Care must be taken in not exceeding media and ambient

temperature range in cluding pipng area.

Do not use the product in locations that water or oil may contact the products.

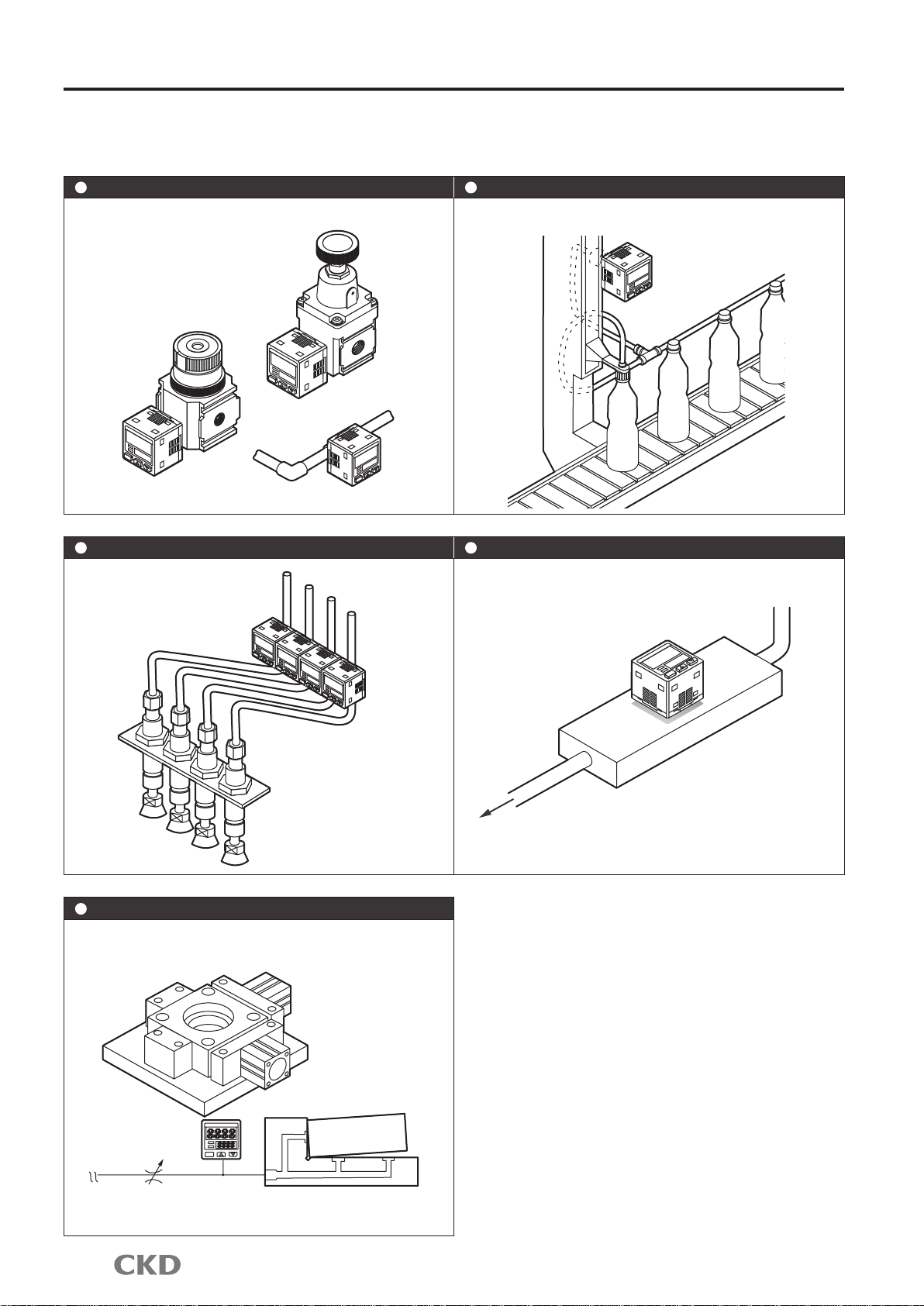

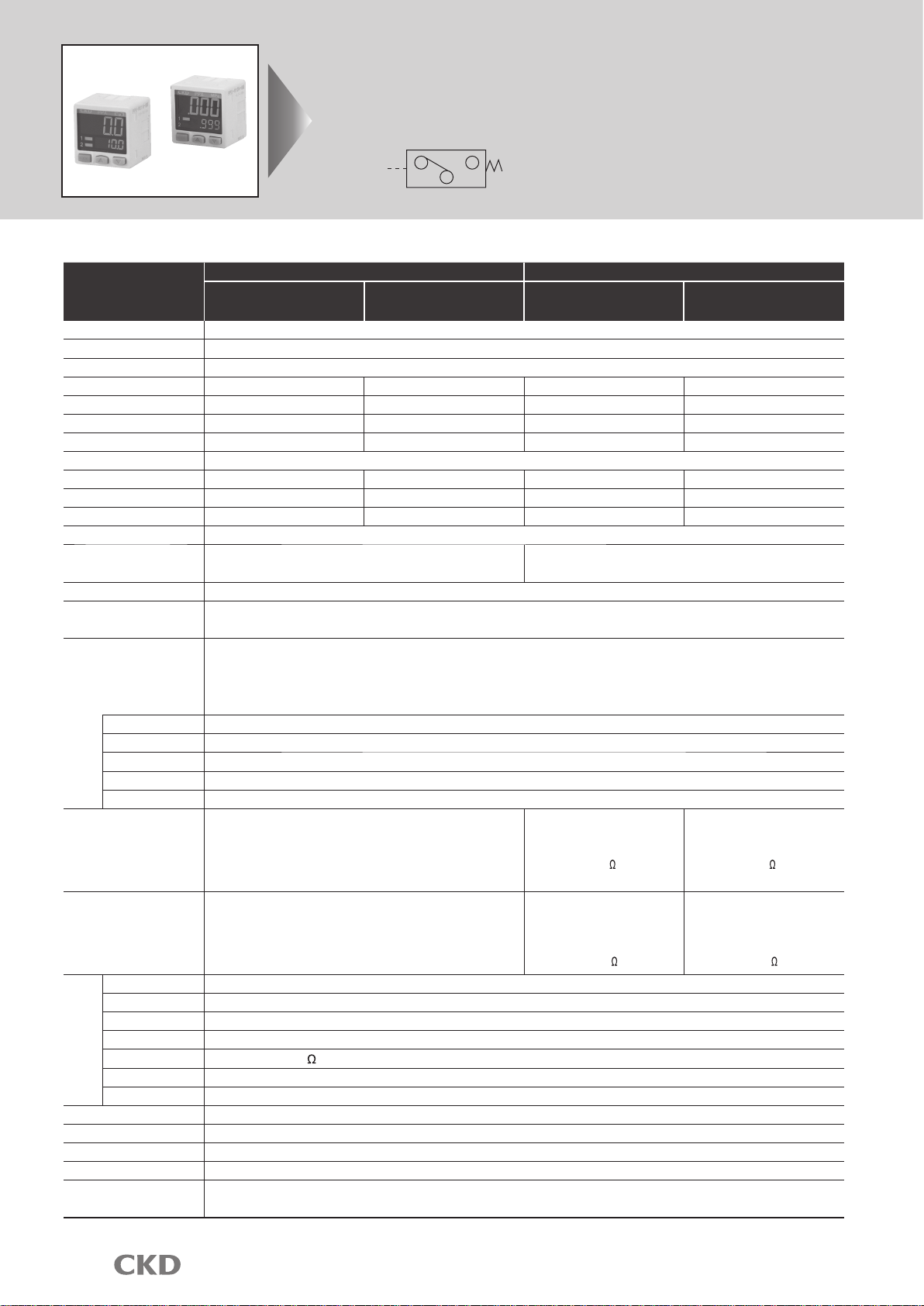

Pneumatic components (electronic pressure switch and sensors)

Design & Selection

Always read this section before starting use.

Refer to "Pneumatic, vacuum and auxiliary components CB-024SA".

Safety precautions

WARNING

Use this product in accordance of specifications.

Applications, load current, voltage, temperature, shock and

working environment, etc. exceeding the specifications

range could lead to destruction and malfunction of periph-

eral equipment.

Do not use oxygen, corrosive or combustible

gas, or toxic fluid for this product.

The pressure switch is not explosion proof. Do not use this

product in flammable atmosphere, or explosions could oc-

cur.

Do not use this product in flammable atmo-

sphere

The internal pressure in the closed chamber could change

if the fluid leaks in an accident. Use this product in the con-

trol box with safety device to control internal pressure, or

indoors with no pressure differential from the outside.

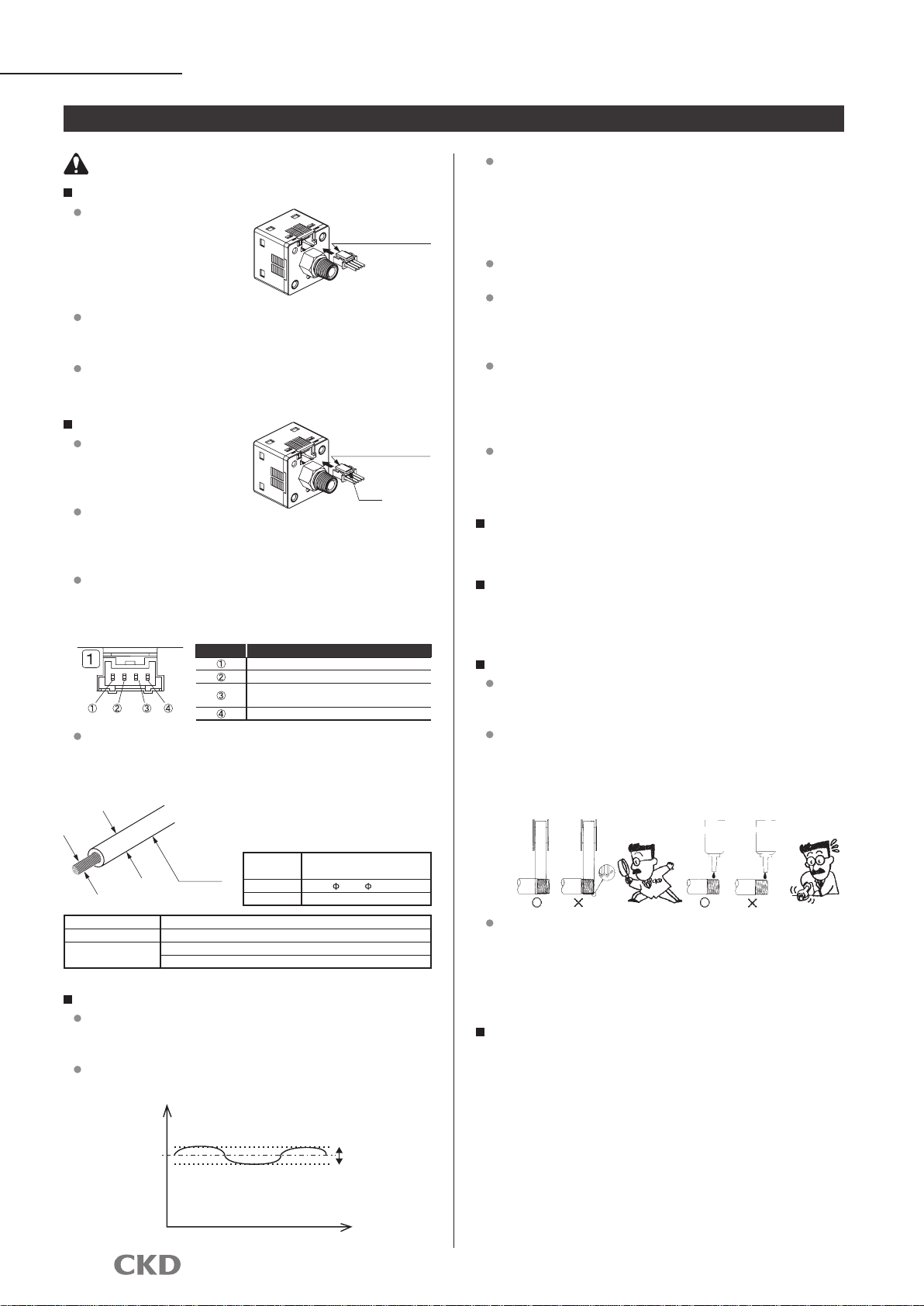

Do not install the product in completely sealed

enclosure.

Power voltage

Use the product within the specified power voltage range. If

voltage exceeding specified rage is applied, or alternating cur-

rent power (100 V AC) is applied, circuit damage could occur.

Load short circuit

Do not short-circuit the load, or circuit damage could occur.

Incorrect wiring

Avoid incorrect wiring such as connecting to the wrong electrode

of the power source, etc., or the circuit damage could occur.

CAUTION

Working fluid

When using working fluid other than air; nitrogen gas, etc.,

oxygen deficiency could be caused. Observe the following in-

structions.

Use this product in well ventilated location.

Ventilate the work area when nitrogen gas is being used.

Inspect piping regularly, so nitrogen gas does not leak.

If this product is used for vacuum suction confir-

mation, care must be taken for following matters.

The pressure exceeding withstanding pressure in the speci-

fications must not be applied to the product if positive pres-

sure of vacuum break is applied.

Working environment

Avoid use in the place that vibration or shock not less than

100m/s2is applied.

Considering errors, etc. caused by precision/

temperature characteristics, decide the setting.

When a pressure switch is used to issue interlock signals, if

high reliability is required, provide mechanical guards for a

failure, or provide dual interlock as a switch (sensor) other

than pressure switch is used. Execute inspection regularly

to check that the normal operation is done.

Care must be taken when this product is used in

an interlock circuit.

Responsiveness is adversely affected depended

on working pressure and volume of loads. Install

a regulator before the sensor if stable repeatabil-

ity is required.

Use conditions to comply with CE marking

PPX series is CE marked products complied with EMC di-

rective. EN61000-6-2; regulation matched to immunity ap-

plies to this product. Conditions below are necessary to

comply with these standards.

Conditions

Length of power line connected to the sensor is to be less than 10m.

Provide a line filter in AC power line.

Do not share power with an inverter or components causing

motor noise, etc.

Remove noise from inductive load (such as solenoid valve

and relay) with a surge suppressor such as CR or diode in

the source side.

When using components (such as switching regulator and

inverter motor) causing noise around the sensor installation

section, ground a frame ground (F.G.) terminal of compo-

nents.

Keep distance between a line connected to sensors and

strong magnetic field.

Connect a line connected to sensors with shield wire.

Connect shield wire to the ground of power side.

Take the following countermeasures to prevent

malfunction caused by noise.

When the secondary side control pressure is re-

leased to atmosphere as air blow, pressure may

fluctuate depended on piping and blow condi-

tions. Execute a test under actual working condi-

tions or contact to CKD.

Select the product whose flow is not less than

the total of that used for sensors when selecting

a dryer, an air filter, an oil mist filter and a regula-

tor.

Intro 3