S225-10-10

1-4

Procedure A: One Bypass Switch and

Two Disconnect Switches

1. Verify from regulator nameplate that control circuit

is connected for proper regulated system voltage.

2. Set power switch to OFF and control switch to OFF.

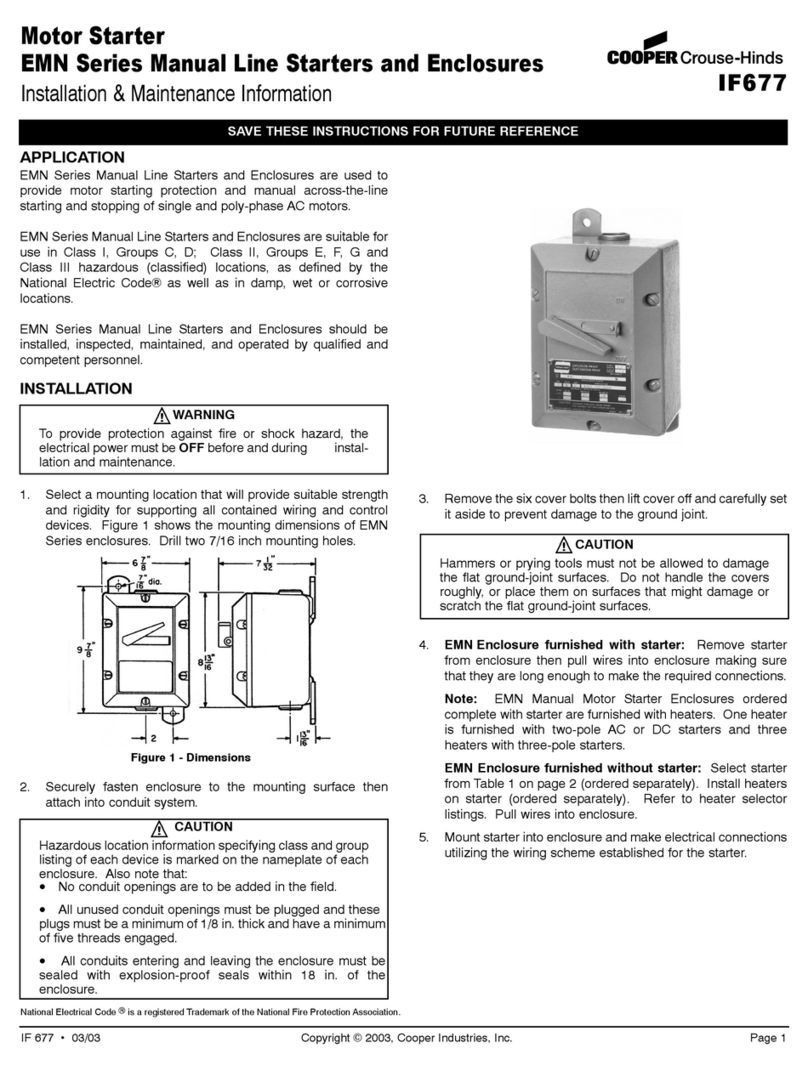

3. Knife switches on back panel should be set with V1

(potential switch) (and V6if present) closed (pushed

in), and C (CT shorting switch) open (pulled out).

See Figure 1-6.

4. Close source-load (SL) disconnect switch if

available.

5. Close source (S) disconnect switch.

6. Set power switch to INTERNAL and control switch

to MANUAL.

7. Lift raise-lower switch to operate tap changer two

or three steps, then depress raise-lower switch

to return tap changer to the neutral position.

(These steps verify that the mechanism is

functional.) When on neutral, neutral light will

glow continuously and position indicator will

point to zero.

8. With regulator in neutral position, set control switch

to OFF, set power switch to OFF, open V1knife

switch (and V6if present), and remove 6 A motor

fuse.

9. Close load (L) disconnect switch.

10. Open bypass switch. The regulator is now

energized.

11. Replace 6 A motor fuse, close V1knife switch and

set power switch to INTERNAL.

12. Go to Setting the Control for Service, following.

Procedure B: Regulator Bypass-

Disconnect Switch

1. Verify from regulator nameplate that control circuit

is connected for proper regulated system voltage.

2. Set control switch to MANUAL and power switch to

EXTERNAL.

3. Knife switches on back panel should be set with V1

(potential switch) (and V6if present) open (pulled

out), and C (CT shorting switch) closed (pushed in).

See Figure 1-6.

4. Apply 120 V (or other voltage as indicated by the

decal) to external source terminals, if available. If

not, proceed to Step 7, below.

5. Lift raise-lower switch to operate tap changer two or

three steps, then depress raise-lower switch to

return tap changer to neutral position. (These steps

verify that the mechanism is functional.) When on

neutral, neutral light will glow continuously and

position indicator will point to zero.

6. Remove the voltage from external source terminals.

7. With regulator in the neutral position, set control

switch to OFF, set power switch to OFF, and

remove 6 A motor fuse.

8. Close source-load (SL) disconnect switch. (Delta

applications only.)

9. Close regulator bypass-disconnect switch. The

regulator is now energized.

10. Replace 6 A motor fuse, close V1knife switch (and

V6if present), open C knife switch, and set power

switch to INTERNAL.

11. Go to Setting the Control for Service, following.

Setting the Control for Service

There are more than 50 parameters on the control which

are user-selectable. Many of these values pertain to the

operation of the advanced features that are not needed

for normal regulator operations. A full detailed

description of each of the features is given in the Control

Advanced Features section, along with set-up

instructions.

The control must be energized to perform the

programming. This can be accomplished by applying

120 V (or other voltage as indicated by the decal) to the

external source terminals and placing the power switch

in the external position. Alternately, the regulator may be

energized at line potential, and the power switch placed

in the internal position. When power is applied to the

control, all segments of the display will light, followed by

a PASS indication. If the FAIL message is encountered,

see Diagnostics, on page 2-5.

Accessing the Control

Before gaining access to change the control settings, the

proper security level must be activated. This is

accomplished by entering a security code at the

Function Code 99 location. Depress the following

keys on the keypad:

FUNCTION, 99, ENTER

12121, ENTER

The proper level of security to change operational

settings has now been activated.

All programming of the control is done through the

keypad or communication ports.

For quick set-up of Cooper Power Systems regulators,

see Table 1-1, page 1-5. For complete set-up, see

Table1-2, page 1-6 for a detailed checklist for control

programming. The only two parameters this checklist

does not address are voltage and current calibration,

Function Codes 47 and 48.