ISO 9001

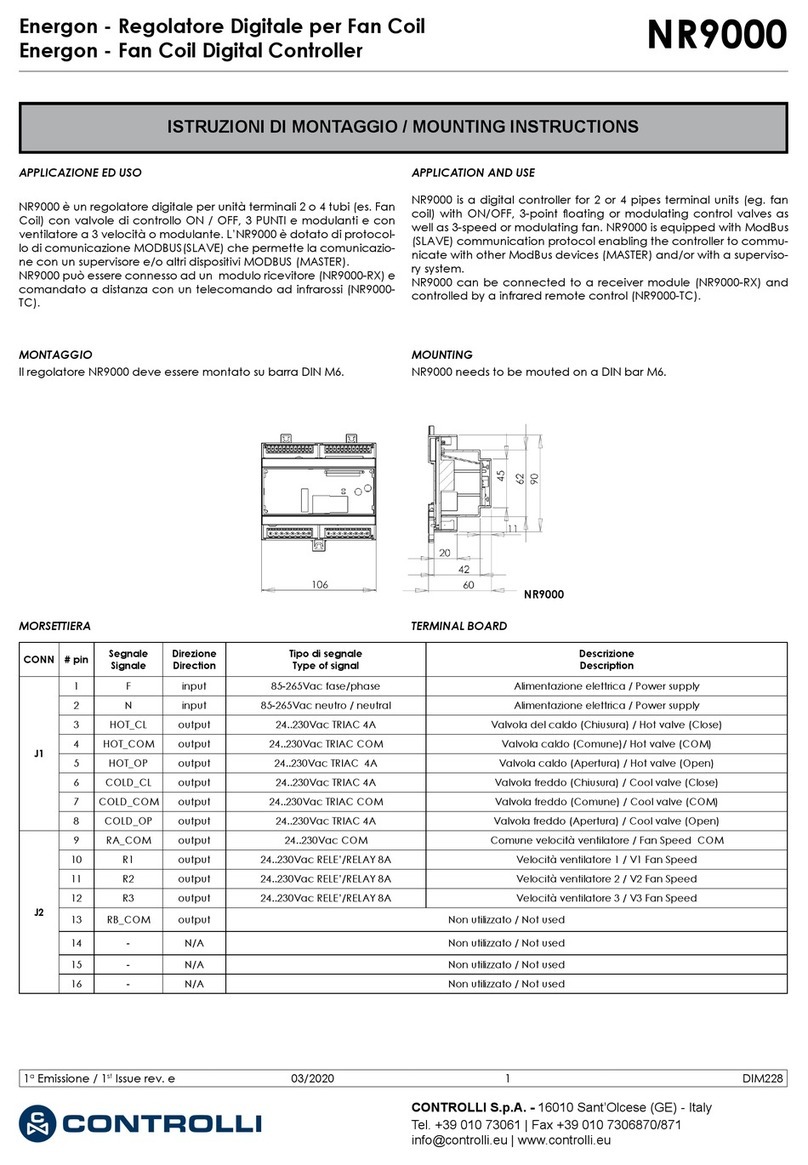

N° LEDs

behaviour Error Actuator use Actuator behaviour

Typical trouble

shooting

condition

Reset

procedure

Automatic calibration

(DIP N. 7 OFF)

Manual calibration

(DIP N. 7 ON)

1RED ON valve stroke

less than 5mm

Calibration/rst

installation

The actuator pushes/pulls

2 times (unexpected stall)

trying to remove the possible

obstacle. After 2 tries an alarm

is signalled and the actuator

moves to initial position and

does not respond to control

signal. Stroke value is not

updated because out of range

The actuator pushes/pulls 2

times against endpoint during

calibration and the actuator

moves to the initial position

and then it does not respond

to the control signal. The

actuator keeps the previous

stroke

Valve with a

stroke length

lower than 5mm

Remove

power and

power up

again

2

RED quick

blinking +

GREEN ON

Stroke longer

than 60mm

Calibration/rst

installation

The actuator exits the 60mm

stroke range and it moves

toward the new stroke limit

signalling an anomaly. The

actuator pushes/pulls 2 times

against the new stroke limit,

then it goes back to the initial

position still signalling the

anomaly until it is not within

60mm. The actuator does not

calibrate the stroke after 10s

(wrong range)

The actuator exits the 60mm

stroke range and it moves

toward the new stroke limit

signalling an anomaly. The

actuator pushes/pulls 2 times

against the new stroke limit,

then it goes back to the initial

position still signalling the

anomaly until it is not within

60mm. The actuator does not

calibrate the stroke after 10s

(wrong range)

Valve with a

stroke length

longer than

60mm

Remove

power and

power up

again

3RED Quick

Blinking

Unexpected

stall within

the calibrated

stroke range

Normal

operation

The actuator tries 5 times

against the new stall condition

and then after 10s the actuator

updates the new stroke length

The actuator tries 5 times

against the new stall

condition. At the end of the

attempts the fault will be

signalled. The actuator does

not update the new stroke

length, but after 60s makes

other attempts to verify the

stall condition

Valve stuck

Inverted

control

signal

4RED Quick

Blinking

Stroke longer

than expected

Normal

operation

The actuator moves toward the

new stall condition with a lower

speed; after 10s the actuator

updates the new stroke value

The actuator moves toward

the new stall condition with

a lower speed; after 10s the

actuator does not update the

new stroke value

Stem connection

loose or valve

damaged

Inverted

control

signal

5RED slow

Blinking

Low Power

Voltage

Normal

operation

The actuator is still working

but performance cannot be

guaranteed

The actuator is still working

but performance cannot be

guaranteed

1. Wrong

transformer size Correct

Voltage

Power

2. Unstable

power

6RED slow

Blinking

High Power

Voltage

Normal

operation

The actuator is still working

but performance cannot be

guaranteed

The actuator is still working

but performance cannot be

guaranteed

1. Wrong

transformer size Correct

Voltage

Power

2. Unstable

power

1° Emissione / 1st Issue rev. a 10/15 7 DIM266