SM-50664-A/4 1.

iv 2018-11-12

CONTENTS

PREFACE........................................................................................................................... i

SAFETY INFORMATION.................................................................................................. ii

Precautions on Product Use..........................................................................................iii

Precautions on Product Disposal ..................................................................................iii

CONTENTS...................................................................................................................... iv

1. PRODUCT OVERVIEW............................................................................................. 1

1.1 Model Number Indication....................................................................................1

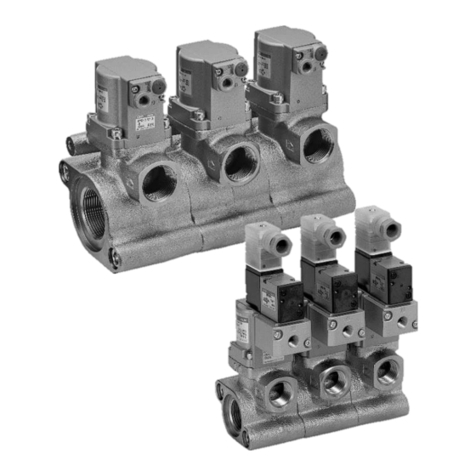

1.1.1 SAB Series.....................................................................................................1

1.1.2 SVB Series.....................................................................................................2

1.2 Internal Structure ................................................................................................3

2. INSTALLATION ......................................................................................................... 9

2.1 Environment........................................................................................................9

2.2 Unpacking.........................................................................................................10

2.3 Mounting...........................................................................................................10

2.4 Piping.................................................................................................................11

2.5 Wiring................................................................................................................13

2.5.1 How to wire the DIN terminal box................................................................. 14

2.5.2 How to wire the T-type terminal box.............................................................15

2.5.3 How to change the orientation of the T-type terminal box...........................15

3. USAGE..................................................................................................................... 16

3.1 Checks to Make Before Use (Checks Made After Mounting)........................... 17

3.2 Safety Instructions ............................................................................................ 18

3.3 Manual Operation............................................................................................. 19

4. MAINTENANCE AND INSPECTION....................................................................... 20

4.1 Maintenance Parts............................................................................................20

4.2 Periodic Inspection............................................................................................20

4.3 Disassembling and Assembling........................................................................ 21

4.3.1 Disassembling..............................................................................................21

4.3.2 Assembling...................................................................................................21

5. TROUBLESHOOTING............................................................................................. 23

5.1 Problems, Causes, and Solutions .................................................................... 23

6. WARRANTY PROVISIONS..................................................................................... 24

6.1 Warranty Conditions .........................................................................................24

6.2 Warranty Period................................................................................................ 24