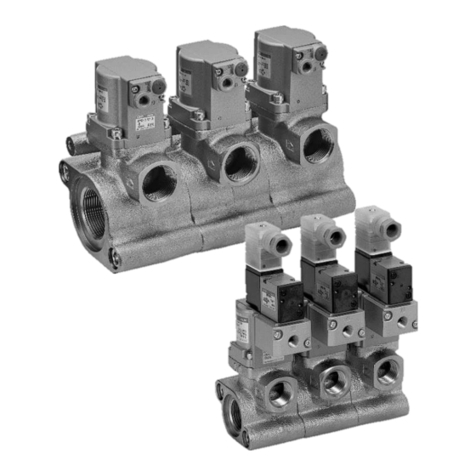

FWD Series

+HDG2IILFH3ODQW 2XML.RPDNL$LFKL

TEL

)$;

6DOHV$QG0DUNHWLQJ'LY 2XML.RPDNL$LFKL

TEL

)$;

2YHUVHDV6DOHV$GPLQLVWUDWLRQGSW

2XML.RPDNL$LFKL

TEL

)$;

2YHUVHDV%XVLQHVVGLY

7RN\R%UDQFK2IILFH )%XQNDKRXVRX0HGLD3OXV+DPDPDWVXFKR

TEL

)$;

0LQDWRNX7RN\R

1DJR\D%UDQFK2IILFH 2XML.RPDNL$LFKL

TEL

)$;

2VDND%UDQFK2IILFH 7RVDERUL1LVKLNX2VDND

TEL

)$;

&$&

1Term of warranty

:DUUDQW\3HULRGLVRQH\HDUIURPWKH¿UVWGHOLYHU\WRWKH customer.

3&RPSDWLELOLW\FRQ¿UPDWLRQ

In no HYHQW VKDOO CKD be OLDEOH for PHUFKDQWDELOLW\ or ¿WQHVV for a SDUWLFXODU purpose, notwithstanding any GLVFORVXUH to

CKD of the use to which the product is to be put.

2Scope of warranty

In case any defect attributaEOetoCKDisfoundduringtheWarrantyPeriod,CKDshaOO,atitsowndiscretion,repairthedefectorrepOace the

rHOeYant product in whoOe or in part, according to its own judgement.

Note that the foOOowing fauOts are excOuded from the warranty term:

(1) 3URGXFWDEXVHPLVXVHFRQWUDU\WRFRQGLWLRQVHQYLURQPHQWUHFRPPHQGHGLQLWVFDWDORJVVSHFLILFDWLRQV

(2) FaiOure caused by other than the deOiYered product

(3) 8VHRWKHUWKDQRULJLQDOGHVLJQSXUSRVHV

(4) Third-party repair/modification

)DLOXUHFDXVHGE\UHDVRQWKDWLVXQIRUHVHHDEOHZLWKWHFKQRORJ\SXWLQWRSUDFWLFDOXVHDWWKHWLPHRIGHOLYHU\

)DLOXUHDWWULEXWDEOHWRIRUFHPDMHXUH

,QQRHYHQWVKDOO&.'EHOLDEOHIRUEXVLQHVVLQWHUUXSWLRQVORVVRISURILWVSHUVRQDOLQMXU\FRVWVRIGHOD\RUIRUDQ\RWKHU

VSHFLDOLQGLUHFWLQFLGHQWDORUFRQVHTXHQWLDOORVVHVFRVWVRUGDPDJHV

'LVFODLPHU

Safety precautions Be sure to read the instructions before use.

Refer also to the precautions of "General Purpose Valves(No. CB-03-1SA)".

WARNING

Design & Selection

:RUNLQJÀXLG

<RXFDQQRWXVHDÀXLGRWKHUWKDQZDWHU

Working environment

Do not use the product where the product is exposed to direct-sunlight or may come in contact with water or oil.

Can not be used outdoors.

CAUTION

Design & Selection

Design for Safety

/HDNDJHFXUUHQWIURPRWKHUÀXLGFRQWUROFRPSRQHQWV

When using a programmable controller, etc., with CR

circuits to absorb the surge voltage generated by switch-

ing elements, leakage current could pass and adversely

DIIHFWWKHRSHUDWLRQRIWKHVROHQRLGYDOYH&RQ¿UPWKDW

WKHOHDNDJHFXUUHQWLVZLWKLQJWKHVSHFL¿FDWLRQRQ

theright.

Installation & Adjustment

Installation

Install in a manner tension will not be applied to the coil section lead wire.

Hold the product body when carrying the product. (Do not hold onto the lead wire)

Piping

Dirt or foreign matter in fluid may prevent the product from functioning correctly. Install a filter finer than 80 mesh.

When the regulator and solenoid valve are directly connected, the parts could mutually vibrate causing resonance and chattering.

If the piping cross section on the fluid supply side is restricted, operation may become unstable because of a differential pressure fault when the valve

functions. Use a pipe that matches the port size on the supply side.

During Use & Maintenance

During use

Instantaneous leakage phenomenon

When using the 2 port pilot operated solenoid valve, sudden application of pressure (e.g. starting up a pump) could momentarily open a closed valve and

FDXVHÀXLGWROHDN

Operation

Do not place a back pressure. There is a risk of malfunction.

Water-hammer

If you experience a water-hammer problem, please consider using CKD "WHL-type" or "RSV-type" solenoid valve or a motor valve.

Differential pressure

Keep the differential pressure 0.02 MPa or above between the primary and secondary sides with the valve open.

'LIIHUHQWLDOSUHVVXUHZLOOEHFRPHGLI¿FXOWWRJHQHUDWHEHWZHHQWKHSULPDU\DQGVHFRQGDU\LQWKHIROORZLQJFDVHV

,IDUHVWULFWLRQVXFKDVDQR]]OHLVDWWDFKHGWRWKHVHFRQGDU\VLGH

When valves are simultaneously opened in a state where multiple solenoid valves are piped in parallel.

Assembling & Disassembling

Tightening torque

7KHVFUHZPXVWEHWLJKWHQHGZLWKWKHWRUTXHVSHFL¿HGRQWKHULJKWIRU

disassembly and assembly.

CR circuit

Triode AC Switch

Leakage

current

C

R

Solenoid valve

Programmable controller side

Voltage

Model no.

AC DC

100 V 200 V 24 V

FWD 3 mA or less 1.5 mA or less 1mA or less

Holder plate set screw Body set screw

WR1ÂP WR1ÂP