408- 4457

Rev J

8of 16

DO NOT attempt to clean the ber after it has

been cleaved.

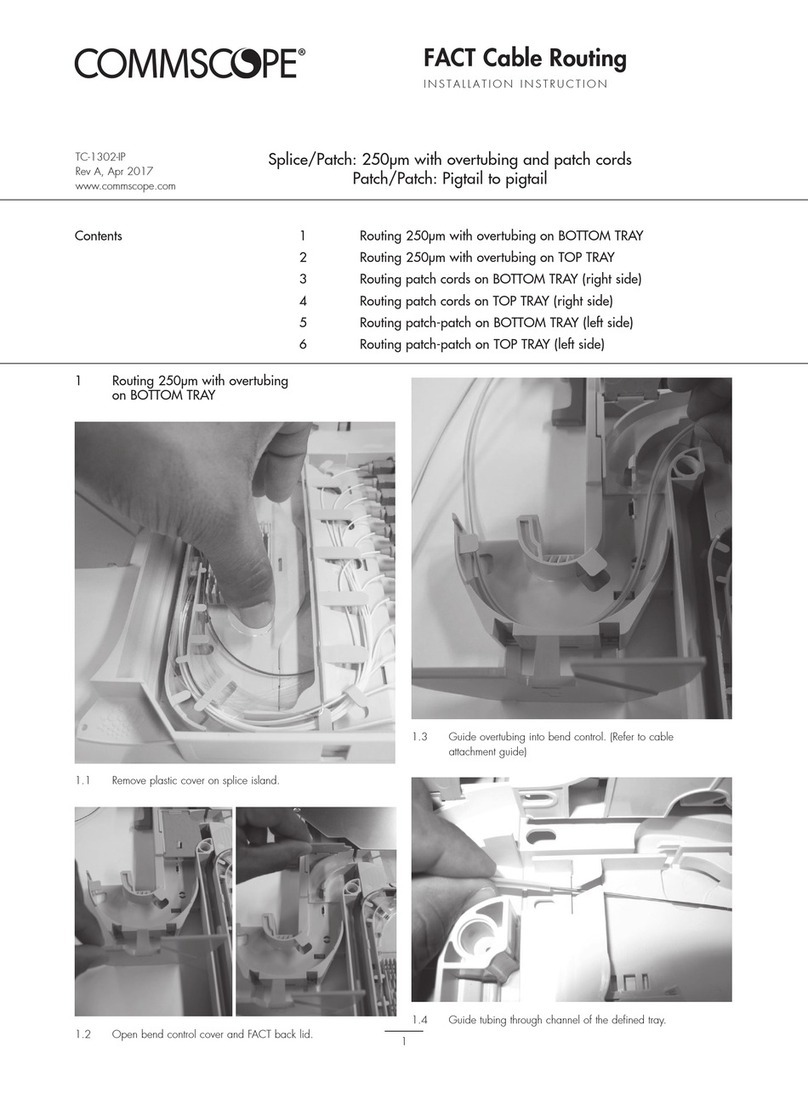

C. Crimping (Figures 9, 10,and 11)

1. Open the cable clamp of the cableholder, and

hold the buer (with the cleaved end of the ber

facing the connector) inside the clamp. Pull the end

of the ber even with the front of the arm of the

cableholder, andholding the buer in place, close

the clamp. See Figure 9, Detail A.

2. Carefullyinsert the berinto the plunger of the

connector assemblyuntil the the berbottoms

against the internal ber. Make sure that the

remaining mark on the buer enters the plunger.

The resultantbend in the buer shouldhold the

beragainst the internal ber. See Figure 9,

Detail B.

It is important that the berbottoms against, and

remains against, the internal ber. If the mark

doesnotenter the plunger or if the berdoesnot

seem to bottom against the internal ber, the

ber may be caught on internalguides. Rotating

the connector andbacking the berout a small

amountand re--entering may help. However, if

the mark willnotenter the plunger, the ber must

be re--stripped.

Make sure that the berdoesnotpull rearward

from the contact (with the internal ber) during

the crimping operation.

3. Squeeze the handles of the hand tooluntil the

ratchet releases. Allow the handles to open fully.

Gently close the handlesuntil you hear three clicks

from the ratchet.

4. With the connector assembly in the cable

holder, position the ferrule protective cover in the

upper cavity of the frontdieand the plunger in the

upper cavity of the reardie. It is importantto make

sure that the tip of the plunger sits in the channel

of the reardiewith the protrudingdisk of the

plungerat against the wall of the cavity. If the

plungerisnotpositioned correctly, it will be

crushedwhen the tool is actuated. See Figure 9,

Detail C.

The arrows marked on the front die indicate the

direction that the ferrule protective cover must be

pointing when the connector is positioned in that

cavity. For proper placement, andtoavoid

damage to the ber, the direction of the arrows

must be observed. Refer to Figure 9, Detail C

and Figure 10, Detail A.

5. Gently push the buer toward the connector to

make sure that the ber is stillbottomed, then

slowly squeeze the toolhandles togetheruntil the

ratchet releases. Allow the handles to open fully,

and remove the connector assembly from the dies.

6. Position the plunger of the connector assembly

in the rst (smallest) cavity of the frontdiewith the

shoulder of the plungeragainst the edge of the

groove in the dieand the ferrule protective cover

pointing in the direction of the arrow. See Figure

10,Detail A.

7. Slowly squeeze the toolhandles togetheruntil

the ratchet releases. Allow the handles to open

fully, and remove the connector assembly from the

die.

8. Slide the crimp eyeletaway from the connector

until the strength members are free, then slide the

crimp eyelet toward the connector until the strength

members and crimp eyeletbutt against the

connector. See Figure 10,Detail B.

For 2.0 -- to 2.4--mm jacketed cable, slide the black

tube forward into the smalldiameter end of the

crimp eyeletuntil it buttsagainst the rear of the

connector.

9. Position the large diameter end of the crimp

eyelet in the last (largest) cavity of the frontdie

with the ferrule protective cover pointing in the

direction of the arrow. See Figure 11, Detail A.

Slowly squeeze the toolhandles togetheruntil the

ratchet releases. Allow the handles to open fully.

10. Position the smalldiameter end of the crimp

eyelet in the middle cavity of the frontdiewith the

ferrule protective cover pointing in the direction of

the arrow. See Figure 11, Detail B.

11. Slowly squeeze the toolhandles togetheruntil

the ratchet releases. Allow the handles to open

fully, and remove the connector assembly from the

die.

12. Open the cable clamp of the cableholder, and

remove the cable from the clamp. Slide the strain

relief over the plungeruntil the strain reliefbutts

against the connector. See Figure 11, Detail C.

13.Remove the connector assembly from the

cableholder.

The assemblyprocedure for 2.0-- to 3.0--mm jacketed

cable is now complete.

"If connecting connectors, inspect the ferruleend

face for cleanliness using200¢Microscope Kit

1754767--1 (includes 2.5--mm adapter cap).

CAUTION

!

NOTE

i

CAUTION

!