2

1.4 INTENDED USE

The product described in this manual is only intended for sterilization of reusable surgical instruments and

materials.

DEVICE INTENDED FOR PROFESSIONAL USE

The use of the device is strictly reserved to qualified personnel. It must never be used or handled by

untrained and/or unauthorized persons.

The device must not be used for the sterilization of fluids, liquids or pharmaceutical products.

The sterilizer is not a mobile or portable device.

1.4.1. IMPORTANT NOTES

Information contained in this manual is subject to change without notice.

The manufacturer is not responsible for direct, indirect or accidental damage resulting from or relating to the provision

or use of this information.

This document may not be reproduced, adapted or translated, in part or in full, without the prior written permission of

the manufacturer.

1.5 GENERAL WARNINGS

When using this product, always follow the instructions in the manual and never use it for anything other than

its intended purpose.

The user is responsible for any legal requirements relating to the installation and use of the product. The

manufacturer will not be held responsible for any breakage, malfunction, property damage or injury to people

in the event that the product is not installed or used correctly, or proper maintenance is not carried out.

Please observe the following precautions in order to avoid injury or property damage:

›Use ONLY demineralized / distilled water of high quality.

The use of water of inadequate quality can severely damage the device.

See technical characteristics appendix in this regard.

›DO NOT pour water or other fluids on the device.

›DO NOT pour flammable substances on the device.

›DO NOT use the system in the presence of flammable or explosive gases or vapours.

›Before performing any maintenance or cleaning intervention, ALWAYS DISCONNECT power supply.

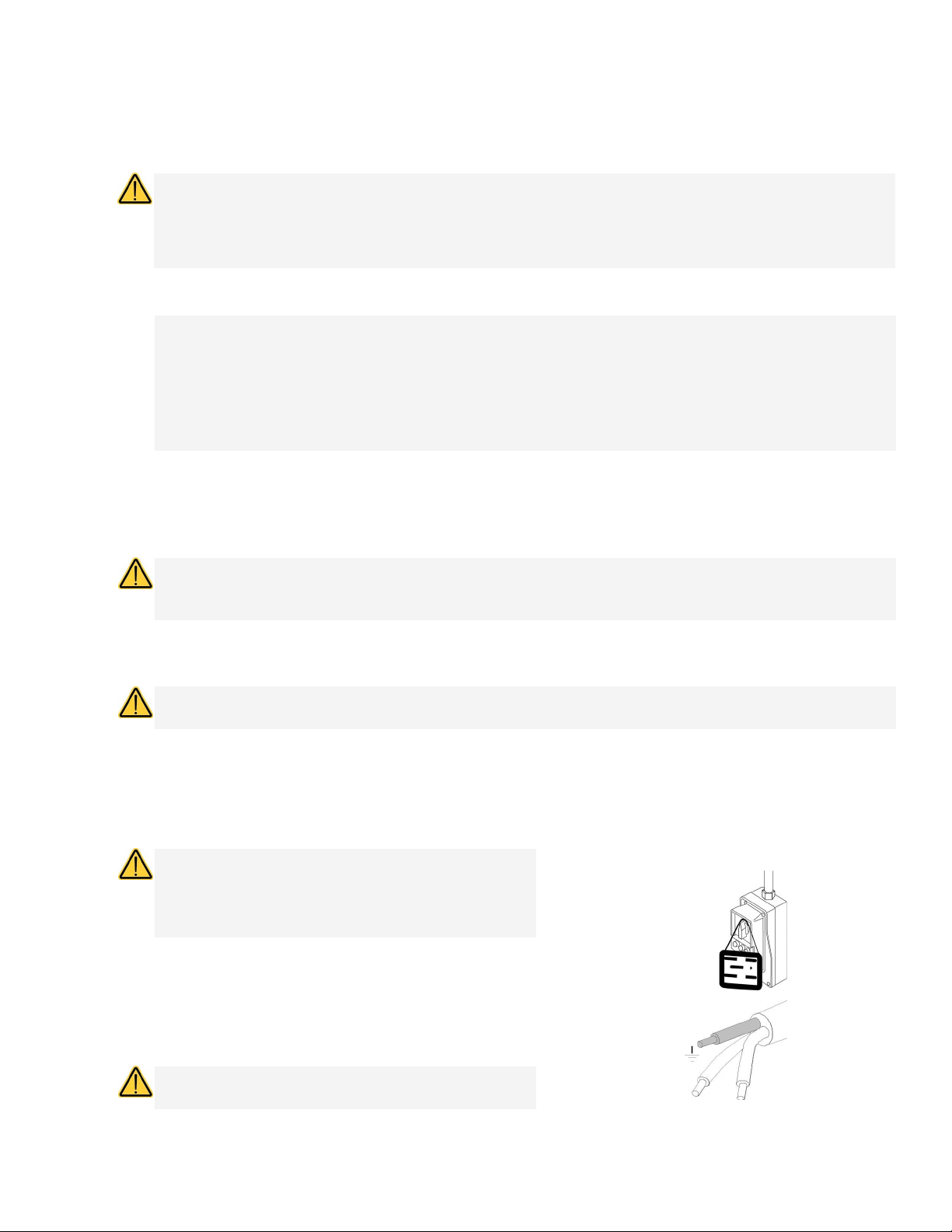

Whenever it is not possible to disconnect the power

supply from the device, or if the external mains

switch is distant or not visible to the maintenance

technician, place a “work in progress” sign on the

external mains switch after having turned it off.

›Make sure the electrical system is grounded

according to current laws and/or standards.

›DO NOT remove any label or nameplate from the device;

request new ones, if necessary.

›Use ONLY original spare parts.

Failure to comply with the above exempts the

manufacturer from all liability.