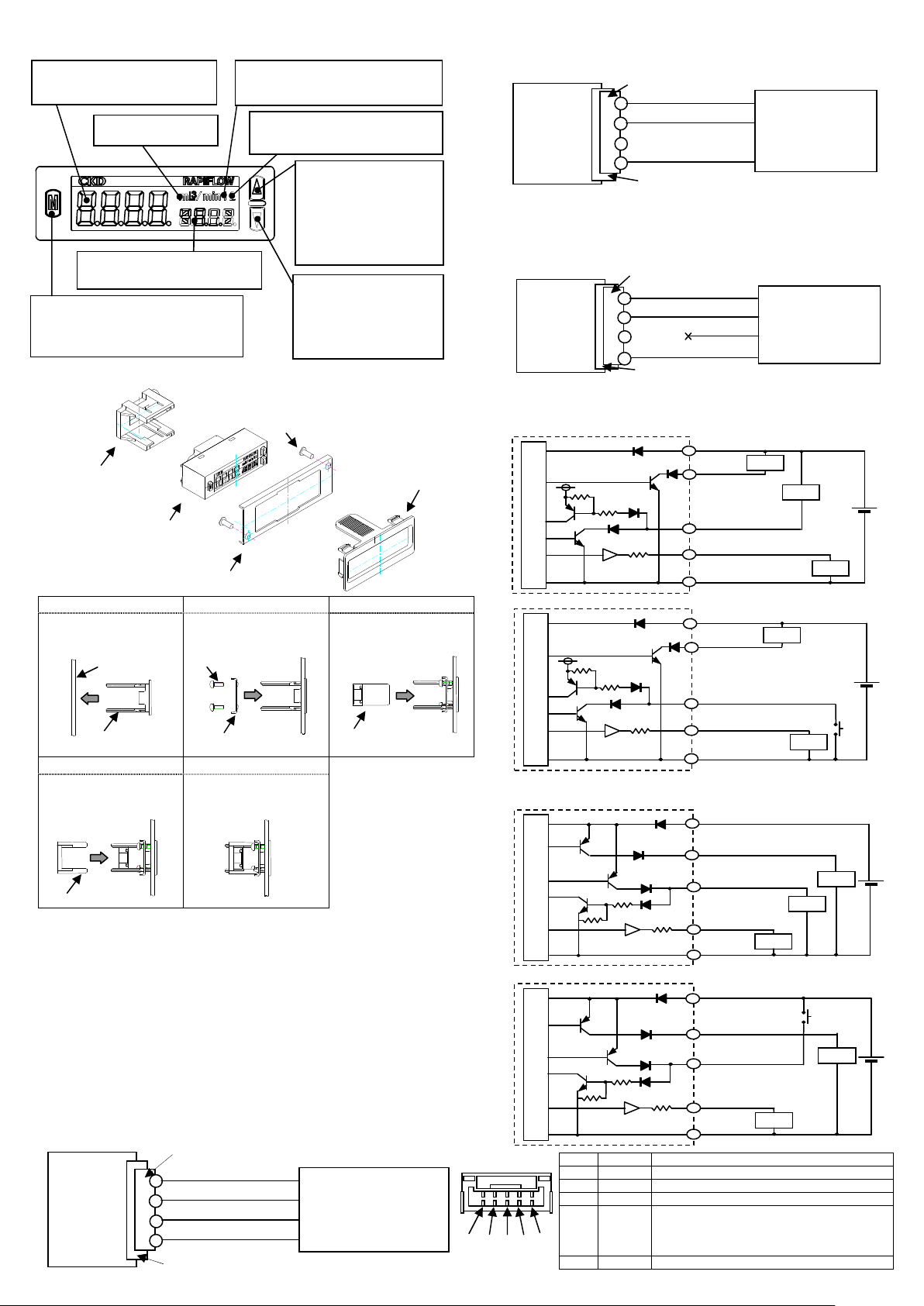

- 2 -

Warning / cautions to secure safety

●Safety cautions are ranked by the safety cautions as

[dan er] [warnin ] [caution] in this section.

●Workin fluid, Workin environment

●Installation

●Wirin

e-con SUMITOMO 3M Wire Mount plu 37104-3122-000FL

●Usa e & maintenance

●The input si nal of the separation indicator is only for (1 to 5V).

When the sensor of other output specifications is connected,

there is a possibility of dama in it.

●For wirin , stop control unit/machinery and equipment, and turn

off the power supply.

●This product and wirin must be installed as far away as possible

from noise source such as stron electric line, etc. Take other

countermeasures for a sur e on the power supply line.

●Do not short-circuit a load, or causin dama e or burn.

●Line color must be checked when wirin . Check the wirin color

with handlin precaution, since improper wire connection may

result in dama e, failure or malfunction of the sensor.

●The flow rate of this product is measured by mass flow not

depended with temperature and pressure. Unit is L/min where

mass flow is converted to volumetric flow at 20 °C and 1

atmospheric pressure (101kPa).

●Please confirm the specification of the sensor used.

●The product can not be used as a business mater. Not

conformed to the Measurement Law, do not use the product for

the commercial purpose. Use the product as an industrial

sensor.

●Do not use the product in an environment containin corrosive

as such as salphur dioxide, etc.

●Use the product within the ambient and fluid temperature ran es

0 to 50 °C. Even in the specified temperature ran e, do not use

the product where ambient and fluid temperatures will chan e

suddenly, and form dew condensations.

●The protective structure of this product is equivalent to IP40. Do

not install the product where moisture, salt, dust or swarf is

contained, or where pressurized, or depressurized, neither.

When a dan erous situation may occur, or when there is hi h

ur ency to a warnin leadin to fatal or serious injuries, if handlin

is mistaken.

When a dan erous situation may occur if handlin is mistaken,

leadin to fatal or serious injuries.

When a dan erous situation may occur if handlin is mistaken,

leadin to minor injuries or physical dama es.

Danger

●A flammable fluid must not be used.

●Do not use the product in flammable as environment. Since

explosion-protection is not taken, explosion or fire may be

caused.

●The display part uses the LCD. The display becomes difficult to

see for the view an le.

●This product can be installed with any attitude; vertical,

horizontal, ri ht or left.

●When you install the panel mountin please fix by the ti htenin

torque of 0.06N・m when you fix the panel bessel suppression.

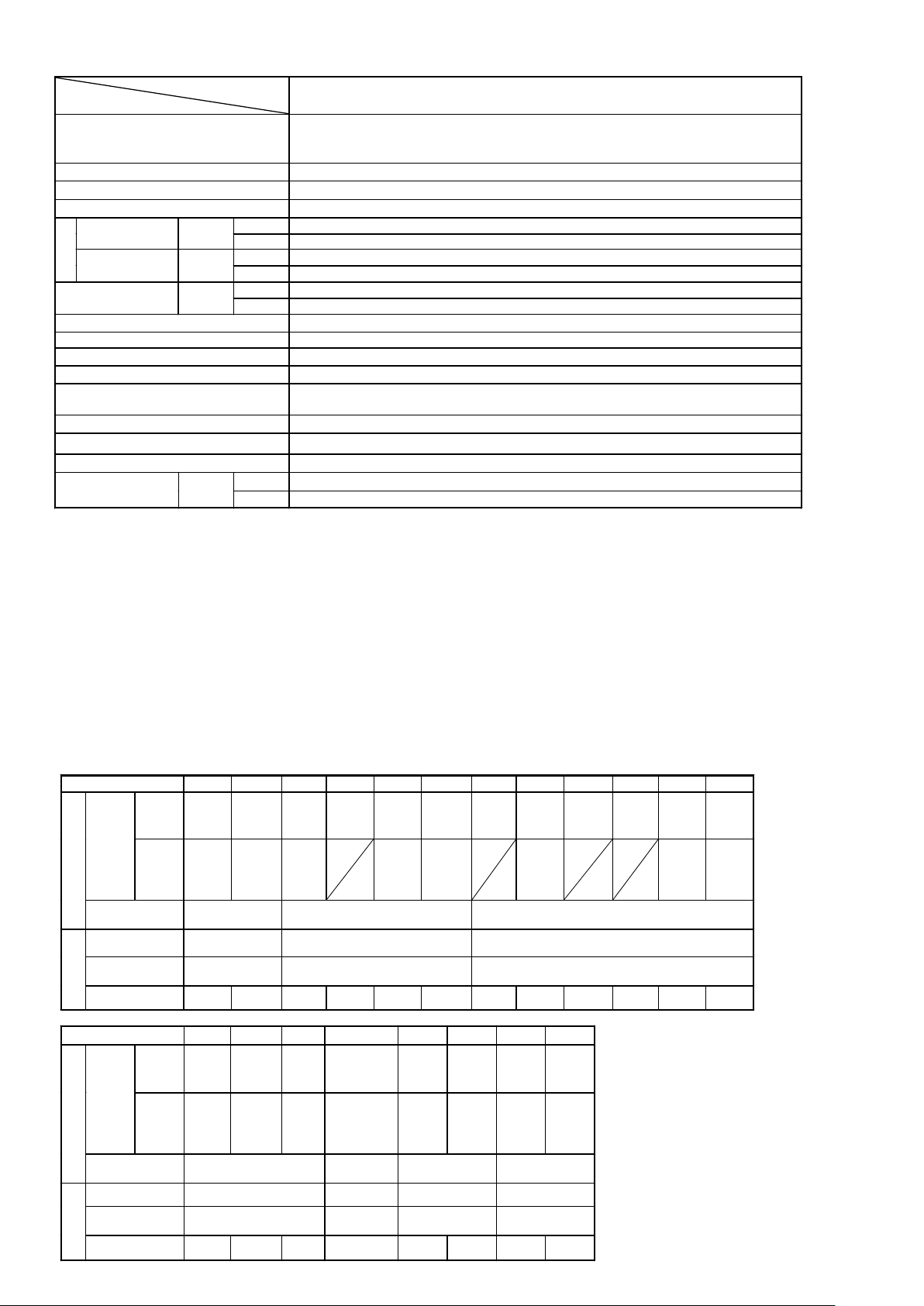

●Power supply volta e and outputs must be used with the

specified volta e. Applyin the volta e more than specified

volta e may cause malfunction, dama e of sensor, electric

shock or fire.

Do not apply load more than the rated output. Dama e or fire of

the output may be caused.

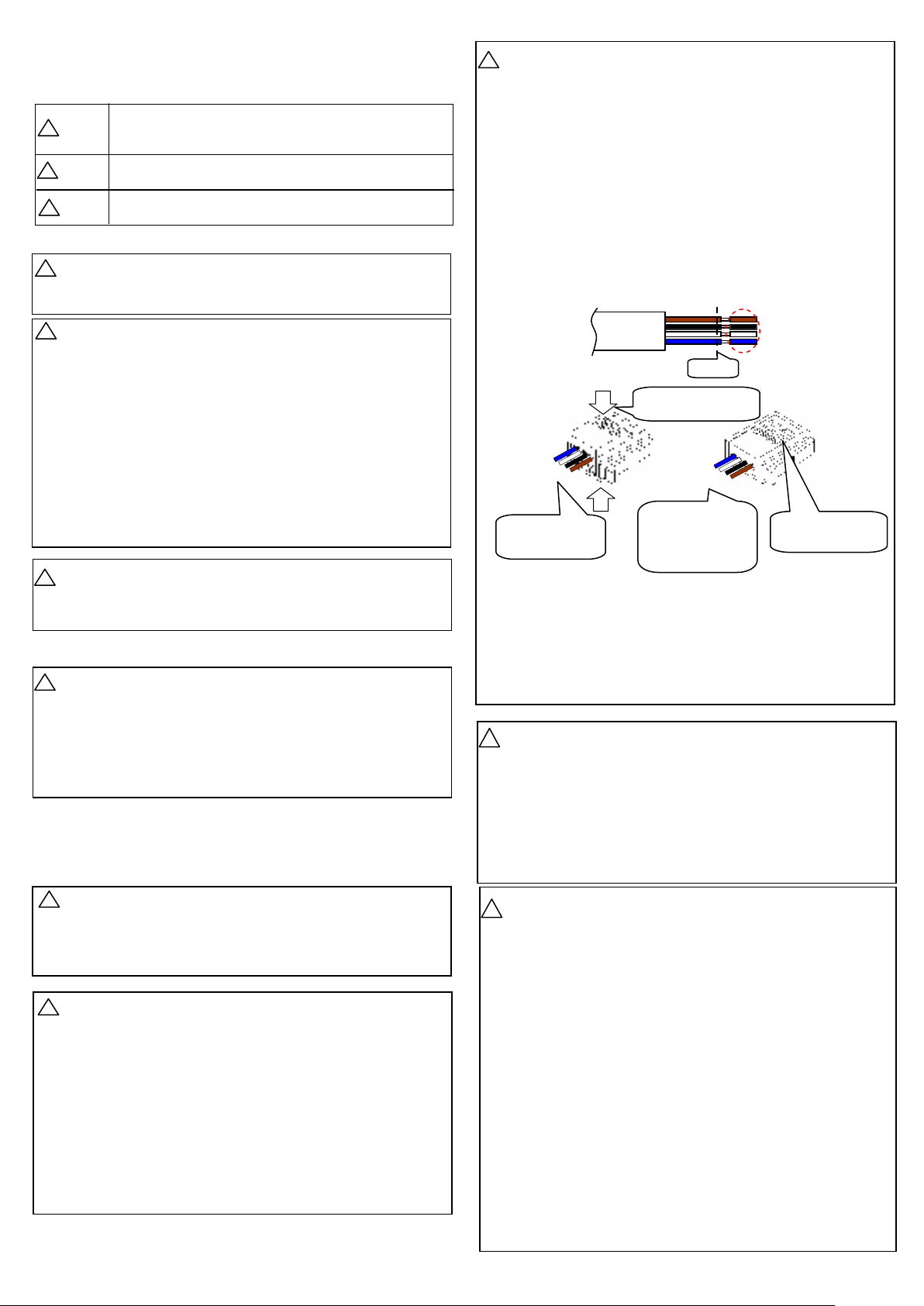

●Output accuracy is affected by self exoer ics caused by

ener izin other than temperature characteristics. When usin ,

stand-by time (5 minutes and over after ener izin ) must be

provided.

●For self-dia nosis, this product does not conduct flow rate

detectin switch operation for proximate 2 seconds immediately

after ener ized. Make a control circuit and pro rams to i nore

si nals for approximate 2 seconds after ener ized.

●When the FSM2 separation display type is connected, and the

power supply is turned on, the model is automatically

reco nized. However, please set the model by the manual

operation when mis-reco nizin it by the noise etc. When other

sensors are connected, the automatic reco nition cannot be

done. In this case, please set it by the manual operation.

●When chan in set-points of the output, stop the equip-ment,

then chan e the set-points, or an accident may occur.

●Disassembly and modification must not be done or causin a

failure.

●When an error occurs durin operation, turn off power supply

immediately, and terminate the operation, and contact to the

sales office.

●The material of case is resin. Solvent/alcohol/cleaner, etc., must

not be used to remove contamination, etc., or causin a resin to

be corroded. Wipe weakened neutral deter ent with ti htly

squeezed waste cloth, etc.

●When out of flow rate ran e, analo output will be provided. [Hi]

or [Lo] will be displayed. However, accuracy is not uaranteed.

●The display part use the liquid crystal. Do not push the display

part., or causin dama e.

Warning

Danger

Warning

Danger

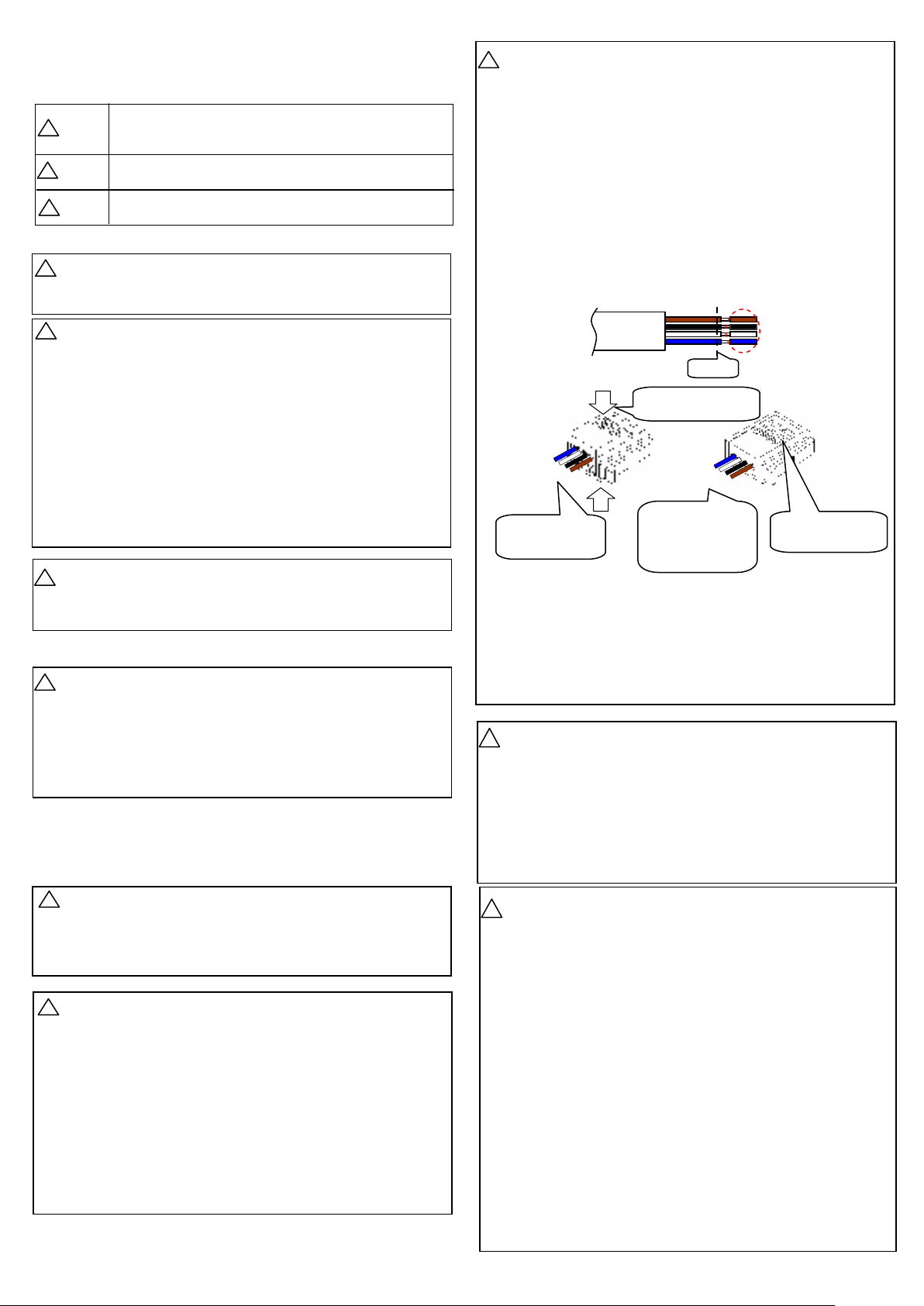

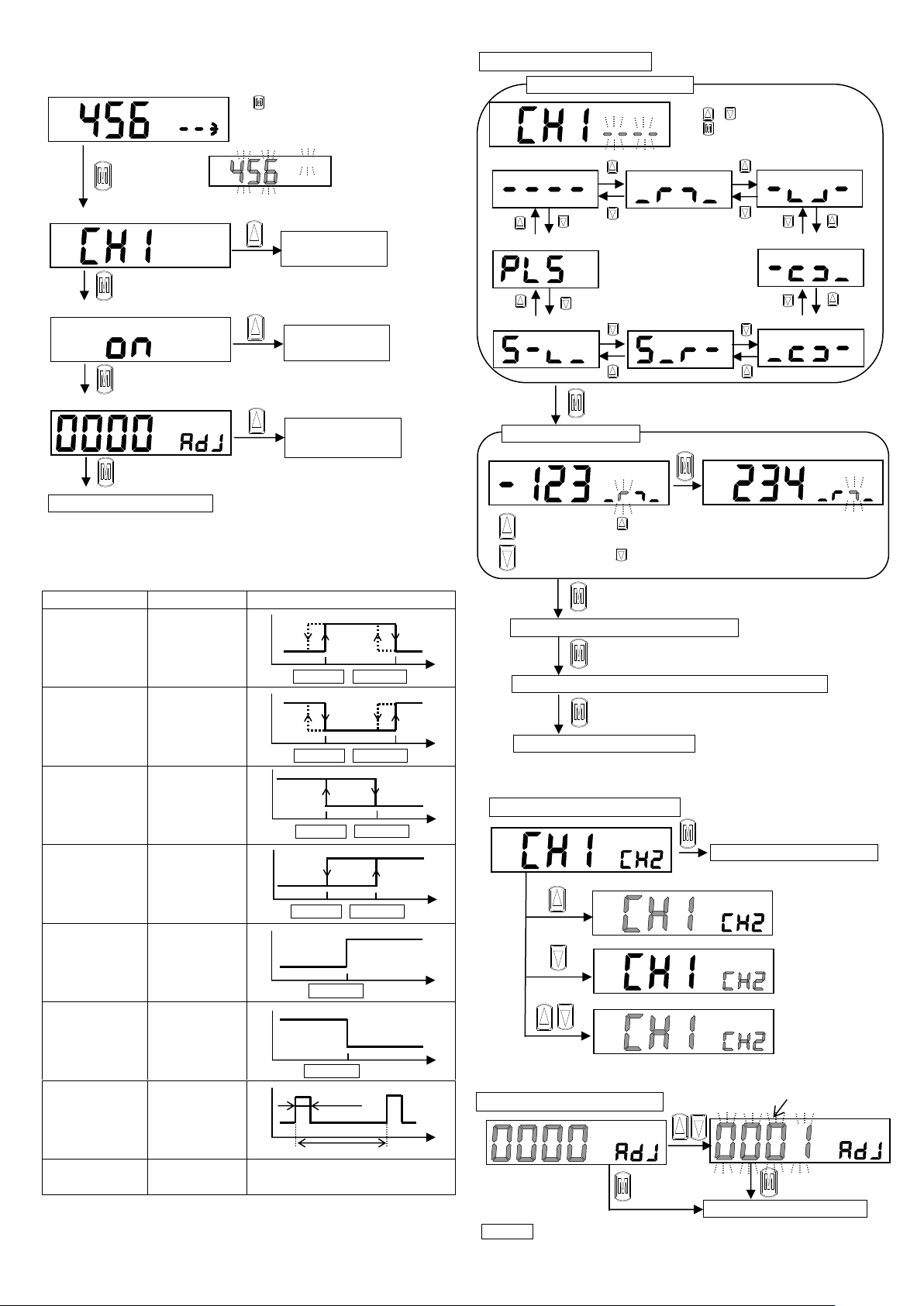

●After the connectors are inserted, lay the connector covers over

the connectors.

●Make sure that stress by forcible bend of pullin is not applies

directly to the sensor cable joint.

●Please connect it by E-CON connector appended to this

product.

●Please use connectin the e-CON connector after cuttin the

half strip part. Please insert the electric wire in the interior of the

connector when you connect the e-CON connector, and please

clamp surely with a tool such as pliers. The removal of the

cover of the electric wire is unnecessary. Please confirm the

color and the number when you connect it, and please do not

make a mistake. The faulty wirin destroys the sensor and the

separation indicator, and causes the breakdown and the

malfunction.

●This product can be connected with the FSM series and the

WFK3000 series of the frow sensor of our company. However,

in this case, the automatic model settin function cannot be

used. Please set the model with the manual. [Please refer to

pa e 8.]

Warning

!

Caution

!

Cable

[1]

Brown

Black

White

Blue

Please insert the

electric wire in the

interior.

Brown

Black

White

Blue

It is not necessary to

make a mistake in

the color order.

1-Brown, 2-Black

3-White, 4-Blue

[2] It is a pliers weldin

with pressure.

Please match this

number and the