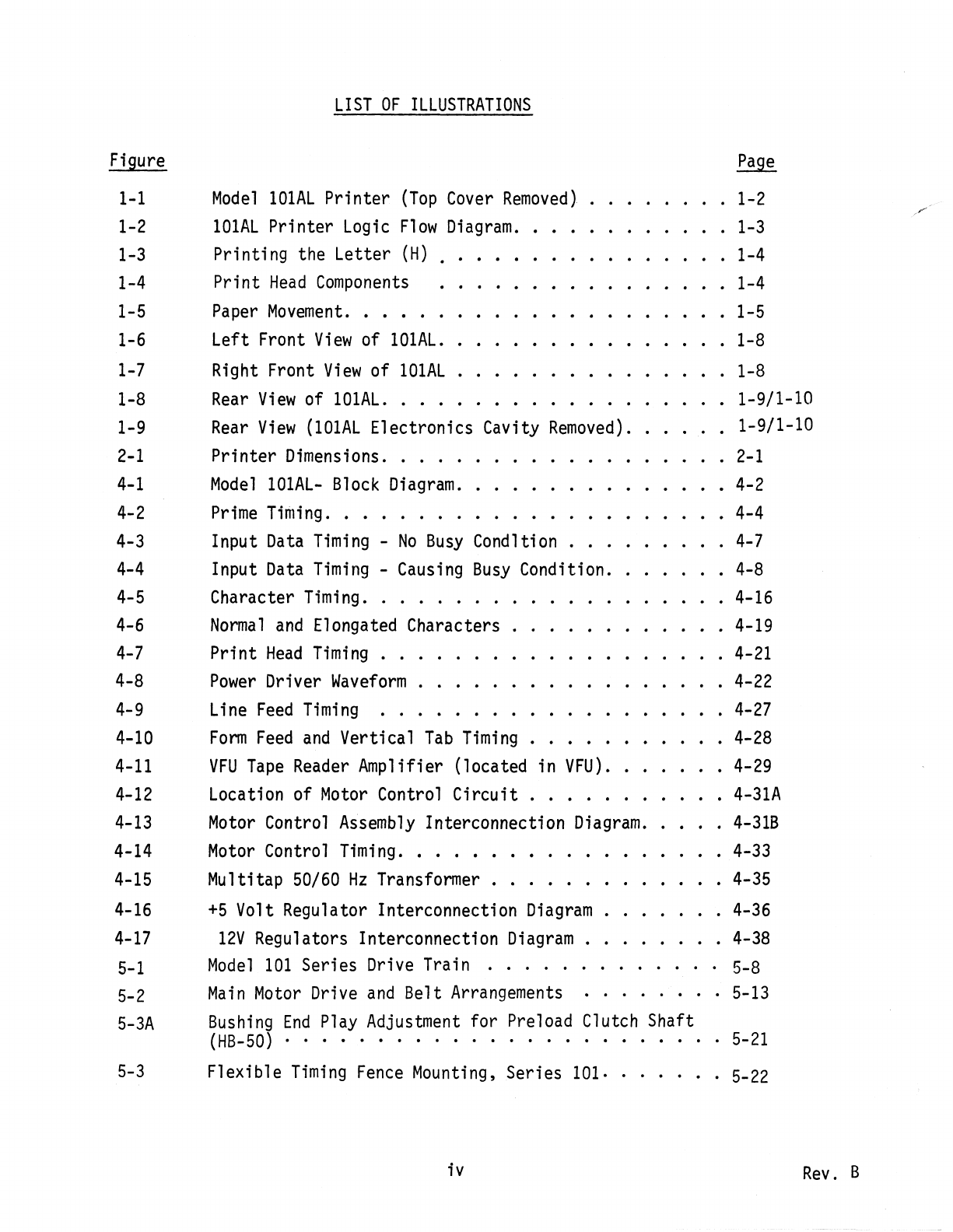

LIST

OF

ILLUSTRATIONS

Figure

Page

1-1

Model

101AL

Printer

(Top

Cover

Removed)

........

1-2

1-2

101AL

Printer

Logic

Flow

Diagram.

...........

1-3

1-3

Printing

the

Letter

(H)

.........4...28

8888

1-4

1-4

Print

Head

Components

........4...2.0880868

1-4

1-5

Paper

Movement.

. .

2. 2.

2 6

ee

ee ee

ew

ew

ew

ew

we

1-5

1-6

Left

Front

View

of

1OIAL........2.2.2.2.2.22.2.4.2.

1-8

1-7

Right

Front

View

of

1O1AL.......2.2.2....28-8

1-8

1-8

Rear

View

of

1OIAL.

.......

2...

ee

ee

eee

1-9/1-10

1-9

Rear

View

(101AL

Electronics

Cavity

Removed).

....

.

1-9/1-10

2-1

Printer

Dimensions.

. .

1...

2.

6

ee ww

te

ee

ee

2-1

4-1

Model

1lOIAL-

Block

Diagram.

.........2.2.+4+6-6

4-2

4-2

Prime

Timing.

.

2...

2

ee

ew

ew

ew

ww

we ew

we

we

et

4.4

4-3

Input

Data

Timing

-

No

Busy

CondItion.........

4.7

4-4

Input

Data

Timing

-

Causing

Busy

Condition.

......

4-8

4-5

Character

Timing.

.

.....

6.

©

ee

we

we we we

ee

4-16

4-6

Normal and

Elongated

Characters

.........e66-.

4-19

4-7

Print

Head

Timing

.

........

6.06606

6

«©

ee ee

4-2]

4-8

Power

Driver

Waveform.

........464.4.448888

4-22

4-9

Line

Feed

Timing

.......

2.6

©

©

© ©

we we

ee

4-27

4-10

Form

Feed

and

Vertical

Tab

Timing.

..........

4-28

4-11

VFU

Tape

Reader

Amplifier

(located

in

VFU).......

4-29

4-12

Location

of

Motor

Control]

Circuit.

.......4...

4-31A

4-13

Motor

Control

Assembly

Interconnection

Diagram.

....

4-31B

4-14

Motor

Control

Timing.

.......

2...

©

«©

ee

we

ew

4-33

4-15

Multitap

50/60

Hz

Transformer

..........2446-.

4-35

4-16

+5

Volt

Regulator

Interconnection

Diagram

.......

4-36

4.17

12V

Regulators

Interconnection

Diagram

........

4-38

5-1

Model

101

Series

Drive

Train

.......4.-+

see.

5-8

5-2

Main

Motor

Drive

and

Belt

Arrangements

........

5-13

5-3A

Bushing

End

Play

Adjustment

for

Preload

Clutch

Shaft

(HB-50)

a

a

5-21

5-3

Flexible

Timing

Fence

Mounting,

Series

101.

......

5-29

iV

Rev.

oc

ty

yf

meer

Figure

5-4

5-4A

9-5

9-6

5-/

5-9

5-10

5-11

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

7-15

7-16

7-17

7-18

7-19

7-20

7-21

7-22

7-23

LIST

OF

ILLUSTRATIONS

(cont'd)

Pade

Location

of

Left

Reed

Switch

(Top

View),

.......

.

.

5-24

Two

Adjustments,

Gear

with

Stop

Cam

(HH-23)

and

Inside

Cam

(HH-14)

2

ow

ke

ee

5-31

Ribbon

Feed

Mechanism

(Rear

of

Printer,

Left

Side)

.

.

.

.

5-36

Backlash

Adjustment,

Bevel

Gear

(HI-43,

59)

......-

5-37

Driving

Slide

Shaft

A

-

Adjustment...

...

+.

-

»

2»

9738

Ribbon

Reversing

Rod

Adjustment

.-

+--+

see

ete

5-39

Ribbon

Reverse

Timing

.

.

,.,.....2

ee

ee

eee

5-40

Fibre

Optics

Head,

Adjustment

from

Optic

Fence

-

+--+

+e.

5-45

Fibre

Optics

Head

Alignment

and

Flexible

Timing

Fence

,

.

5-45

Schematic

Diagram,

Logic/P.S.

Board

+5V

(Sheet

1

of

4)

.

.

7-3

Schematic

Diagram,

Logic/P.S.

Board

+5V

(Sheet

2

of

4)

.

7-4

Schematic

Diagram,

Logic/P.S.

Board

+5V

(Sheet

3

of

4)

.

7-5

Schematic

Diagram,

Logic/P.S.

Board

+5V

(Sheet

4

of

4)

..

7-6

Schematic

Diagram,

Power

Driver

Board

(Sheet

1

of

2)

.

7-7

Schematic

Diagram,

Power

Driver

Board

(Sheet

2

of

2)...

7-8

Schematic

Diagram,

Video

Amplifier

............

7-9

Schematic

Diagram,

Power

Connections

1OIAL........

7-10

Schematic

Diagram,

Motor

Control

.........4.4..

7-11

Multitap

Transformer

50/60

Hz

.......46424808-4

7-12

Wiring

Diagram,

Printer

Mechanism

........-2.2.6-4

7-13

Interconnection

Diagram,

Connector

Board

and

Power

Supply.

7-14

101AL

Connector

Configuration

.........60

6488-8

7-15

Component

Board

Assembly,

Logic/P.S.

Board

+5V

—

|

(Sheet

1

of

3)

2...

ww ee

ee ee

ee

ke

ee

we

7-17

Component

Board

Assembly,

Logic/P.S.

Board

+5V

(Sheet

3

of

3)

7

ww

wk

ee

ee

ee

ee

ee

ee

7-18

Component

Board

Assembly,

Power

Driver

..........

7-23

Component

Board

Assembly,

Video

Amplifier.

........

7-25

Component

Board

Assembly,

Connector

Board.

........

7-27

Component

Board

Assembly,

Motor

Control

.........

7-29

Electronics

Cavity

Assembly

........6

64.4068

7-31

Harness

Assembly

(W1)

...

2...

ee

eee

ee

eee

7-33

-

Input

Cable

Assembly

..

0...

eee

ee ee

ee

7-35

Power

Cable

Assembly

(W3).

....

2.0...

0

ee ee

ee

7-37

-\-

Rev.

B

Figure

8-4

8-1

8-2

8-3

8-3A

g-4

8-5

8-6

8-7

8-8

8-9

8-10

8-12

LIST

OF

ILLUSTRATIONS

(cont'd)

Mechanical

Sub

Assemblies

Cover

Assembly

-

Carriage

Mechanism

.

Drive

Mechanism

.

Drive

Mechanism

(Preload

Clutches).

Spring

Drum

Damper

Frame

Paper

Feed

Mechanism

.

ee

Pin

Feed

Mechanism

(Left

and

Right)

Form

Feed

Mechanism.

Ribbon

Feed

Mechanism

.

Print

Head

and

Associated

Assemblies

.

-Vi-

Page

8-2A

8-3

8-5

8-9

8-11

8-13

8-15

8-17

8-19

8-21

8-23

8-26

Rev.

SECTION

1

INTRODUCTION

This

manual

describes

the

Model

1O1AL

printer,

manufactured

by

Centronics

Data

Computer

Corporation.

It

provides

general

information,

detailed

theory

of

operation

and

maintenance

information

enabling

field

service

personnel

to

maintain

the

printer.

For

serial

input

or

other

detailed

interface

information,

a

separate

document

for

each

interface

is

published

for

your

reference.

purpose.

Section

1

Section

2

Section

3

Section

4

-

Section

5

Section

6

Section

7

The

manual

is

grouped

into

eight

sections,

each

with

its

specific

INTRODUCTION,

introduces

the

reader

to

the

scope

and

content

of

the

manual,

and

provides

the

reader

with

a

general

description

of

the

printer.

INSTALLATION,

contains

unpacking

and

installation

in-

structions

for

the

printer.

OPERATION,

describes

the

function

of

all

operator

con-

trols

and

indicators

and

how

they

are

used.

THEORY

OF

OPERATION,

contains

a

detailed

description

of

each

major

operation

performed

by

the

printer

electronics,

including

timing

diagrams

and,

where

applicable

simplified

circuit

diagrams,

all

keyed

to

the

schematic

drawings.

REMOVAL,

REPLACEMENT

AND

ADJUSTMENT

PROCEDURES,

includes

step-by-step

removal

and

replacement

procedures

for

all

major

assemblies

and

sub-assemblies

in

the

printer.

MAINTENANCE,

includes

preventive

and

corrective

maintenance

procedures

and

a

maintenance

schedule.

ELECTRICAL

DRAWINGS

AND

LIST

OF

MATERIALS,

contains

a

complete

set

of

schematic,

wiring

and

component

board

layout

diagrams

and

their

associated

list

of

materials

for

the

electrical

portion

of

the

printer.

1-1

Rev.

A

Section

8

-

MECHANICAL

DRAWINGS

AND

PARTS

LISTS,

includes

all

printer

assembly

drawings

and

their

associated

parts

lists

for

the

mechanical

portion

of

the

printer.

At

the

end

of

the

manual

are

several

appendices

which

include

a

glossary

of

signal

mnemonics,

a

standard

9

x

7

64-character

set,

and

parallel

interface

specifications.

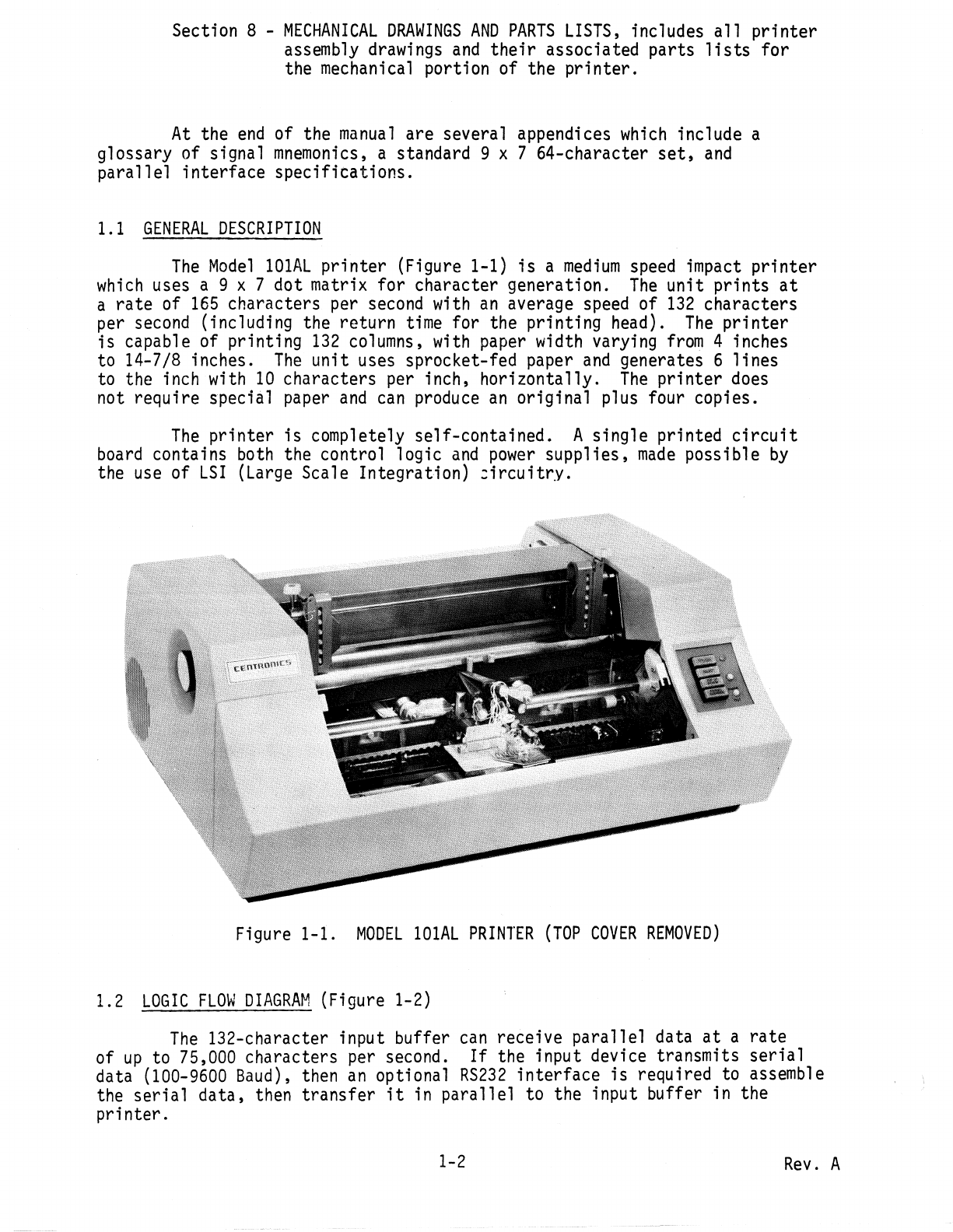

1.1

GENERAL

DESCRIPTION

The

Model

101AL

printer

(Figure

1-1)

is

a

medium

speed

impact

printer

which

uses

a

9

x

7

dot

matrix

for

character

generation.

The

unit

prints

at

a

rate

of

165

characters

per

second

with

an

average

speed

of

132

characters

per

second

(including

the

return

time

for

the

printing

head).

The

printer

is

capable

of

printing

132

columns,

with

paper

width

varying

from

4

inches

to

14-7/8

inches.

The

unit

uses

sprocket-fed

paper

and

generates

6

lines

to

the

inch

with

10

characters

per

inch,

horizontally.

The

printer

does

not

require

special

paper

and

can

produce

an

original

plus

four

copies.

The

printer

is

completely

self-contained.

A

single printed

circuit

board

contains

both

the

control

logic

and

power

supplies,

made possible

by

the

use

of

LSI

(Large

Scale

Integration)

zircuitry.

Figure

1-1.

MODEL

101AL

PRINTER

(TOP

COVER

REMOVED)

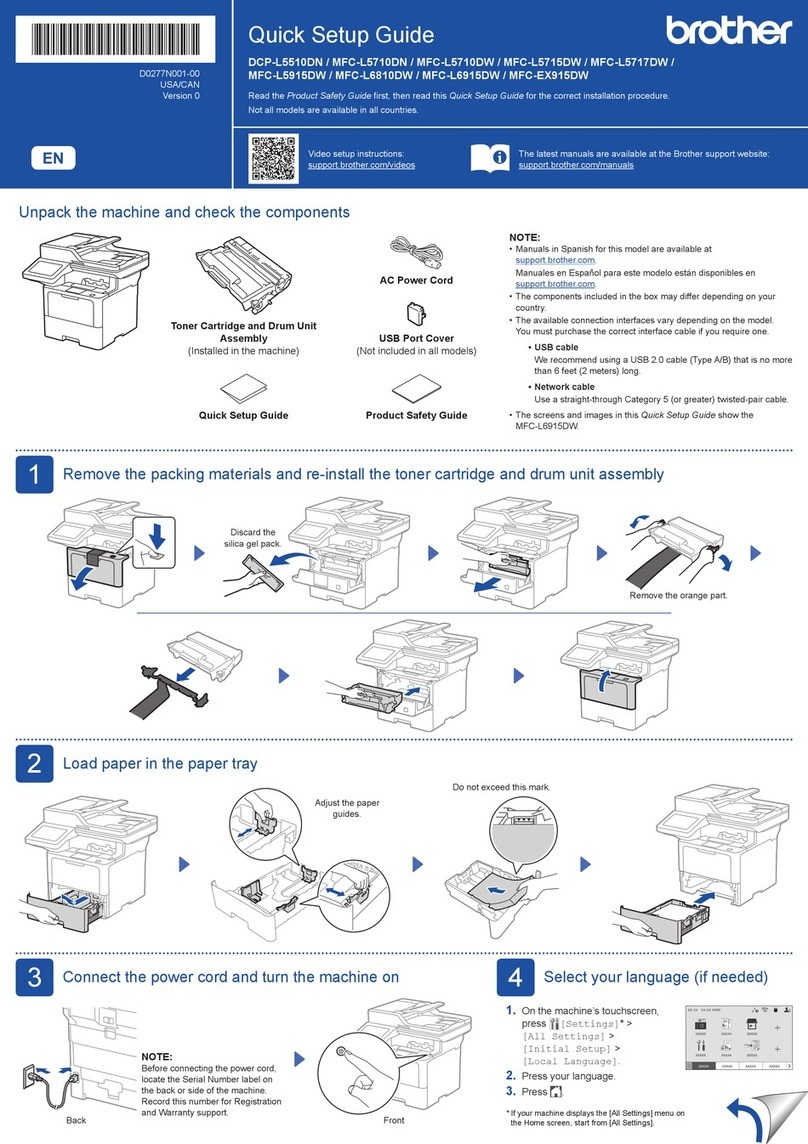

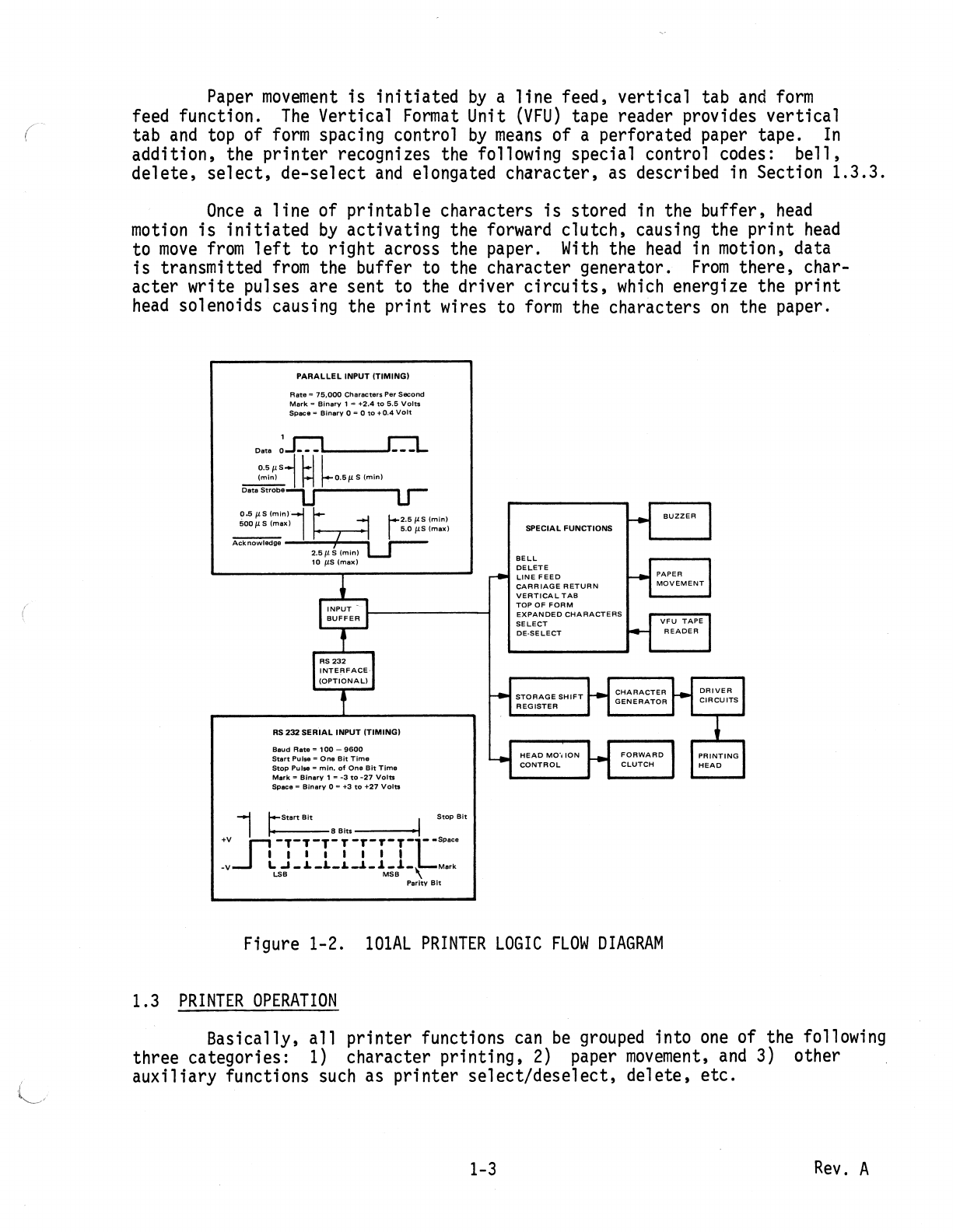

1.2

LOGIC

FLOW

DIAGRAM

(Figure

1-2)

The

132-character

input

buffer

can

receive

parallel

data

at

a

rate

of

up

to

75,000

characters

per

second.

If

the

input

device

transmits

serial

data

(100-9600

Baud),

then

an

optional

RS232

interface

is

required

to

assemble

the

serial

data,

then

transfer

it

in

parallel

to

the

input

buffer

in

the

printer.

1-2

Rev.

A

Paper

movement

is

initiated

by

a

line

feed,

vertical

tab

and

form

feed

function.

The

Vertical

Format

Unit

(VFU)

tape

reader

provides

vertical

tab

and

top

of

form

spacing

control

by

means

of

a

perforated

paper

tape.

In

addition,

the

printer

recognizes

the

following

special

control

codes:

bell,

delete,

select,

de-select

and

elongated

character,

as

described

in

Section

1.3.3.

Once

a

line

of

printable

characters

is

stored

in

the

buffer,

head

motion

is

initiated

by

activating

the

forward

clutch,

causing

the

print

head

to

move

from

left

to

right

across

the

paper.

With

the

head

in

motion,

data

is

transmitted

from

the

buffer

to

the

character

generator.

From

there,

char-

acter

write

pulses

are

sent

to

the

driver

circuits,

which

energize

the

print

head

solenoids

causing

the

print

wires

to

form

the

characters

on

the

paper.

PARALLEL

INPUT

(TIMING)

Rate

=

75,000

Characters

Per

Second

Mark

=

Binary

1

=

+2.4

to

5.5

Volts

Space

= Binary

0

=

0

to

+

0.4

Volt

1

Data

on

oe

ew

x.

0.5

[1S

(min)

Pt

0.5

1

S

(min)

Data

Strob

Ly

0.5

2S

(min)

=»

ke

500

11S

(max)

2.5

HS

(min)

BUZZER

+

7

>

5.0

LS

(max)

SPECIAL

FUNCTIONS

Acknowledge

7

2.5

[LS

(min)

10

[LS

(max)

BELL

DELETE

—Oy

LINE

FEED

Ley

PAPER

CARRIAGE

RETURN

MOVEMENT

|

v

|

VERTICAL

TAB

INPUT

EXPANDED

CHARACTERS

BUFFER

SELECT

VFU

TAPE

DE-SELECT

—_—

READER

RS

232

INTERFACE:

(OPTIONAL)

CHARACTER

[gy

DRIVER

a

fi

STORAGE

SHIFT

GENERATOR

CIRCUITS

REGISTER

RS

232

SERIAL

INPUT

(TIMING)

Baud

Rate

=

100

—

9600

.

Start

Pulse

=

One

Bit

Time

Le

HEAD

MO‘

ION

FORWARD

PRINTING

Stop

Pulse

=

min,

of

One

Bit

Time

CONTROL

CLUTCH

HEAD

Mark

=

Binary

1

=

-3

to

-27

Volts

Space

=

Binary

0 =

+3

to

+27

Volts

"sen

Bit

|

Stop

Bit

8

Bits

a

5

+V

—T7-T

"TO

ToT

rer

a

w=Space

|

terest

bb

|

|

-V

L

Jobb

it_i_li.

Mark

MSB

\

LSB

iH

Parity

Bit

Figure

1-2.

1O1AL

PRINTER

LOGIC

FLOW

DIAGRAM

1.3.

PRINTER

OPERATION

-

Basically,

all

printer

functions

can

be

grouped

into

one

of

the

following

three

categories:

1)

character

printing,

2)

paper

movement,

and

3)

other

auxiliary

functions

such

as

printer

select/deselect,

delete,

etc.

1-3

Rev.

A

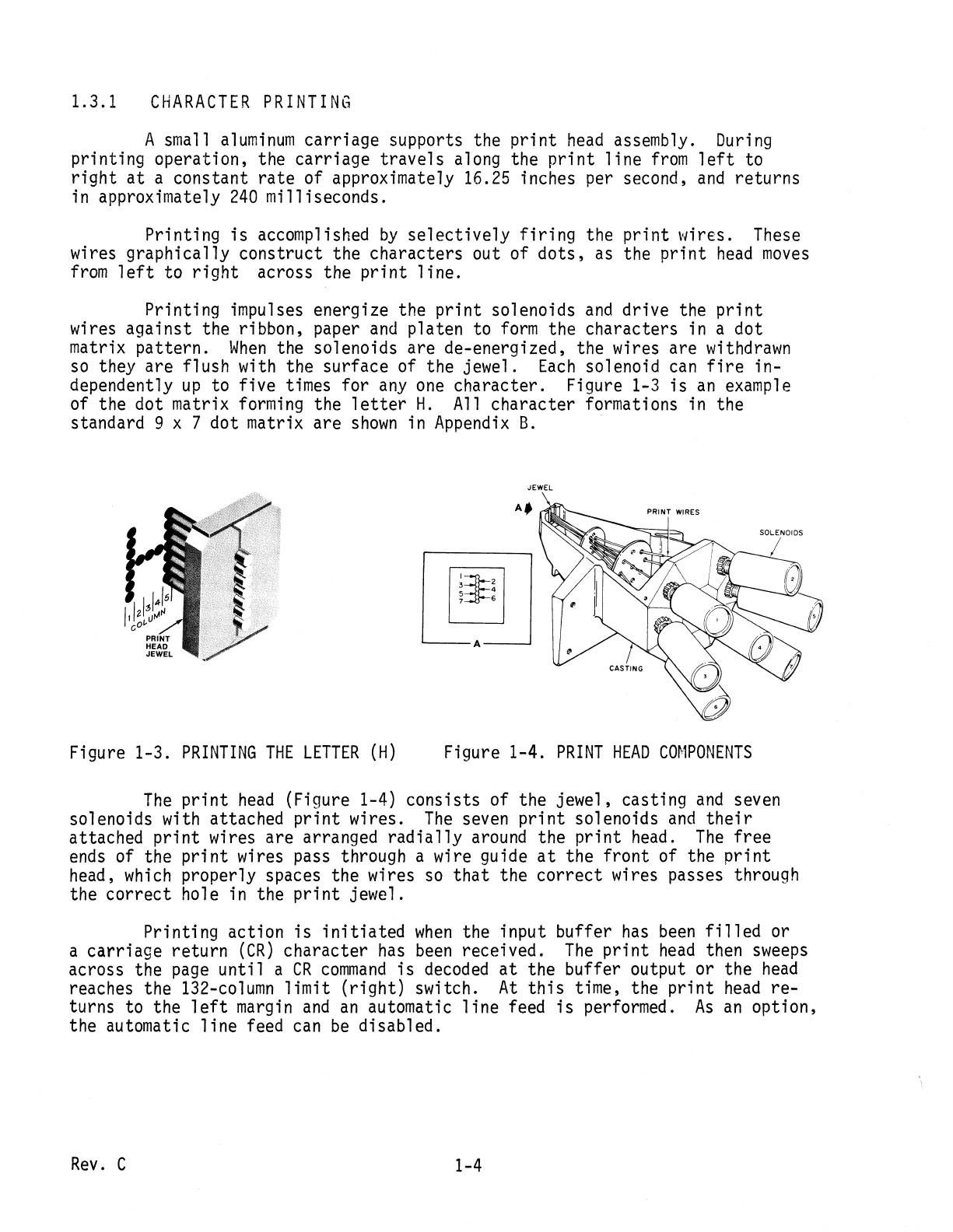

1.3.1

CHARACTER

PRINTING

A

small

aluminum

carriage

supports

the

print

head

assembly.

During

printing

operation,

the

carriage

travels

along

the

print

line

from

left

to

right

at

a

constant

rate

of

approximately

16.25

inches

per

second,

and

returns

in

approximately

240

milliseconds.

Printing

is

accomplished

by

selectively

firing

the

print

wires.

These

wires

graphically

construct

the

characters

out

of

dots,

as

the

print

head

moves

from

left

to

right

across

the

print

line.

Printing

impulses

energize

the

print

solenoids

and

drive

the

print

wires

against

the

ribbon,

paper

and

platen

to

form

the

characters

in

a

dot

matrix

pattern.

When

the

solenoids

are

de-energized,

the

wires

are

withdrawn

so

they

are

flusn with

the

surface

of

the

jewel.

Each

solenoid

can

fire

in-

dependently

up

to

five

times

for

any

one

character.

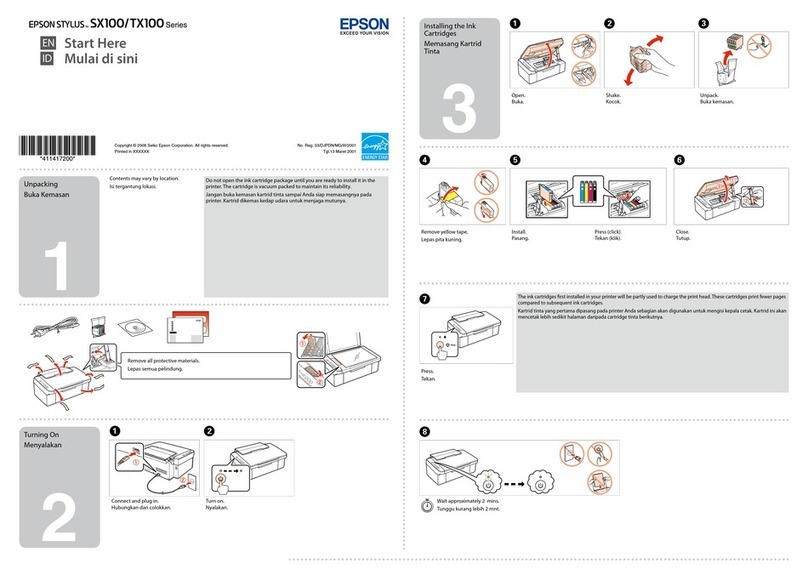

Figure

1-3

is

an

example

of

the

dot

matrix

forming

the

letter

H.

All

character

formations

in

the

standard

9

x

7

dot

matrix

are

shown

in

Appendix

B.

|

SOLENOIDS

NOW

—

nN

DNM

CASTING

Figure

1-3.

PRINTING

THE

LETTER

(H)

Figure

1-4,

PRINT

HEAD

COMPONENTS

The

print

head

(Figure

1-4)

consists

of

the

jewel,

casting

and

seven

solenoids

with

attached

print

wires.

The

seven

print

solenoids

and

their

attached

print

wires

are

arranged

radially

around

the

print

head.

The

free

ends

of

the

print

wires

pass

through

a

wire

guide

at

the

front

of

the

print

head,

which

properly

spaces

the

wires

so

that

the

correct

wires

passes

through

the

correct

hole

in

the

print

jewel.

Printing

action

is

initiated

when

the

input

buffer

has

been

filled

or

a

carriage

return

(CR)

character

has

been

received.

The

print

head

then

sweeps

across

the

page

until

a

CR

command

is

decoded

at

the

buffer

output

or

the

head

reaches

the

132-column

limit

(right)

switch.

At

this

time,

the

print

head

re-

turns

to

the

left

margin

and

an

automatic

line

feed

is

performed.

As

an

option,

the

automatic

line

feed can

be

disabled.

Rev.

C

1-4

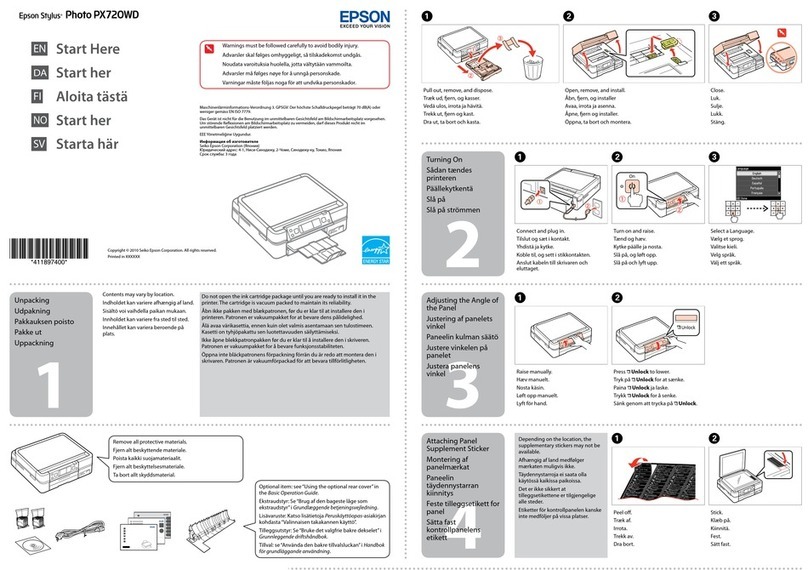

1.3.2

PAPER

MOVEMENT

Paper

can

be

moved

manually

by

rotating

the

platen

knob

(shown

in

Figure

1-5)

or

automatically

by

any

of

three

paper

movement

commands:

Tine

feed,

vertical

tab

and

form

feed.

PAPER

ADVANCE

FORM

FEED

(RELEASE)

CLUTCH

FORM

FEED

HOLE

Figure

1-5.

PAPER

MOVEMENT

A

small

independent

motor

not

shown

in

Figure

1-5,

provides

the

power

necessary

to

move

the

sprocket-feed

tracotrs

which

control

paper

movement.

To

move

the

paper,

the

printer

electronics

activates

a

line

feed

solenoid

which

activates

a

clutch

that

mechanically

links

the

motor

to

the

sprocket-feed

tractors.

To

initiate

a

single

line

feed,

the

line

feed

solenoid

is

energized

for

15

milliseconds

to

initiate

paper

motion.

Upon

completion

of

the

line

feed

command,

a

60

millisecond

delayed

line

feed

is

generated. This

allows

the

clutch

pawl

and

clutch

mechanism

to

return

home

before

another

line

feed

is

allowed.

Vertical

forms

movement

is

accomplished

hy

applying

a

DC

level

to

the

paper

feed

solenoid

until

a

hole

is

detected

in

the

Vertical

Format

Unit

(VFU).

The

tape

consists

of

two

tracks;

one

used

for

Top

of

Forms

and

the

other

for

Vertical

Tab.

The

movement

of

the

paper

tape

is

caused

by

direct

mechanical

.

linkage

to

the

gear

train

which

drives

the

paper

feed

tractors.

When

the

printer

runs

out

of

paper,

a

sensing

switch

activates

a

two-second

audible

tone

in

a

speaker

located

at

the

rear.

The

printer

also

Stops

printing

and

lights

the

PAPER

EMPTY

light

on

the

control

panel.

1-5

Rev.

C

Rev.

1.3.3

SPECIAL

FUNCTION

In

addition

to

the

printable

characters

shown

in

Appendix

B,

the

printer

can

recognize

the

following

special

functions:

1.4

Carriage

Return

(Octal

015)

-

Initiates

the

printing

of

a

line.

Form

Feed

(Octal

014)

-

Moves

the

paper

until

the top

of

the

form

hole

in

Tape

Reader

Channel

7

is

reached.

Vertical

Tab

(Octal

013)

-

Moves

the

paper

until

the

next

hole

in

Tape

Reader

Channel

5

is

reached.

Line

Feed

(Octal

012)

-

Advances

the

paper

one

line.

Delete

(Octal

177)

-

Primes

the

printer

electronics

to

an

idle

state

and

deletes

any

characters

stored

in

the

printer.

Bell

(Octal

007)

-

Generates

a

two-second

audible

tone

in

the

speaker

at

the

rear

of

the

printer.

7

Select

(Octal

021)

-

Allows

printer

to

receive

data,

same

as

activating

SELECT

switch.

De-Select

(Octal

023)

-

Inhibits

printer

from

receiving

data,

same

as

deactivating

SELECT

switch.

SYSTEM

FEATURES

1.4.1

FEATURES

Standard

features

optional

features

e

Vertical

format

control

e

Character

sets

of

64,

96

or

128

characters

e

Audio

alarm

e

Popular

parallel!

and

serial

interfaces

e

Form

feed

control

(via

paper

tape

loop)

e

Automatic

motor

control

e

Elongated

boldface

characters

(line-by-line)

e

Selectable

single

character

elongation

e

Parallel

data

input

e

Elapsed

time

indicator

e

4

inches/second

slew

rate

e

Prints

original

plus

four

copies

e

Fixed

vertical/horizontal

registration

e

Paper

runaway

inhibit

e

Separate

prime

line

and

fault

line

to

output

connector

Provision

for

additional

character

set

Remote

select/deselect

Available

with

50

or

60

Hertz,

115

or

230

Volts

AC

Automatic

line

feed disabled

9x

7or5x/7

dot

matrix

1-6

1.4.2

SPECIFICATIONS

SUMMARY

Printing

Method

Printing

Rate

—

Characters

—

Full

Lines

—

Short

Lines

Transmission

Rate

—

Serial

—

Parallel

Data

Input

‘Character

Structure

Code

Indicator-Switch

Controls

Indicator

Manual

Controls

Character

Buffer

Format

Paper

Feed

Paper

Number

of

Copies

Dimensions

Weight

Electrical

Requirements

Temperature

—

Operating

—

Storage

Humidity

—

Operating

|

—

Storage

1.5

PHYSICAL

DESCRIPTION

photo.

Impact,

character-by-character,

one

line

at

a

time

165

characters

per

second

60

lines

per

minute

(132

character

line)

200

lines

per

minute

(20-30

characters)

100

to

9600

baud

(with

Serial

option)

Up

to

75,000

characters

per

second

Parallel

(Serial

option

available)

9

x

7

dot

matrix,

10-point

type

equivalent

USASCII

—

64

characters

printed,

lower

case

Characters

recognized

and

printed

as

upper

case

equivalent

|

ON/OFF,

SELECT,

TOP

OF

FORM,

FORMS

OVERRIDE,

LINE

FEED

PAPER

OUT

|

Form

Thickness,

Paper

Advance

Knob

132

characters

(1

line)

132

characters

maximum

per

line,

6

lines

per

inch

Sprocket

feed,

adjustable

from

4”

to

147/s”

width

Standard

sprocketed

paper

Original

and

up

to

four

carbon

copies

11'/2"

high,

20”

deep,

2773/4"

wide

118

pounds

115

VAC

£10%,

60

Hz

or

115/230

VAC

+£10%,

50

Hz

40°

to

100°

F

—40°

to

160°

F

5°/o

to

90°/o

(no

condensation)

0°/o

to

95°%/o

The

printer

is

approximately

113;"

high,

20"

deep,

27-3/4"

wide

and

weighs

approximately

118

pounds.

views

of

the

printer

taken

with

the

covers

removed.

Each

major

printer

assembly

is

located

on

these

figures

and

identified

in

the

table

below

the

Figures

1-6

through

1-9

are

photographic

Rev.

C

1.

Print

Head

Assembly

4.

VFU

Tape

Reader

7.

Spring

Drum

10.

Timing

Fence

2.

Carriage

5.

Pin

Feed

Mechanism

8.

Platen

Knob

11.

Main

Drive

Belt

3.

Form

Feed

Mechanism

6.

Ribbon

Feed

Mechanism

9.

°

Damper

Figure

1-6.

LEFT

FRONT

VIEW

OF

101AL

1.

Operator

Control

Panel

5.

Optical

Pick-Up

9.

Penetration

Control

Knob

13.

Cooling

Fan

2.

Form

Feed

Motor

6.

Optic

Bundle

10.

Forward

Clutch

14.

Ribbon

Feed

3.

Video

Amplifier

and

Cable

Assembly

7.

Ribbon

Cable

11.

Main

Pulley

and

Drive

Belt

Mechanism

4.

Light

Source

8.

Power

Driver

Board

12.

Reverse

Clutch

15.

Line

Feed

Figure

1-7.

RIGHT

FRONT

VIEW

OF

101AL

Rev.

C

1-8

1.

Connector

Card

6.

Jil

11.

Logic/Power

Supply

Board

2.

J4

7.

Fuse

F5

12.

Speaker

3.

J6

8.

AC

Power

Input

13.

Electronics

Cavity

4.

J3

9.

+30V

Power

Supply

14.

Input

Connector

5.

J2

10.

Fuse

F4

Figure

1-8.

REAR

VIEW

OF

101AL

1.

Main

Motor

4.

Electronics

Connector

7.

Ribbon

Reversing

Rod

2.

Motor

Starting

Capacitor

5.

Power

Transformer

8.

Ribbon

Drive

Rod

3.

AC

Power

Connector

6.

Power

Distribution

Fiero

te,

NL

a

,

Figure

1-9.

REAR

VIEW

(101AL

ELECTRONICS

CAVITY

REMOVED

-1-9/1-10-

Rev.

C

Other manuals for 101AL

1

Table of contents

Other Centronics Printer manuals

Centronics

Centronics 101A User manual

Centronics

Centronics 352 User manual

Centronics

Centronics 101 User manual

Centronics

Centronics 101 User manual

Centronics

Centronics 306 User manual

Centronics

Centronics 704 User manual

Centronics

Centronics 306 User manual

Centronics

Centronics 730-1 User manual

Centronics

Centronics 705 User manual

Centronics

Centronics 101AL Guide