Valve Actuators MVB

Rev. l 11/06 1 DIM001E

CONTROLLI

16010 SANT’OLCESE Genova - Italy

Tel.: +39 01073061 Fax: +39 0107306870/871

ISO 9000

CONTROLLI

MOUNTING INSTRUCTIONS

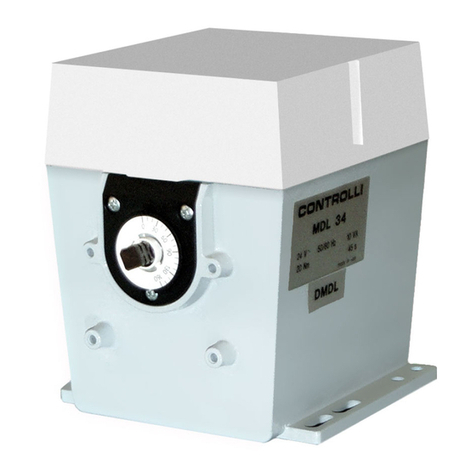

FOR MVB 36-52-56 ONLY

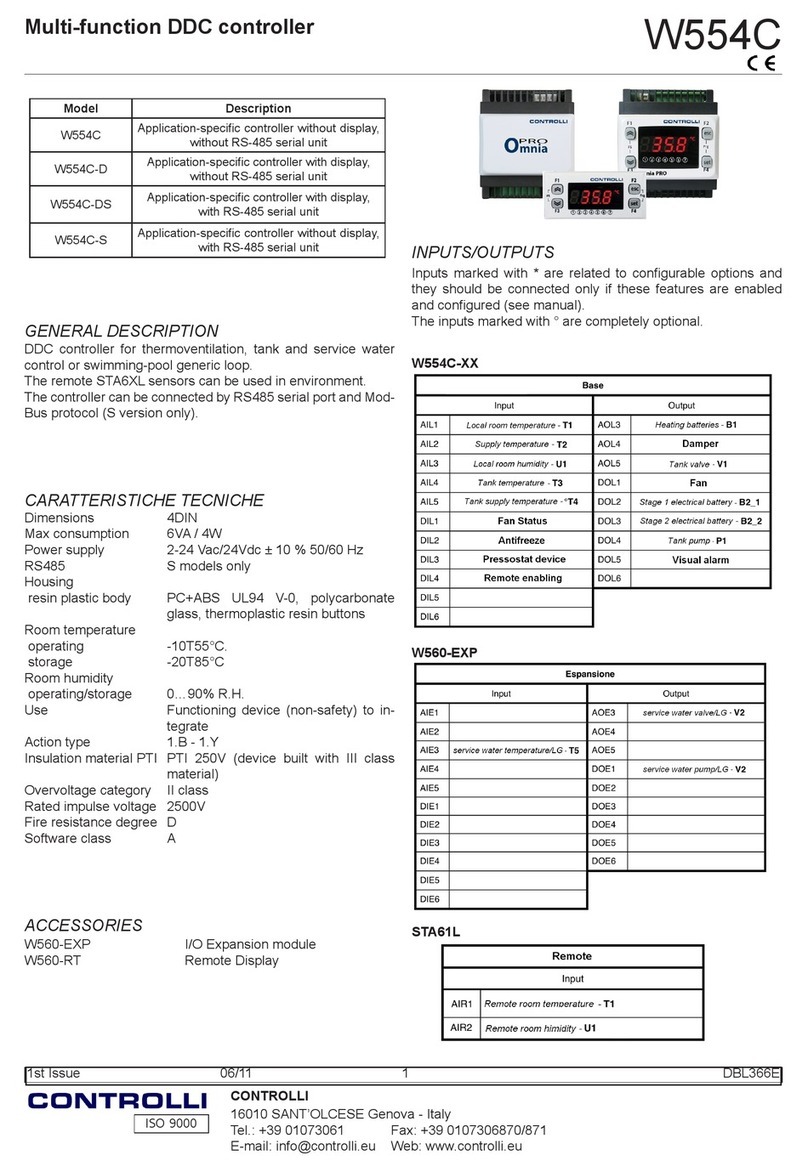

FIG. 2

N3133

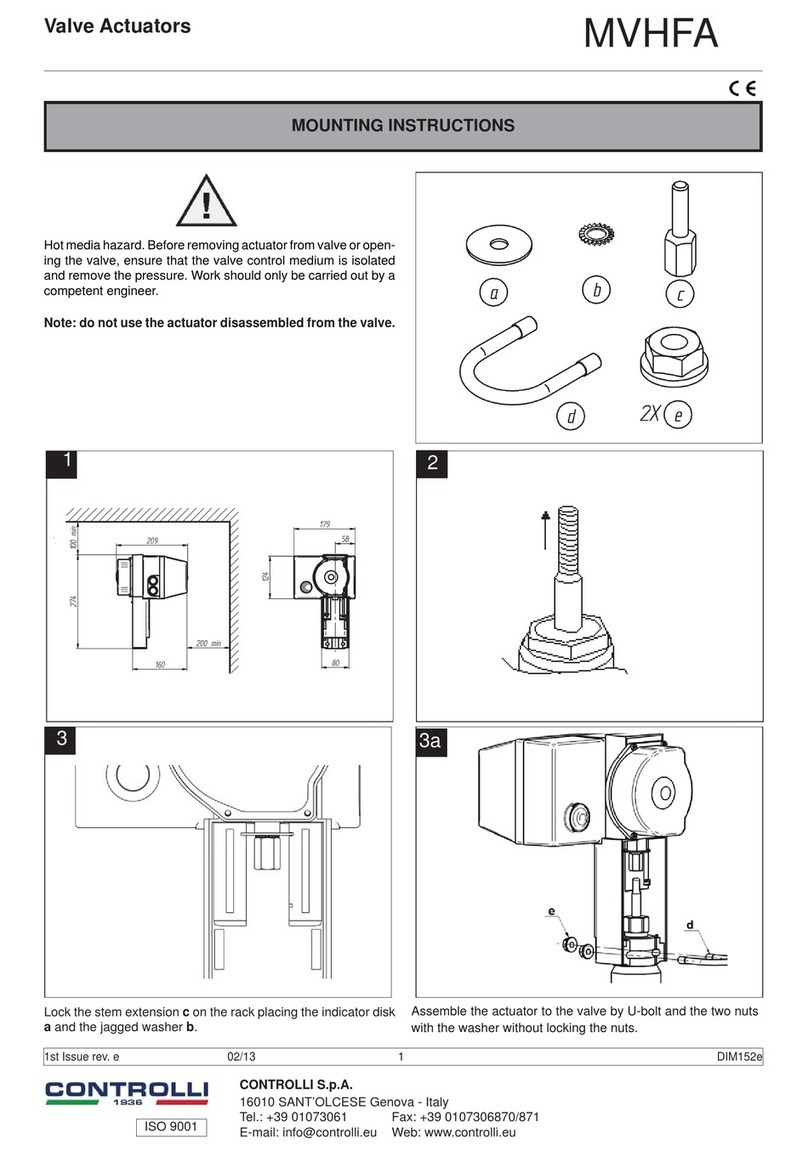

The actuator can be mounted in any position for applica-

tions in which the fluid temperature is not higher than 120

°C, otherwise it should be mounted in horizontal position.

It is necessary to leave 10 cm. above and beside it, so as

to operate on the internal parts, on the terminal board for

the electric connections and for assembling-disassembling

operations.

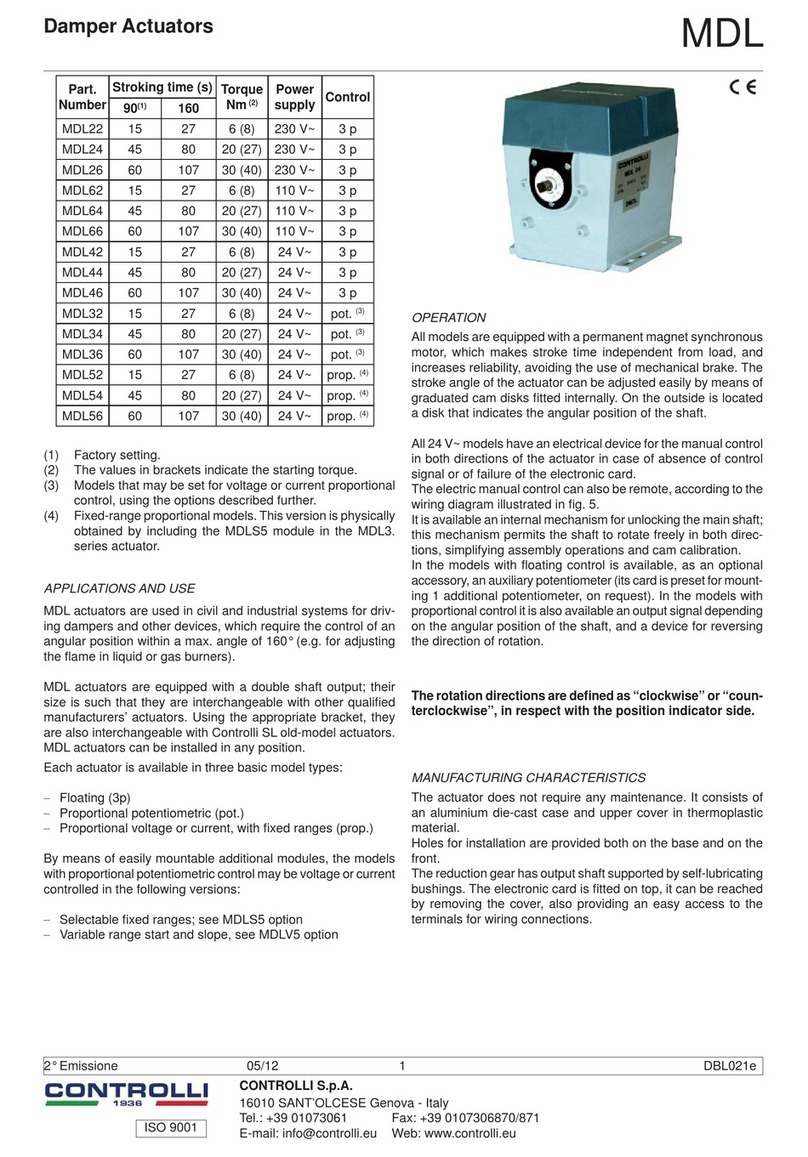

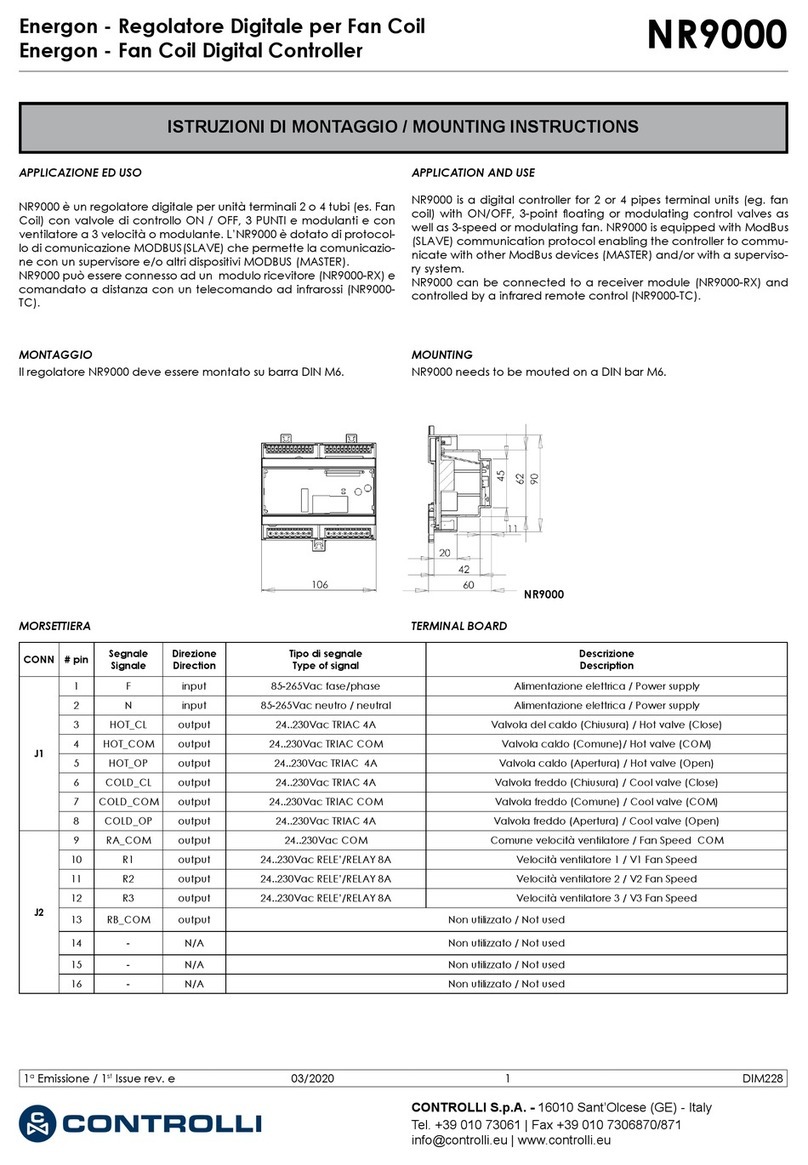

2. VSB-VMB/VSBF-VMBF/VSBPM-VMBPM/

VSBPMF-VMBPMF VALVES ASSEMBLY

(Fig.1)

•Pull and turn counter-clockwise the manual knob 1until

the joint reaches the upper mechanical stop.

•For VSB-VMB/VSBF-VMBF: Pull out the knob 1 and

rotate clockwise (max 1/4 turn) until it enters the first

rest position.

•For VMBPM-VSBPM/VMBPMF-VSBPMF: Pull out the

knob 1and rotate clockwise (max 1/2 turn) until it en-

ters the second rest position.

•Make sure the plug reaches upper seat by lifting the

valve stem.

•If a spacer for high temperatures is needed, insert the

MVBHT accessory 4onto the valve neck.

•Position the actuator on the valve interposing the ring

nut 3between the stem and the mounting bracket.

•Rotate the actuator until the bracket rests on the valve

body.

•Tighten the ring nut 3 using the supplied spanner.

•Keeping the valve stem steady, force counter-clockwise

the lower hexagonal part of joint 2(which acts as a

locknut) until it detaches.

•Then screw clockwise the part which has been detached

so as to tighten it on the rest of the joint, thus blocking

the valve stem.

•Remove the back cover (opposite the knob).

•For MVB52/56 only, make sure that jumper SW2 is in A

position (Fig. 2).

•Supply the actuator between L1 and L2 terminals with Y

terminal disconnected.

•Wait the actuator to reach the lower stroke end.

•Connect the positive of the voltmeter to S2 terminal and

the negative to M.

•Rotate P1 trimmer until the voltmeter indicates 0 V.

FIG. 1

N4161

3. ACTUATOR STROKE CALIBRATION ONLY

FOR STROKES DIFFERENT FROM 16.5 mm

1. INSTALLATION