ClearSpan 105595 User manual

Other ClearSpan Shelter manuals

ClearSpan

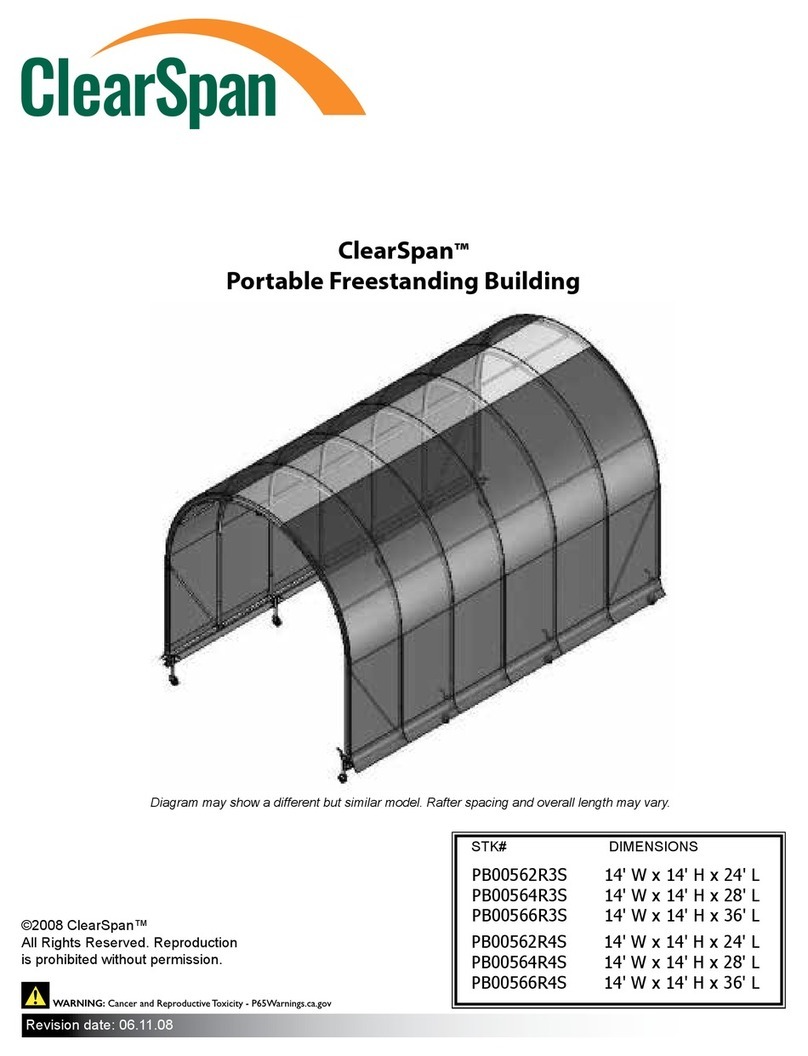

ClearSpan PB00562R3S User manual

ClearSpan

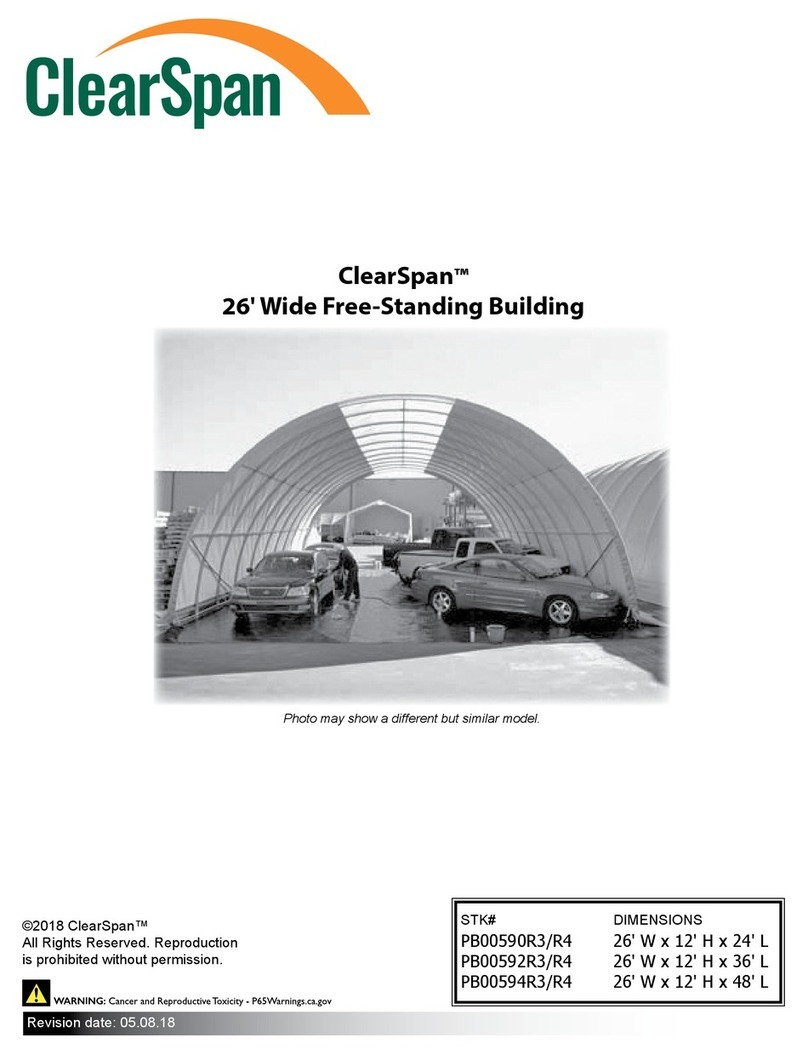

ClearSpan PB00590R3 User manual

ClearSpan

ClearSpan 103476 User manual

ClearSpan

ClearSpan 4040SS User manual

ClearSpan

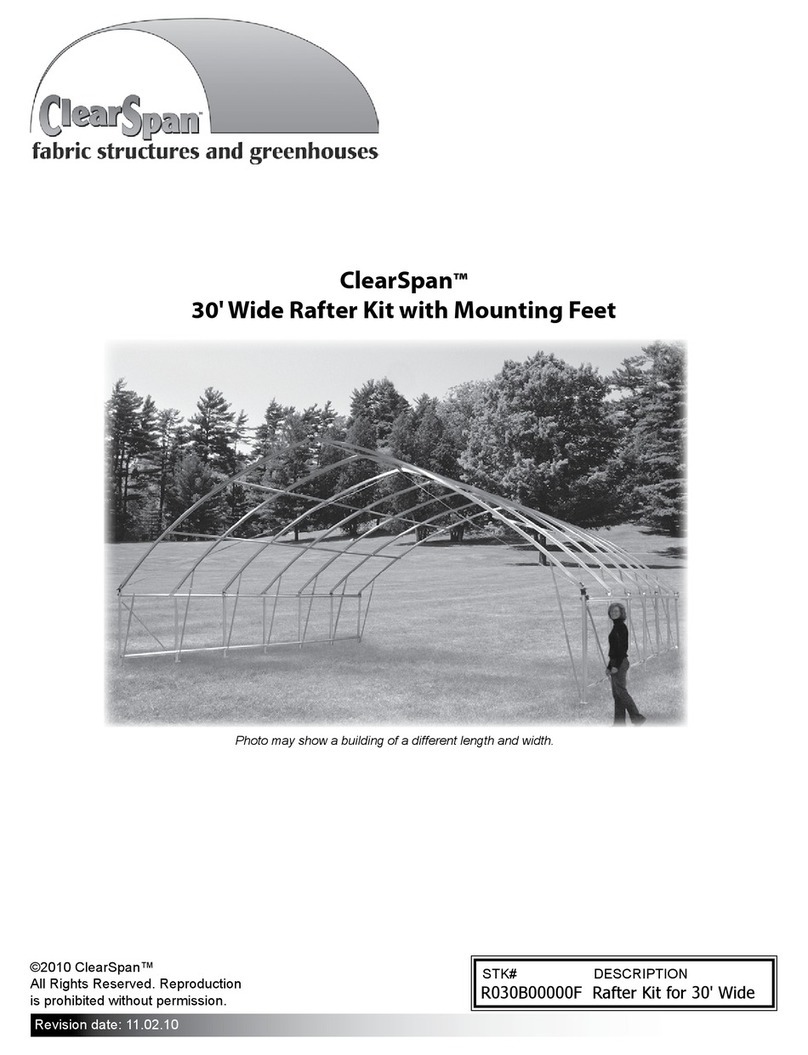

ClearSpan R030B00000F User manual

ClearSpan

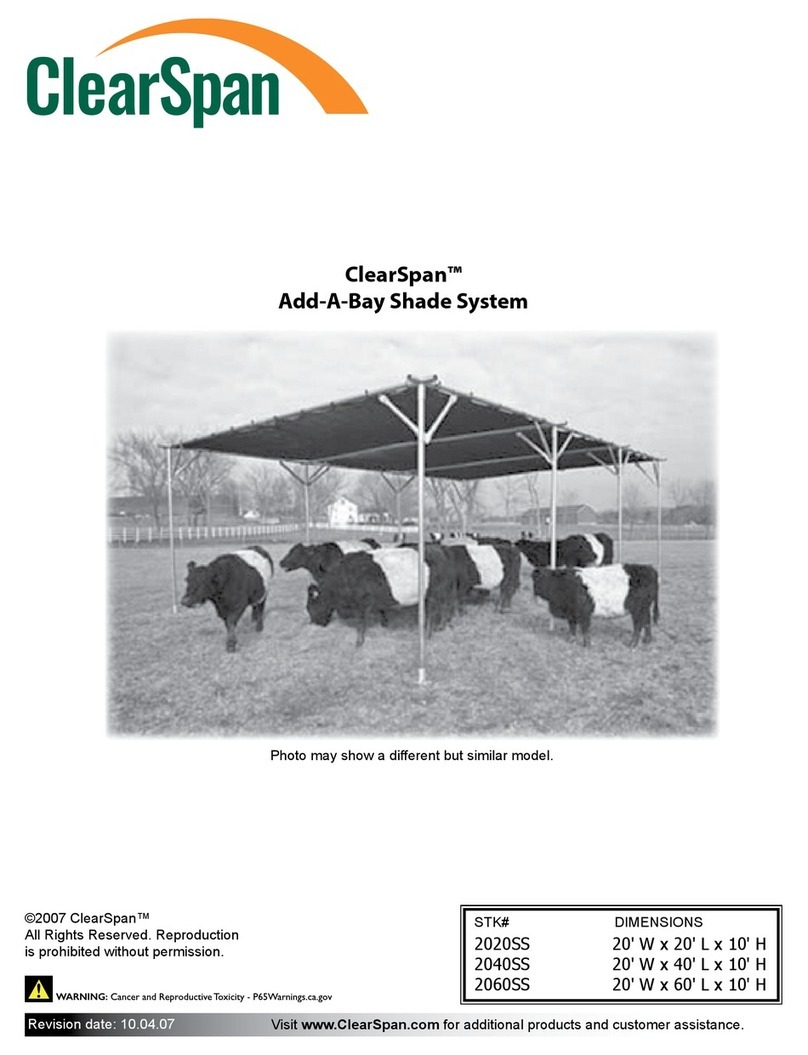

ClearSpan 2020SS User manual

ClearSpan

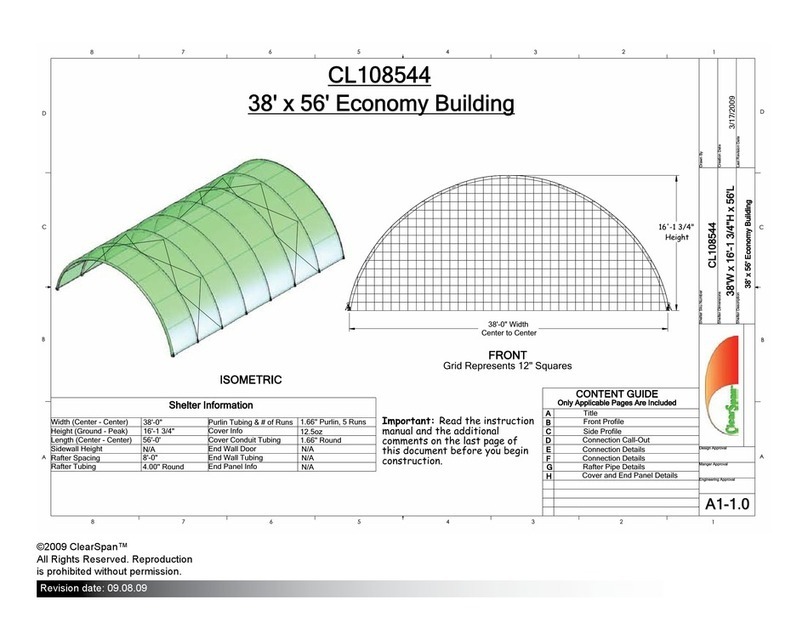

ClearSpan CL108544 User manual

ClearSpan

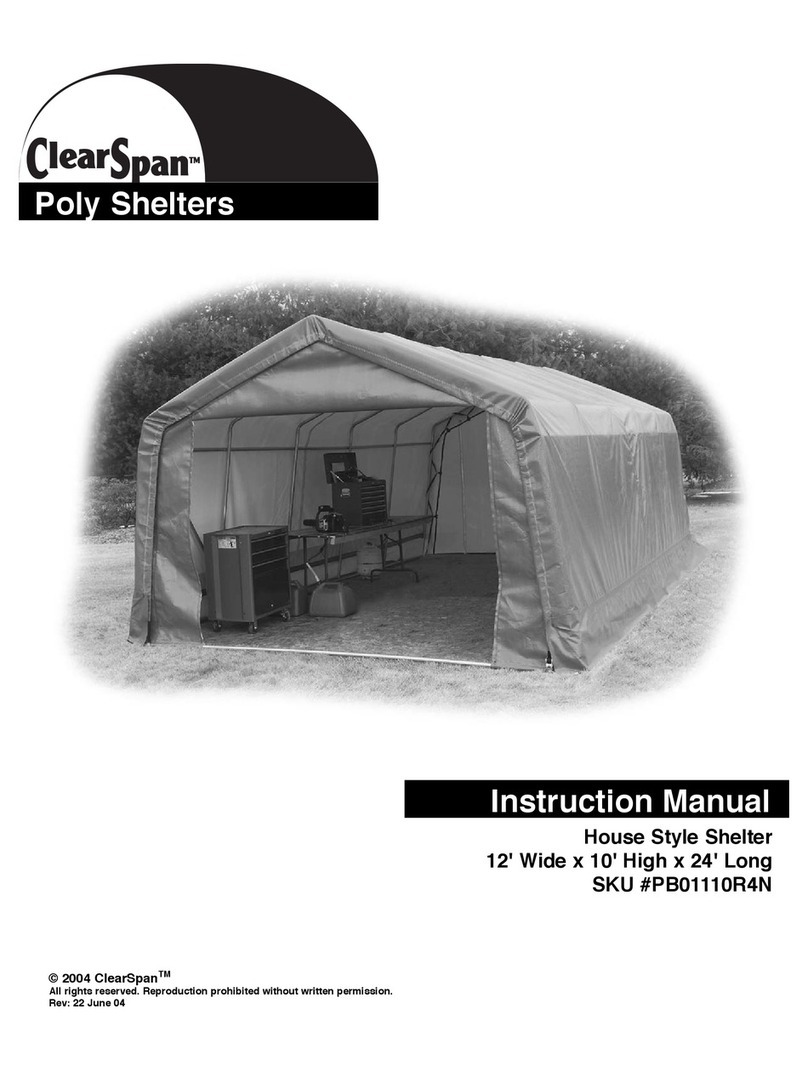

ClearSpan PB01110R4N User manual

Popular Shelter manuals by other brands

Storage Canopy

Storage Canopy C3340R Assembly instructions

Frabill

Frabill ICE HUNTER 195 instruction manual

Shelters4Less

Shelters4Less SR1588 Assembly instructions

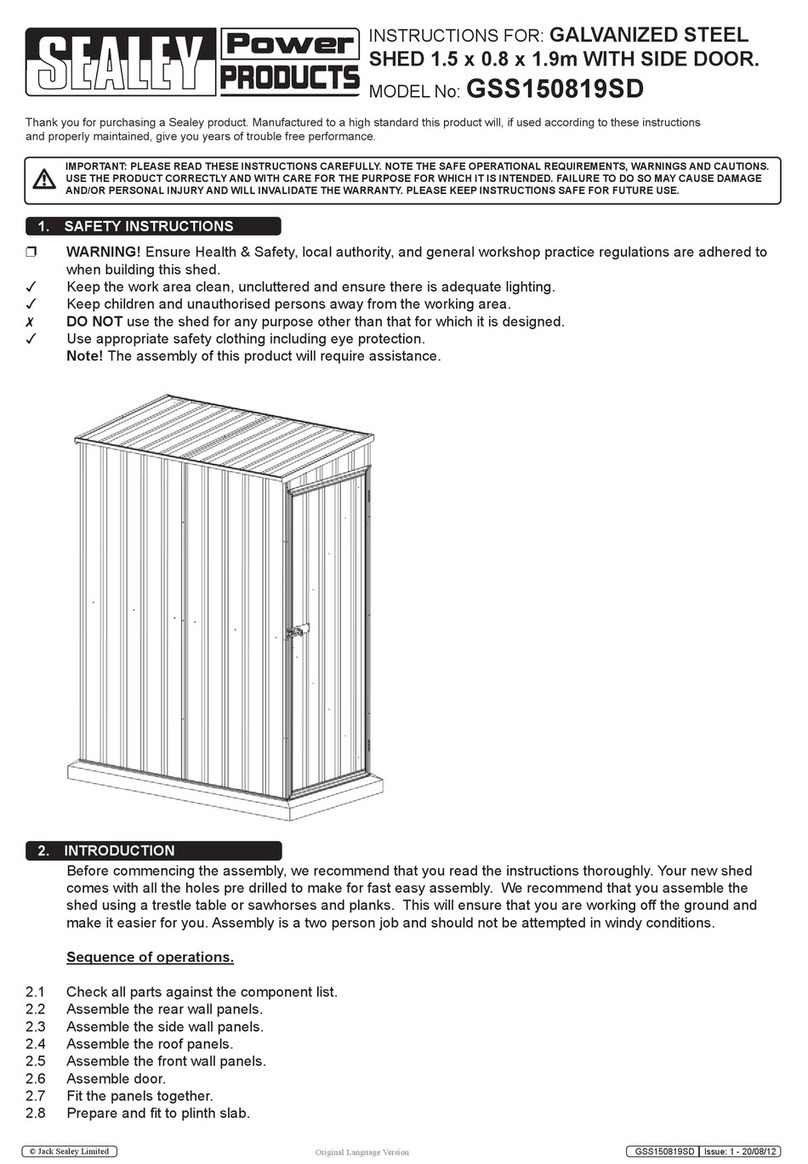

Sealey

Sealey Power Products GSS150819SD instructions

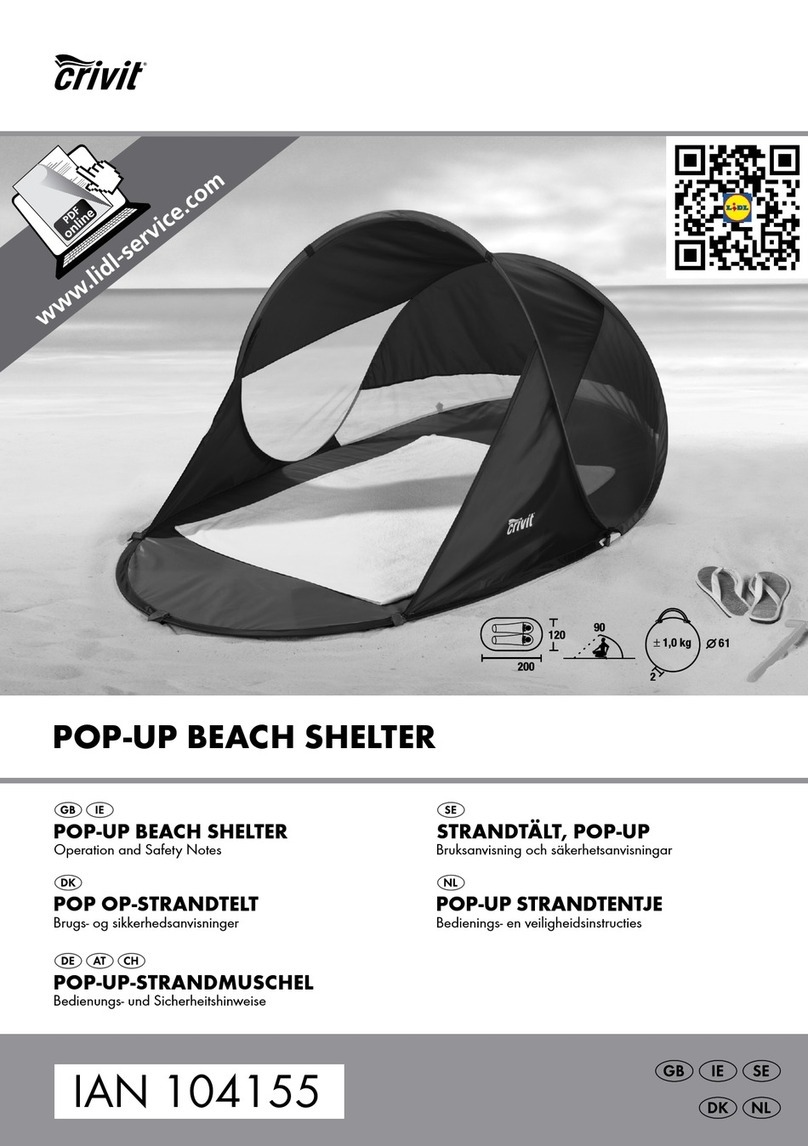

Crivit

Crivit 104155 Operation and safety notes

No Butts Bin

No Butts Bin SR1558-F Assembly instructions