CETAC LSX-213 User manual

CETAC

LSX-213 Laser Ablation System

Manual Part Number 480141 Rev 2e

Operator’s Manual

COPYRIGHT

© 2006-2010 CETAC Technologies

480141 Rev 2e, December, 2010

CETAC Technologies authorizes its customers

to reproduce, transmit, or store this document

in its entirety, including this page, for the

express purpose of installing, operating, or

maintaining the product described herein.

CETAC Technologies

Customer Service & Support

14306 Industrial Road

Omaha, Nebraska 68144, USA

Phone (800) 369-2822 (USA only)

Phone (402) 733-2829

Fax (402) 733-1932

E-mail custserv@cetac.com

REVISIONS

CETAC Technologies strives to provide the

scientific community with an unparalleled

combination of effective technology and

continuing value. Modular upgrades for

existing instruments will continue to be a

prime consideration as designs progress.

CETAC Technologies reserves the right to

revise this document and/or improve

products described herein at any time without

notice or obligation.

TRADEMARK ACKNOWLEDGEMENTS

Windows is a registered trademark of

Microsoft Corporation in the United States and

other countries.

PharMed and Tygon are registered

trademarks of Saint-Gobain Performance

Plastics.

DuPont™, Kapton®, Teflon®, Tefzel® and

Viton® are trademarks or registered

trademarks of E.I. du Pont de Nemours and

Company.

All other marks are the property of their

respective owners.

3

Contents

1Introduction ..............................................................................................................7

Overview.................................................................................................................................... 7

Principles of Operation ....................................................................................................... 8

Laser Ablation Processes............................................................................................. 8

System Overview ............................................................................................................ 8

Laser Ablation System.................................................................................................. 9

Laser Head and Optics ...............................................................................................10

Laser Characteristics..................................................................................................10

Viewing Optics and Video System..........................................................................11

Sampling System ..........................................................................................................11

Computer Hardware and Software.......................................................................11

System Characteristics...............................................................................................12

Options .............................................................................................................................12

Laser and High Voltage Safety Features.............................................................12

Laser Ablation System Components ...........................................................................12

Who Should Use This Product—Operator Qualifications..................................13

Where to Go for More Information..............................................................................13

Preparing for Installation.................................................................................................14

Ventilation ......................................................................................................................14

2Using the LSX-213 Laser Ablation System................................................... 15

Establishing Optimal Operating Conditions ............................................................15

Creating the Lab Environment ...............................................................................16

Replacing Laser Ablation System Components ................................................17

Purchasing Supplies....................................................................................................17

Connecting the Laser Ablation System.......................................................................18

Connections to the Host Computer........................................................................18

Connections to the Power Supply/Cooler...........................................................19

Gas Connections............................................................................................................20

Using the Laser Ablation System ..................................................................................20

Front Panel Indicators...............................................................................................20

Starting the Laser Ablation System .............................................................................21

Methods of Analyses...........................................................................................................22

Optimization ..........................................................................................................................23

Bulk Analysis..................................................................................................................24

Elemental or Spatial Mapping................................................................................24

Depth Profiling..............................................................................................................25

Sample Preparation............................................................................................................26

Sample Size.....................................................................................................................26

Surface Conditions.......................................................................................................26

Powder Samples ...........................................................................................................26

Shutting Down the Laser Ablation System...............................................................28

CETAC LSX-213 Operator’s Manual

Contents

4

3Using the DigiLaz III Software..........................................................................29

What’s New ............................................................................................................................29

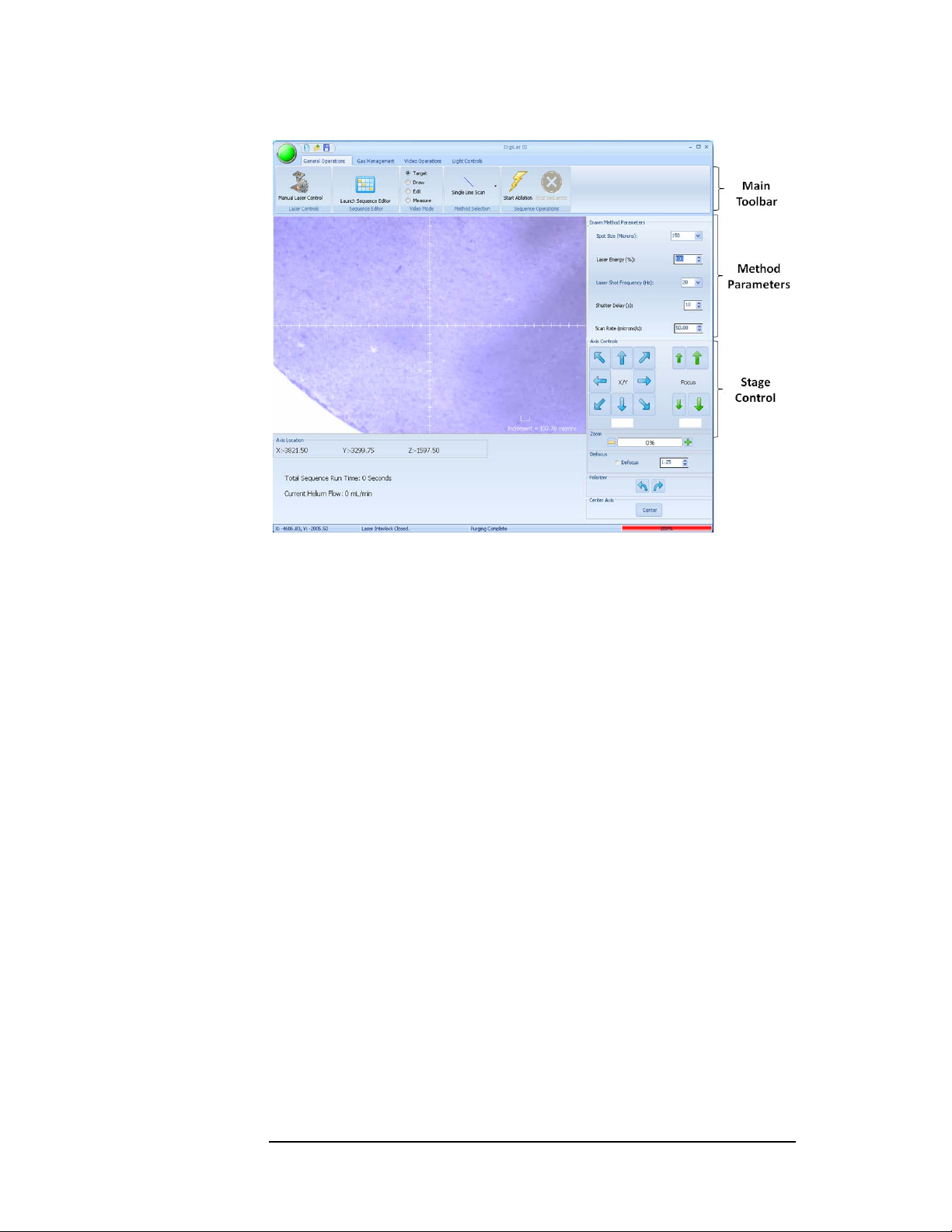

Software Overview .............................................................................................................29

Installing the DigiLaz III™Software .............................................................................30

Running the DigiLaz III™Software...............................................................................31

Essential Tasks .....................................................................................................................32

Emergency Stop............................................................................................................ 32

In Case of Electrical Hazard.................................................................................... 32

Starting the Laser Ablation System...................................................................... 32

Shutting Down the Laser Ablation System ........................................................ 33

Menus in the DigiLaz III™Operating Software........................................................33

General Operations ..................................................................................................... 33

Gas Management ......................................................................................................... 37

Video Operations.......................................................................................................... 40

Light Controls................................................................................................................ 42

Using the Sequence Editor ..............................................................................................43

General............................................................................................................................. 44

Sequence ......................................................................................................................... 45

Help ................................................................................................................................... 46

Drawing and Editing Method Graphics .....................................................................46

Drawing a Method Graphic ..................................................................................... 46

Deleting a Method Graphic...................................................................................... 47

Editing a Method Graphic ........................................................................................ 47

Setting Method Parameters..................................................................................... 48

Triggering and Timing ......................................................................................................48

Gas Blank ........................................................................................................................ 49

Pause Between Samples............................................................................................ 49

Trigger Delay ................................................................................................................ 49

Examples .................................................................................................................................49

Service Calibration Tools.................................................................................................50

4Software Methods .................................................................................................51

Spot Scan.................................................................................................................................51

Description ..................................................................................................................... 51

Parameters..................................................................................................................... 51

How to Draw ................................................................................................................. 51

Example........................................................................................................................... 52

Line Scan .................................................................................................................................52

Description ..................................................................................................................... 52

Parameters..................................................................................................................... 52

How to Draw ................................................................................................................. 52

Example........................................................................................................................... 53

Segmented Line Scan.........................................................................................................53

Description ..................................................................................................................... 53

Parameters..................................................................................................................... 53

How to Draw ................................................................................................................. 54

Example........................................................................................................................... 54

Line Raster .............................................................................................................................55

Description ..................................................................................................................... 55

Parameters..................................................................................................................... 55

How to Draw ................................................................................................................. 55

Example........................................................................................................................... 56

Scanning ..................................................................................................................................56

CETAC LSX-213 Operator’s Manual

Contents

5

Description .....................................................................................................................56

Parameters.....................................................................................................................56

How to Draw..................................................................................................................56

Example ...........................................................................................................................57

Area Raster.............................................................................................................................58

Description .....................................................................................................................58

Parameters.....................................................................................................................58

How to Draw..................................................................................................................58

Example ...........................................................................................................................59

Depth Profiling......................................................................................................................60

Parameters.....................................................................................................................60

How to Draw..................................................................................................................60

Example ...........................................................................................................................61

Multiple Method Drawing................................................................................................62

Sequence Editor ...................................................................................................................63

5Maintaining the Laser Ablation System ....................................................... 65

Safety Systems/Maintenance Schedule .....................................................................65

Safety System Inspection .................................................................................................66

Cooling System Maintenance..........................................................................................66

Periodic Checks of the Cooling System ................................................................67

Filling and Draining the Power Supply ...............................................................67

De-Ionizing Cartridge Maintenance (Inline Filter) ........................................69

De-Ionizing Cartridge Maintenance (Internal Filter) ...................................70

Internal Tubing Replacement.........................................................................................74

6Troubleshooting the Laser Ablation System.............................................. 75

Power System Problems...................................................................................................76

Fuses..........................................................................................................................................77

Interface Problems..............................................................................................................78

RS-232 Cable Problems..............................................................................................78

Stepper Interface Cable Problems.........................................................................78

Software Configuration Problems.........................................................................78

Safety Interlock Problems................................................................................................79

Laser module interlocks ............................................................................................79

Laser Controller Interlocks ......................................................................................79

Laser Problems.....................................................................................................................80

No Laser Output ...........................................................................................................80

Low Laser Efficiency ...................................................................................................81

Carrier Gas System..............................................................................................................82

Contamination ..............................................................................................................82

Returning the Product to CETAC for Service...........................................................83

Shipping the Product..................................................................................................83

Product Warranty Statement .................................................................................83

Returned Product Procedures.................................................................................84

Returned Product Warranty Determination ....................................................85

7Safety and Regulatory Information ............................................................... 87

Characteristics ......................................................................................................................87

Environmental Characteristics...............................................................................87

Safety Notices ........................................................................................................................89

Laser Safety....................................................................................................................89

U.S. Regulations – Class 1 Laser Product............................................................89

CETAC LSX-213 Operator’s Manual

Contents

6

CDRH Laser Product Regulations.......................................................................... 89

Coolant............................................................................................................................. 90

Ventilation...................................................................................................................... 90

Power Cord Set Requirements ................................................................................ 90

Power Cord Safety Maintenance ........................................................................... 90

Mains Disconnect......................................................................................................... 90

Cleaning Instructions ................................................................................................. 91

Operating Environment ............................................................................................ 91

Explanation of Caution and Warning Notices ................................................. 92

Avertissements en Français............................................................................................93

Electromagnetic Interference........................................................................................94

Explanation of Regulatory Marks.................................................................................95

8Glossary....................................................................................................................97

7

1Introduction

Overview

The CETAC LSX-213 Laser Ablation System is the next generation UV laser

ablation system from CETAC Technologies. The LSX-213 system features a

high-energy 213nm laser, with improved viewing optics and an improved

version of the operating software, DigiLaz™ III.

The LSX-213 system is a self-contained solid sampling accessory that can be

installed on any ICP-OES or ICP-MS.

Figure 1-1 The LSX-213 Laser Ablation System.

CETAC LSX-213 Operator’s Manual

Chapter 1: Introduction

8

The LSX-213 Laser Ablation System generates particulate aerosols from solid

material by an extremely rapid interaction between a high energy UV laser

pulse and the sample surface. This process is referred to as ablation. Adjusting

laser energy, spot size and pulse frequency using the DigiLaz III software

optimizes signal intensity and stability.

Ablated material is swept into the ICP-MS or ICP-OES by the helium carrier gas.

Many types of samples can be analyzed using laser ablation sample

introduction including glasses, coatings, refractory materials, powders,

ceramics, geological samples, process materials and polymers.

Some of the features of the LSX-213 Laser Ablation System include:

Ultraviolet laser, >4 mJ at 213 nm with a pulse width of < 6 nsec

Low ppb detection limits possible with ICP-MS

Ultra-stable laser system, < 1% RMS

Q-switched control of laser frequency, 1-20 Hz

User-friendly DigiLaz III software with on screen sample viewing and host

ICP computer integration

Microstepping X-Y-Z translation stage with 0.25 µm step size

Additional sampling methods for additional flexibility

Included thin-section or petrographic slide holder (grooved to accept

standard size slides)

New illumination system provides extraordinary lighting clarity in both

transmitted and reflected sample viewing

Fast auto-ramping sample navigation (no abrupt starts or stops while

moving)

Sample image and image map save, retrieval, and export

The LSX-213 system provides a means of rapid, direct analysis of solid samples

without dissolution and with minimal sample preparation. Ablation may be

performed on samples of electrically conductive or non-conductive materials.

Principles of Operation

Laser Ablation Processes

Laser ablation ICP-MS, as an analytical technique in itself, has been described

in books and review articles in detail; it is an ablation process in which a laser

is used as the primary energy source. When a laser beam of sufficient power

density strikes a solid material, it generates particle aerosols into the gas

phase. This ablation process is caused by the interaction of laser photons with

the solid material.

Typically, a solid sample is placed inside an enclosed chamber (the sample cell)

and a laser beam is focused on the surface of the sample. When the laser is

fired, a cloud of particles is produced. These particles are removed from the

sample cell by the helium carrier gas, and are swept into the ICP plasma for

atomization and ionization and subsequent analysis.

System Overview

The LSX-213 Laser Ablation System is a stand-alone unit supplied with a cart

for easy portability. The system includes the laser system and an external

power supply/chiller.

CETAC LSX-213 Operator’s Manual

Chapter 1: Introduction

9

The LSX-213 is shipped fully operational and is easily installed.

Hardware interlocks and other safety features are included in the laser and

power supply modules. These interlocks monitor the status of the entire

ablation system and will ensure that all safety contacts are closed and the

hookups are correct before the laser can be operated. The laser will

immediately switch off should any interlock be opened or in any other way

defeated.

Laser Ablation System

The LSX-213 employs a specially designed Nd:YAG laser, frequency quintupled

to the ultraviolet wavelength of 213 nm. These features provide a uniform

energy profile (“flat-top profile) across all spot sizes ranging 10 µm to 200 µm

and, consequently, a flat-bottomed crater on the sample. The aperture system

uses a motor driven ceramic wheel with six spot size choices that are accessed

within the laser software.

The laser can be operated at a high repetition rate of 20 Hz for increased

sampling efficiency, and thus provide better ICP-MS sensitivity and

importantly, the pulse repetition rate is controlled via the laser Q-switch. The

pulse repetition rate varies from 1–20 Hz.

The LSX-213 sampling cell is mounted on an X-Y-Z translation stage, with a

step size of 0.25 m.The translation stage provides X-Y positioning control for

laser targeting on the sample and is under computer control. The Z-axis of the

translation stage is used to focus the laser via the CCD camera viewing system.

The sample image is viewed directly in the DigiLaz III software. The interface

achieves superior optical viewing of the digital image created by the sample

(see Figure 1-2).

Since air is unavoidably admitted into the sampling cell when changing

samples, removing the air from the carrier gas flow path prior to switching

back to the ICP-MS is required to prevent plasma collapse. To purge the sample

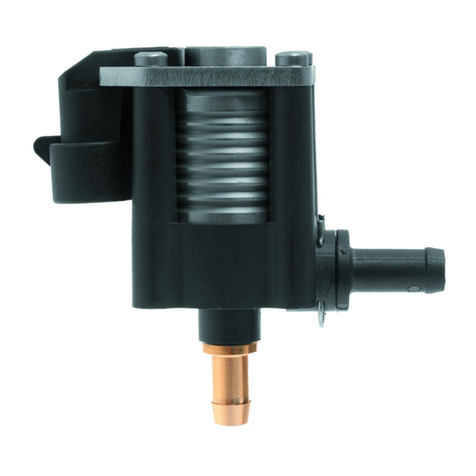

cell and prevent plasma collapse, the LSX-213 is equipped with 3-way

electrically actuated valves to direct the carrier gas flow to either the ICP-MS,

to a purge position or to a bypass position.

The CCD camera microscope system provides a means of visual identification

of the sample areas of interest and also for laser focusing. A digital crosshair is

an integral part of the digital image and can be adjusted depending on the

visual aspect of the samples. This crosshair provides a targeting mechanism

for the sample positioning at the point of laser impact.

CETAC LSX-213 Operator’s Manual

Chapter 1: Introduction

10

Figure 1-2 Sample Viewing Within the DigiLaz III software

Laser Head and Optics

The laser head is located in the upper chamber of the laser module. It is a

compact, rigid and stable-structured unit with a folded resonator geometry.

The opto-mechanical design of the Compact Folded Resonator (CFR) has

evolved over many generations of iterative refinements based on usage and

experience.

All of the optical elements are kept in precise relative alignment through

precision mounting techniques onto a single, stable optical table which is both

thermally and mechanically isolated from the rest of the system to minimize

any environmental influence on the laser or optics. The laser system used for

the LSX-213 system uses a liquid chiller which maintains a constant

temperature on the optical plate whether the unit is running at 100% or idle.

This results in unsurpassed laser stability and reliability.

Laser Characteristics

Frequency quintupled, Q-switched Nd:YAG laser, 213 nm

Spot size range: 10–200 µm (apertured)

>4mJ/pulse laser energy, 1% RSD, 1% RMS, computer controlled

Laser output energy is adjustable from 0–100%

Flat-top laser beam energy profile

Laser pulse width: < 6 nsec

Q-switch controlled laser frequency selection 1–20 Hz

CETAC LSX-213 Operator’s Manual

Chapter 1: Introduction

11

Viewing Optics and Video System

High intensity reflected and/or transmitted light illumination

Computer controlled focusing

5X, 40 mm focal length UV achromatic lens

Computer controlled polarizers for transmitted and reflected light

Thin-section holder for petrographic slides and other transparent samples

Real-time image acquisition at 1152 x 864 pixel resolution

Sampling System

Standard cell is 52 mm diameter by 52 mm high

Multiple cell types available to suit nearly any sample type

Quick release sample stage for easy sample exchange

Motorized X-Y-Z translation stage, 52 mm travel axis

0.25 µm step size, 0.05 µm resolution

3-stage motor drivers with manual override, auto-ramping up to 2 cm/sec

Adaptable volume, Teflon®and Viton™ construction

Automated valve system switches between cell purge, bypass, and online

modes

Ablation cell with removable quartz window for easy cleaning or

replacement

Computer Hardware and Software

The DigiLaz™ III software controls all laser functions and runs on the same

computer which controls the ICP for maximum ease of use

Compatible with the Microsoft Windows XP, Windows 2000, Vista, and

Windows 7 operating systems

Communication via serial port or USB

On-screen display of safety interlocks and laser status including laser firing,

door open, coolant temperature and flow interlocks

Universal communication protocol for synchronization of ICP-MS and laser

system using contact closure

Built-in laser ablation methods including multi-spot analysis, line scans and

raster, segmented line scanning, area scan and raster and advanced depth

profiling

Method/sequence saving, export and loading with sample image capture

and export. Method file management and text (*.txt) file management

access

Spot size and feature measurement functions

Single shot or automated repetition (burst or continuous mode)

Computer adjustable spot size using aperture focusing of the laser beam

CETAC LSX-213 Operator’s Manual

Chapter 1: Introduction

12

Automated video zoom and sample motion control

System Characteristics

Dimensions: Laser Module 69 x 46 x 51 cm

Weight: approximately 57 kg (125 pounds)

Power supply:20 x 30 x 37 cm

Power requirement: 100-250 VAC +/- 10%

Class 1 enclosure with safety interlocks

Independent programmable laser power supply module

Closed loop water cooling system with integrated DI cartridge

Options

GeoPro™ data handling software for geological analysis and transient data

collection

Custom designed sampling cells, oversize cell, document cell, core cell,

small sample cell. Inquire about custom designs

Laser and High Voltage Safety Features

The LSX-213 system has built in safety interlocks to disable the laser in the

event the cover is opened or the front door is opened during operation.

Another interlock on the laser power supply deactivates the laser if its

cover is opened during operation.

The laser power supply is controlled by a key switch and the key can be

removed only when the switch is in the OFF position to prevent unintended

operation.

Laser Ablation System Components

The LSX-213 Laser Ablation System is composed of the following components.

LSX-213 Module. The laser module contains the laser itself, all optics,

apertures, lighing etc. The sample cell on the translation stage is accessible

through the door and is pulled forward for easy access to the sample cell.

Power Supply. The LSX-213 power supply and integrated laser head

cooling unit contains all electronics for interfacing with the LSX-213 system

and safety interlocks for the laser head.

Host Computer. The control computer, whether integrated into the ICP

computer or a stand alone laser specific computer, executes the LSX-213

DigiLaz III software. The user-programmable software issues commands

that control LSX-213 functions, such as X-Y-Z sample positioning, laser

firing mode, laser power, CCD camera digital zoom, sample cell illumination

level, and sample cell purge/ICP argon flow control. System safety and laser

firing status are also monitored and displayed.

Host Computer Monitor. The real-time sample image and software

controls are displayed on the monitor.

CETAC LSX-213 Operator’s Manual

Chapter 1: Introduction

13

NOTE:

Please contact CETAC Technologies (800-369-2822, 402-733-2829) if you need

additional accessories not listed, need added features to integrate the LSX-213

Laser Ablation system into your analytical system, or have unique

requirements. Research and development of new features and accessories for

the LSX-213 Laser Ablation System are inspired by customer requests, and

responding to such requests is a continuing activity of CETAC Technologies.

Who Should Use This Product—Operator

Qualifications

The laser ablation system, along with this book, is intended for use analytical

chemists and lab technicians. To use this product safely and effectively, at least

a beginning level of knowledge and experience about laser safety, electrical/

electronic equipment operation and maintenance, personal computers and

ICP-MS or ICP-OES are required.

CHEMICAL INJURY HAZARD

The autosampler is intended for use only by qualified operators who have

been trained in safe laboratory practices. Make sure you know the hazards

associated with all of the chemicals you are using, and take the appropriate

precautions. Exposure to laboratory chemicals may result in serious injury.

Where to Go for More Information

New versions of this manual may be available under “Service and Support” on

CETAC’s Web site:

www.cetac.com

In addition to theLSX-213 Laser Ablation System Operator’s Manual, you can

refer to the following resources for citation material or for further information:

“Safe Use of Lasers" (Z136.1)

American National Standards Institute (ANSI)

11th West 42nd Street

New York, NY 10036

Phone: (212) 642-4900

www.ANSI.org

"A Guide for Control of Laser Hazards" (Publication 0165)

American Conference of Governmental and Industrial Hygienists (ACGIH)

6500 Glenway Avenue, Bldg. D-7

Cincinnati, OH 45211

Phone: (513) 661-7881

www.ACGIH.org

Occupational Safety and Health Administration (OSHA)

WARNING

CETAC LSX-213 Operator’s Manual

Chapter 1: Introduction

14

U.S. Department of Labor

200 Constitution Avenue NW

Washington, DC 20210

Phone: (202) 523-8148

www.OSHA.gov

"Performance Standards for Laser Products"

United States Code of Federal Regulations

21 CFR 1040.10(d) and 1040.11.

The CETAC LSX-213 Laser Ablation System Service Manual.

CETAC Technologies Customer Service and Support:

Phone: 1 (800) 369-2822 (USA only)

1 (402) 733-2829

Fax: 1 (402) 733-1932

E-mail: custserv@cetac.com

Preparing for Installation

Ventilation

Allow at least 5 cm clearance on all sides of the instrument for ventilation.

Do not operate the instrument if the cooling fans are blocked or obstructed in any

manner.

CAUTION

15

2Using the LSX-213

Laser Ablation

System

The LSX-213 system is both reliable and easy to use. Before using the LSX-213

system, however, ensure that your lab environment provides operating

conditions that will prolong the life of the LSX-213 system. Once the proper

operating conditions are met, you can load samples and perform analysis with

the laser ablation system.

This chapter explains how to create the proper operating conditions for using

the LSX-213 system. It also explains laser safety precautions, how to prepare

and load the samples, start and shut down the laser ablation system, analysis

procedures and initial operating parameters.

Establishing Optimal Operating Conditions

The LSX-213 system operates reliably even under less than ideal conditions. It

is not, however, indestructible. Malfunction or damage can occur if specific

operating conditions are not met. Meeting these conditions requires that you

create the proper lab environment, replace laser ablation system components

that wear out under normal use and purchase the appropriate supplies for use

with the laser ablation system. The following sections explain how to meet

these conditions.

NOTE:

Damage or malfunction that results from unsatisfactory operating conditions

may constitute misuse and abuse and be excluded from warranty coverage.

CETAC LSX-213 Operator’s Manual

Chapter 2: Using the LSX-213 Laser Ablation System

16

Creating the Lab Environment

To create satisfactory operating conditions in your lab environment, follow

these guidelines:

Operate the LSX-213 system in a conventional lab environment where the

temperature is 50–85 °F (10–30 °C); the humidity is 20–70%

non-condensing; and the unit is not exposed to excessive flammable or

corrosive materials.

Avoid rough handling of the LSX-213 system. Do not expose the laser

ablation system to vibration or shock.

Protect the LSX-213 system from long-term exposure to condensation,

corrosive materials, solvent vapor, standing liquids, liquid spills into the

electrical equipment or operation inside an acid hood or glove box.

Exposures of this type can degrade the optics, corrode and damage

mechanical drive mechanisms, as well as the electronics.

Observe the same general electrostatic discharge precautions as with any

other integrated circuit electronic devices. Low humidity environments,

especially when combined with static-generating materials, require

maximum care.

Discharge static buildup and ground to the laser ablation system base or LSX-213

system cabinet before performing any maintenance. Do not touch or short-circuit

bare contacts of any communications ports.

Avoid exposing the LSX-213 system to high levels of electromagnetic or

radio frequency interference (EMI/RFI), or radioactivity. EMI/RFI can

cause erratic operation, high levels of radioactivity may cause electronic

component failure, and will prohibit factory repair if so contaminated.

Contact CETAC Technologies for assistance if the LSX-213 system will be

required to operate in a hostile environment.

CAUTION

CETAC LSX-213 Operator’s Manual

Chapter 2: Using the LSX-213 Laser Ablation System

17

Replacing Laser Ablation System Components

The following LSX-213 system components wear out, or become contaminated

under normal use, and must be replaced periodically.

System Tubing

Chiller water

Laser flashlamp

Chiller de-ionizer

If you fail to replace these components when they deteriorate, the laser

ablation system will not function properly.

Purchasing Supplies

Because the usage rate of consumable materials and the life span of

expendable components will vary, you should maintain an adequate supply of

spares. When you need to purchase additional supplies, it is important that

you choose the appropriate components and materials. A one-year

consumables kit is available from CETAC.

When you purchase replacement parts or consumable supplies, make sure

they meet the following requirements:

Use only distilled water (not 18MΩ laboratory water, bottled distilled water

works best) when changing coolant. Tap water or any other coolant will

leave deposits in the cooling system, may damage the cooling unit or laser

head, or cause other malfunctions.

Do not attempt to use a substitute laser flashlamp; otherwise, leakage and

laser head damage will result. Service only with an exact replacement.

Only a factory trained service engineer should do laser flashlamp replacement.

Contact CETAC Technologies at 800-369-2822 or 402-733-2829 for more

information, or a certified laser system technician.

Use of unsuitable coolants, consumable supplies or inferior replacement

parts may result in laser ablation system malfunctions, ICP malfunctions,

invalid analysis results or hazardous conditions. Be sure all replacements

meet the specified requirements.

To order additional supplies, contact the CETAC Technologies Customer

Service department.

CAUTION

WARNING

CETAC LSX-213 Operator’s Manual

Chapter 2: Using the LSX-213 Laser Ablation System

18

Connecting the Laser Ablation System

Two people are required to lift the unit. Lifting should be done with a

person situated on either side of the instrument.

Connections to the Host Computer

Assuming that the LSX-213 has been installed by a qualified CETAC

representative, the electronic connections from the host computer to the LSX-

213 should already be in place. These include the 52-pin control cable, the

RS232 cable to COM 1 (or USB if desired) and the BNC coaxial video cable from

the video card on the computer to the video out port on the back of the LSX. If

the system is being self-installed, contact your CETAC representative for

detailed installation instructions.

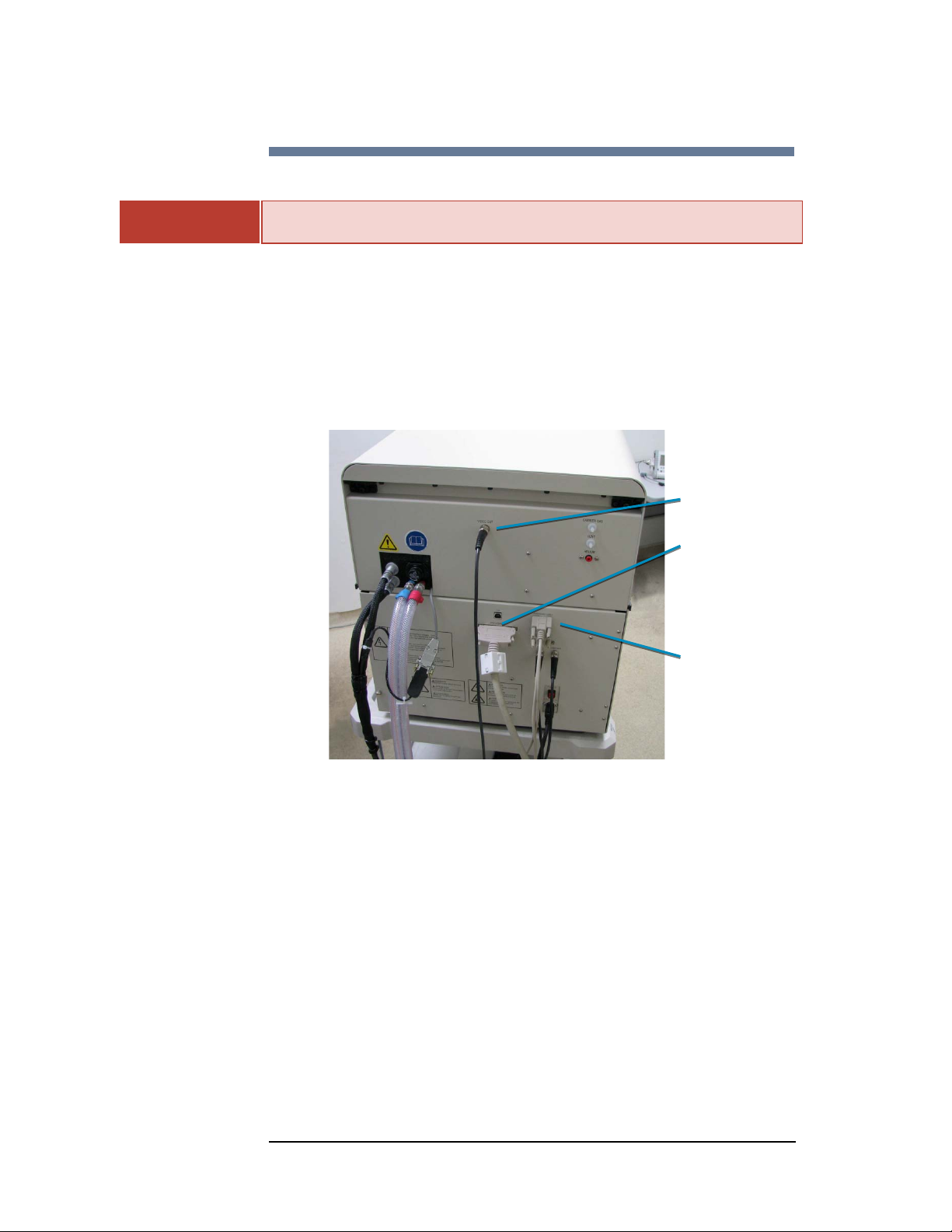

Figure 2-1 Connections to Host Computer

WARNING

Video Out

(to Converter)

52-Pin Control Cable

RS232 Serial Data

CETAC LSX-213 Operator’s Manual

Chapter 2: Using the LSX-213 Laser Ablation System

19

Figure 2-2 Host Computer

Connections to the Power Supply/Cooler

Likewise, all connections between the Laser and the power supply should be in

place including the water lines, the primary power cable connecting the power

supply and laser, the RS232 cable from the power supply to the laser, the BNC

coaxial connecting the “remote link” connector on the power supply to the

“Laser Safe” connector on the laser and another BNC cable connecting the “Q-

switch sync” on the power supply to “Q-switch” on the laser.

Figure 2-3 Connections to Power Supply/Cooler

Laser Power from

Power Supply

Serial Connection from

Power Supply

Electronics Power

from Power Supply

Q-Switch and

Laser Safe from

Power Supply

Coolant from

Power Supply

USB-Mouse and Keyboard

52-Pin Control Cable

RS232 Serial Data

USB-Video to PC

USB-

Video to PC

Video from LSX-213

CETAC LSX-213 Operator’s Manual

Chapter 2: Using the LSX-213 Laser Ablation System

20

Figure 2-4 Power Supply/Cooler

Gas Connections

The LSX-213 uses both argon and helium during operation. The argon source

is from the nebulizer gas from the host ICP. Using the tubing and fittings

supplied to connect the nebulizer gas out port on the ICP to the “Argon” port on

the back of the LSX-213. For the helium connection, use the supplied fittings to

connect 1/8” tubing from the source to the push fitting on the rear of the laser.

The vent port may be left open to atmosphere unless very hazardous material

is being used which would require complete containment of residual sample

material.

Figure 2-5 Gas Connections

Using the Laser Ablation System

Front Panel Indicators

Status Indicator: LED located on upper front left of the LSX-213 system.

Informs the operator of the current instrument conditions as follows:

Argon In

(Nebulizer Gas)

Argon Out

(To Analytical

Instrument)

Helium In

Coolant Out

Coolant In

Laser Power, Electronics

Power, and Serial Connection

Table of contents

Other CETAC Laboratory Equipment manuals

CETAC

CETAC ASXpress User manual

CETAC

CETAC ASX-260 User manual

CETAC

CETAC ASXPRESS PLUS User manual

CETAC

CETAC ASX-520 Use and care manual

CETAC

CETAC ASX-520 User manual

CETAC

CETAC ASX-500 Series User manual

CETAC

CETAC ASX-510 Guide

CETAC

CETAC ASX-1400 User manual

CETAC

CETAC ASX-520 Instruction Manual

CETAC

CETAC ASXPRESS PLUS User manual

Popular Laboratory Equipment manuals by other brands

Keysight

Keysight N777-C Series user guide

ThermoFisher Scientific

ThermoFisher Scientific invitrogen Countess 3 user guide

Edvotek

Edvotek Mezzo 533 manual

Stag

Stag AC W03 user manual

Thermo Scientific

Thermo Scientific Dionex IonPac AS31 product manual

VistaLab

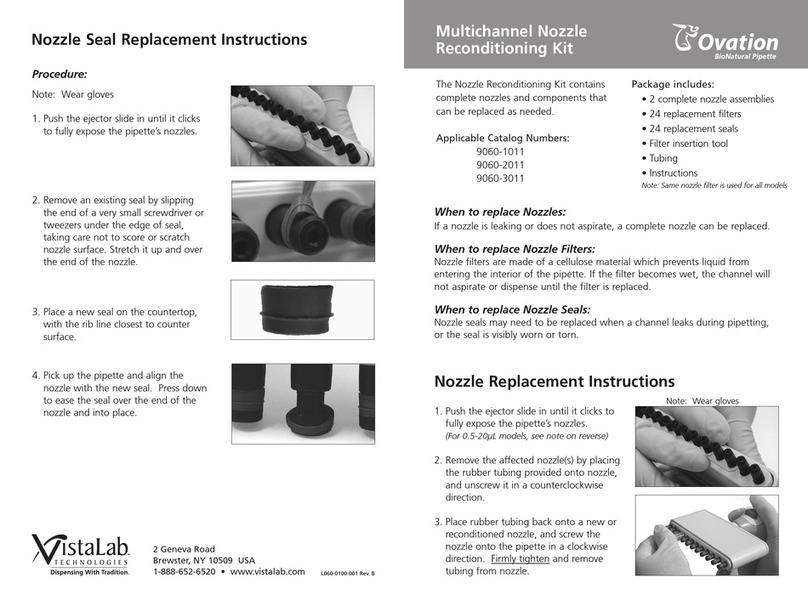

VistaLab Ovation 9060-1011 Replacement instructions