Warning / cautions to secure safety

●Safety cautions are ranked by the safety cautions as

[danger] [warning] [caution] in this section.

●Working fluid, Working environment

●Installation

●Wiring

●Usage & maintenance

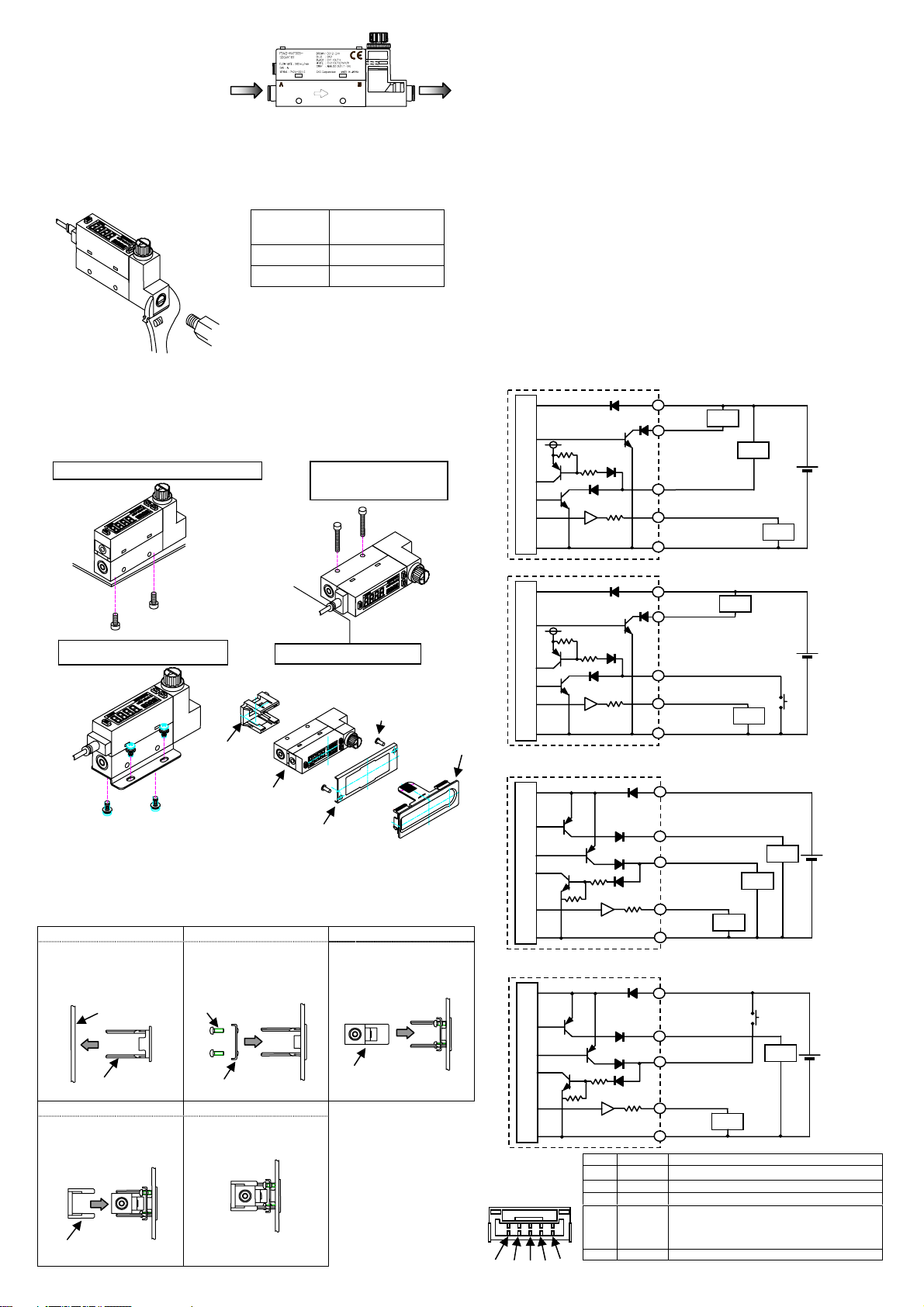

[1]Names and Functions of Each Parts

■The flow rate of this product is measured by mass flow not

depended with temperature and pressure. Unit is L/min where

mass flow is converted to volumetric flow at 20 °C and 1

atmospheric pressure (101kPa).

■The product can not be used as a business mater. Not conformed

to the Measurement Law, do not use the product for the

commercial purpose. Use the product as an industrial sensor.

■Do not use the product with other than applicable working fluids,

or the accuracy can not be guaranteed. Do not use for corrosive

and flammable gases.

■Install a filter, an air dryer and an oil mist filter (micro alescer) onto

the primary side (upstream) of the sensor since the compressed

air from the compressor contains drain (water, oil oxide and

foreign material, etc.)

■When using this product with adsorption verification, etc., always

install an air filter onto the upstream of suction side to prevent

suction of foreign materials.

■Do not use the product in an environment containing corrosive

gas such as salphur dioxide, etc.

■Use the product within the ambient and fluid temperature ranges

0 to 50 °C. Even in the specified temperature range, do not use

the product where ambient and fluid temperatures will change

suddenly, and form dew condensations.

■Use the product in accordance with specifications. If used out of

the maximum working pressure and working flow range, the

product may result in failures.

■The protective structure of this product is equivalent to IP40. Do

not install the product where moisture, salt, dust or swarf is

contained, or where pressurized, or depressurized, neither.

When a dangerous situation may occur, or when there is high

urgency to a warning leading to fatal or serious injuries, if handling

is mistaken.

When a dangerous situation may occur if handling is mistaken,

leading to fatal or serious injuries.

When a dangerous situation may occur if handling is mistaken,

leading to minor injuries or physical damages.

Danger

!

■A flammable fluid must not be used.

■Do not use the product in flammable gas environment. Since

explosion-protection is not taken, explosion or fire may be

caused.

■Arrange piping so that the flow direction agrees with the direction

of the arrow indicated on the sensor body.

■When piping a sensor, do not apply excessive screw-in and load

torques to the port.

■Flash the pipe to remove foreign substances and swarf, etc., in

inside of pipe before piping.

■When piping, apply a spanner on the metal section not to apply

forces onto the resin section.

■When piping, care must be taken that sealing tape and adhesive

must not enter into the inside.

■When using the metal body with OUT side released, always

connect a joint, or the port filter may be removed.

■If a push-in joint is used, the tube must be inserted certainly. Pulls

the tube to check that the tube not be come out.

■Make sure that the joint and tube are not twisted or pulled, and

that moment load is not applied.

■The display part uses the LCD. The display becomes difficult to

see for the view angle.

■This product can be installed with any attitude; vertical, horizontal,

right or left.

■This product cannot be used as a stop valve with zero leakage.

Slight leakage is allowed in product specifications.

■Dust generation inside the paths of the needle valve is not zero.

Install a final clean filter in circuits where dust generation causes

problems.

■When you install the panel, please install this product after piping

etc.

■Check that lock nuts are not loose. Actuator speed cannot be

controlled if the lock nut is loose.

■A stopper mechanism is provided, but damage could result if the

needle is turned too far.

■Power supply voltage and outputs must be used with the

specified voltage. Applying the voltage more than specified

voltage may cause malfunction, damage of sensor, electric

shock or fire.

Do not apply load more than the rated output. Damage or fire of

the output may be caused.

■For wiring, stop control unit/machinery and equipment, and turn

off the power supply.

■This product and wiring must be installed as far away as possible

from noise source such as strong electric line, etc. Take other

countermeasures for a surge on the power supply line.

■Do not short-circuit a load, or causing damage or burn.

■Line color must be checked when wiring. Check the wiring color

with handling precaution, since improper wire connection may

result in damage, failure or malfunction of the sensor.

■Use DC safety power supply thoroughly insulated from the AC

primary side for a power supply for the metal body (stainless

steel and aluminum bodies) type, while connecting either + or -

side on the power supply to F.G.

■After the connectors are inserted, lay the connector covers over

the connectors.

■Make sure that stress by forcible bend of pulling is not applies

directly to the sensor cable joint.

■Output accuracy is affected by self exoergics caused by

energizing other than temperature characteristics. When using,

stand-by time (5 minutes and over after energizing) must be

provided.

■For self-diagnosis, this product does not conduct flow rate

detecting switch operation for proximate 4 seconds immediately

after energized. Make a control circuit and programs to ignore

signals for approximate 2 seconds after energized.

■This product cannot be used as a stop valve with zero leakage.

Slight leakage is allowed in product specifications.

■Dust generation inside the paths of the needle valve is not zero.

Install a final clean filter in circuits where dust generation causes

problems.

■When changing set-points of the output, stop the equip-ment,

then change the set-points, or an accident may occur.

■Disassembly and modification must not be done or causing a

failure.

■When an error occurs during operation, turn off power supply

immediately, and terminate the operation, and contact to the

sales office.

■The material of case is resin. Solvent/alcohol/cleaner, etc., must

not be used to remove contamination, etc., or causing a resin to

be corroded. Wipe weakened neutral detergent with tightly

squeezed waste cloth, etc.

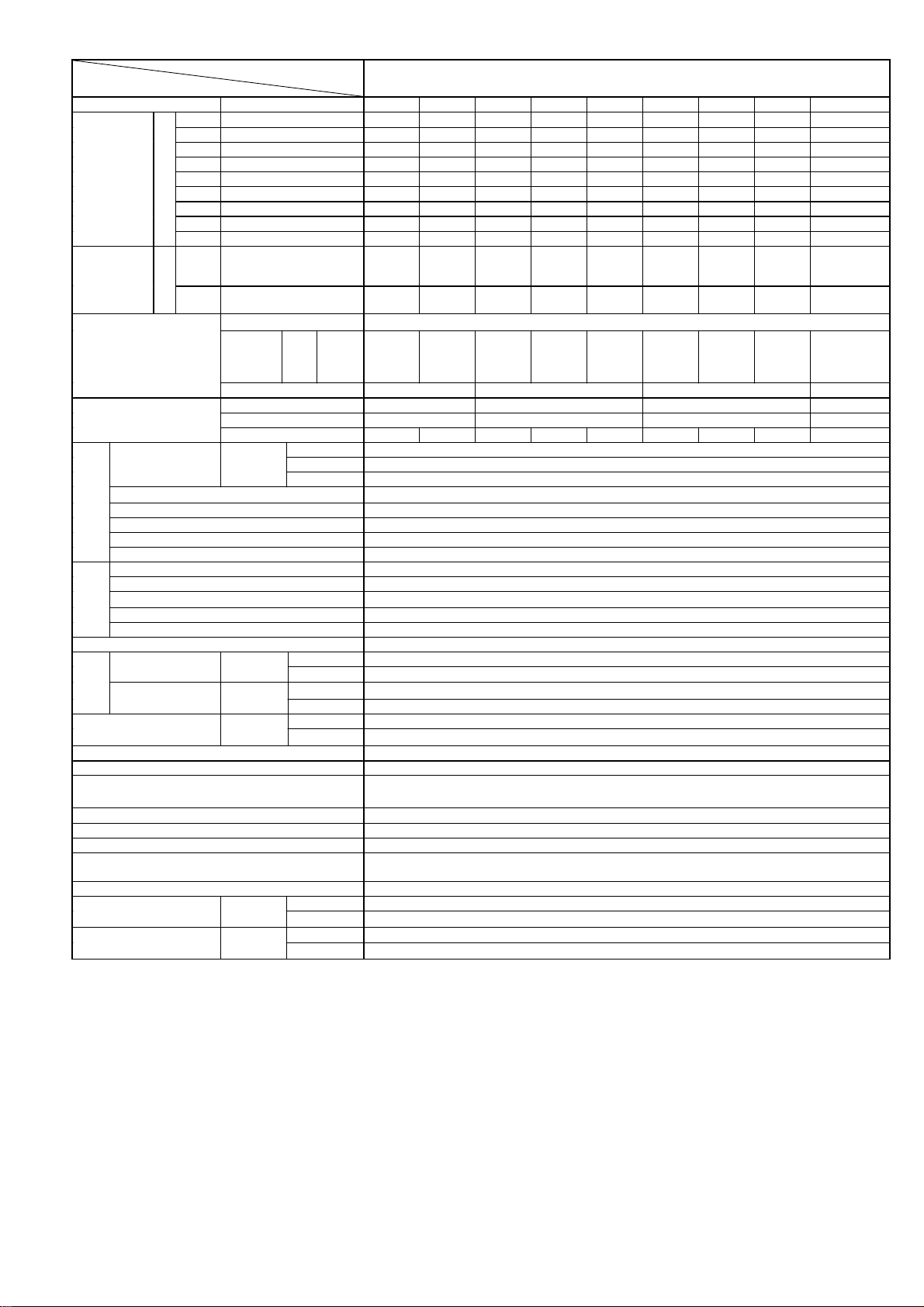

■When out of flow rate range, analog output will be provided. [Hi]

or [Lo] will be displayed. However, accuracy is not guaranteed.

■Do not push the display part., or causing damage.

■Do not turn the knob too forcibly when fully closing or opening

the knob (within 0.05N-m). As well, do not pinch the lock nut

when adjusting the needle. Otherwise the needle will gall or be

broken.

Warning

!

Caution

!

Danger

!

Warning

!

Caution

!

Caution

!

Danger

!

Caution

!

Warning

!

Caution

!

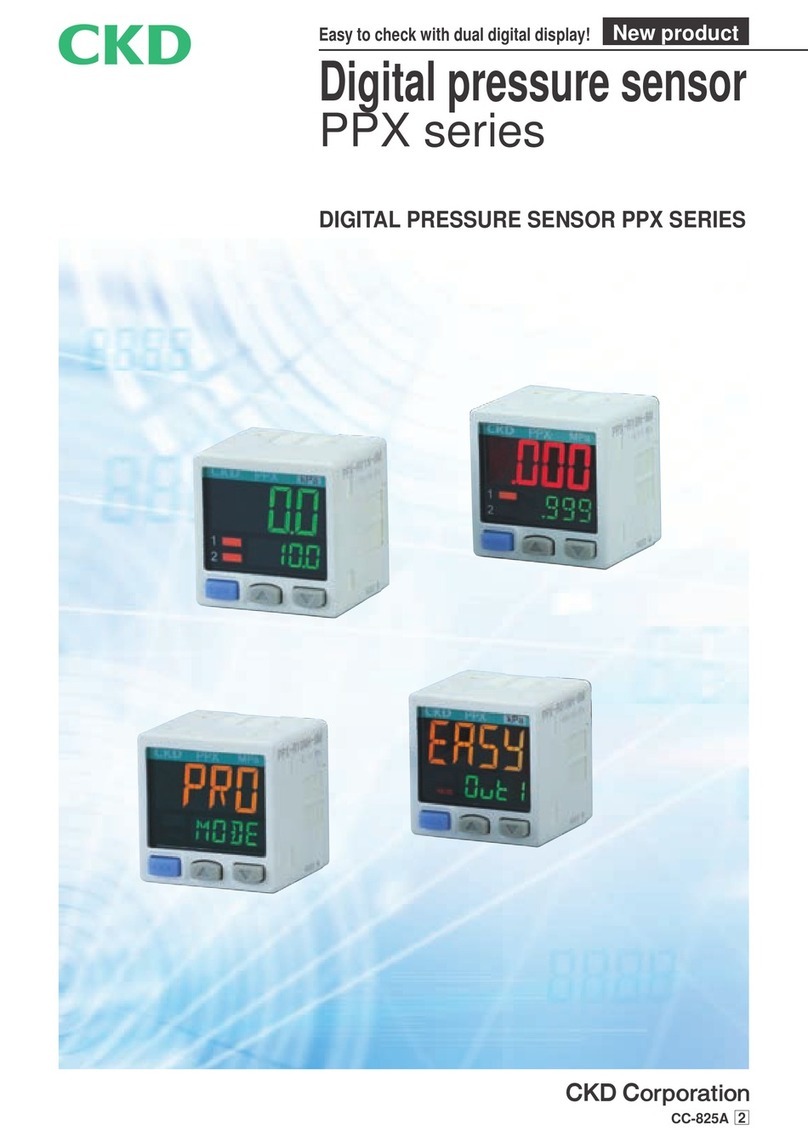

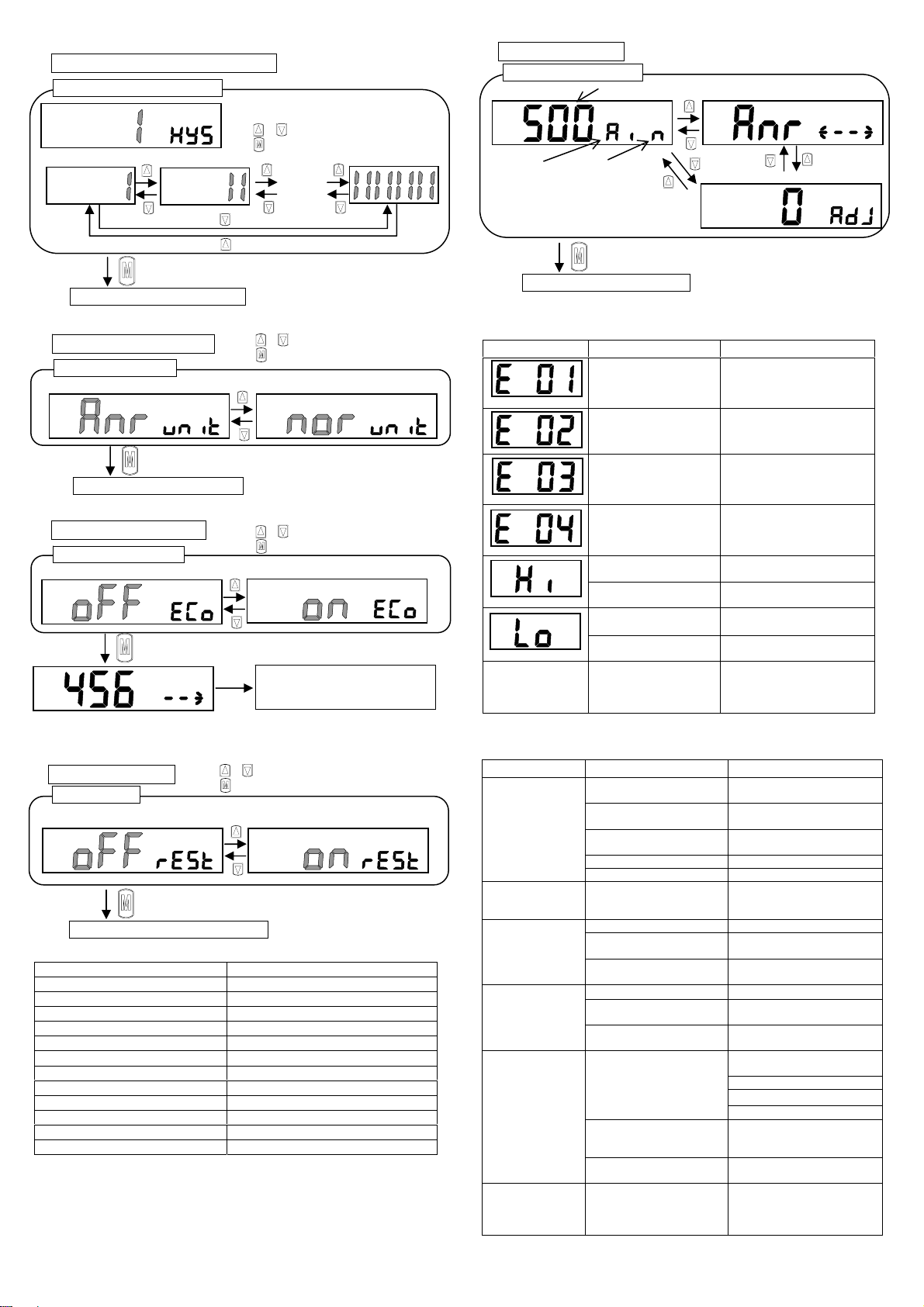

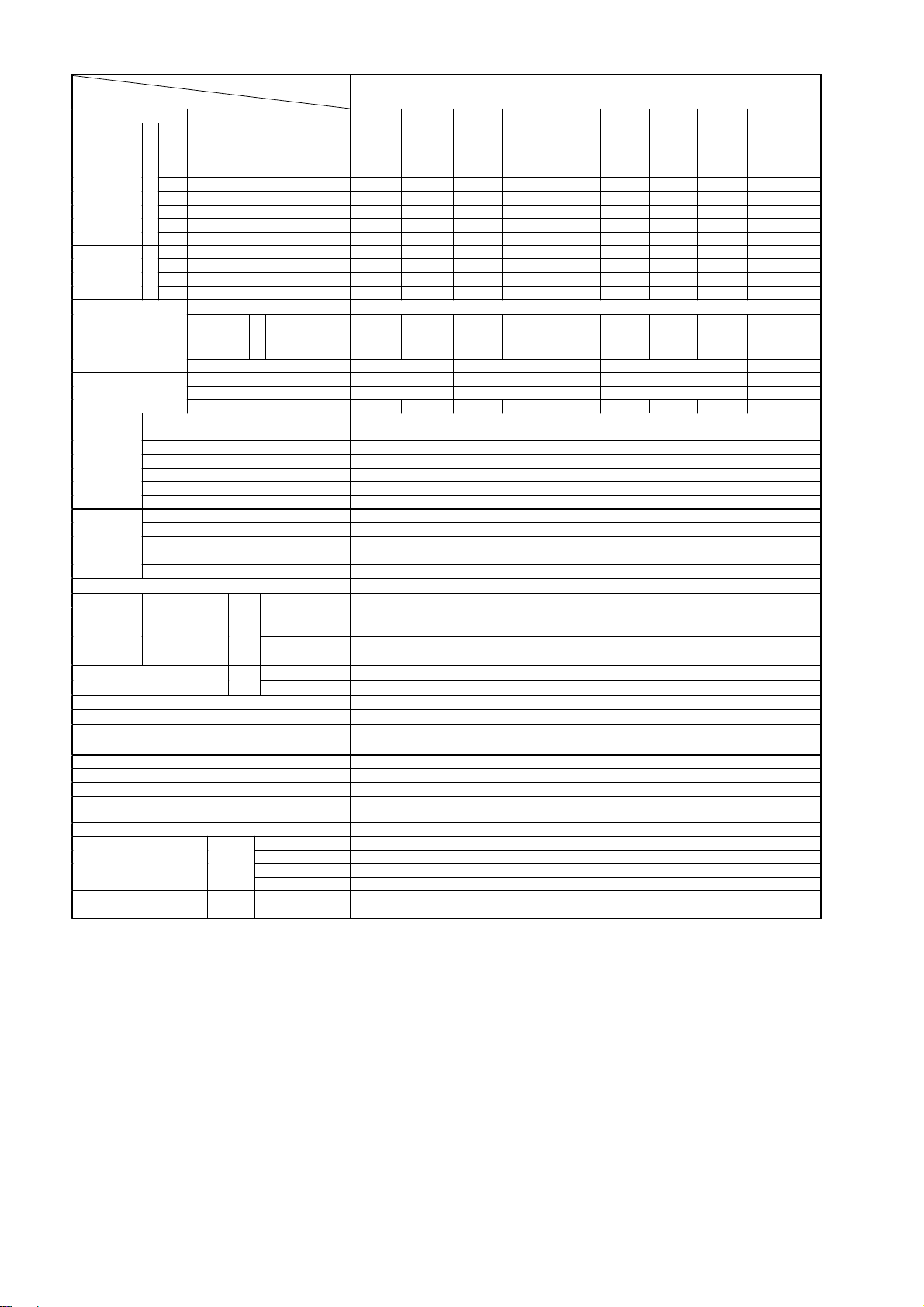

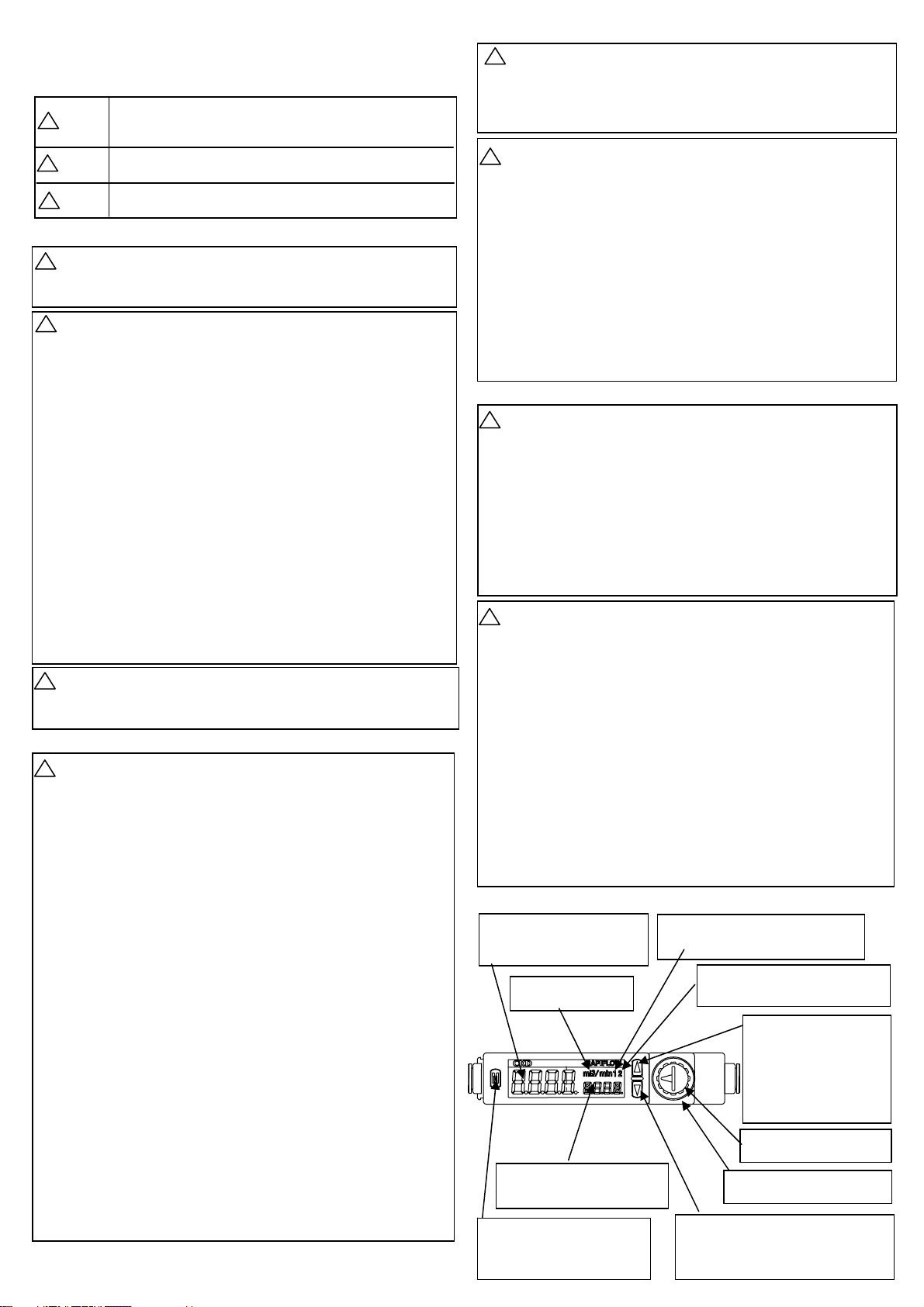

Mode key

■Press to enter each setting mode

■Press to advance setting mode

■Press to return to flow rate display

■Press to cancel peak hold operation

Up key

■When flow rate is displayed =

Displays the CH1 data

■During peak hold operation =

Displays the maximum value

■When selecting a mode =

Sets the mode

■When setting each data =

Increases the value, etc.

Down key

■When flow rate is displayed = Displays the CH2 data

■During peak hold operation =Displays the maximum

value

■When setting each data =Increases the value, etc.

Main display (Green/Red)

■Displays flow rate, various switch

settings.

■Indication color is selectable.

Sub-display (Green/Red)

●Displays flow direction, machine status.

●Indication color is selectable.

Unit display (Green)

■Displays flow rate unit

Switch output indicator (CH1)

■Lights when switch output (CH1) turns on.

■Blinks when over current protection is operating

Switch output indicator (CH2)

■Lights when switch output (CH2) turns on.

■Blinks when over current protection is operating

Knob

■Flowing quantity is adjusted.

Lock nut

■When the knob is fixed, it uses it.

-1-