CETAC ASX-260 User manual

ASX-260 Auto Sampler Operator’s

Manual

Product Warranty Statement

SD Acquisition, Inc., DBA CETAC Technologies (“CETAC”) warrants

any CETAC unit manufactured or supplied by CETAC for a period of

twenty five (25) months from the date of shipment. Units found in the

reasonable judgment of CETAC to be defective in material or

workmanship will be repaired or replaced by CETAC without charge for

parts and labor. CETAC reserves the right to change or improve the

design of any unit without assuming any obligation to modify any unit

previously manufactured.

This warranty does not cover any unit that has been subject to misuse,

neglect, negligence, or accident. The warranty does not apply to any

damage to the unit that is the result of improper installation or

maintenance, or to any unit that has been operated or maintained in

any way contrary to the instructions specified in the CETAC instruction

and operation manual. Operation of the CETAC unit inside a

laboratory fume hood is contra-indicated and will void the warranty.

Any attempt to repair or alter any CETAC unit by anyone other than by

CETAC authorized personnel or agents will void this warranty. If any

non-CETAC component is installed in the CETAC manufactured unit

without the approval of CETAC, the warranty will be voided. In

addition, this warranty does not extend to repairs made necessary by

the use of parts, accessories or fluids which are either incompatible with

the unit or adversely affect its operation, performance or durability.

CETAC’s obligation under this warranty is strictly and exclusively

limited to repair or replacement of defective CETAC parts and no claim

of breach of warranty shall be cause for cancellation or rescission of the

contract of sale of any unit.

The foregoing express warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability and

fitness for a particular purpose. CETAC shall not be bound by any

representations or statements on the part of its employees or agents

whether oral or in writing and including any made in catalogues and

other promotional material including technical details and

specifications except where such representations and statements are

expressly made part of this contract. CETAC assumes no responsibility

for incidental, consequential or other damages, even if advised of such a

possibility, including but not limited to loss or damage of property, loss

of revenue, loss of use of the unit, loss of time, or inconvenience.

CETAC’s liability on any claim for loss or damage arising out of the

sale, resale or use of any of its products shall in no event exceed the

selling price of the unit.

Purchaser shall indemnify CETAC against any claim or liability which

may be asserted as relates to the following: (i) the use to which any

product supplied hereunder is put infringes the patent, copyright or

other intellectual property rights of any third party; or (ii) any liability

resulting from the failure by Purchaser to observe the terms of this

Warranty.

Returned Product Procedures

Claims for shipment damage (evident or concealed) must be filed with

the carrier by the buyer. CETAC must be notified within ninety (90)

days of shipment of incorrect materials. No product may be returned,

whether in warranty or out of warranty, without first obtaining

approval from CETAC. No replacements will be provided nor repairs

made for products returned without such approval. Any returned

product must be accompanied by a return authorization number. The

expense of returning the unit to CETAC for service will be paid by the

buyer. The status of any product returned later than thirty (30) days

after issuance of a return authorization number will be subject to

review. Shipment of repaired products will generally be made forty

eight (48) hours after the receipt.

Products may not be returned which are contaminated by radioactive

materials, infectious agents, or other materials constituting health

hazards to CETAC employees.

Returned Product Warranty Determination

After CETAC’s examination, warranty or out of warranty status will be

determined. If a warranted defect exists, the product will be repaired

at no charge and shipped prepaid back to the buyer. If the buyer

desires an air freight return, the product will be shipped collect.

Warranty repairs do not extend the original warranty period.

If an out of warranty defect exists, the buyer shall be notified of the

repair cost. At such time the buyer must issue a valid purchase order

to cover the cost of repair and freight, or authorize the products to be

shipped back as is, at the buyer’s expense. Failure to obtain a purchase

order number approval within fifteen (15) days of notification will

result in the products being returned as is, at the buyers expense.

COPYRIGHT

Copyright 204-2012 CETAC Technologies

480123 Version 1.1, March, 2012

REPRODUCTION

All rights reserved. Reproduction or

transmission of this document in whole or

in part, and by any means without the

express written consent of the copyright

owner or authorized agent is prohibited.

Requests for additional copies of this, or

any other CETAC publication, can be

filled by contacting an authorized

distributor or

CETAC Technologies

Customer Service & Support

14306 Industrial Road

Omaha, Nebraska 68144, USA

Phone (800) 369-2822 (USA only)

Phone (402) 733-2829

Fax (402) 733-1932

E-mail custserv@cetac.com

DISCLOSURE

This document contains CETAC

proprietary data and is provided solely to

its customers for their express benefit of

safe, efficient operation and maintenance

of the product described herein. Use or

disclosure of CETAC proprietary data for

the purpose of manufacture or

reproduction of the item described herein,

or any similar item, is prohibited, and

delivery of this document shall not

constitute any license or implied

authorization to do so.

REVISIONS

CETAC Technologies strives to provide

the scientific community with an

unparalleled combination of effective

technology and continuing value.

Modular upgrades for existing

instruments will continue to be a prime

consideration as designs progress.

CETAC Technologies reserves the right to

revise this document and/or improve

products described herein at any time

without notice or obligation. Warranty

registration entitles the named owner

exclusively to manual change pages/new

editions as they are published.

SAFETY

Instruments, accessories, components or

other associated materials may not be

returned to CETAC Technologies if

contaminated with biohazard or

radioactive materials, infectious agents, or

any other materials and/or conditions that

could constitute a health or injury hazard

to CETAC employees. Call Customer

Service and Support if there is any

question or doubt relative to

decontamination requirements.

CAUTION and WARNING statements, as

applied in this document, shall be

interpreted consistent with the following

context: CAUTION applies only to

potential property damage conditions;

WARNING applies to potential personal

injury conditions, in combination with or

exclusive of potential property damage.

WARNING

The handling of organomercurial

concentrates which may be used in the

preparation of process standards presents

a substantial (potentially lethal) safety

hazard. Only an experienced,

professionally trained organo-metallic

chemist, knowledgeable and skilled

specifically in the safe handling of

organomercurials (using approved

apparatus and approved protection

measures in an approved facility) should

attempt to prepare diluted

organomercurial process standards from

concentrates.

NOTE

SD Acquisition, Inc., DBA CETAC

Technologies assumes no liability for the

handling of organomercurial concentrates

or the preparation, handling, or use of

diluted organomercurial process

standards. Instead

All user-serviceable components are

specifically identified in this document as

such; the balance shall be assumed to

, CETAC Technologies

recommends use of appropriate standard

reference materials to validate sample

preparation (dissolution/digestion) and

use of inorganic mercury standards for

instrument calibration.

require the expertise of a factory service

technician/engineer for adjustment,

repair, replacement, modification, etc.

Others not so qualified and performing

these actions shall do so at their own risk.

ORIGINAL PACKAGING

Furthermore, never operate the

instrument without first reading and

understanding the ASX-260 Operator’s

Manual and ensuring that it is operated

safely and properly.

Retain original factory packaging for

moves and factory return shipments.

Shipping in anything other than the

original fitted foam and container can

result in incidental damage from which

the purchaser will not be protected under

warranty.

Under all conditions the user must observe safe laboratory

procedures during the operation of this product.

WARNING

Operator’s Manual Addendum

Notices and Compliance Declarations

AD-1

FEDERAL COMMUNICATIONS

COMMISSION (FCC) NOTICE

This equipment has been tested and found

to comply with the limits for a Class A

digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to

provide reasonable protection against

harmful interference in a commercial

installation.

This equipment generates, uses, and can

radiate radio frequency energy and, if not

installed and used in accordance with the

instructions, may cause harmful

interference to radio communications.

Operation of this equipment in a

residential environment is likely to cause

harmful interference, in which case the

user will be required to correct the

interference at his own expense.

MODIFICATIONS

The FCC requires the user to be notified

that any changes or modifications made to

this device that are not expressly approved

by CETAC may void the user's authority to

operate the equipment.

CABLES

Connections to this device must be made

with shielded cables with metallic RFI/EMI

connector hoods to maintain compliance

with FCC Rules and Regulations.

CANADIAN NOTICE

This digital apparatus does not exceed the

Class A limits for radio noise emissions

from digital apparatus as set out in the

interference-causing equipment standard

entitled "Digital Apparatus." ICES-003 of

the Department of Communications.

AVIS CANADIEN

Cet appareil numerique respecte les

limites de bruits radioelectriques

applicables aux appareils numeriques de

Classe A prescrites dans la norme sur le

materiel brouilleur: "Appareils

Numeriques," NMB-003 edictee par le

ministre des Communications.

Operator’s Manual Addendum

Notices and Compliance Declarations

AD-2

POWER CORD SET REQUIREMENTS

The power cord set supplied with your

instrument meets the requirements of the

country where you purchased the

instrument.

If you use the instrument in another

country, you must use a power cord set

that meets the requirements of that

country.

This equipment is designed for connection to a grounded (earthed) outlet. The

grounding typeplug is an important safetyfeature. To reduce the risk ofelectrical

shock or damage to the instrument, do not disable this feature.

To reduce the risk of fire hazard and electrical shock, do not expose the unit to rain or

humidity. To reduce the risk of electrical shock, do not open the cabinet. All maintenance

is to be performed by an Authorized CETAC Service Provider.

Protection provided by the equipment may be impaired if the equipment is used in a

manner not specified by the manufacturer.

CLEANING INSTRUCTIONS

To clean the exterior surfaces of the instrument, complete the following steps:

1

Shut down and unplug the instrument.

2

Wipe the instrument exterior surfaces

only using a towel dampened with a

lab-grade cleaning agent.

3

Repeat step 2, using a towel dampened

with clear water.

4

Dry the instrument exterior using a dry

towel.

Do not allow any liquid to enter the instrument cabinet, or come into contact with

any electrical components. The instrument must be thoroughly dry before you

reconnect power, or turn the instrument on.

COOLING FAN OBSTRUCTION

The instrument cooling fan(s) shall remain unobstructed at all times. Do not operate the

instrument if the cooling fan(s) are blocked or obstructed in any manner.

ENVIRONMENTAL

Operating Temperature: 10°to 30°C

Relative Humidity 0% to 95%

Altitude 0 to 10000 Ft

WARNING

CAUTION

WARNING

Operator’s Manual Addendum

Notices and Compliance Declarations

AD-3

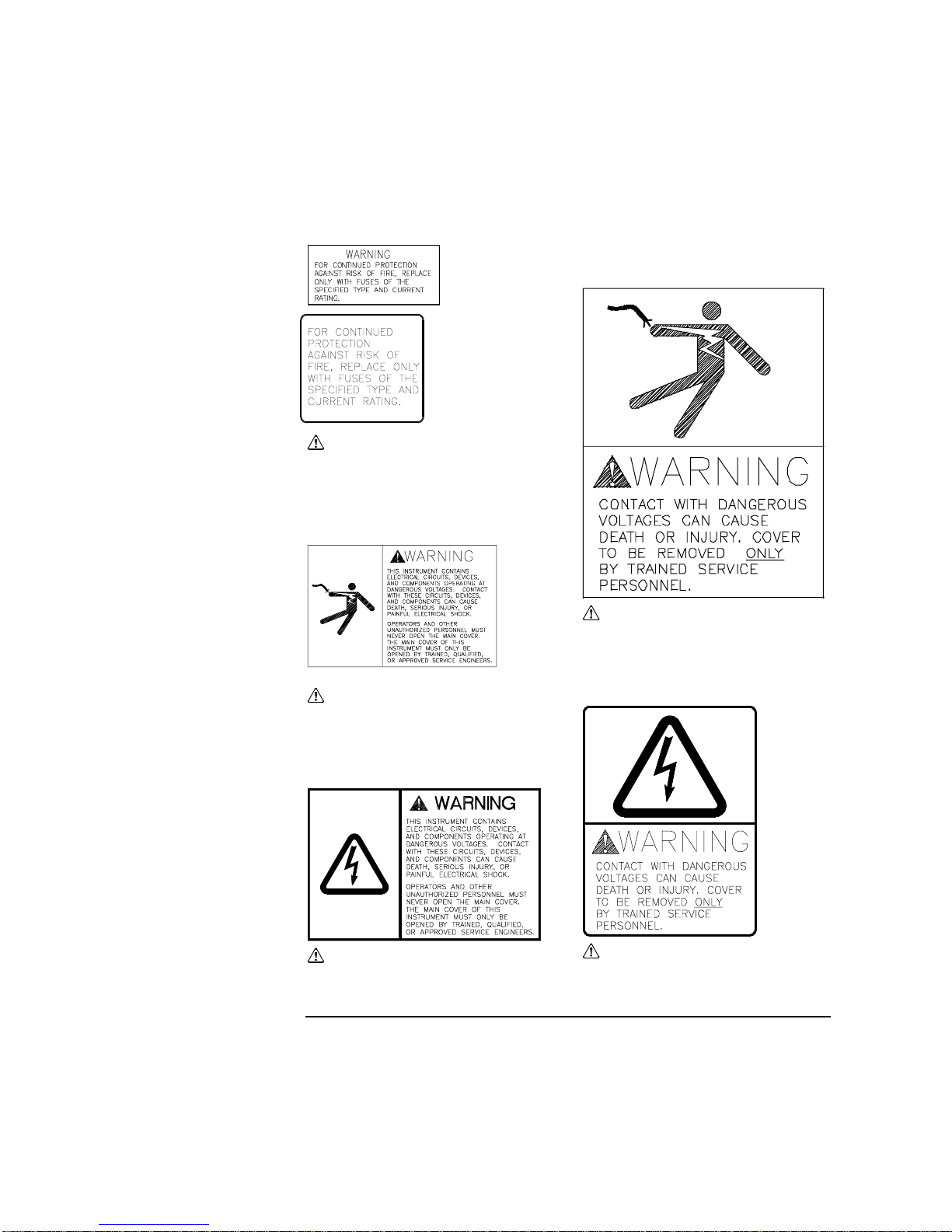

AVERTISSEMENT

POUR UNE PROTECTION CONTINUÉ

CONTRE LES RISQUES D’INCENDIE,

REMPLACER UNIQUEMENTPAR DES

FUSIBLES DE MÊME TYPE ET

AMPÈRAGE.

AVERTISSEMENT

TOUT CONTACT AVEC LES HAUTES

TENSIONS PEUT ENTRAINER LA MORT

OU DES BLESSURES SÉVÈRES. CE

PANNEAU NE DOIT ÊTRE ENLEVE QUE

PAR UN RÉPARATEUR QUALIFIÉ.

AVERTISSEMENT

TOUT CONTACT AVEC LES HAUTES

TENSIONS PEUT ENTRAINER LA MORT

OU DES BLESSURES SÉVÈRES. CE

PANNEAU NE DOIT ÊTRE ENLEVE QUE

PAR UN RÉPARATEUR QUALIFIÉ.

AVERTISSEMENT

TOUT CONTACT AVEC LES HAUTES

TENSIONS PEUT ENTRAINER LA MORT

OU DES BLESSURES SÉVÈRES. CE

PANNEAU NE DOIT ÊTRE ENLEVE QUE

PAR UN RÉPARATEUR QUALIFIÉ.

AVERTISSEMENT

TOUT CONTACT AVEC LES HAUTES

TENSIONS PEUT ENTRAINER LA MORT

OU DES BLESSURES SÉVÈRES. CE

Operator’s Manual Addendum

Notices and Compliance Declarations

AD-4

Pinch point on X, Y, Z axis movement.

Attention –refer to the manual. This symbol

indicates that information about usage of a

feature is contained in the manual.

WARNING

If the auto sampler is used in a manner not specified by CETAC

Technologies, the protection provided the equipment may be

WARNING

The power switch on the rear panel is not the mains disconnect.

Mains disconnect is accomplished by disconnecting the detachable

power supply cord at the appliance coupler or at the mains plug.

Ensure the power cord is easily accessible and removable, in the

event of an emergency, which requires immediate disconnection.

PANNEAU NE DOIT ÊTRE ENLEVE QUE

PAR UN RÉPARATEUR QUALIFIÉ.

AVERTISSEMENT

COURANT DE FUITE ÉLEVÉ — FORNIR

UNE MISE À LA TERRE EFFICACE.

WARNING

HIGH LEAKAGE CURRENT -

ENSURE PROPER GROUNDING

Operator’s Manual Addendum

Notices and Compliance Declarations

AD-5

CAUTION

The CAUTION notice denotes a hazard. It calls attention to a

procedure, practice, or the like, that, if not correctly performed or

adhered to, could result in personal injury. Do not proceed beyond a

CAUTION notice until the indicated conditions are fully understood

and met.

WARNING

This is a Safety Class 1 Product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall only be

inserted in a socket-outlet provided with a protective earth contact.

Intentional interruption is prohibited.

Safety Maintenance

The operator should check the detachable power supply cord

condition. The equipment should not be operated if the mains inlet is

cracked or broken. Any obvious damage to the case (from a drop or

fall) should be checked by service personnel for loose or damaged

parts. See individual parts lists for approved replacement parts.

Safety and Regulatory Information

Review this product and related documentation to familiarize with

safety markings and instructions before you operate the instrument.

WARNING

The WARNING notice denotes a hazard. It calls attention to a

procedure, practice, or the like, that, if not correctly performed or

adhered to, could result in personal injury. Do not proceed beyond a

WARNING notice until the indicated conditions are fully understood

Operator’s Manual Addendum

Notices and Compliance Declarations

A

D-6

WARNING

Ensure that power is diconnected before removal of any covers.

DC Voltage and Current

24V

3.33A

AC Voltage and Current

100-240V ~

47-63Hz 1.9A

TM of the European community

Other Fuse(s) – The equipment

uses one 2A 250V AC fuse which

Is not operator replaceable.

WARNING

Equipment is not intended for wet locations. Miscellaneous liquids in the

e

q

ui

p

ment could cause hazardous conditions.

WARNING

Pollution Degree - 1

WARNING

Do not o

p

erate in ex

p

losive atmos

p

here.

WARNING

A

ll terminals allow a maximum current of 500MA @ 24VDC.

NOTE: For instructions on how to return end-of-life

equipment, producer-supplied electrical accessories, or

auxiliary items for proper disposal please contact the

supplier or importer. In the event a supplier cannot be

reached, contact CETAC Technologies customer service

de

p

artment at 1

(

800

)

369 2822.

Contents

Contents

Preface xii

Who Should Read This Book xii

How to Use This Book xii

Conventions Used in This Book xiii

Instructions xiii

Menu Items xiv

Terminology xiv

Notes xv

Cautions xv

Warnings xv

Where to Go for More Information xvi

1Introduction 1–2

Auto Sampler Standard Components 1–2

Optional Accessories 1–6

2 Preparing for Installation 2–2

Choosing a Location 2–2

Space Requirements 2–2

Water Requirements 2–2

Power Requirements 2–3

Unpacking the ASX-260 2–4

ASX-260 Auto Sampler Operator’s Manual

Contents

vii

3 Installing the Auto Sampler 3–2

Mounting the Z-Drive Assembly 3–3

Attaching the Z-drive Assembly to the

Auto Sampler Arm 3–4

Attaching the Z-drive Mounting Blocks 3–4

Installing the Sample Probe 3–6

Setting the Z-Axis Travel 3–7

Connecting the Rinse Station 3–9

Pumped Drain Arrangement 3–10

Gravity Drain Arrangement 3–12

Assembling and Placing the Sample Vial Racks 3–14

Establishing External Connections 3–15

Connecting the Auto Sampler to the Power Source 3–16

Connecting the Auto Sampler to an Analytical Instrument 3–16

Connecting the ASX-260 Auto Sampler

to the Host Computer 3–16

Establishing a Serial Communications Interface 3–18

Establishing an IEEE Communications Interface 3–19

4 Verifying Installation 4–2

Testing the Interface 4–2

ASX-260 Auto Sampler Operator’s Manual

Contents

viii

Checking the Auto Sampler Components 4–6

Testing the Sample Probe 4–6

5 Using the Auto Sampler 5–2

Establishing Optimal Operating Conditions 5–2

Creating the Lab Environment 5–3

Replacing Auto Sampler Components 5–4

Purchasing Supplies 5–4

Arranging the Sample Vial Racks 5–5

Starting the Auto Sampler 5–5

Shutting Down the Auto Sampler 5–7

Flushing the Rinse Station and Flow Path 5–7

6 Maintaining the Auto Sampler 6–2

Cleaning the Auto Sampler 6–2

Daily External Cleaning 6–3

Weekly Cleaning 6–3

Checking for Leaks 6–5

Replacing Peristaltic Pump Tubing 6–6

Replacing the Sample Probe 6–7

Replacing the Rinse Station Tubing 6–7

Replacing the Sample Tray 6–8

ASX-260 Auto Sampler Operator’s Manual

Contents

ix

7 Troubleshooting the Auto Sampler 7–2

Power System Problems 7–2

Interface Problems 7–3

RS-232 Cable Problems 7–3

Software Configuration Problems 7–3

Z-Drive Assembly Problems 7-4

Glossary G–2

Preface

Preface

The ASX-260 Auto Sampler Operator’s Manual explains the procedures

for installing, using, and maintaining the CETAC ASX-260. It also

provides information about troubleshooting ASX-260 problems and

describes the design of the Auto Sampler.

Who Should Read This Book

The primary audience for the ASX-260 Operator’s Manual consists of

analytical chemists and lab technicians. To use this manual effectively,

you should have a strong knowledge of chemistry, a basic knowledge of

electronic sampling equipment, at least a beginning level of computer

experience, and working knowledge of the analytical instrument being

used with the ASX-260.

How to Use This Book

The ASX-260 Auto Sampler Operator’s Manual contains seven

chapters. You should read the chapters sequentially the first time.

Thereafter, refer to the chapters separately as needed. The first

chapter provides an introduction to the Auto Sampler. Subsequent

chapters detail the primary tasks associated with the ASX-260.

This manual contains the following chapters:

Chapter 1, “Introduction,”

provides you with an overview of the

ASX-260 Auto Sampler’s function and design.

Chapter 2, “Preparing for Installation,”

discusses space and power

requirements that must be met before the ASX-260 is installed. It also

provides instructions for unpacking the Auto Sampler.

ASX-260 Auto Sampler Operator’s Manual

Preface

xiii

Chapter 3, “Installing the Auto Sampler,”

provides step-by-step

procedures for installing the ASX-260 and connecting it to the

analytical instrument.

Chapter 4, “Verifying Installation,”

explains how to test the

communications interface between the ASX-260 and the host computer.

It also explains how to check Auto Sampler components and test the

sample probe.

Chapter 5, “Using the Auto Sampler,”

describes the tasks you

perform during daily operation of the ASX-260.

Chapter 6, “Maintaining the Auto Sampler,”

explains daily,

weekly, and periodic maintenance tasks.

Chapter 7, “Troubleshooting the Auto Sampler,”

describes how to

diagnose and correct ASX-260 problems.

These chapters are followed by a glossary of related terms.

Conventions Used in This Book

This book uses certain conventions to distinguish different types of

information easily. This section describes these conventions.

Instructions

All step-by-step instructions are numbered and in bold, as in the

following example.

1 Replace the sample vial racks.

Many numbered instructions are followed by more detailed

explanations.

ASX-260 Auto Sampler Operator’s Manual

Preface

xiv

Menu Items

This book uses the following format for referring to menu items:

Settings»Communication

The text before the arrow symbol is the name of the menu; the text

after the arrow symbol is the menu choice. This example refers to the

Communications menu choice in the Settings menu.

Terminology

This book frequently uses the following terms:

ASX-260

The ASX-260 Auto Sampler.

Host computer

The computer that controls operation of the ICP-AES

or ICP-MS instrument to which the Auto Sampler is

attached.

Hz

Hertz.

ICP-AES

An inductively coupled plasma atomic emission

spectrometer.

ICP-MS

An inductively coupled plasma mass spectrometer.

ID

Inside diameter.

LED

Light-emitting diode.

PEEK

Polyetheretherketone.

VAC

Volts alternating current.

VDC

Volts direct current.

Table of contents

Other CETAC Laboratory Equipment manuals

CETAC

CETAC ASXPRESS PLUS User manual

CETAC

CETAC ASX-1400 User manual

CETAC

CETAC ASXPRESS PLUS User manual

CETAC

CETAC LSX-213 User manual

CETAC

CETAC ASXpress User manual

CETAC

CETAC ASX-510 Guide

CETAC

CETAC ASX-520 Instruction Manual

CETAC

CETAC ASX-510 Guide

CETAC

CETAC ASX-520 Use and care manual

CETAC

CETAC ASX-520 User manual

Popular Laboratory Equipment manuals by other brands

BD

BD CSampler Plus installation guide

Oxford Instruments

Oxford Instruments ANDOR Sona 4.2B-6 Hardware guide

Lifescan

Lifescan OneTouch Ultra user guide

Thermo Scientific

Thermo Scientific Sterile Samco 95kPa Clicktainer Vial Instructions for use

RIGGTEK

RIGGTEK DissoPrep X8 manual

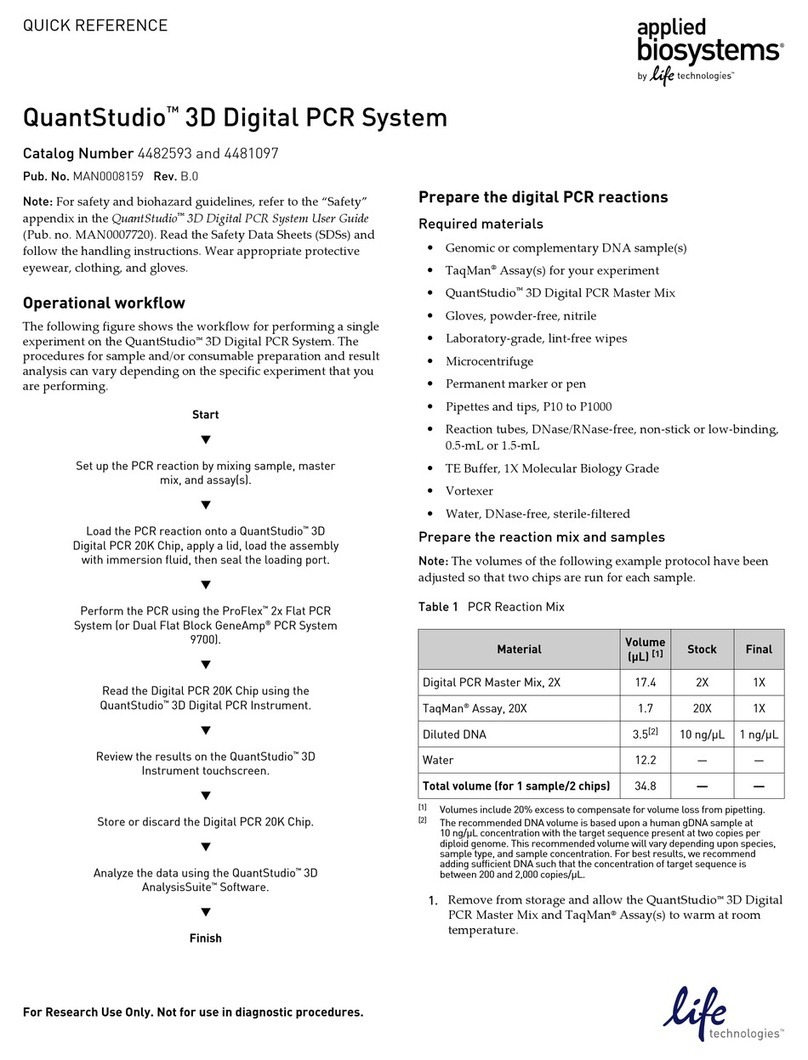

Applied Biosystems

Applied Biosystems QuantStudio 3D quick reference