-1-

Cautions on safety

1. Preconditions for use

The unit is to be installed inside an indoor instrumentation panel.

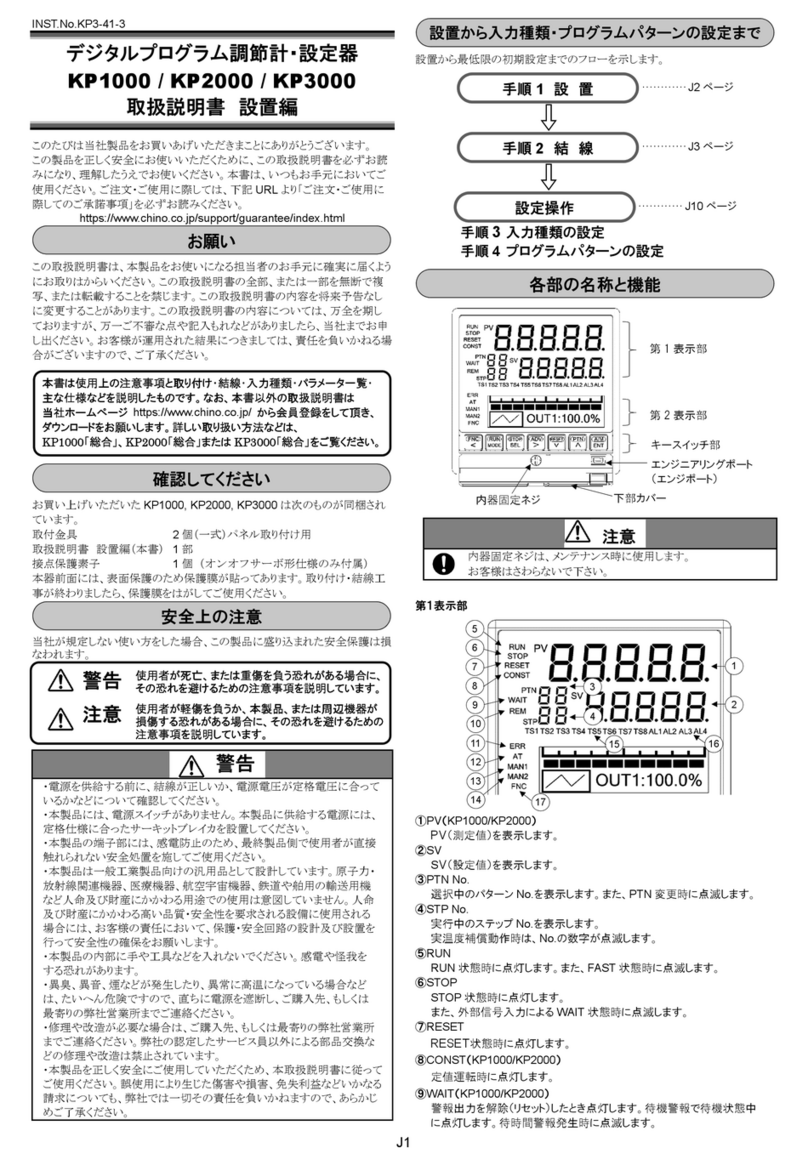

2. Symbol marks employed in the unit

Use in the unit

Labels Meanings

Caution on handling for

prevention of an electrical shock,

injuries or other accidents

Caution on a hot place (heat

sink) for preventing burn

Caution on a rotating place

(cooling fan) for preventing

injuries

Connect the grounding part

(mounting hole) to the protective

conductor terminal of the power

supply equipment.

Use in this manual

Labels Meanings

The nonobservance of

information under this symbol

may result in death, or

hazardous, critical or serious

injury.

The nonobservance of

information under this symbol

may result in a hazardous

situation or a light injury or in

physical damage to a

property.

Information that you can use

as a reference

3. Summary

This JU series single-phase thyristor regulator is the power regulator for controlling of power to a

heater of electric furnaces or other equipment, depending on the signal from a controller or a manual

setting unit. This unit is designed as a general-purpose product for general industrial products. It is not

intended for use in human-life and property related applications such as nuclear and radiation related

equipment, medical equipment, aerospace equipment, railroad, and marine transportation equipment.

To use this unit for equipment that requires high quality and safety that affects human-life and property,

design and install the protection and safety circuits to ensure safety at your own responsibility.

Warnings/Cautions

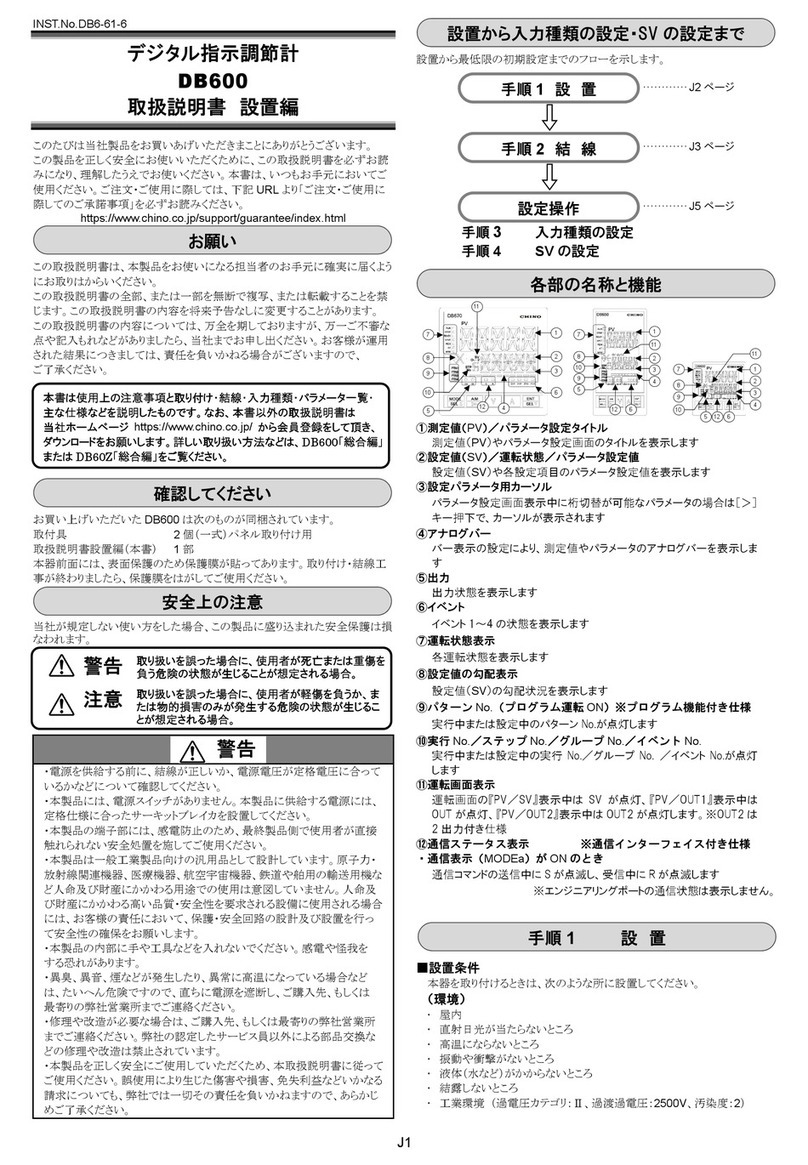

1. Installation direction

Make sure to install the unit vertically with its UP

mark ( UP) placed upward to ensure air-cooling

effect.

2. Don’t use the unit on any desk.

Make sure to install the unit on a panel to prevent

its trouble or an injury by its falling down.

3. Installation environment

Don’t operate the unit at a place where an

explosive gas, an inflammable gas, vapor, or

conductive substances like carbon, iron powder,

etc. exist.

4. Don’t repair or modify the unit

To prevent an electrical shock accident, a fire, or

its trouble, don’t repair, modify, or disassemble the

unit by any person other than our qualified

servicemen.

5. Turn off the power supply for an abnormal

symptom.

If you have abnormal odor, abnormal heating, or

other abnormal symptoms, turn off the power and

inform of it to your nearest agent of CHINO

Corporation.

6. Heavy product

When working on a product more than 18kg, do

not work alone.

Request for securing safety

1. Use the unit at the rated current or lower.

Confirm the rated current on the label pasted on

the upper panel or front panel of the unit.

2. Connect a load before turning on the power

supply

Never turn on the power supply without

connecting a load in advance to prevent its

trouble.

3. Applicable load

A resistive load is applicable. An inductive load

(transformer primary control, magnetic flux density

1.2T or less) is applicable only when the

phase-angle firing system is selected.

4. Mounting of a rapid fuse

For the models without a rapid fuse, mount a rapid

fuse externally for protecting the thyristor element.

5. Countermeasure against digital units

Higher harmonic noises are generated when the

unit is used with the phase-angle firing system.

Use an insulation transformer, separate the unit

from a power line, or take other countermeasures.

6. Don’t use any unused terminals.

Don’t connect any signal to any unused terminals

to prevent a trouble.

Reference

lert

symbol

mark

Caution

on high

temperature

aution on

moving

arts

Grounding

terminal

Warning

Caution