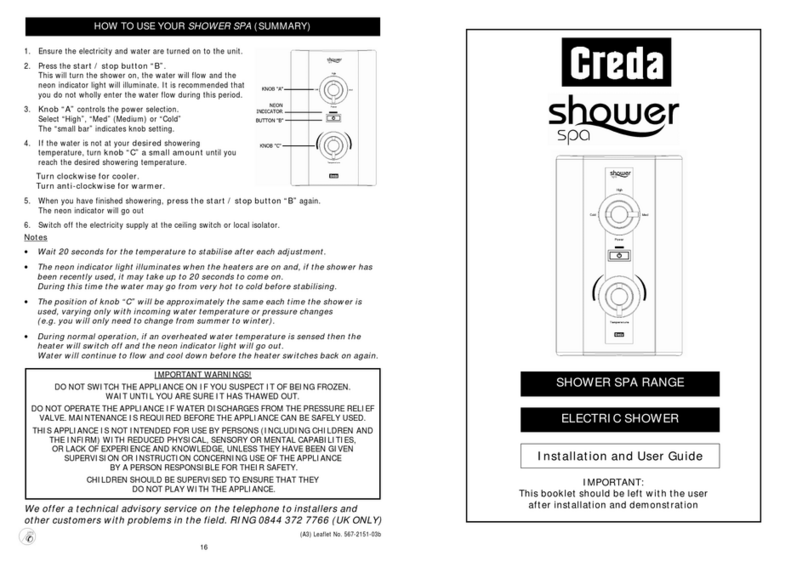

8. Yourshowerisprovidedwith3 fixing

positionsin the backplate (seeDiagram 6).

The top-fixinghole is a “key-

andshouldbe markedand drilledfirst.

Tighten topscrew wi

about 10mm from thewall andhookthe

bac

kplate overthe screw head.

Thisallowsforcorrectand accurate

alignment of yourshower before marking

andfixingthe bottompositions.

You maynot wish totighten upboth screws at this

stage asthe holesareelongatedtoallowforadjustment after otherconnectionshave taken place.

b. PLUMBING (For yourconveniencea coldwater inletconfiguration diagramisshown on page 5)

WARNING: ENSURE THAT THE MAINS WATER SUPPLY MEETS THE REQUIREMENTS BELOW

BEFORE CONTINUINGWITH INSTALLATION.

The heater must be connectedtothe mains cold water supply.

Thismust have a minimumrunningpressure of69kPa (0.7bar, 10 psi)

anda maximum pressure of690kPa(7.0 bar, 100 psi).

WARNING: BEFORE CONNECTINGTHE PIPE WORK TO THESHOWER,

ENSURE THAT THE PIPE WORK IS FULLY FLUSHED OUT.

1. Unscrew the “RedCap”from the showeroutletpipe anddiscard it in a suitable manner.

It has been usedtoseal the showerduringtransit, and is nolongerrequired.

2. It is recommendedthat a WRAS (Water RegulationsAdvisory Scheme) listedisolatingvalveisfitted

tothe incomingmainscoldwaterbefore the shower unit. Thiswill allow the unit tobe serviced or

exchangedwithouthavingtoturn offthe mains water at the waterstop valve.

3. The heater can be fedfrom a header tankprovided thishasa minimum headof7 metres (23ft).

4. The coldwaterinlet connection

suppliedis a plain Ø15mm straightshank/shaft.

Thisconnectorwill accept eithera Ø15mmcompressionelbowor a Ø15mm“push-onelbow”.

Ø15mm copper, stainless steelor suitable plasticpipeshould beused.

Foryour convenience,acold waterinletconfiguration diagramisshownonpage 5

Ifrearentryisrequired, treatastopentrywithan additional “Yorkshire”elbow (solderedtype) for

fitting intotherearchannel.

Toaid installation, youmayfind itconvenienttomovetheflexiblepressurereliefvalveoutlet

assembly byremoving thetwosecuring screws (Se

Inmultipleinstallations,correctpipeworksizes shouldbecalculatedtomaintain adequateflowto

eachshower.

5. It is permissible to use a WRAS (WaterRegulationsAdvisory Scheme)approved sealant sparingly

whilstavoidingexcess findingits way intothe showeroperatingparts.

6. With isolating valve connected, flush the pipework through to remove any particles etc,

before makingthe final connectiontothe shower.

Blockage in the waterways(particularly the handset andsolenoidvalve)will prevent the heater

workingproperly. Note: You maybe chargedfor aservice call if itisdue toincorrect installation.

7. The showerisdesignedtohavean open outletandshouldonly be used with “Creda” recommended

fittings.

Do not connect thehandset until afterthe front coveranddetachable bottom section are fitted.

WARNING: DO NOT FIT A TAP ON THE SHOWER OUTLET.

WARNING: TAKE CARE TO AVOID RESTRICTING THE OUTLET OF THE

PRESSURE RELIEF VALVE. 9

WHAT TO DO IF THINGS GO WRONG (2)

SELF HELP

If the shower is notworking satisfactorily, make the following checks before calling out the installer.

Any one oftheseadjustmentscould restore the performance.

The shower cycles

from HOT toCOLD Temperature is settoo hot causing the thermal cut-out (safety device) to operate.

Turn knob“E” clockwise toincrease water flow.

Slowly increase the water temperature by turningknob “E” anti-clockwiseuntil a

comfortable showering temperature hasbeen reached.

WAITapproximately 20secondsfor eachadjustmenttoaffectthe watertemperature.

“ (Medium)” setting may need to be selected.

Water tooHOT Increasewater flow by adjusting knob“E” clockwise.

“ (Medium)” setting may need to be selected.

Increasepressure towater supplye.g. fully open service valve or stop cock.

Check hoseis notkinkedrestrictingthe water flow and clean handset.

Water tooCOLD Check power is on by LED indicator being illuminated.

Decrease water flow by adjusting knob “E” anti-clockwise.

“(High)” setting mayneed to be selected.

Select inner orouter only handsetspraypattern.

Spray pattern poor Clean the showerhandset.

Water takeslonger

to heat up Thermal cut-outhas operated after previoususe and the LED indicator has gone out

(automatically resetswhen unitcools down).

“(High)” setting mayneed to be selected.

Water goescold

while using

shower

Check LED indicator isilluminated.

Check water pressure has not fallen so far asto let pressure switch cutout,

e.g. Another tapdrawing water off.

Raiseposition of shower handset.

Broken parts Please contactour spares department on 0870 9000 420(UK only).

Water continues to

flow when button

“D” pressed to stop

Thisis normal.

The shower includesa shutdown feature thatmeans the water will continue to flow

for up to7seconds after“ (stop)” hasbeen selected.

PROFESSIONAL SERVICE

If the previous “SelfHelp” checks fail to restore the performance, you should seekprofessional help.

The person whoinstalled the shower isprobably the best one to investigateand correct it and iscertainly the

person tocontact if you have had a problem in the guarantee period.

The following additional checklistis provided for the benefitof the qualified service person.

WARNING: SWITCH OFF THE ELECTRICITY ATTHE LOCAL ISOLATOR

BEFORE REMOVING THE COVER TO MAKE CHECKS

Water tooHOT Water flow restricted by blockage in filter ofsolenoid valve. Replace solenoid valve.

Water tooCOLD Check circuitthrough thermal cut-out and/or through pressure switch microswitches.

Aschematic wiring diagram is available from our technical advisory service.

Check eachelementcircuit andcheck tightnessof electrical connections.

No control over

water flow Check control knob is correctly engaged onto the stabiliser valve drive gear.

Undo headworks of stabiliser valve.

Check stabiliser isin placeand remove anydebris in valve then re-assemble.

Water discharges

from pressure

relief valve

Check for causeof high pressure and removeit.

Blockage on outlet e.g. blocked shower handset.

Replace the pressure relief disc (not covered by guarantee).

Water doesnot

flow when button

“A B C” is pressed.

Ensure thatthe flying leadfromthe PCB is connected to the Front Cover.

Check circuitthrough solenoid coil and/or through pressure switch microswitches.

Possible PCB fault.If defective then replace. Power supplynot reaching shower.

WHAT TO DO IF THINGS GO WRONG (1)