Chell flightDAQ-Mk2 User manual

Chell Instruments Ltd

Folgate House

Folgate Road

North Walsham

Norfolk NR28 0AJ

ENGLAND

Tel: 01692 500555

Fax: 01692 500088

flightDAQ-Mk2

Pressure Scanner

Acquisition System

INSTALLATION

AND

OPERATING MANUAL

e-mail:- info@chell.co.uk

Visit the Chell website at:

http://www.chell.co.uk

900203-1.9

Page 1

Please read this manual carefully before using the instrument.

Use of this equipment in a manner not specified in this

manual may impair the user’s protection.

Chell Document No. : 900203 Issue 1.9

ECO : 3801 Date: 27th November 2020

Chell’s policy of continuously updating and improving products means that this manual may contain

minor differences in specification, components and software design from the actual instrument

supplied.

Chell Instruments Ltd

Folgate House, Folgate Road, North Walsham, Norfolk. UK NR28 0AJ

http://www.chell.co.uk info@chell.co.uk +44 (0) 1692 500555

Page 2

CONTENTS

1 Description ............................................................................................................................ 4

1. Specification ...................................................................................................................... 5

1.1. Power Supply:.............................................................................................................................................. 5

1.2. CAN specifications: ..................................................................................................................................... 5

1.3. Ethernet Specifications: .............................................................................................................................. 5

1.4. Operating conditions: .................................................................................................................................. 5

2. Installation and Interconnections ..................................................................................... 6

2.1. Connector – Mating connector: TV06ZN-11-35PN-UWBSB2.................................................................. 6

2.2. Mounting Holes............................................................................................................................................ 6

2.3. Earthing........................................................................................................................................................ 6

3. Mechanical Specifications ................................................................................................ 7

3.1. Product Mechanical Drawing (32 channel SQDC version)....................................................................... 7

3.2. Product Mechanical Overview (73 ZOC Version) ..................................................................................... 8

3.3. Product Mechanical Overview (QDCM 64 Channel Version)................................................................... 9

3.4. Measurement Connector –32 channel – Chell SQDC............................................................................ 10

3.4.1. Mating connectors.............................................................................................................................. 10

3.4.2. Service Connections.......................................................................................................................... 11

3.5. Measurement Connector – 64 channel - Scanivalve 73ZOCFB-040 (use gasket 6557-1).................. 12

3.6. Measurement Connector – TE QDCM-3601000101 (use gasket QDCM-3600000100)...................... 13

4. Internal Valving ................................................................................................................ 14

4.1. Scanner in run mode................................................................................................................................. 15

4.2. Scanner in calibrate or purge mode......................................................................................................... 15

5. Operation of the instrument ............................................................................................ 16

5.1. Powering up the flightDAQ ....................................................................................................................... 16

5.2. Connecting to the FlightDaq..................................................................................................................... 16

5.2.1. Connecting to the Webserver ........................................................................................................... 16

5.2.2. Connecting using the MicroDaq-X Software. ........................................................................................ 17

5.2.3. Connecting to Custom Software (Ethernet and CAN) ............................................................................ 17

6. flightDAQ Configuration Webserver ............................................................................... 18

6.1. Introduction. ............................................................................................................................................... 18

6.2. Common Controls Sidebar ....................................................................................................................... 19

6.2.1. Valve Rezero Routine........................................................................................................................ 19

6.2.2. Valve Purge Routine.......................................................................................................................... 20

6.3. The 'Setup' Page ....................................................................................................................................... 21

6.3.1. Introduction......................................................................................................................................... 21

6.3.2. Data Streaming .................................................................................................................................. 21

6.3.3. TCP Parameters ................................................................................................................................ 21

6.3.4. UDP Parameters................................................................................................................................ 22

6.3.5. CAN Parameters................................................................................................................................ 23

6.4. 'Live Data' Page......................................................................................................................................... 24

6.5. 'Calibration' Page....................................................................................................................................... 25

6.6. 'DTC Information’ Page............................................................................................................................. 27

6.7. ‘Advanced’ Page........................................................................................................................................ 28

6.7.1. Filtering ............................................................................................................................................... 28

6.7.2. Advanced communication settings ................................................................................................... 29

6.7.3. Valve Control...................................................................................................................................... 29

6.7.4. Miscellaneous..................................................................................................................................... 30

6.7.5. Span and Zero Coefficients............................................................................................................... 32

6.8. Timestamp ................................................................................................................................................. 32

6.9. Abs Cal....................................................................................................................................................... 33

7. Hardware Trigger ............................................................................................................. 33

7.1. Hardware Trigger Input. ............................................................................................................................ 34

7.2. Timing Information..................................................................................................................................... 34

7.3. Software Control........................................................................................................................................ 34

Page 3

8. Service and Calibration ................................................................................................... 35

8.1. Service ....................................................................................................................................................... 35

8.2. Calibration .................................................................................................................................................. 35

8.3. Adjustment ................................................................................................................................................. 35

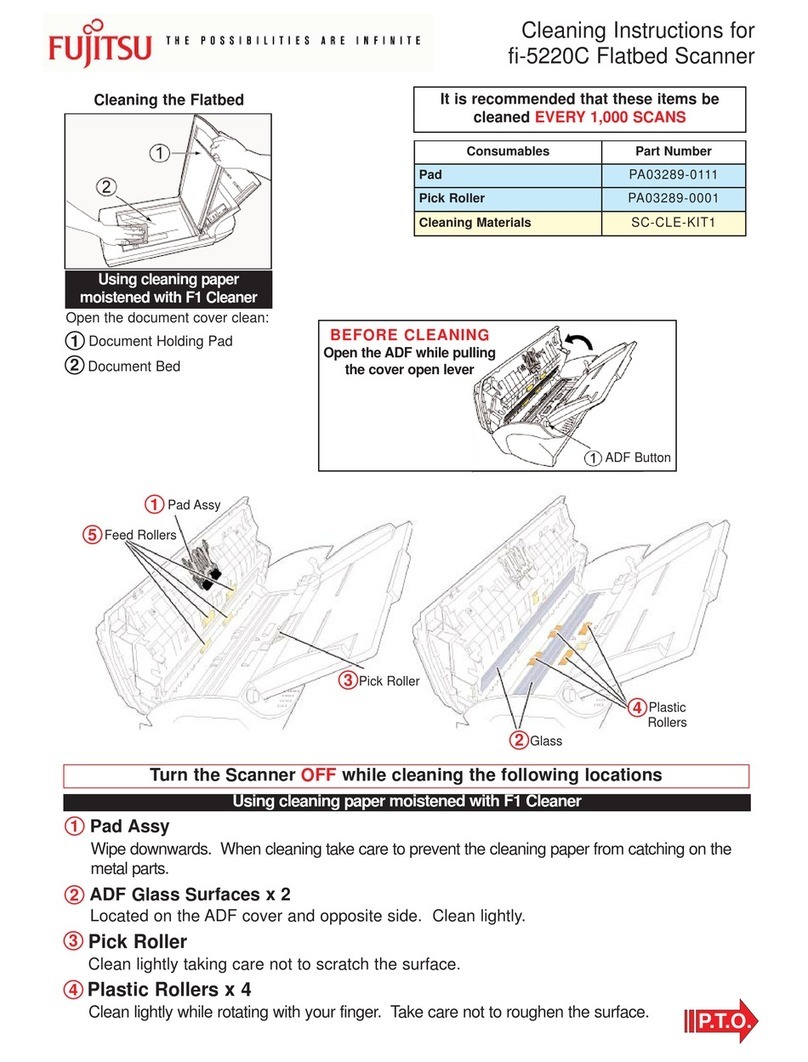

8.4. Cleaning ..................................................................................................................................................... 35

9. flightDAQ-INT Connector interface adaptor ................................................................... 36

9.1. Case Assembly.......................................................................................................................................... 36

9.2. Power Connector - Mating connector 2.1mm DC power jack ............................................................... 36

9.3. Can Connector – Mating connector 9-way D-type male......................................................................... 36

9.4. Trigger Connector - Mating connector 50 Ohm BNC............................................................................. 36

9.5. MicroDAQ – Mating connector: DEUTSCH ASDD606-09SN-HE.......................................................... 36

Page 4

1 Description

The flightDAQ is a self-contained acquisition system and combined pressure scanner that acquires

and transmits data to a host via Ethernet or a CAN bus all contained within a heated box. It is a variant

of the popular Chell MicroDaq pressure acquisition system that has been subjected to enhanced

testing in line with the expectations of flight test environmental conditions. Full details of the tests are

available on request.

The flightDAQ comes in several variants to accommodate both conventional HD series scanners and

Digital Thermal Compensation (DTC) scanners with 32 and 64 channels. The flightDaq2 features an

SQDC quick disconnect coupling for the measurement lines meaning a wide variety of tubing types

can be connected to it. Other pneumatic interfaces are also available.

The flightDAQ contains all the necessary valving to control the internal scanner valve for re-zero and

purge operations.

The flightDAQ has within it an embedded web server for configuration and data review. It can also be

used with the MicroDaqX software to display and log the data to disk. For data synchronisation, the

flightDaq2 features IEEE 1588 PTPv2 time stamping and a hardware trigger.

All electrical connections are made to the flightaq2 through one connector. To make connecting up

easier, Chell can supply a cable and interface with standard connectors on it (RJ45 for Ethernet, D

type for CAN and BNC for hardware trigger).

Page 5

1. Specification

1.1. Power Supply:

Line voltage:

24-28 VDC

Absolute Max. Line voltage

60V (note the product will not operate >32VDC)

Consumption:

With a 64-channel scanner:

Max 100VA

1.2. CAN specifications:

CAN type

2.0B

CAN baudrate

Configurable (by internal switch) from 1M, 500K, 125K

and 100K.

Programmable variables:

Address 0x?nn

Most significant programmable device ID

Address 0xn?n

Next most significant programmable device ID

BRP

CAN bus timing – see Infineon data sheet

TSEG1

CAN bus timing – see Infineon data sheet

TSEG2

CAN bus timing – see Infineon data sheet

SJW

CAN bus timing – see Infineon data sheet

1.3. Ethernet Specifications:

TCP/IP

10Mb/s & 100Mb/s via Auto Negotiation

TCP & UDP protocols supported

1.4. Operating conditions:

Operating temperature range:

-55°C to +90°C

Storage temperature range:

-55°C to +90°C

Maximum Relative humidity:

95% at 50°C (non condensing)

.

Page 6

2. Installation and Interconnections

Consideration must be given to the installation location of the product. The product is heated so

must be installed in a manner allowing heat dissipation though conduction with the outer case or

convection. The product will not operate and will power-down once the internal temperature reaches

100 degrees centigrade.

2.1. Connector – Mating connector: TV06ZN-11-35PN-UWBSB2

Pin Number

Designation

1

28V DC Supply

2

Power Supply Return (0V)

3

Ethernet RX+

4

Ethernet RX-

5

Ethernet TX+

6

Ethernet TX-

7

TRIGGER IN (TTL)

8

CAN Hi

9

CAN Lo

Power supply return is internally bonded to the product case. EMC ground may be made via the

product mounting flange.

Hot plugging the power to the flightDAQ at the

connector can cause permanent damage to the unit.

Always switch the power at the power supply source.

2.2. Mounting Holes.

The FlightDAQ2 has 4 mounting holes suitable for a M6 bolt or stub. It is advisable that all these

holes are used in service.

2.3. Earthing

One of the four mounting holes will have been masked during the anodizing process to make it

conductive. It is always recommended that the FlightDAQ2 is connected to a good ground but

grounding this mounting hole.

Note: The connection pinouts for the flightDAQ-INT interface adapter can

be found at the end of this document (Section 7).

Page 7

3. Mechanical Specifications

3.1. Product Mechanical Drawing (32 channel SQDC version)

A 3D CAD model of the product is available from Chell Instruments Ltd on request.

Page 8

3.2. Product Mechanical Overview (73 ZOC Version)

A 3D CAD model of the product is available from Chell Instruments Ltd on request.

Measurement Port 73ZOC

Power and Communication

Connector TVP02ZN

Control/Purge Air Supply

Swagelok 1/8”

Page 9

3.3. Product Mechanical Overview (QDCM 64 Channel Version)

A 3D CAD model of the product is available from Chell Instruments Ltd on request.

Page 10

3.4. Measurement Connector –32 channel – Chell SQDC

3.4.1. Mating connectors

The Chell SQDC range provides a wide range of possible mating connectors. Please refer to the

SQDC data sheet for more information.

Part Number

Description

SQDC-R-32-02

Mating connector for 1/16” o/d solid tubing

SQDC-R-32-03

Mating connector for 0.040” (1.0mm) i/d flexible tubing.

SQDC-R-32-04

Mating connector for 0.063” (1.6mm) i/d flexible tubing.

SQDC-R-32-07

Mating connector for 1mm o/d solid tubing

SQDC-R-32-02

Mating connector for 1/16” solid tubing

SQDC-R-32-08

Plastic cap for the FlightDAQ2 SQDC connector

SQDC-R-32-05

Stainless steel blank (all ports sealed) for the FlightDAQ2 SQDC

connector

SQDC-R-32-06

Aluminium blank (overall seal) for the FlightDAQ2 SQDC

connector

Please refer to the SQDC data sheet (SL0009-X.X and manual 900147-X.X)

Page 11

3.4.2. Service Connections

The service connections on the top of the FlightDAQ2 cover the supply gas, purge gas, calibrate

and reference ports. These connections can be made either by 1/8” Swagelok compression fittings

or Chell AS205 quick disconnects. These fittings can be interchanged as they both mate with the

M5 feature in the top plate.

Port

Description

Supply

Supply pressure for the internal

shuttle valve

Clean, dry gas with a pressure 7 to 8 bar

gauge.

Purge

Purge supply pressure

Clean, dry gas with a pressure 7 bar gauge.

Care must be taken if the purge pressure

exceeds the pressure range of the

scanner.

Calibration

Calibration source for calibrating

the FlightDAQ2

Clean, dry gas with a maximum differential

pressure (relative to the reference pressure)

equal to the differential range of the scanner.

Reference

Reference for pressure

measurement

Reference pressure (usually left open to

atmosphere). Maximum positive or

negative gauge pressure applied to the

reference must not exceed the full-scale

pressure of the internal scanner.

Page 12

3.5. Measurement Connector – 64 channel - Scanivalve 73ZOCFB-040 (use gasket

6557-1)

Page 13

3.6. Measurement Connector – TE QDCM-3601000101 (use gasket QDCM-

3600000100)

Channels 1-32 (Connector 1)

Channels 33-64 (Connector 2)

Page 14

4. Internal Valving

The flightDAQ2 contains the necessary valving to purge the measurement lines of the flightDAQ2

and to perform a re-zero – even when the measurement lines are subject to pressures.

The schematics below illustrates the function of the internal valves. There are two states of the

scanner shuttle valve – run mode and calibrate mode. The shuttle valve is shifted by applying

pneumatic pressure (from the supply gas port) which is switched by additional internal valves.

In run mode, the measurement ports on the integral SQDC are connected to each measurement

port on the scanner. The reference port is connected to the barometric sensor and the reference

cavity of the differential pressure scanner. In this mode normal differential or absolute pressure

measurements can be performed.

In calibrate or purge mode, the differential pressure transducers are all connected to the calibrate

port and the measurement lines are connected to the purge supply valve. Purge gas supplied to the

purge port on the top of the flightDAQ2 can then be switched (by using the internal valve) to purge

the measurement lines of contaminants and moisture.

Please see note in section 6.7.3 on purge methods for on-ground and in-flight situations.

As all the differential transducers are connected to the calibration port in this mode, it is possible to

re-zero the scanner and remove any zero offset – even when the system is subjected to pressures.

This is simply achieved by externally connecting the calibrate and reference port together (as shown

in the cal / purge mode schematic) which will ensure that the differential transducers have no

pressure differential across them.

All of the internal valves are controlled via the embedded web server or over the communications

protocol used. In addition to manually actuating each valve, we offer a re-zero and purge routine

that will actuate all the necessary valves in the appropriate sequence.

Page 15

4.1. Scanner in run mode.

4.2. Scanner in calibrate or purge mode.

Page 16

5. Operation of the instrument

5.1. Powering up the flightDAQ

The flightDAQ has one connector and cable which supplies the unit with power and also provides

CAN and Ethernet comms. Ensure all the connections are made before powering up the flightDAQ.

The flightDAQ should not be hot plugged with the power connector. Doing so can cause

permanent damage to the unit. Always switch the power at the power supply source.

Upon power up, after 3 seconds the blue LED will light constantly while the flightDAQ boots up. This

boot-up period will vary depending on the type of scanner and the number of channels. The boot up

time is also influenced by the Ethernet initialisation process. This process requires a valid network

connection to perform auto negotiation and link check status. If there isn’t a valid connection the

process waits until either a network is found or the timeout occurs. This timeout is configurable via

setup and ranges from 0 to 30 secs per check (2 checks).

When the flightDAQ has finished booting, the blue LED will flash at a constant rate to show that the

system is running (unless auto hardware trigger enable has been set – see later).

It should be noted that the flightDaq2 features a smart power supply that will only enable operation

between 18 and 32 VDC. If the power supply should move outside of these limits, the FlightDaq will

sense this and shut itself off until a correct power supply is restored.

5.2. Connecting to the FlightDaq

One the blue LED is flashing, the flightDaq2 can be connected to by any one of the following methods

[1] By using Ethernet and the embedded web server

[2] By using Ethernet and the Chell MicroDaqX software

[3] By using Ethernet and custom software

[4] By using CAN and custom software

5.2.1. Connecting to the Webserver

To connect to the internal web server, simply connect the flightDAQ to a suitable PC and simply type

the i/p address of the flightDAQ (found on the label) into a web browser. The web server will allow

you to read data (both absolute and differential) as well as view all the configuration options available

on the flightDAQ.

For a PC to successfully connect over Ethernet, the first three parts of the i/p address must be the

same on the FlightDaq and the PC that is making the connection. For example, if the i/p address of

the FlightDaq is 192.168.1.190, the PC must have an i/p of 192.168.1.XXX. Once connection has

been made, the i/p address can be changed to suit the user’s network.

NOTE. If the i/p or subnet mask of the flightDaq is changed, it must be recorded (we recommend

that it is written on a new label) as it will not be possible to connect to the flightDaq is these are not

known. In this instance, the flightDaq will need to be returned to the factory so the i/p address can be

reset.

Page 17

5.2.2. Connecting using the MicroDaq-X Software.

Chell supply the MicroDaqX software free or charge that can be used to view data and save it to disk.

It also allows many of the run time configuration settings to be adjusted (such as re-zero and hardware

trigger control). See the MicroDaqX manual for further information (900170-X.X).

When using high data rates, Windows® may require some registry modifications to enable the higher

speeds. Please refer to section 4.1.4 in the MicroDaq2 and flightDaq2 user programming guide

(900204-X.X) for further details.

5.2.3. Connecting to Custom Software (Ethernet and CAN)

The full command structure for both the Ethernet (TCP and UDP) and CAN can be found in the

Microdaq2 and flightDaq2 manual (900204-X.X). In addition, Chell can also supply LabView VI’s for

this product. Please contact us for further details.

Page 18

6. flightDAQ Configuration Webserver

6.1. Introduction.

The flightDAQ web Configuration provides the means of setting up, calibrating and demonstrating the

flightDAQ unit from a standard PC with an ethernet port and browser.

The software is divided by tabs into seven areas of functionality, namely 'Setup’, 'Live data',

'Calibration', 'DTC Information’, ‘Advanced’, ‘Timestamp’, ‘Abs Cal’ and ‘Factory Tools’

'Setup’ provides the means to set flightDAQ’s operating parameters and its identification information.

The unit's function may be checked and demonstrated using 'Live Data' to show attached pressure

scanner raw readings and flightDAQ’s calibrated output. 'Calibration' gives access to flightDAQ's

existing on board, non-DTC calibration coefficients, the tools for performing a new calibration, namely

calculating and downloading new coefficients, and the means to managing calibration data. Data

from the calibration procedure and resulting coefficients may be loaded, stored and exported for filing,

reuse and examination in other packages. 'DTC Information' provides a means for interrogating a

DTC variant of the flightDAQ, the user having access to identification information, the current status

of the calibration shuttle valve and both excitation and temperature voltages. ‘Advanced’ has extra

functions that some users might not need but might be necessary for other users. ‘TimeStamp’

provides a means for the user to control the timestamping settings of the flightDAQ. ‘Abs Cal’ allows

the user to calibrate the three absolute pressure chips on the flightDAQ. ‘Factory Tools’ provides

some functionality to read DTC coefficients and current scanner values and change the MAC address

of the Ethernet hardware. This tab is not readily available to everyone and further detail is beyond the

scope of this document.

Figure 5.1, Main Setup page

Page 19

6.2. Common Controls Sidebar

Figure 5.1 above shows the first page viewed when navigating to the webserver. The menu at the top

allows the user to choose what is visible in the central window, and the sidebar shows information

and has a select few commands that are useful regardless of the central page the user is on. The

function of the controls on the sidebar is detailed in the subsequent table (Table 5.1)

6.2.1. Valve Rezero Routine

When a rezero routine is called either by clicking the ‘Rezero’ button or calling the routine via an

interface, the following procedure is followed:

Step

Function

1

Actuate C1 valve to move the scanner to cal / purge.

2

Wait 1 second.

3

Vent C1 valve.

4

Wait 0.5 second.

5

Acquire 128 pressure values, average them together and calculate the zero

offsets .

6

Actuate C2 valve to move the scanner to run mode.

7

Wait 1 second.

8

Vent C2 valve.

Control

Function

'REBOOT' button

Resets the flightDAQ, similar to power cycling the device. Use to

activate new settings and/or rebuild calibration tables.

'Rezero' button

Starts a flightDAQ rezero operation.

‘Valve zero’ button

Runs the Valve Rezero routine.

‘Valve Purge’ button

Runs the Valve Purge routine

'Full Scale'

Displays the value of the full-scale that the flightDAQ is set up to use

.

'Channels'

Displays the number of channels that the flightDAQ is set up to use.

‘Burn to EEPROM”

button

Burns all changes made to the local settings into the EEPROM

Table 5.1, Common sidebar control functions.

Table of contents

Other Chell Scanner manuals