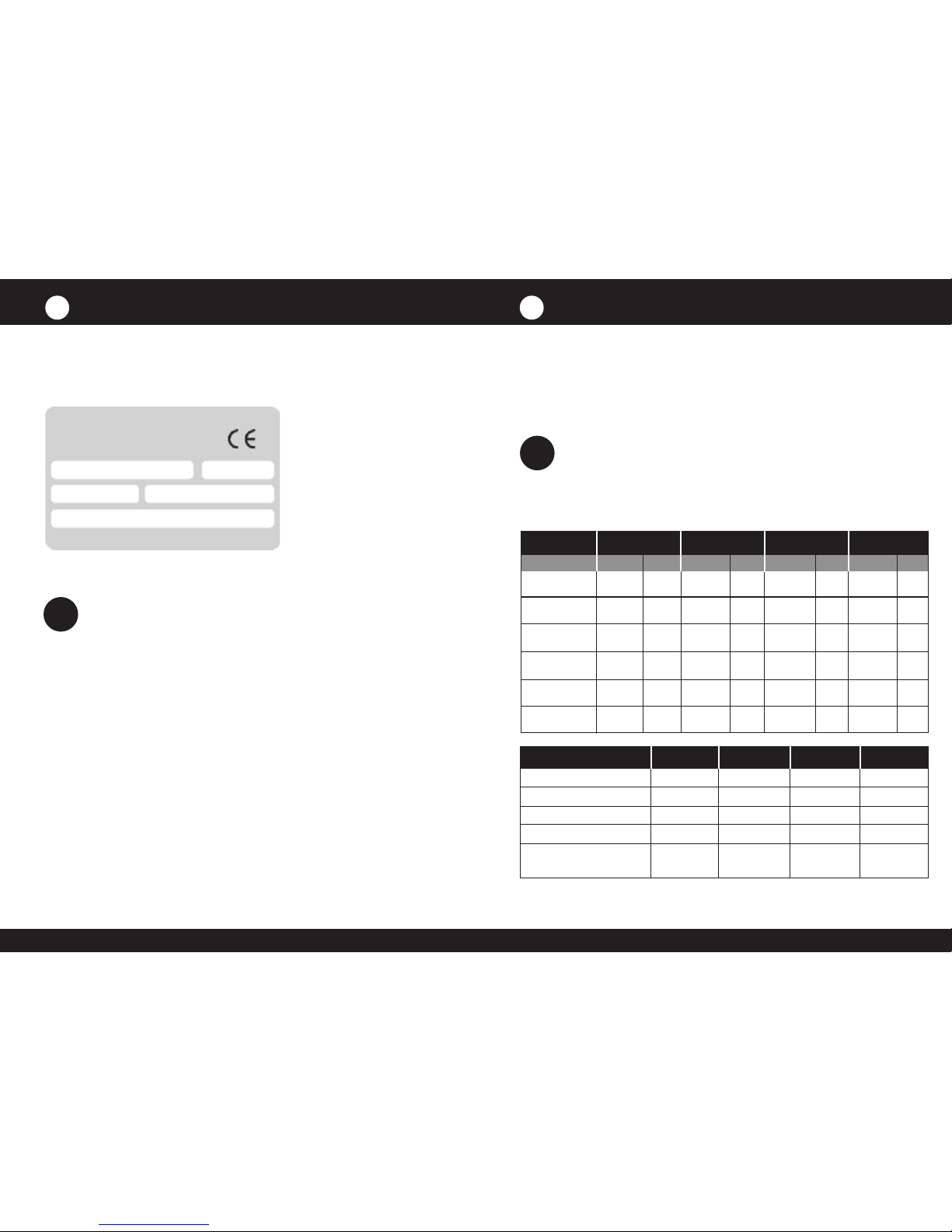

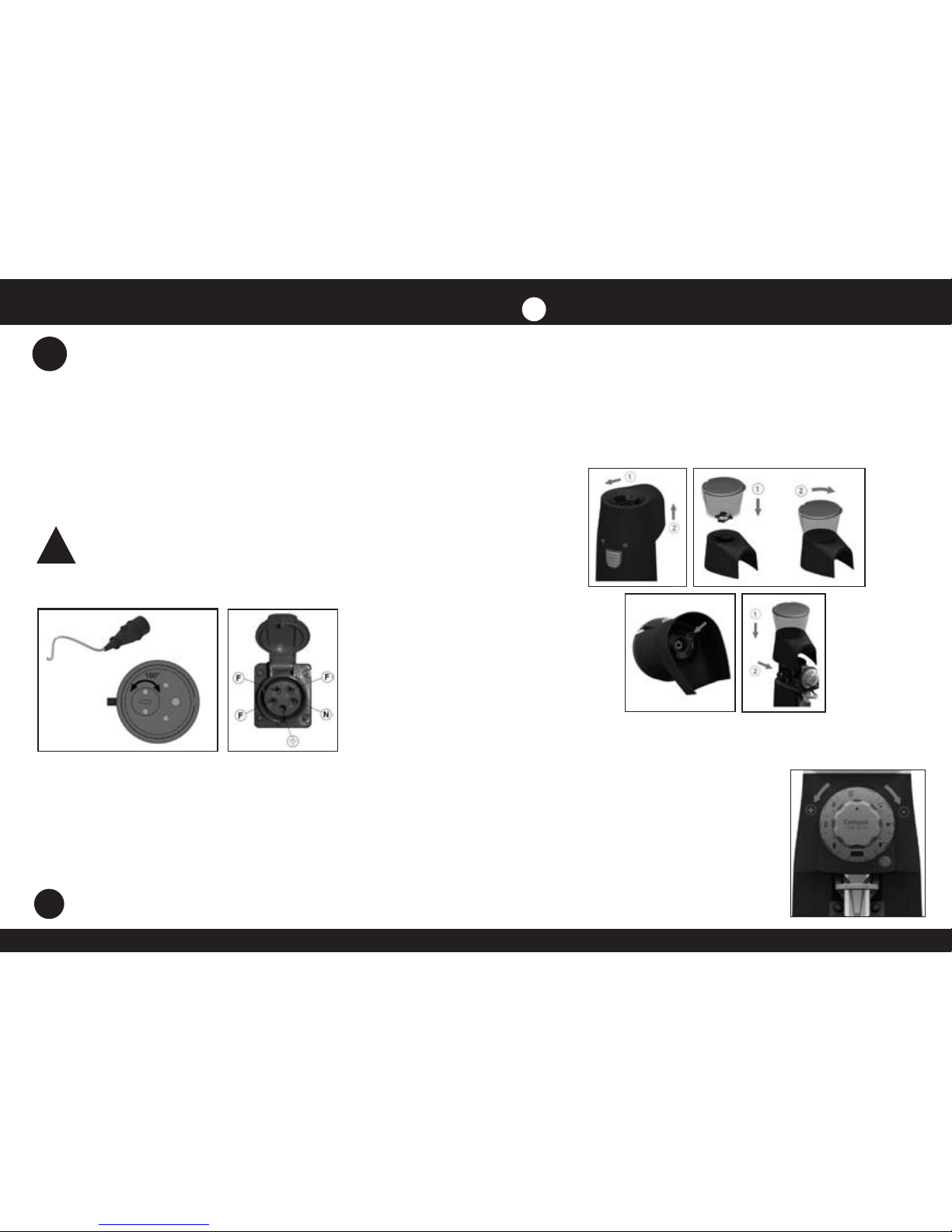

Replace the burrs by unscrewing them from their upper and lower

supports. During this operation, it is recommended to block the

rotation of the lower burrs with a flat-head screwdriver. Clean the

coffee remains from burr holders. Take out the used burrs and put in

the new ones. Assemble to setting screws (a) of the upper burr holder

to the grinding cup.

10.4. Reset the burrs to the 0 position

(the point in which the burrs no longer touch)

Turn the front dial (4) clockwise until the burrs are as close as possible

without touching. Loosen, with the help of the key wrench that comes

with the grinder, the screw (b), until the chain is released.Turn the front

dial (4) clockwise as far as possible.Tighten the screw (b). Assemble the

upper body (3), tightening the two rear screws and replace the hopper.

11 Safety measures

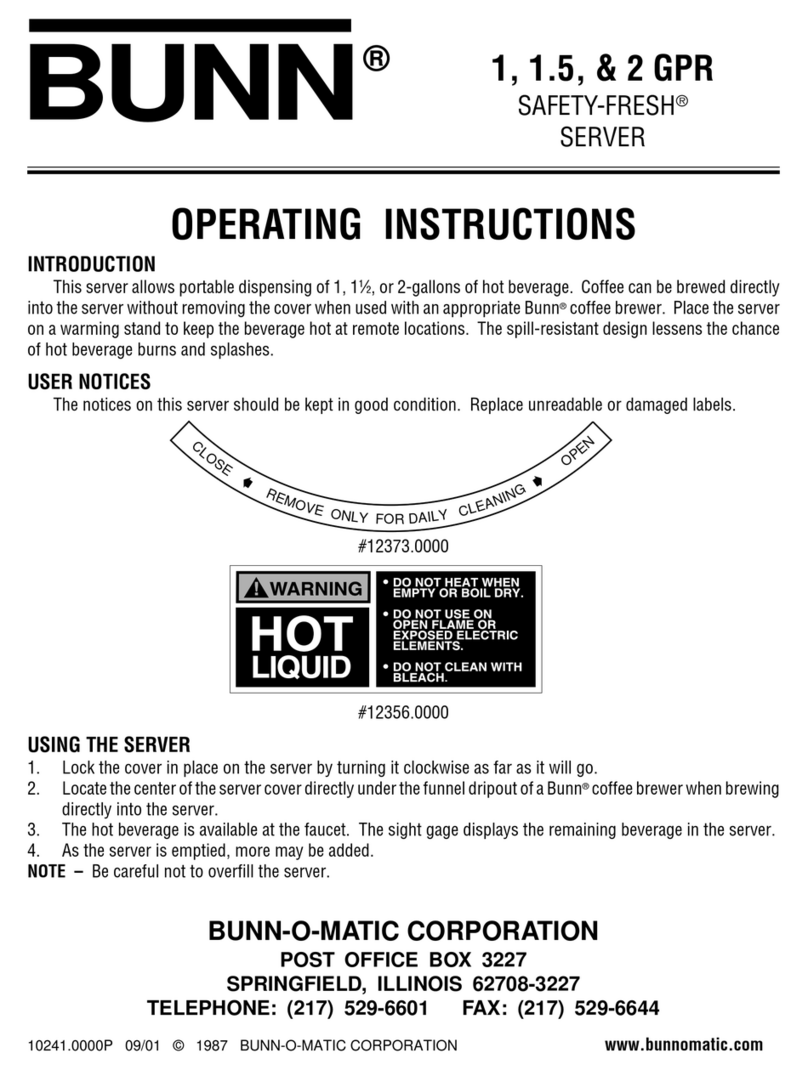

10.3. Grinding group maintenance

To effect grinding group maintenance work, the following instructions

should be followed:

Turn the front setting dial (4) all the way to the left.Turn the machine off,

using the ON-OFF switch (12). Disconnect the cable from the power

supply. Remove hopper (2) from upper body (3) according to section 7.

Dismantle upper body (3), by unscrewing the two rear screws.

Remove the 4 setting screws (a) of the upper burr holder from the

grinding cup (Allen wrench 4), according to Fig. 8.

NOTE: The manufacturer cannot accept responsibility for any damage

caused by improper use of the machine or failure to respect the safety

measures indicated.

Users are asked to pay careful attention to the following indications:

• The coffee grinder should only be used for grinding coffee beans.

• Do not use the machine to grind other types of foods such as nuts,

dried fruits or to fine-grind granulated foods such as sugar, etc.

• Do not allow minors or disabled people to use the machine.

• Any other use of the machine will be considered improper and

dangerous.

• Do not allow liquids to come into contact with the internal or external

surfaces of the machine at any time, except for those parts that have

been expressly referred to in section 9. If, for any reason, this should occur,

immediately disconnect the machine from the power supply and dry all

surfaces carefully. Should it be necessary to access the internal parts of the

machine, where the electrical components are located, take the machine

to your local technical service.

• In the event of any broken components or intervention, we recommend

that you contact your local technical service, who will repair or replace

the part, guaranteeing the maintenance of the safety standards.

• Replacement of the main power cable of any grinder model should only

be done by an authorized supplier.

!

i

(a)

(a)

(a)

(a)

(b)

Fig. 8