Intro 4

Smooth cam curve drive is achieved.

Five types* of cam curves are provided as a standard. Shock during

movement and stopping is minimized.

* Modified sine (MS), modified trapezoid (MT), modified constant

velocity (MC, MC2), and trapecloid (TR) are used.

Four types of cam curves with the outstanding operation properties

shown below are selected using parameters, enabling smooth

transfer positioning not possible with simple acceleration/

deceleration time setting control.

Easy design

A socket and spigot on the main console and table mounting facilitate

alignment.

Easy connection

An integrated driver and controller eliminate the need for

connections.

Flexible programming

Positioning at a random point is possible with NC language. Up to

256 NC programs are saved in the driver.

Variety of external interfaces

Program input, parameter setting, and reading of internal states,

etc., are implemented with RS-232C serial communication.

Different external interfaces, including M codes, are provided for

PLC connection.

Using the serial transmission slave, two types of open networks --

CC-Link and Device-Net -- are selectable.

Easily create programs

The equal index program is created easily by interactively inputting

the number of divisions and movement time, etc., with the optional

interactive terminal, so the system is ready for use right after instal-

lation.

If programs are created in NC language, even complex operations

are possible.

The driver stores up to 6000 characters of programs (256 programs).

Programs are created and saved using a personal computer and

Windows communication software Teaching Note.

CE marking

CE marking compatible parts (option) complying with Low Voltage

Directives and EMC Directives are used. Refer to the instruction

manual for information on installing the system to comply with stan-

dards, etc.

Refer to the CKD EU Standard Compatible Part Guide for details

on compatible models and standards.

The Low Voltage Directive

EN60034-1, EN60034-5, EN50178

EMC directive

EN55011, EN61800-3, EN61000-6-2, EN61000-3-2

Certificating body

TÜV Rheinland

Dowel hole convenient for positioning available

A flexible cable is used as an option for applications with cable

bends.

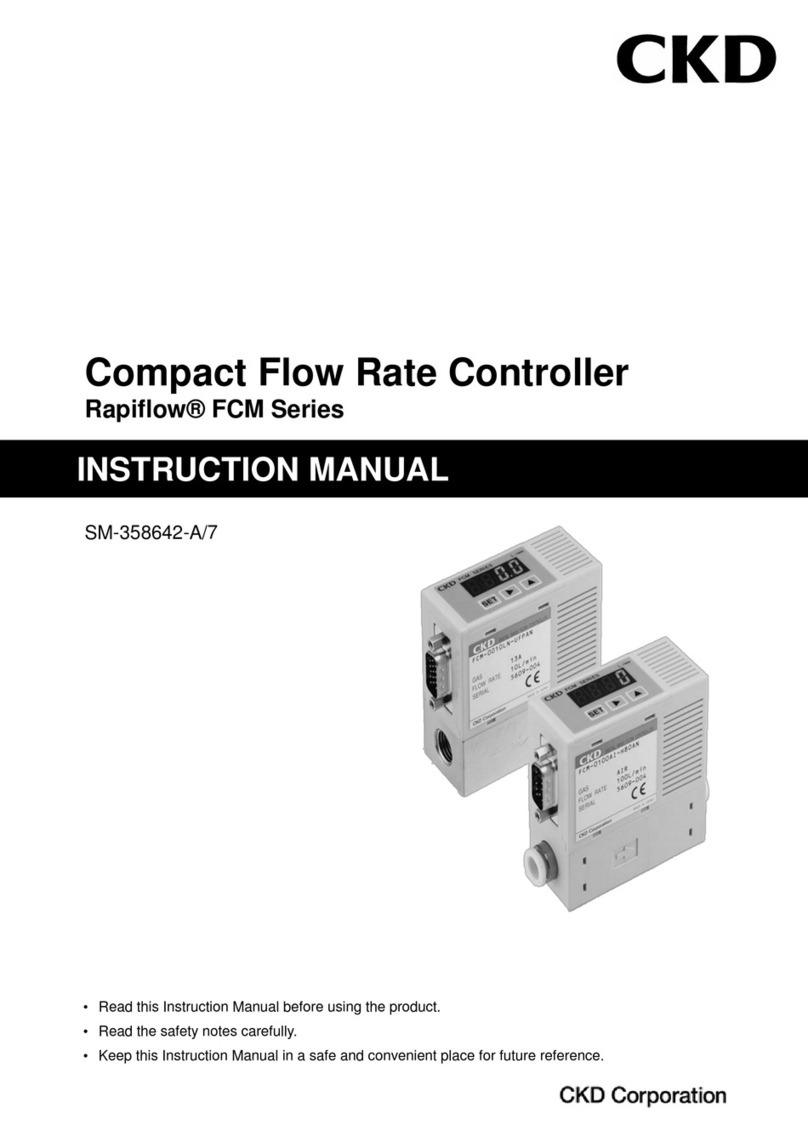

Conditions of measuring examples

Model No. AX1045

Operating conditions Index angle 90˚

Index time 0.5 second

Load moment of inertia 1.67 x 10-2 kg·m2

Vm Am Jm

Name

Acceleration curve

Measuring example

MODIFIED

SINE

(MS)

MODIFIED

TRAPEZOID

(MT)

MODIFIED

CONSTANT

VELOCITY

(MC)

TRAPECLOID

(TR)

Speed

Speed

Speed

Speed

Acceleration

Acceleration

Acceleration

Acceleration

MODIFIED SINE

MODIFIED TRAPEZOID

MODIFIED CONSTANT VELOCITY

TRAPECLOID

Large hollow diameter (AX4000, AX4000G Series)

Large hole diameter specifications are incorporated for easy

piping and wiring to the rotary table. A ball spline enables the

axis of the P&P mechanism to transfer small parts.

(Consult with CKD for ball spline installation.)

Non-backlash negative actuation type with electromagnetic brake

(option) is available. (AX4000, AX4000G Series)

Brake integrated type (AX5000, AX8000 Series)

The integrated pneumatic brakes ensure the output shaft is

clamped when stopping and holding rigidity is increased.

•

This is used for work in which rotational force is applied to the table.

•

Fine vibration in table rotation, caused by the servomotor, is suppressed.

• Holding torque exceeds the motor's maximum output torque.

(At 0.5MPa compressed air)

High-level dust-proof/waterproof structure (AX8000 Series)

IP65* of IEC60529 standards compliant

TÜV Rheinland certified

Enhanced waterproofing is attained with air purging.

*Use low pressure (0.05 MPa) dry clean compressed air for air purging.

Features

Cam curve characteristics and measuring examples