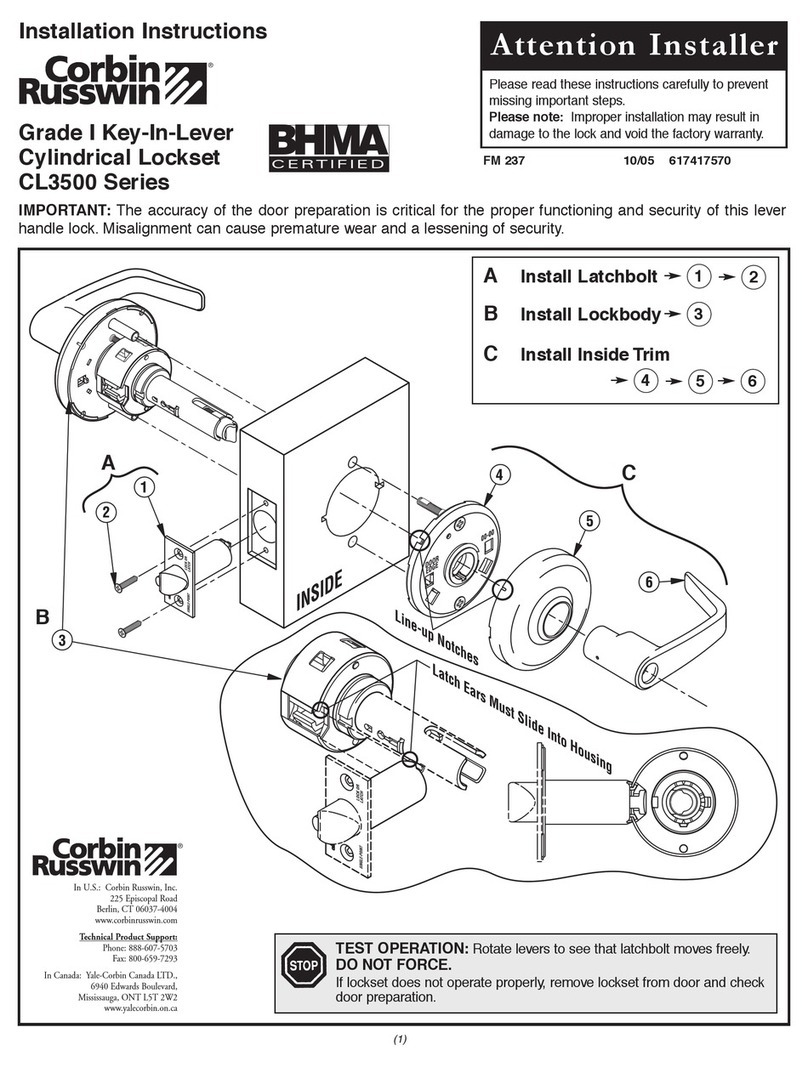

A. Install Tailpiece

To Install Interchangeable Core

(With lever already installed on lock)

Tailpiece

Other product brand names may be trademarks or registered trademarks of their respective owners and are mentioned for reference only.

(2)

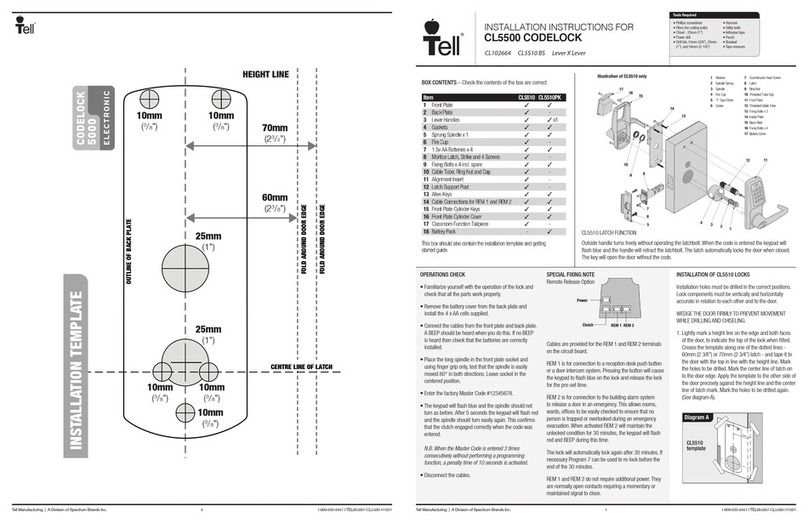

Mark door

Locate and mark horizontal center line at desired height above

floor. Fold template over edge of door, centering on horizontal

line. Mark centers of holes at proper backset. Mark both sides

of the door.

Note:

Be sure to verify backset before marking & drilling door.

Drill door

A. 2-1/8” (54mm) hole thru door. Cut ANSI tab notches

as shown on template (except CL3850 and CL3870).

B. Drill 1” (25mm) hole in edge of door. Cut out for

latch front 5/32” (4mm) deep. 1-1/8” (29mm) wide

x 2-1/4” (57mm) high. Check latch unit for proper

width front and square or round corners

(except CL3850 and CL3870).

C. Drill two (2) 11/32” (8mm) Dia. holes through door

for all functions.

Caution:

To avoid splintering wood doors, drill holes from both sides.

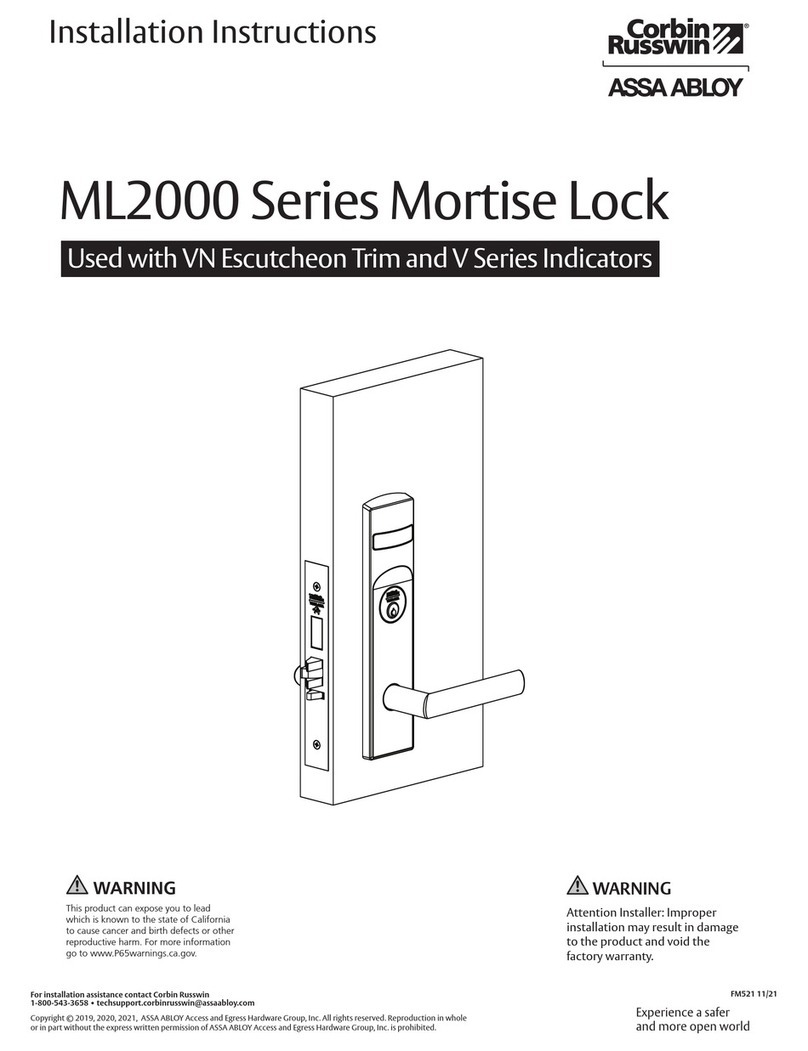

Door & Frame Preparation Adjust Lock for Door Thickness

Adjust lock to door thickness if other than 1-3/4”

(44mm) doors*.(Lock pre-set from factory for 1-3/4” door).

A. Remove outside lever (see page 4)

B. Slide off outside cassette assembly.

C. Rotate rose liner to adjust lock to fit door thickness, so

that the distance (Dim. “A”) from the inside of the liner to

the centerline of the retractor is one half of the thickness

of the door (see chart and use door marker).

D. Re-assemble outside cassette assembly onto chassis

assembly (except CL3880 and CL3881 functions).

*Note: For doors more than 2”, verify

lock package is labeled with “D214” option.

Door

Thickness* “A”

1-3/8” (35)

1-3/4” (44)

2” (50)

2-1/4” (57)

11/16” (17)

7/8” (22)

1” (25)

1-1/8” (29)

C. Insert core into lever and return

key to its original horizontal

position locking core in place.

See Figure 3.

D. Withdraw key.

Test lockset for

correct function

with operating key.

E. Control key has no

further use in lockset

installation and must

be safeguarded for

return to Security personnel

when installation is complete.

A. Insert key marked

CONTROL and turn

clockwise approximately

15 degrees. See Figure 4.

B. Pull core and tailpiece

completely out of lever.

Cylinder Installation

Make sure lock is unlocked.

A. Make sure cylinder tailpiece is aligned in same direction as

cylinder bible. Slide cylinder all the way into lever.

•For 6-pin cylinder: Fold retainer at hinge and press fit

retainer halves together as shown.

•For 7-pin cylinder: Break retainer at hinge and discard

spacer section. Also remove black cylinder spacer from

inside of chassis rollback for clearance.

7/8"

(22) 11/16"

(17)

Standard Cylinder Tailpieces

6 PIN 7 PIN

ACTUAL

SIZE

SHOWN

Tailpiece

Corbin Russwin

Core

Security Disc

B. Insert key marked

CONTROL and turn

clockwise approximately

15 degrees.

See Figure 2.

Schlage®Core

Tailpiece

Set for

Primus

Tailpiece set

for all Schlage

cores except

Primus

Corbin Russwin conversion kit for Schlage®

cylinders with CL3800 lockset.

1. Remove threaded collar and Schlage®tailpiece.

2. Install CL3800 tailpiece

with threaded collar.

(adjust collar for proper

end play of plug.)

Figure 4

Figure 2

Figure 3

To Remove Interchangeable Core

Install Standard Cylinder

Install Strike

Screw

Length

1-1/2” (38)

2” (50)

2-1/4” (57)

2-1/4” (57)

Outside

Rose Liner

Chassis

Assembly

Outside

Cassette

Assembly Lever

Catch

CORRECT WRONG

Cam

Lever Catch

6

3

9

12

6

3

9

12

CL3855 Classroom Function Timing

Before installing cylinder:

• Turn Cam so points are up and down, 6 o’clock and 12 o’clock

(See Below)

(Use door template to set Dim. “A”)

After installing

cylinder, test

operation:

• Key should rotate

180° both ways

• If cylinder rotates 360°,

remove cylinder and check cam orientation.