8

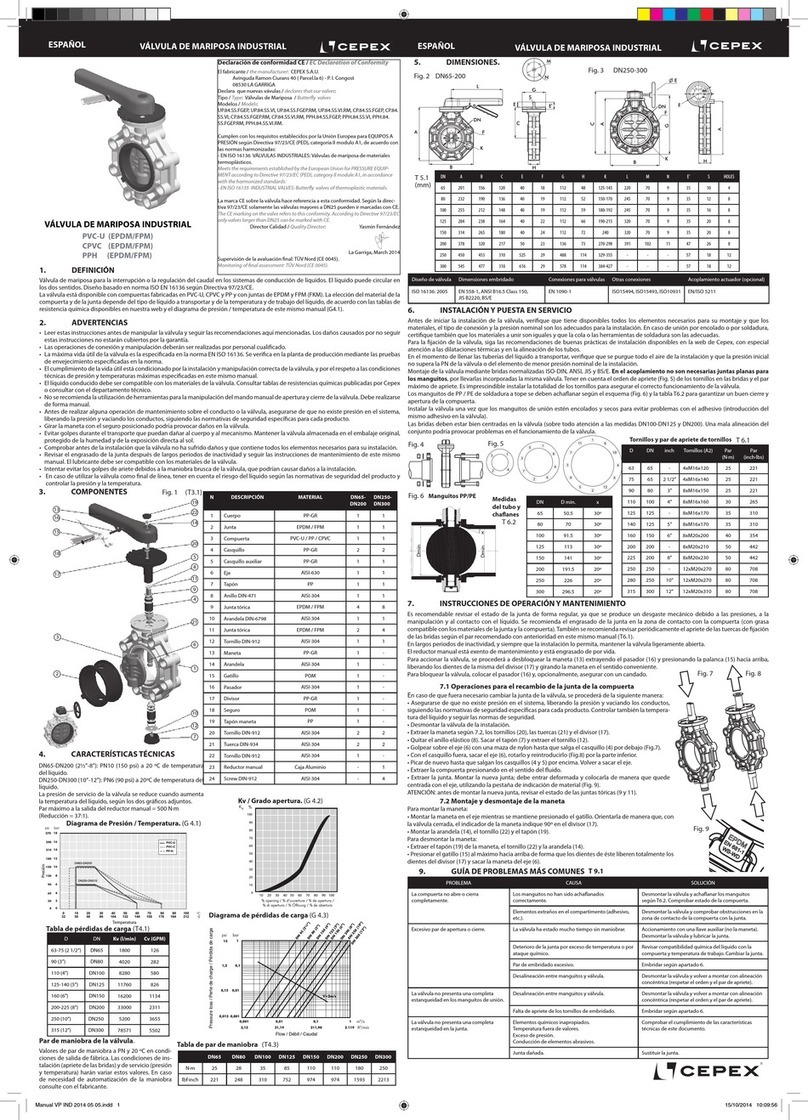

7.2 Assembling and Removing the Handle

To assemble the handle:

Fit the handle on the shaft while holding the lever. Place it so that, with the valve closed, the handle

indicator shows 90º on the throttle plate (21).

Fit the washer (16), screw (26) and cap (23).

To remove the handle:

Remove the round cap (23) from the handle, the screw (26) and the washer (16).

Press the lever (17) fully upwards so that its teeth are fully disengaged from the teeth on the

throttle plate (21). Remove the handle from the shaft (7).

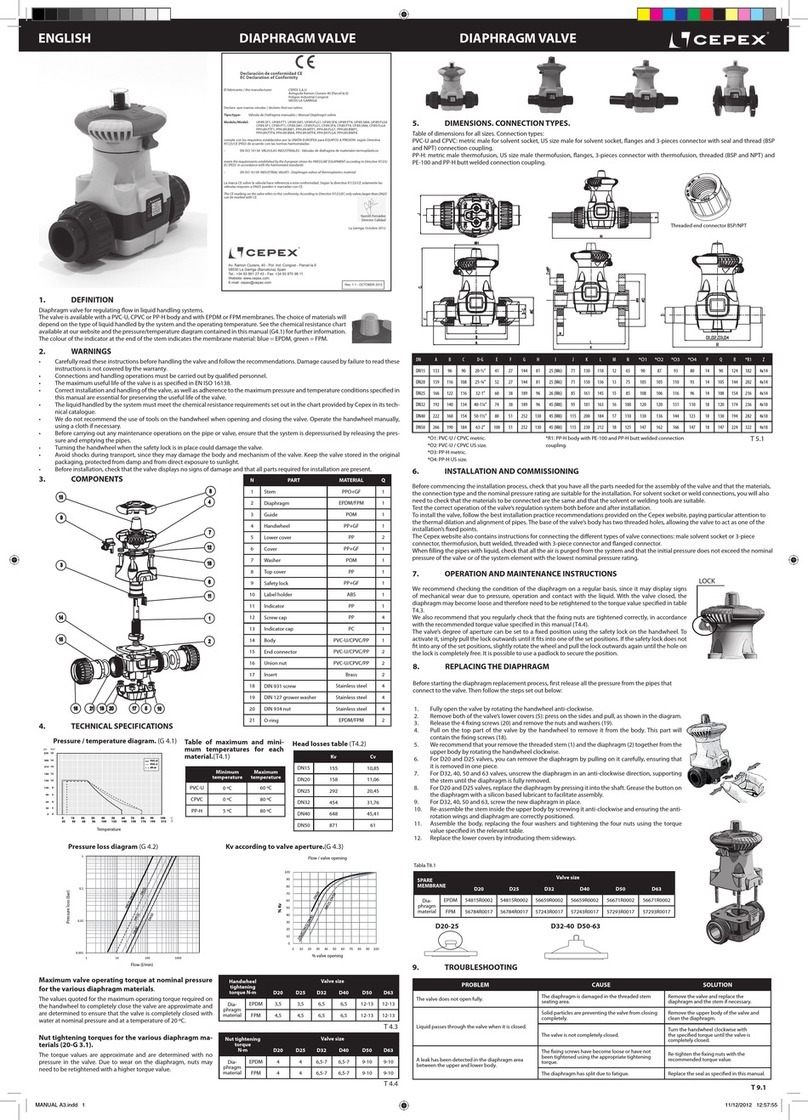

7.1 Replacing the Sealing Gasket

Should it be necessary to replace the sealing gasket, proceed as follows:

· Ensure that the system is depressurised by releasing the pressure and emptying the pipes, fo-

llowing the specic safety regulations of each product. Also check the temperature of the liquid

and follow safety standards of temperature.

· Remove the valve from the installation.

· Remove the handle as per 7.2, screws (24), nuts (25) and throttle plate (21).

· Remove the ring (9). Take o the cap (8) and remove the screw (14).

· Tap on the shaft (7) with a rubber mallet until the bearing (14) is exposed from the bottom (Fig. 7).

· Once the bearing is out, remove the shaft (7), turn it and re-insert it (Fig. 8) from the bottom.

· Tap again until the bearings (5 and 6) emerge from the top. Remove the shaft again.

· Remove the disc by pressing in the direction of the uid.

· Remove the sealing gasket. Fit the new sealing gasket; it needs to be warped and placed so that it

lines up with the shaft, according to the indication tab of the gasket (Fig. 9).

WARNING: Before installing the new gasket, check the condition of the O-rings (10, 11 and 13).

Fig. 7 Fig. 8

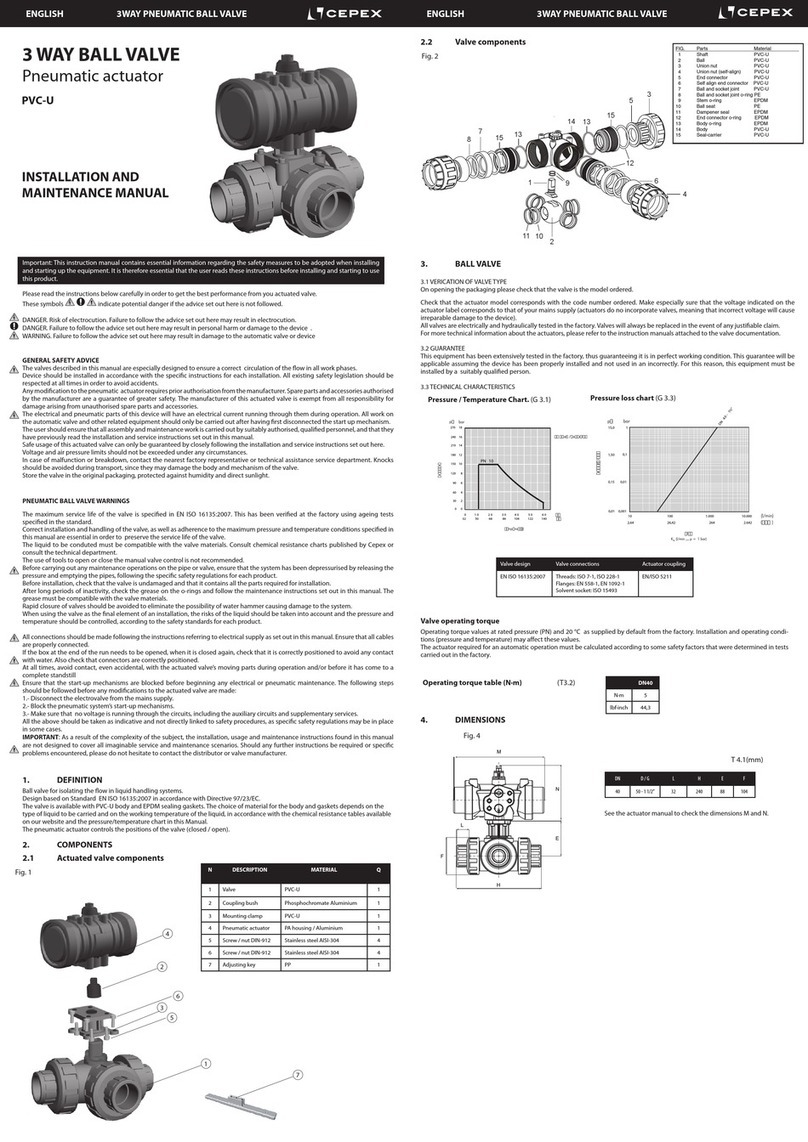

7. OPERATION AND MAINTENANCE INSTRUCTIONS

It is recommended that the condition of the sealing gasket is checked regularly, since it may display signs of mechanical wear due

to pressure, handling and contact with the liquid. The sealing gasket should be greased in the disc contact area (the grease must

be compatible with the materials of the gasket and the disc). It is also advisable to check regularly that the ange xing nuts are

tightened correctly, as per the recommended torque values specied above (T6.1).

In long periods of inactivity, and in case that the installation allows it, maintain the valve slightly open. It is recommended to force a

periodic movement to avoid the lock of the valve in long periods of time in closed position. It is advisable to pass the liquid before

maneuvering the valve.

The manual gearbox is maintenance-free and greased for life.

To operate the valve, unlock the handle (13) removing the pin (16) and pulling the lever (15) upwards, releasing its teeth from the

throttle plate (15), then turning the handle in the appropriate direction.

To lock the valve, insert the pin (16) and, optionally, secure with a padlock.

Fig. 9

8. SOLUCIÓN DE PROBLEMAS T 8.1

FAULT POSSIBLE CAUSE FAULT CLEARANCE

The disc does not fully open or

close.

The sockets were not correctly bevelled. Disassemble the valve and bevel the sockets as indicated

in table T6.2.

Foreign materials in the compartment (adhesive, etc.). Disassemble the valve and check for obstructions in the

disc and gasket contact area.

Excessive opening or closing

torque.

The valve has been inactive for a long time. Operate with an auxiliary release key (not plastic handle).

Disassemble the valve and lubricate the sealing gasket.

Overtemperature or chemical attack cause damage to

the gasket.

Check the chemical compatibility of the liquid with the

disc and the working temperature. Replace the gasket.

Excessive ange torque. Tighten anges as indicated in section 6.

Misalignment between sockets and valve. Disassemble the valve and reassemble with concentric

alignment (observe the correct tightening sequence and

torque).

The valve is not fully watertight at

the sockets.

Misalignment between sockets and valve. Disassemble the valve and reassemble with concentric

alignment (observe the correct tightening sequence and

torque).

Flange screws not tight enough. Tighten anges as indicated in section 6.

The valve is not completely

watertight at the sealing gasket .

Inadequate chemicals.

Temperature out of range.

Excess pressure.

Conduction of abrasive elements.

Check compliance with the specications in this

document.

Damaged sealing gasket. Replace the gasket.

ENGLISHEXTREME BUTTERFLY VALVE