3

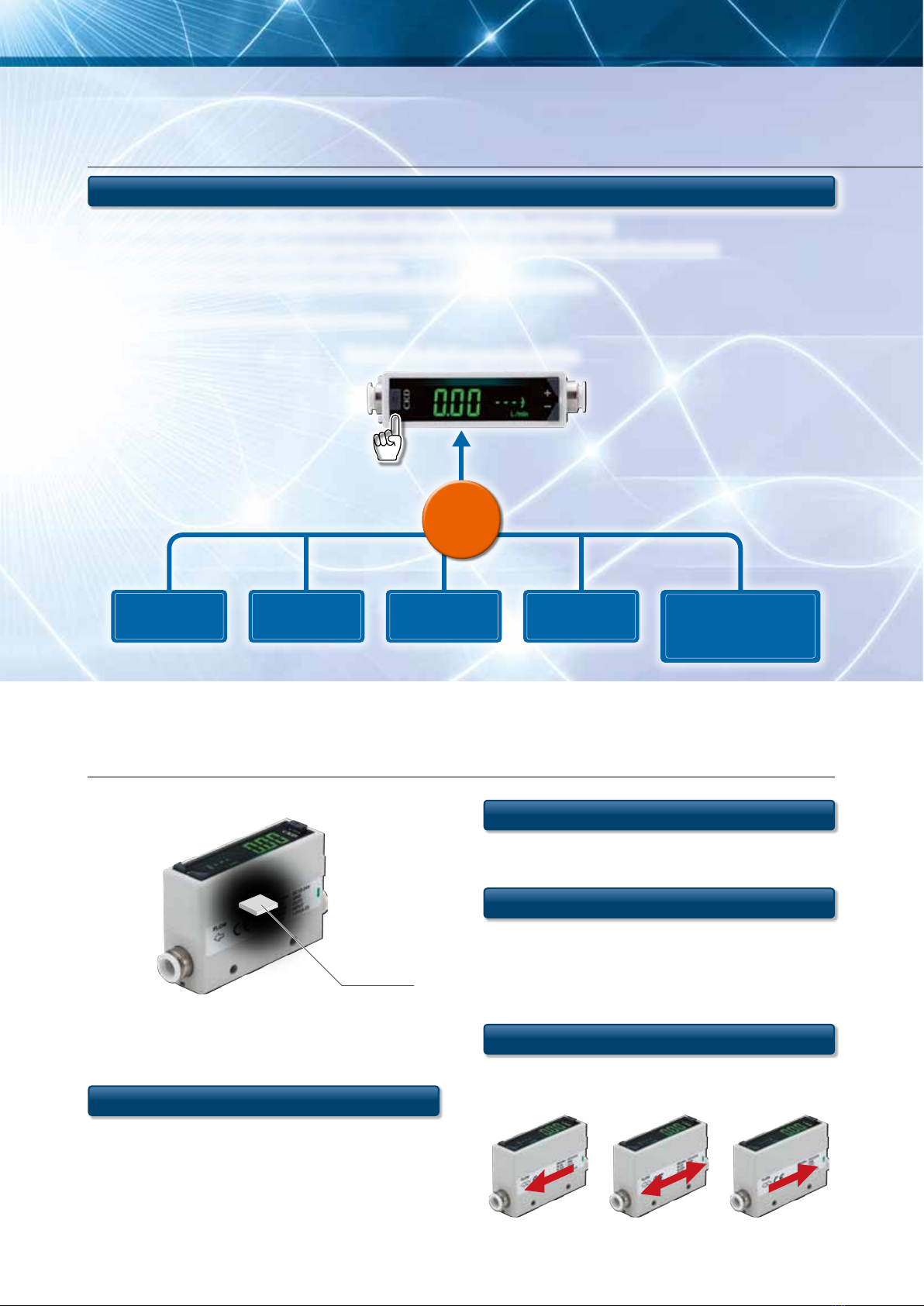

FSM3 Series

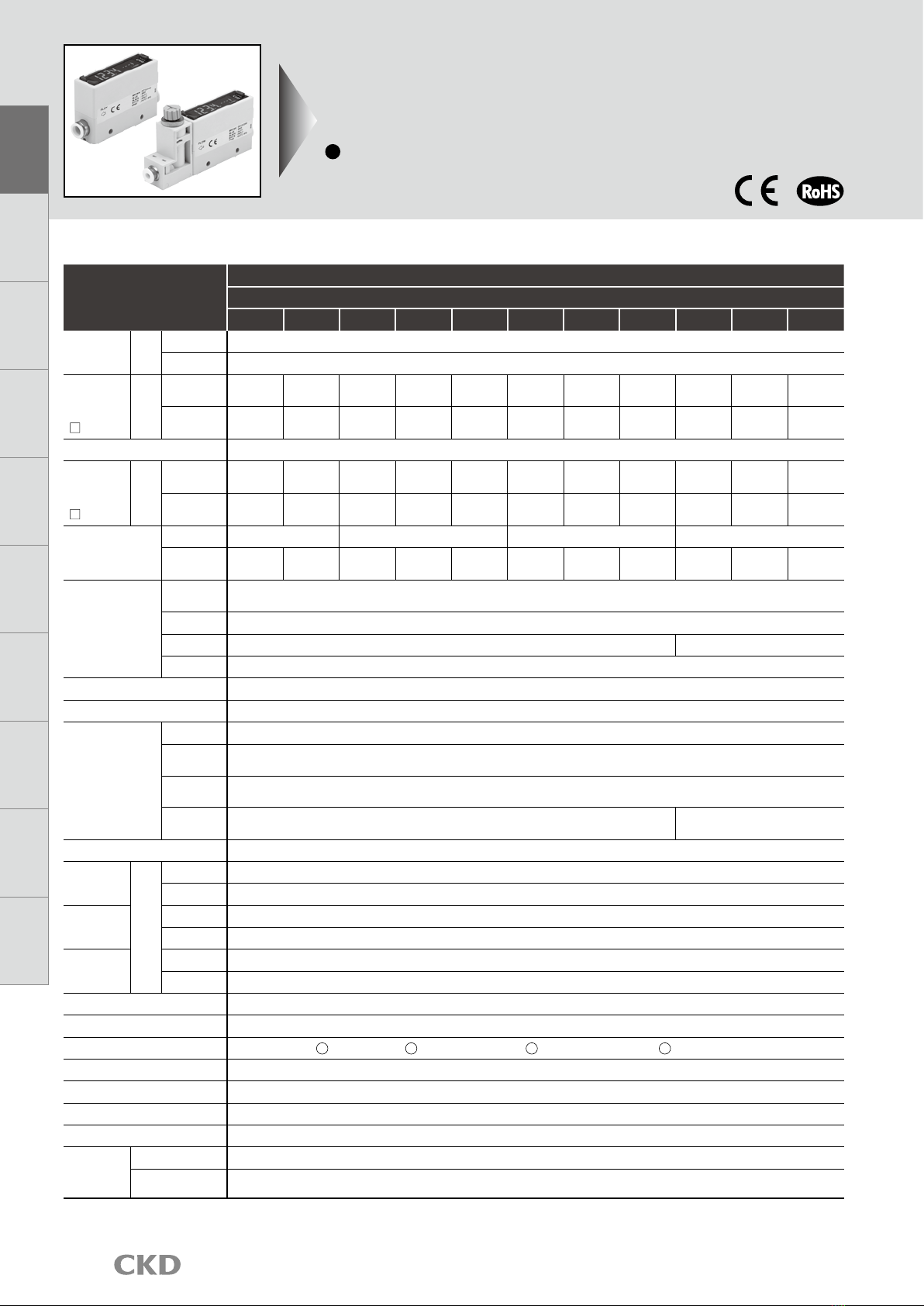

How to order

C Flow direction

D Body material/compatible uids

A Display

Model No.

E Port size

H Unit specications

L Attachments

F Piping direction

G Output specications

J Cable

M Clean-room

specications

FSM3

BH

P80

UL 1 1 A N1 B M R Code Content

ADisplay

LLiquid crystal display

BFlow rate range (full scale ow rate)

005 500 mL/min 500 50 L/min

010 1 L/min 101 100 L/min

020 2 L/min 201 200 L/min

050 5 L/min 501 500 L/min

100 10 L/min 102 1000 L/min

200 20 L/min

CFlow direction

UUni-direction

BBi-direction

DBody material/compatible uids

Body material Compatible uids

1Resin

Air (Gas can be changed)

EPort size

BH Push-in (for φ4 mm tube) AB G1/8 *2

CH Push-in (for φ6 mm tube) BB G1/4 *2

DH Push-in (for φ8 mm tube) CB G1/2 *2

EH Push-in (for φ10 mm tube) AC NPT1/8

HH Push-in (for φ1/4" tube) BC NPT1/4

JH Push-in (for φ3/8" tube) CC NPT1/2

AA Rc1/8

BA Rc1/4

CA Rc1/2

FPiping direction

1Straight

2Elbow *3

GOutput specications

Analog output Switch output Copy function

A1-point

(Voltage

output)

1-5 V

1-point (NPN) With

B2-point (NPN) -

C1-point (PNP) With

D2-point (PNP) -

E1-point

(Current

output)

4-20 mA

1-point (NPN) With

F2-point (NPN) -

G1-point (PNP) With

H2-point (PNP) -

HUnit specications

1SI units only

2

With unit change function (only for overseas) *4

IValve option

NNone

T

With needle valve (only for models 200 L or less)

E

EXA connecting tting (EXA sold separately) *5, *6

JCable

Blank None

A5 conductor 1 m

B5 conductor 3 m

KMounting attachments *7, *8

Blank None

HBracket 1 (for models 200 L or less)

JBracket 2 (for models 500 or 1000 L)

K

Panel mounting (for sensor products of models 200 L or less)

L

Panel mounting (for needle valves of models 200 L or less)

MDIN rail mounting (for models 200 L or less)

LAttachments

Blank None

RCompany certication

SCompany certication + traceability certicate

MClean-room specications

Blank None

P70 Anti-dust generation *9

P80 Oil prohibited *10

Precautions for model No. selection

*1: During selection, always check the compatibility table on the

next page.

*2: Note that if you mount the elbow fitting in a downward position,

it will interfere with the DIN rail mounting.

*3: Check using the connection shape and dimensions (page 5) of

the G screw when selecting.

*4: The model with unit change cannot be sold in Japan.

*5: Connection to solenoid valves (EXA Series) is possible with the

dedicated fitting. Refer to page 41.

*6: Be sure to set EXA to the OUT side of the product. Use a lead

wire for the EXA coil option. The DIN terminal box cannot be

mounted because it will cause interference. After making sure it

is connected firmly, confirm that there is no external leakage.

*7: Note that the bracket mounting position may interfere with the

elbow fitting.

*8: Optional parts will come with the product. They are not pre-

assembled.

*9: Product surface is degreased before packaging and heat sealed

into an antistatic bag on the clean bench (Class 1000 and over).

*10: The wetted section is degreased in addition to the

specifications on P70.

I Valve

option

K Mounting

attachments

[Example of model No.]

FSM3-L005U1BH1A1N-BMR-P80

Model: RAPIFLOW FSM3 Series

ADisplay L :

Liquid crystal display

BFlow rate range

005

:500 mL/min

CFlow direction U:Uni-direction

D

Body material/compatible fluids

1:Resin/air

EPort size BH :Push-in

(φ4 mm for tube)

FPiping direction 1:Straight

GOutput

specifications

A :

Analog voltage output ×1,

NPN Switch output ×1,

with copy function

HUnit specifications 1:SI units only

IValve option N:None

JCable B:5 conductor 3m

K

Mounting attachments

M:DIN rail mount

LAttachments R : Company certification

M

Clean-room specifications

P80

:Oil prohibited

B Flow rate range

(full scale ow rate)

005

LCD displayBar display

IO

-

Link

Internal

structure

Separate

display

Technical

data

Operating

method

Optional

products

Safety

precautions

Related

products