Contents

Information for the installer

Fixing the Shower to the wall . . . . . . . .

Plumbing . . . . . . . . . . . . . . . . . . . . . . . .

Electrical . . . . . . . . . . . . . . . . . . . . . . .

What to do ifthings go wrong. . . . . . . .

AssemblyofAccessories. . . . . . . . . . .

Guarantee and contact details . . . . . . .

Page

2

3

4

6

7

8

Contents

Information for the user

How to use your Creda Shower . . . . . .

How to maintain your Creda Shower

What to do ifthings go wrong. . . . . . . .

How your Creda Shower works . . . . . .

Creda After Sales Service . . . . . . . . . .

Guarantee and contact details .. . . . . .

Page

5

5

6

7

7

8

Installation Instructions .

ALL WIRING AND INSTALLATION MUST BE SUPERVISED BY ASUITABLY QUALIFIED PERSON.

WARNING: DO NOTINSTALL THIS SHOWER IN AROOM WHERE ITMAY BE SUBJECT TO FREEZING.

Werecommend that the installation is done in thefollowingsequence.

a. Fixing the shower to thewall b. Plumbing c. Electrical connections

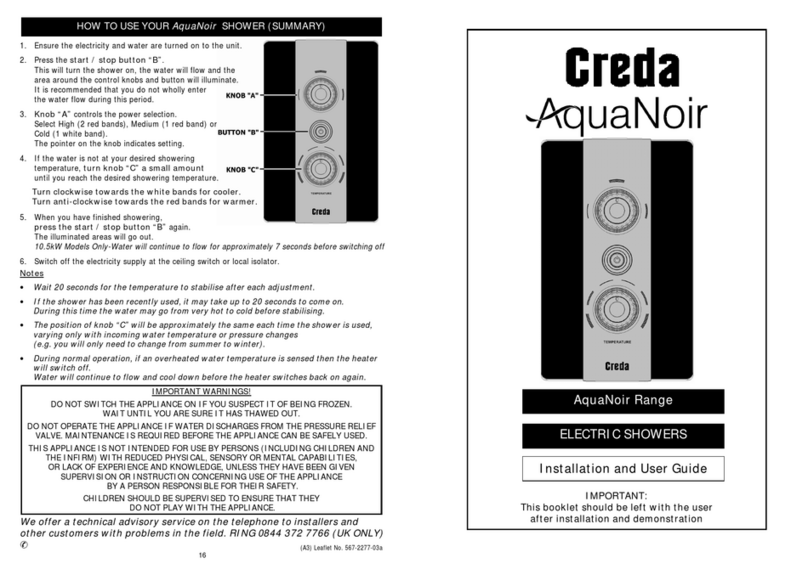

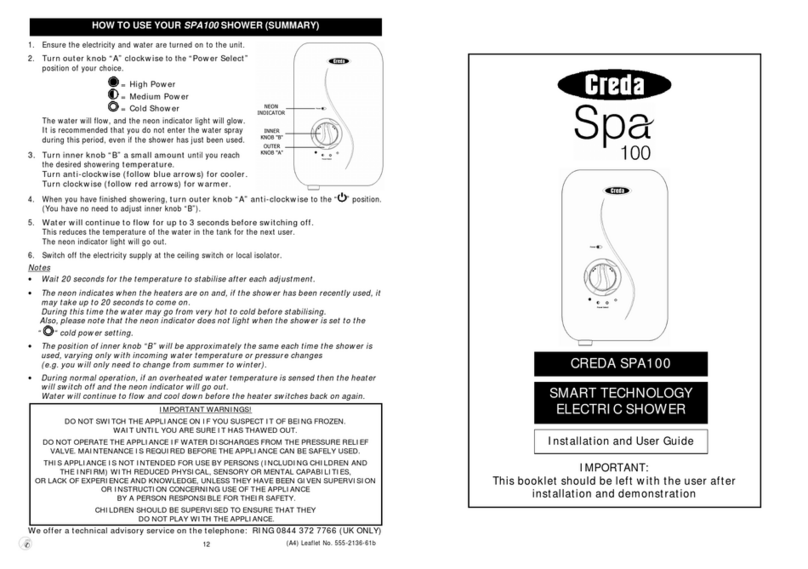

a. Fixingthe shower to the wall

1. Position the riser rail at a height convenient for majorityof users

as detailed in diagram 1 and mark its position.

2. Position the heater so that the top of the unit is horizontal and

level with, or upto 0.6metres (2ft) maximum belowthetop

of the riser rail.

Choose a flat piece ofwalltoavoid the possibilityofdistorting

the backplate, as this maymake the front cover apoor fit.

3. Adjust the positiontogetthe most convenientarrangement

takingthe followinginto account.

•The heater must not be mounted in thedirect sprayfrom

the handset.

•The handset must not be able to come into contact with used water inthe cubicle, bath or basin.

If it can, then a vacuum breaker must befitted.

4. Fixthe riser rail with suitable screws.

The fixing holes at thebase of thebrackets will be disclosed byremoving the

(See diagram 9).

5. Decide theposition of the electrical cable to the unit.

If top or bottom entryischosen (according to diagram 3),

cut awaythewalls inthe backplateas shown in diagram 2.

6. Decide the entry position of thecold water pipe intothe unit.

If top, cut awaythe backplate.

If rear, please read the sectionon plumbing.

If bottom, remove the front cover (complete with knobs),

andcutawaythedetachable corner sectionas shown.

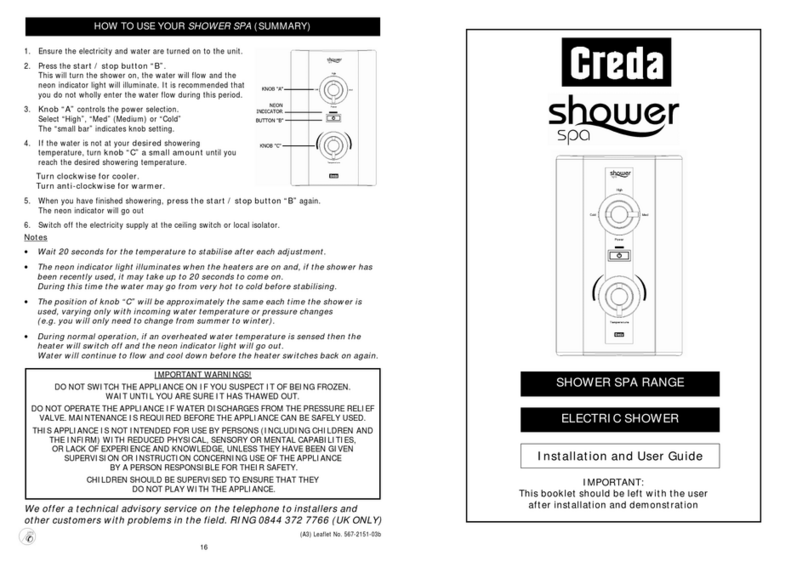

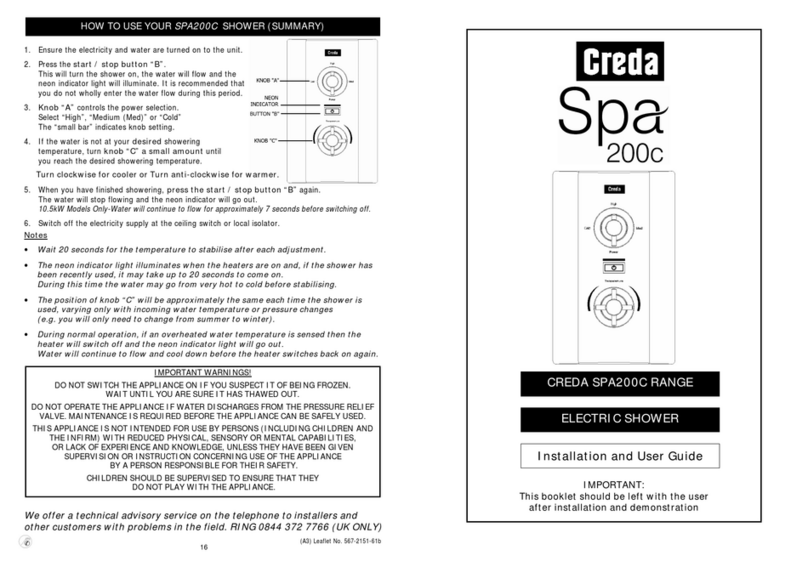

How your Creda Shower Works s

Your shower is designed for convenience, economy and safetyof use.

1. Water isheated instantaneouslyas it flows over the heating elements in the copper cylinder (diagram 7)

2. The heaters are onlyswitched on when sufficient water isflowing.

This is done automaticallywith aswitch, whichworkson water pressure.

3. The water is turned on and off bythe solenoid valve

built into the shower.This is switched on bybutton “B”.

4. The flow of water is automaticallyheldat the levelset

by the user even though the supplypressure mayvary.

5. Ifthe water supplyfalls below a set limit, the pressure

switch willoperate switching off the power to the elements.

6. As a further safeguard, a thermalcut-out switches the

power off if the water temperature climbsabove the setlimit.

This cut-out,which gives an audible click, mayalso operate

due to residual heat when the showeris switched off.

Itwill reset itself if water isrun through the shower for

10 to20 seconds.

7. The pressure relief device istosafeguard against safeguard against

abnormal pressure conditions,and provides a level of appliance

protection should an excessive build of pressure occur withinthe shower.

8. The required water temperature is achieved byadjusting the rate of water flow.

Diagram 8 shows the principle involved inrelating temperature rise to flow rate.

The higher the water rate the lower the temperature and vice versa.

The temperature of the water supplied from the mains can varyconsiderably

throughout the year from 5 to 20°C.

Thismeans that in the winter, flowrate willbe less than in the summer to achieve the

same outlettemperature.

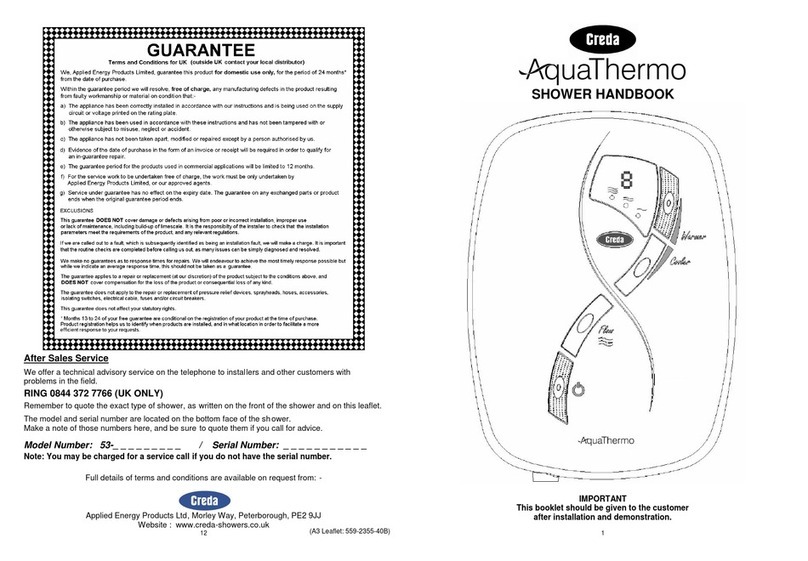

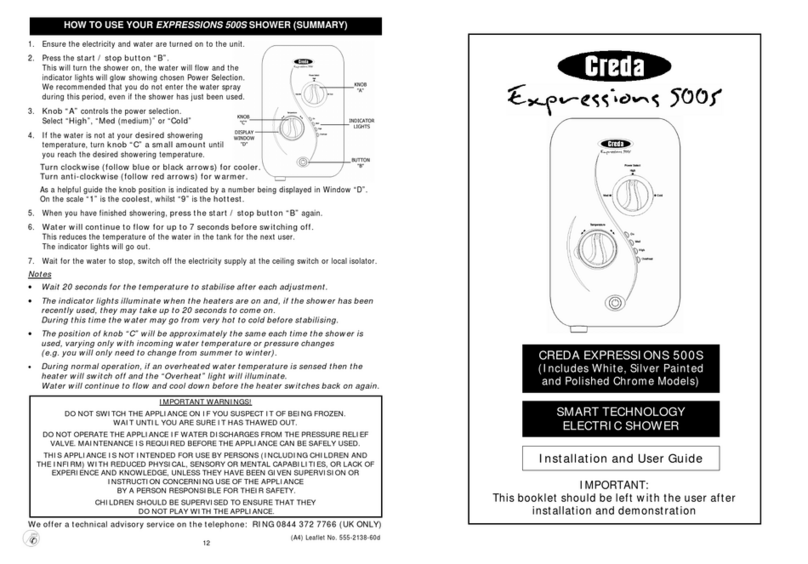

Creda After Sales Service e

Weoffer a technical advisoryservice on the telephone to contractors and other customers with problems in the field.

TELEPHONE 0844 3727766

Spare parts (shown below) can be supplied against Credit or Debit cards.

TELEPHONE 0844 3727750

Remember to quote the exact type of shower,as written on the frontof the shower and on thisleaflet.

The model and serialnumber are located on the bottom face of the shower.

Make a note of those numbershere,and be sure to quote them if you call foradvice.

Model Number: 53- _ _ _ _ _ _ _ _ __ _ _ _

Serial Number: _ __ _ _ _ __ _ __ __ _ __

Note: You maybe charged for a service call if you do not havethe serial number.

AdditionalAccessories .

White 2 metre Shower Hose Catalogue No.83-593529

1 metre Riser Rail Catalogue No. 83-593530

WRASapproved isolating valve Catalogue No. 93-792452

Curtain and RailPack Catalogue No. 83-792812

Curtain and RailPack c/w Mat Catalogue No. 83-792811

Spares .

The fitting ofall sparesshould be supervised by a suitablyqualified person.

Front cover assembly Catalogue No. 93-550854

Solenoid Valve(Plain Shank) Catalogue No. 93-593588

Thermal Cut-Out 50/88°C Catalogue No. 93-597871

Heat exchanger (8.5kW) Catalogue No. 93-597803

Heat exchanger (9.5kW) Catalogue No. 93-597804

Flowvalve assembly Catalogue No. 93-597806

Chrome Shower Hose Catalogue No. 93-797641