III

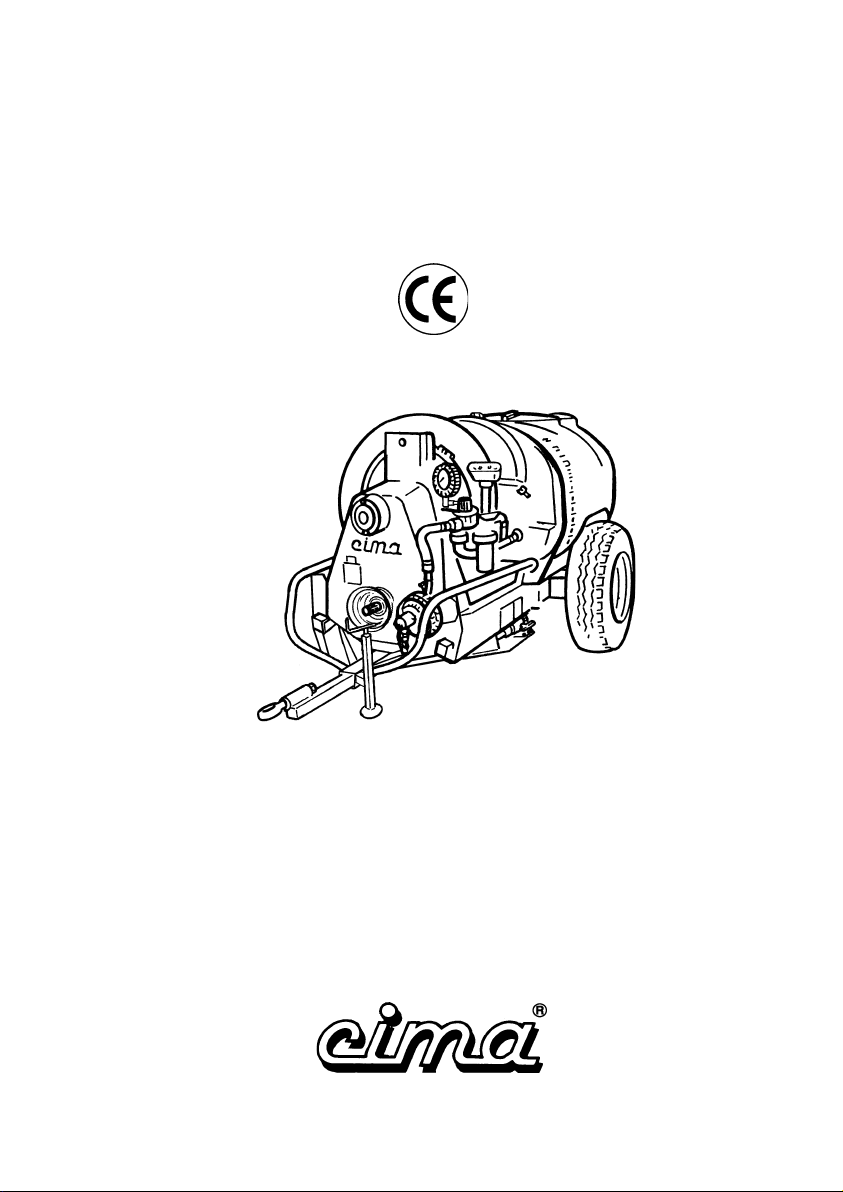

BLITZ 5-1996

TABLE OF CONTENTS

1 INTRODUCTION ...............................................................................................................................1

1.1 PUBLICATION IDENTIFICATION ....................................................................................................... 1

1.2 PUBLICATIONS ATTACHED ............................................................................................................. 1

1.3 PURPOSE OF THE PUBLICATION................................................................................................... 1

1.4 REFERENCES TO REGULATIONS .................................................................................................. 1

1.5 USE OF THE MANUAL .................................................................................................................... 1

1.6 UPDATES ......................................................................................................................................... 2

2 GLOSSARY ...................................................................................................................................... 3

2.1 TERMINOLOGY ................................................................................................................................ 3

2.2 ABBREVIATIONS ............................................................................................................................. 3

2.3 SAFETY DECALS ............................................................................................................................ 3

3GENERAL INFORMATION ............................................................................................................... 7

3.1 IDENTIFICATION OF THE MACHINE ................................................................................................ 7

3.2 TECHNICAL ASSISTANCE ............................................................................................................... 7

3.3 SAFETY WARNINGS ....................................................................................................................... 7

3.4 SAFETY DEVICES ........................................................................................................................... 8

3.5 HANDLING OF AGROCHEMICAL PRODUCTS ................................................................................. 9

3.5.1 Storage ............................................................................................................................................. 9

3.5.2 Specific equipment ........................................................................................................................... 9

3.5.3 Disposal of empty containers and agrochemical residue ................................................................... 9

3.5.4 Personal protection means ..............................................................................................................10

4 STRUCTURAL ANALYSIS OF THE MACHINE ................................................................................11

4.1 DRAWBAR ......................................................................................................................................12

4.2 SWIVELLING DRAWBAR (OPTIONAL) ...........................................................................................13

4.3 FAN DRIVE .....................................................................................................................................14

4.4 HYDRAULIC CIRCUIT COMPONENTS ............................................................................................15

4.5 TECHNICAL DATA ...........................................................................................................................19

4.5.1 Machines dimensions and weights ...................................................................................................19

4.5.2 Wheels: sizes and working pressure ................................................................................................19

4.5.3 Fan-pump functional characteristics .................................................................................................19

4.5.4 Fan technical characteristics ...........................................................................................................20

5 COUPLING MODE ..........................................................................................................................21

5.1 TRACTOR HOOK-UP .......................................................................................................................21

5.1.1 Sprayer with standard drawbar .........................................................................................................21

5.1.2 Sprayer with swivelling drawbar ........................................................................................................21

5.2 PTO SHAFT FITTING .......................................................................................................................22

5.2.1. Pto shafts ........................................................................................................................................23

5.2.2. Transmission with a single homokinetic wide angle joint (machine side) ..........................................24

5.3 INSTALLATION OF REMOTE CONTROLS .......................................................................................24

5.3.1 P8 - 2 lever manual distributor ..........................................................................................................24

5.3.2 E8 - Electric control unit ..................................................................................................................25

6 DISTRIBUTION DEVICES ...............................................................................................................26

6.1 TYPES AND IDENTIFICATION CODES ...........................................................................................26

6.2 ELBOW FITTINGS FOR THE DISTRIBUTION DEVICES ..................................................................27