................~.~.~~......................:.:.,

~ :$$::::$&y::<: :yyg$:yy.

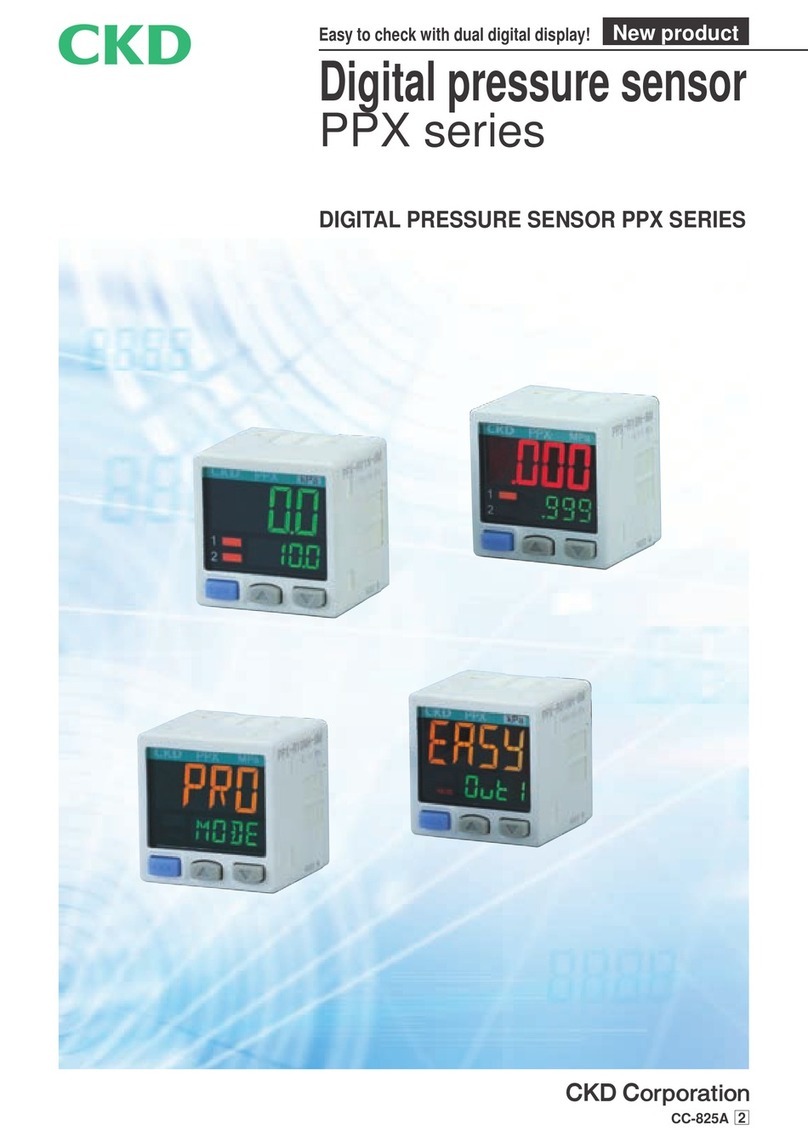

PRODUCT

*.:.:.:<<.:.:.:.p

*.*...v.-2.2.

..;.:.:.#y

.*.%..-.v..

v

‘:$@

f:.’

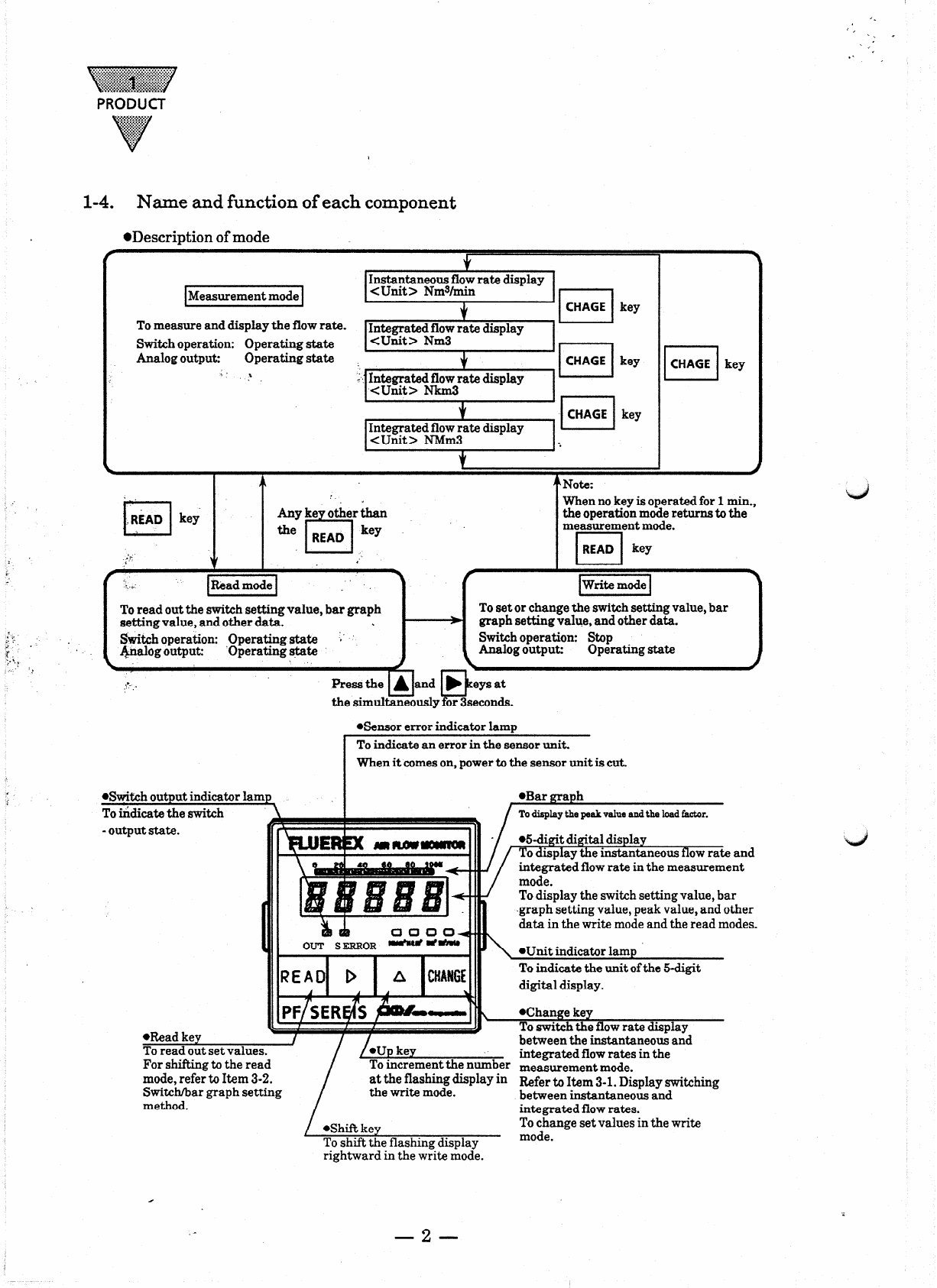

l-4, Name and function of each component

*Description of mode

Measurement mode

To measure and display the flow rate. Integrated flow rate display

Switch operation: Operating state <Unit> Nm3

Analog output: Operating state +

CHAGE

key

‘ . ? .r Inngr-.d&rate display ‘lzl

I Jr I

. I 4

+Note:

1CHAGE 1

key

’ !

cl

.R~AD kei

Anyke otherthan

the READ lrey

T-l

When no key is operated for 1min.,

the operation mode returns to the

m;asuremyt mode.

L-J

READ key

pE%ZiZ]

To read out the switch setting value, bar graph

setting value, and other data. \

Switch operation: Operating state ;.

&.lalog output: ‘Operating state

To set or change the switch setting value, bar

graph setting value, and other data.

Switch operation: Stop

halog output: Operating state

the simulGuslyforseconds.

*Sensor error indicator lamp

When it comeson, power to the sensor unit is cut.

-output state. and

nt

switch setting value, bar

value, peak value, and other

ite mode and the read modes.

digital display.

To shift the flashing display

rightward in the write mode.

measurement mode.

Refer to Item 3-1. Display switching

between instantaneous and

integrated flow rates.

To change set values in the write