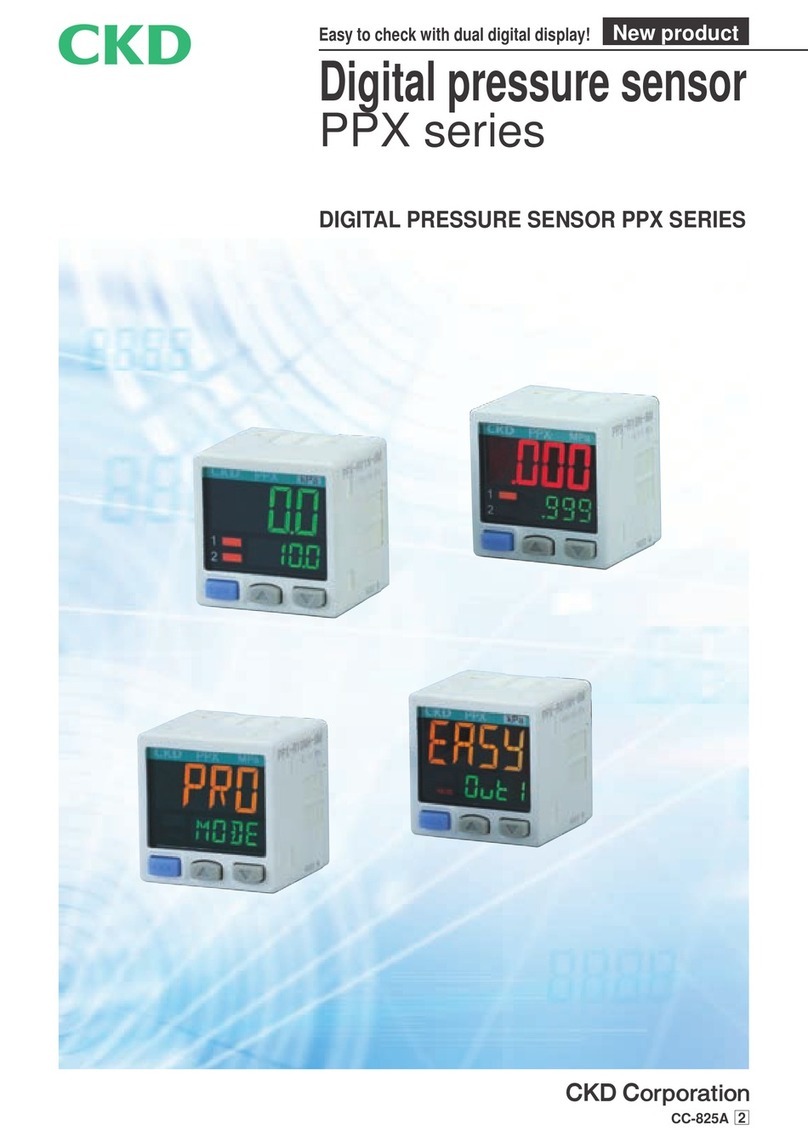

Flow sensor for compressed air PF Series

Strongly supports energy-saving activitiesStrongly supports energy-saving activities

Integrating flow and instantaneous flow rate displays can be

switched with a single operation

.

Correction of pressure/temperature is not required.

·

No need for pressure correction = Due to the mass detection

method used, there is no effect due to pressure change.

Hence, pressure correction is not required.

Displays the flow rate converted to atmospheric pressure (1 atm).

·

No need for temperature correction = Fluid temperature

is detected by the platinum thin film temperature sensor,

and is always displayed after being converted to flow

rate at 0°C.

·Maintenance and measurement of air quality

available in one unit.

·Piping space/piping processes

can be reduced.

3/8

(10)

1/2

(15)

3/4

(20)

1

(25)

11/2

(40)

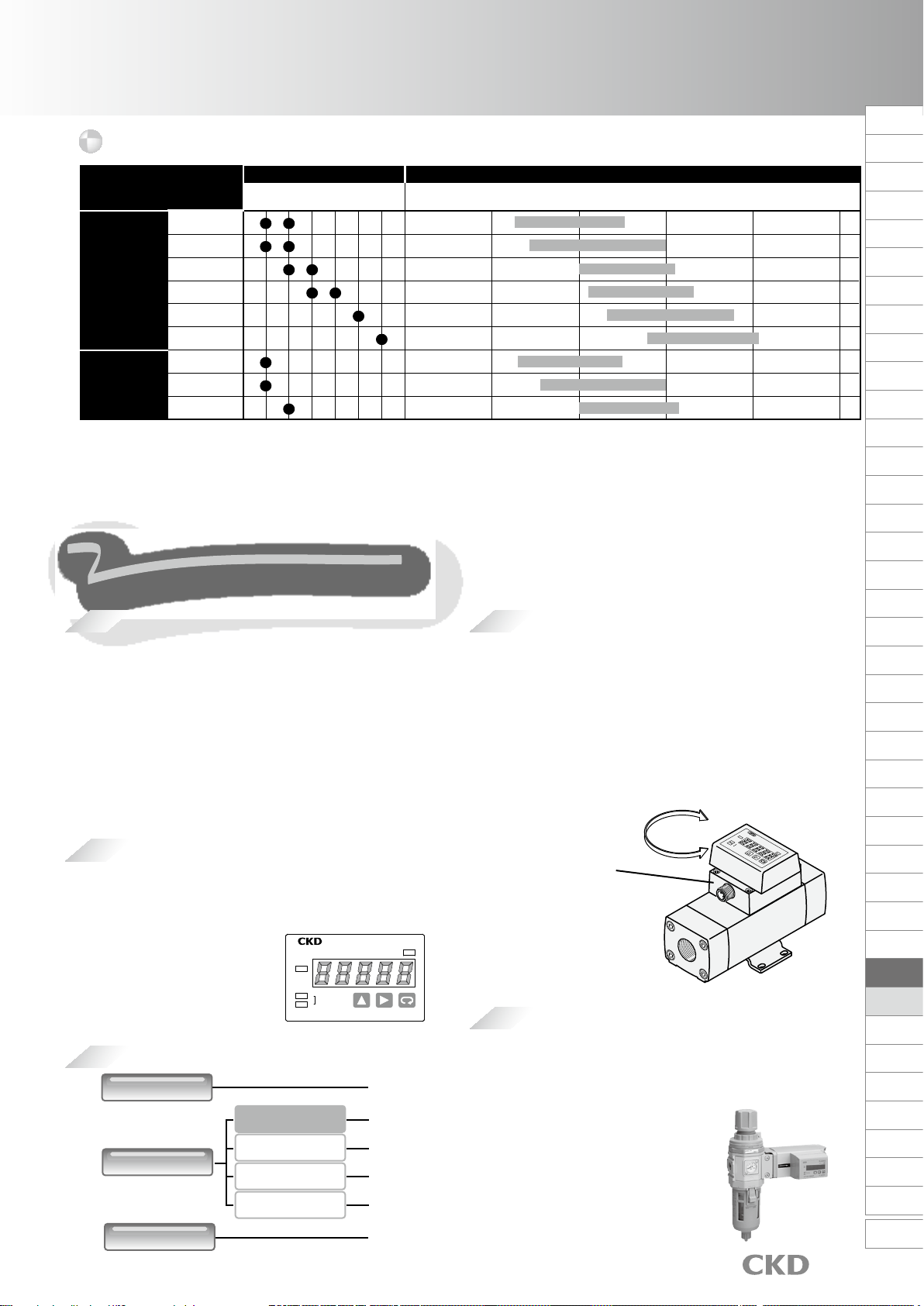

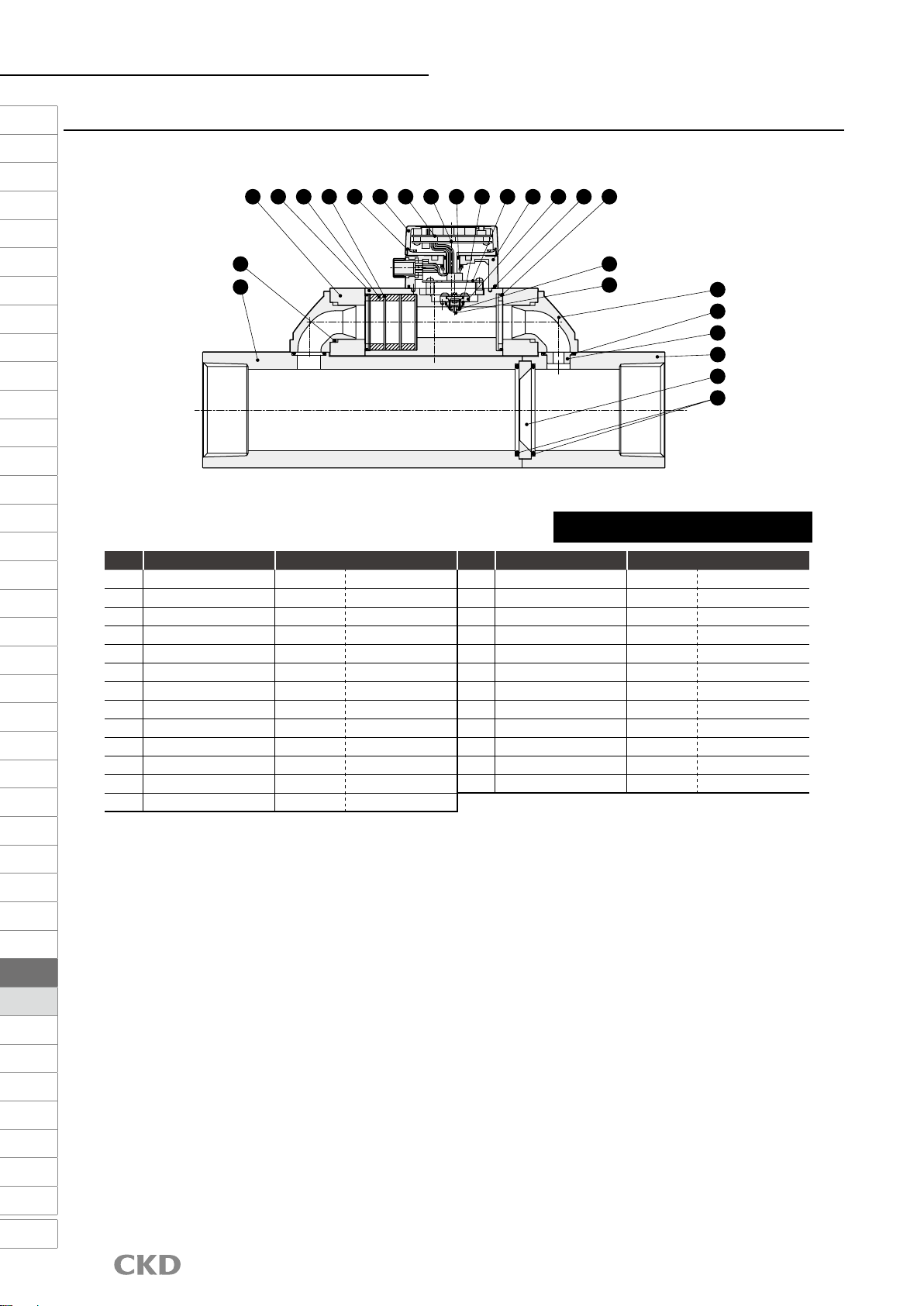

Port size Rc

Module

Standard

PFU1000F

PFU2000F

PFU500F

PF16000F

PF8000F

PF4000F

PF2000F

PF1000F

PF500F

2

(50)

0 10 100 1000 10000 100000

25 500

50 1000

100 2000

200 4000

400 8000

800 16000

25 500

50 1000

100 2000

Flow rate range L/min(normal)

Model

Series

●

Secure design that is hard to break even with drain (water drops)

(double the environment-resistance compared to conventional products)

·Improved water resistance by applying

a special coating to the platinum thin-film sensor.

·Overheating of the sensor element is prevented

by a protection circuit.

Reliable

Easy to use

Easily visible LED is used. Integrating flow 5-digit display.

High performance

Digital direct-reading, correction not needed

The display and sensor are housed in one compact body.

A wide range of output variations

Filter and regulator are integrated

into a unit by modular design

(PFU500F,PFU1000F,PFU2000F)

Unrestricted installation

Heavy duty design

Degree of protection IP64 equivalent

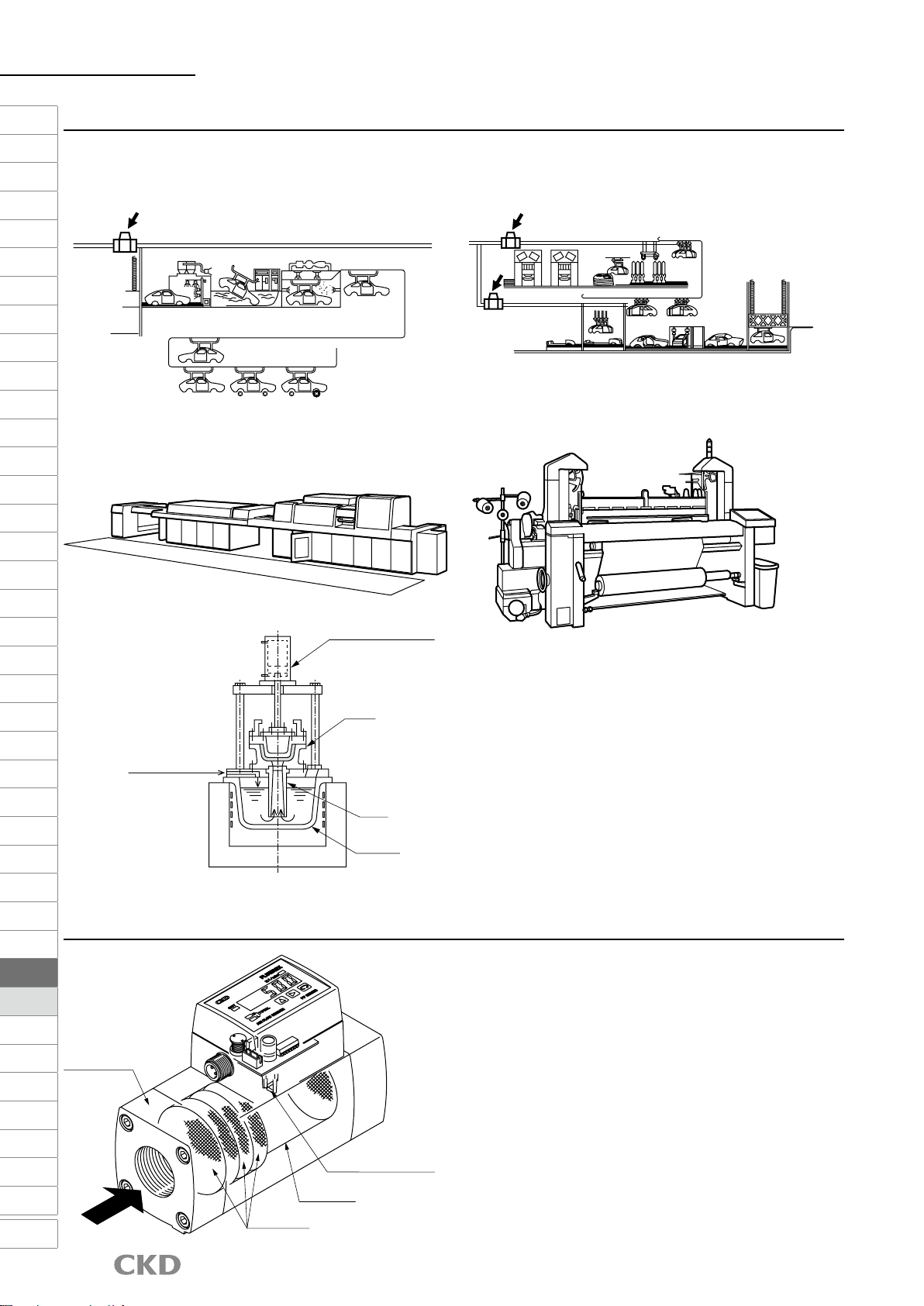

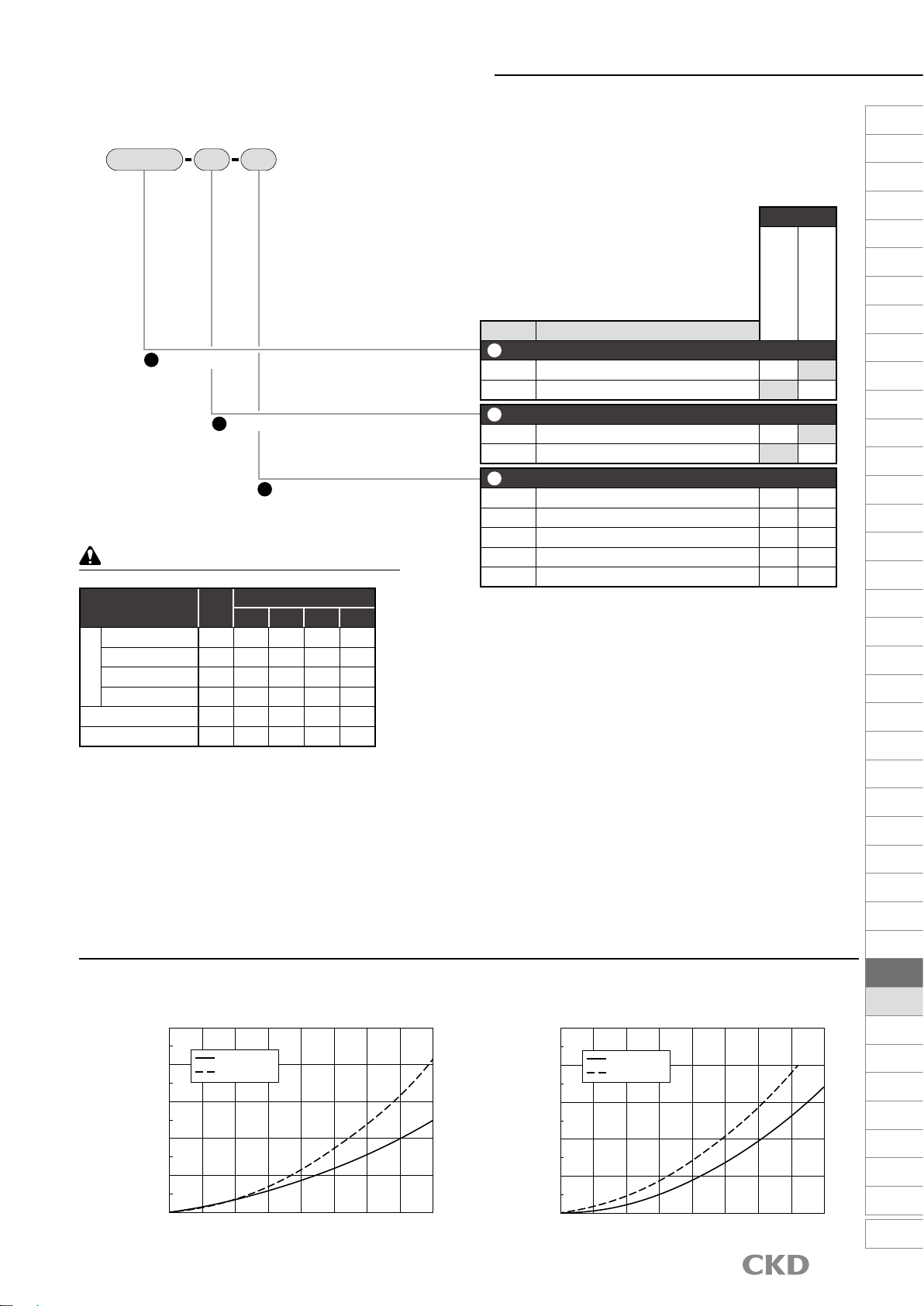

Flow distribution is constant

Flow rate distribution leans towards the outer circumferential direction

due to the elbow.

Rectifier Sensor

Air

High precision of practical precision ±3% F.S.

Pressure loss 0.005 MPa (primary pressure: 0.7 MPa)

is realized

*1

By laminating the rectification filter,

pressure loss is reduced to 0.005 MPa.

(*1: Applicable models only)

Straight piping section not required *2

Thanks to the rectifier, there is no impact even if the elbow and

T-shaped socket are piped just before the sensor.

(*2: Excluding PF8000/PF16000F)

With no need for correction, practical precision ±3% F.S. is realized at

temperature 0 to 40°C and pressure 0.1 to 1.0 MPa.

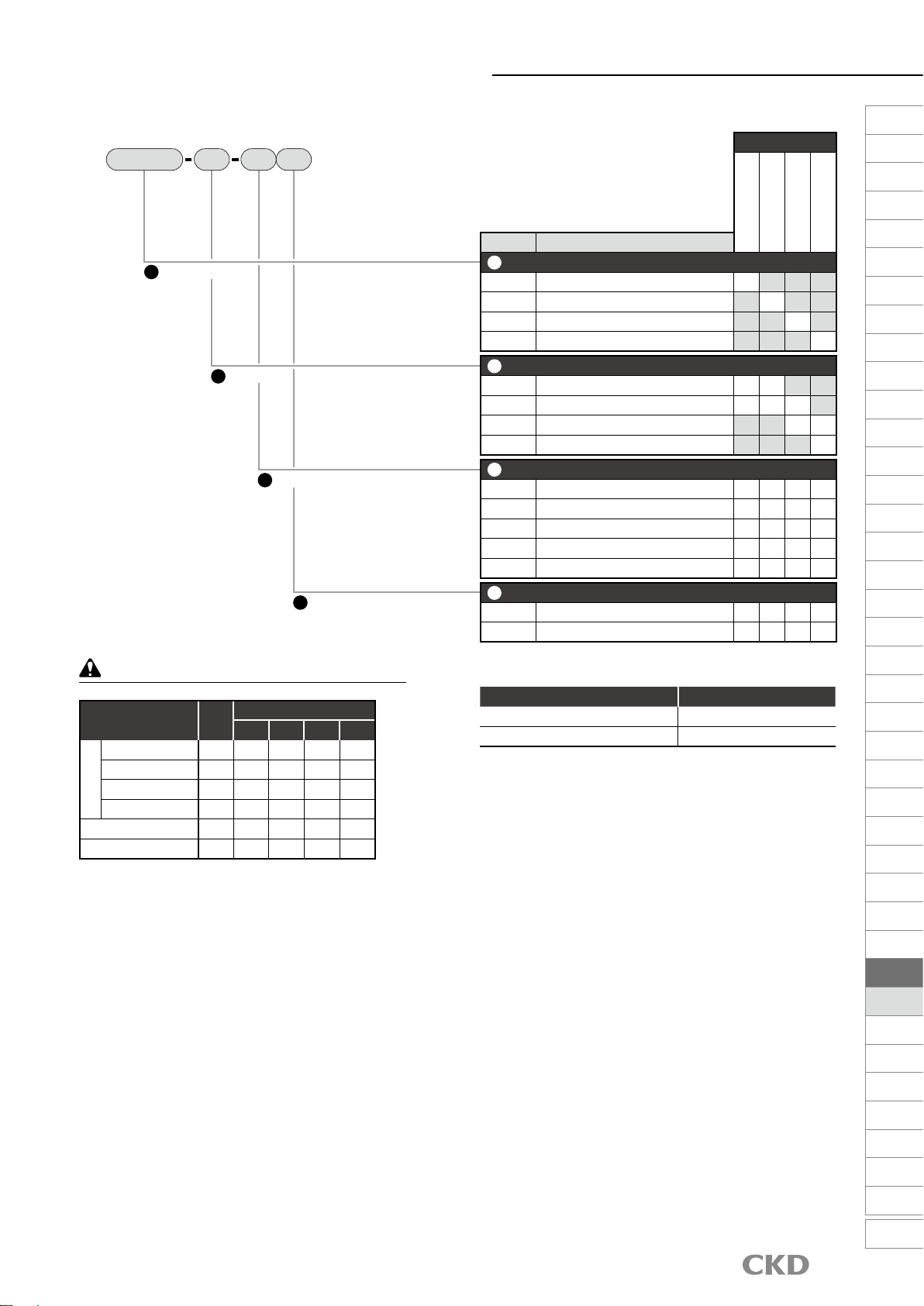

■Pipes can be installed in any orientation, vertical,

horizontal, etc.

·

The display unit can be rotated up to 270° as desired.

·Connector wires can be drawn out along the piping

and do not occupy space.

·Connector wires can be drawn from either IN or OUT

side by rotating the connector case 180°.

OUT

TOTAL

H

L

FLOW SENSOR PF SERIES

FLUEREX

L/min(normal)

Connector case

FLUEREX

L/min

PF SERIES

FLOWSENSOR

TOTAL

OUT

H

L

Analog output

Pulse output

4 to 20 mADC

0 to 5 VDC

1 to 5 VDC

0 to 10 VDC

Switch output Standard

Standard

Option

Option

Option

Option

●

Measure the status of flow rate

●

Consider countermeasures

Plan

Grasp the current situation

Do

Implement measures

Action

Correction/continuation

Check

Effect confirmation

●

Measurement with flow rate sensor

●

Cost conversion is possible using integrating function

●

Standardization of equipment/line consumption

●

Application in other lines

●

Stop the air pressure supply during non-operation

●Blow time reduction

●

Application of energy saving nozzle

●Lower pressure

Very useful in grasping the current situation and confirming the effect of energy

It can be safely used even in harsh environments

such as dust and water splashing from all directions.

F.R.L

F(Filtr)

R(Reg)

L(Lub)

PresSW

Shutoff

SlowStart

FlmResistFR

Oil-ProhR

MedPresFR

No Cu/

PTFE FRL

Outdrs FR

F.R.L

(Related)

CompFRL

LgFRL

PrecsR

VacF/R

Clean FR

ElecPneuR

AirBoost

SpdContr

Silncr

CheckV/

other

Jnt/tube

AirUnt

PrecsCompn

Mech/

ElecPresSw

ContactSW

AirSens

PresSW

Cool

AirFloSens/

Contr

WaterRtSens

TotAirSys

(Total Air)

TotAirSys

(Gamma)

RefrDry

DesicDry

HiPolymDry

MainFiltr

Dischrg

etc

Ending

1368